Dry gypsum grinding

.jpg)

An experimental study on the ultrafine grinding of gypsum ore in a dry

2016年4月1日 In response, in this study, we have systematically investigated how certain grinding parameters (ie, mill speed, ball filling ratio, ball size distribution, powder filling ratio, 1996年4月1日 Dry grinding of gypsum (CaSO 4 2H 2 O) with hydrated minerals, such as talc, kaolinite or montmorillonite as an additive was conducted in a planetary ball mill in order to Mechanochemical changes in gypsum when dry ground with At this stage, it is possible to further reduce the moisture content of the rock by drying In a more specific example, dried rock is passed through a Raymond roller mill to produce “landplaster” Grinding Natural Gypsum Preparation Gypsum2016年4月1日 The paper is aimed to investigate the influence of operating parameters on dry fine grinding of calcite in a laboratory scale conventional ball mill Within the context, the An experimental study on the ultrafine grinding of gypsum ore in a dry

.jpg)

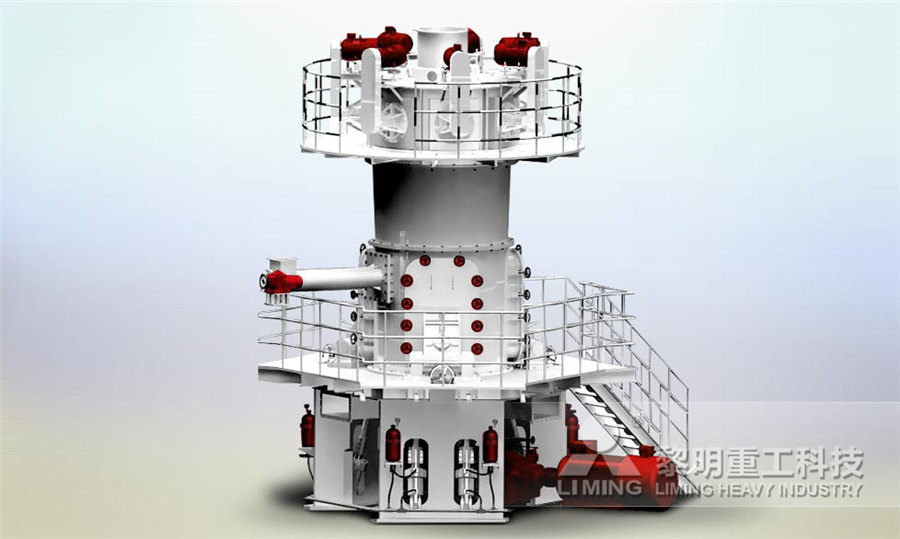

GLOBAL GYPSUM: GRINDING Gebr Pfeiffer

2020年5月20日 GLOBAL GYPSUM: GRINDING Above right: One of the world’s two largest gypsum mills Both grind natural gypsum, one in Asia, the other in North America Capacity = 2016年12月19日 One option is direct calcining in a Pfeifer vertical roller mill of the type MPSGC (Fig 2) In this process, the gypsum is dried and ground to the required fineness of the plaster Grinding and calcining of gypsum with Pfeiffer grinding 2017年8月25日 In an arid country the chronic shortage of water may dictate the use of dry grinding methods Where a dry endproduct is called for and can be processed up to the re DRY GRINDING Springer2016年12月19日 In 1998, the MPSGC roller mill for drying, grinding and calcination in one step was introduced (Figure 1) Up to now, 26 gypsum calcining mills have been sold, among them PFEIFFER GC mills type MPS for grinding, drying and

.jpg)

An experimental study on the ultrafine grinding of gypsum ore in a dry

2015年12月1日 In response, in this study, we have systematically investigated how certain grinding parameters (ie, mill speed, ball filling ratio, ball size distribution, powder filling ratio, 2021年4月19日 Gypsum (C 0 G 100) is the softest material among the studied; however, it has a sharp feed PSD and low size, which can increase the resistance to grinding This is seen by gypsum’s initial fineness (n = 142), which has a narrower PSD than limestone (n = 070) The uniformities of the materials were very similar after being ground by the ball Resistance to Grinding and Cement Paste Performance ofNormally, grinding aids are added in a 15% concentrated solution (1:7 grinding aid to water – helps the dispersal of grinding aid in mill), at approximately 225 Lb/Ton for medium fineness and 34 Lb/Ton for high fineness cementEverything you need to know about 1996年4月1日 Dry grinding of gypsum (CaSO 4 2H 2 O) with hydrated minerals, such as talc, kaolinite or montmorillonite as an additive was conducted in a planetary ball mill in order to investigate the transformation of gypsum into its hemihydrate form (CaSO 4 1 2 H 2 O)This transformation of gypsum is accelarated by grinding and by the presence of hydrated mineralsMechanochemical changes in gypsum when dry ground with

GYPSUM TECHNOLOGIES – Baumak

GRINDING AND CLASSIFYING In gypsum powder production, we stand by our customers by offering options of rotary kilns and vertical kilns, enabling them to achieve the best results GYPSUM BASED DRY MORTAR PLANTS CALCITE PRODUCTION PLANTS EXPANDED PERLITE PRODUCTION PLANTS Center Office +90 312 219 13 50Grinding Natural Gypsum Preparation Gypsum Connecting Science and Technology ( Recentlyed No results found Tags Similarly, dry FGD gypsum may consolidate 共bridge兲 and resist mixing under certain conditions Kettle calciners operate most efficiently when the calcining mass is wellGrinding Natural Gypsum Preparation Gypsum2023年5月11日 What is dry grinding? Dry grinding refers to a type of grinding method that uses hard abrasives to process materials without the addition of any liquid medium Common dry grinding equipment includes ball mills, highpressure roller mills, and grinding machines Such as metal ores, coal, limestone, gypsum, etc Pharmaceutical preparation 3 mins knowing Wet Grinding vs Dry Grinding: Which Grinding 2016年4月12日 A Open End, End Peripheral Discharge, CPD Rod Mills and Grate Discharge Ball Mills are particularly efficient for dry grindingSuch materials as limestone, cement clinker, gravel, phosphates, clays, gypsum, oil shale, terra cotta mixtures, coal and coke are economically reduced in size through their useDry Grinding Coke Grinding 911Metallurgist

.jpg)

Analysis of grinding aid performance effects on dry fine

2022年3月1日 The efficiency of most grinding processes which are performed wet or dry is very low Dry grinding, in particular, is a difficult process in terms of material transportation since the particles are prone to form agglomerates and coating on the media and mill liners due to the static forces that occur during the grinding operation [1]Chemicals that are known as “grinding aids 2016年12月19日 this mill offers the possibilities of grinding, drying, partly calcining as well as grinding, drying and complete calcining into beta hemihydrate plaster Due to the mill’s technical design, the first gypsum is fed into the mill and the grinding rollers are lowered The initial feed rate is lower than the nominal Below Figure 1 PFEIFFER GC mills type MPS for grinding, drying and 2024年8月20日 Gypsum, when dry, contains calcium (23%) and sulfur (17%) Uses of Gypsum in Cement Gypsum acts as a binding agent in the cement and controls various factors in it It is also used in the walls where fire protection is required since it has a natural fireresistance property Calcium sulfate also known as gypsum during grinding, can be A Comprehensive Guide on the Uses of Gypsum in Cement2019年9月1日 To select dry or wet grinding, the differences between their process conditions should be taken into consideration Transfer and motion of particles by air in case of dry grinding or water may significantly affect power draw and energy consumption of grinding circuits [5]Particularly, these energy differences become significant when considering that around 3% A comparative study on the effects of dry and wet grinding

A critical review on the mechanisms of chemical additives

2020年7月1日 In mineral beneficiation, wet grinding is much preferred compared to dry grinding, but the growing scarcity of portable water poses a threat to mining activities, especially in arid regions An experimental study on the ultrafine grinding of gypsum ore in a dry ball mill Powder Technol, 291 (2016), pp 186192, 101016/jpowtec2015120272018年3月12日 A modified gypsum set accelerator and a method of preparing the same is provided, which includes dry loose finely ground particles of a mixture of ground dry calcium sulfate dihydrate and a grinding aid selected from one or more of betanaphthalene sulfonate formaldehyde condensate, trimetaphosphate phosphate salt, tripolyphosphate salt, tetra GYPSUM SET ACCELERATOR AND METHOD OF PREPARING Gypsum drying In most cases, the dry gypsum needs processing Sometimes the water hydrate needs to be removed, resulting in a hemihydrate or anhydrite form Whatever form is required (dihydrate, hemihydrate or anhydrite), it is always very important to control the hydration state The dryer you select should be able to control this state Efficient Gypsum Mixing Drying Solutions Hosokawa 2016年12月19日 the case when the gypsum is calcined indirectly in a Pfeiffer GK gypsum calcining kettle In this process, the natural gypsum is first fed to a Pfeiffer MPS mill where the material is dried and simultaneously ground to the required fineness for plaster Subsequently, the ground and dried gypsum is delivered to the gypsum kettle ( Fig 3)Grinding and calcining of gypsum with Pfeiffer grinding

.jpg)

Limestone Grinding Mill That You Need To Know Dry

2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, ChinaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills湿法研磨和干法研磨是用于材料加工的两种不同方法。 每种方法都有自己的一套技术和应用。 湿法研磨和干法研磨的 4 个主要区别 1湿法研磨:使用水或冷却剂什么是湿法研磨和干法研磨?您需要了解的 4 个关键区别What is the role of gypsum in drywall? Gypsum, the star player in drywall, provides the panel’s primary structural element, imparting durability and ease of finishing Transformed into plaster of Paris, it becomes a versatile binder that, when combined with water, returns to a gypsum state and sets the stage for drywall’s solid form 2Drywall Guide: Composition, Installation Tips

Effect of wet and drygrind fly ash on the durability of

This paper presents a series of experimental studies on the durability properties of concretes containing wetgrind and drygrind fly ash The durability performance of fly ash concrete was assessed from measurements of compressive strength, drying shrinkage, chloride permeability, seawater corrosion resistance and pore structure testsThe FGD gypsum content and the percentage of water in the material being ground was determined over the period of the grinding from the start of gypsum feed until stable plant operation was achieved again Zencirci, S; Toprak, Gypsum dehydration potential and mean 2024年9月10日 Gypsum, a mineral consisting of Calcium Sulphate, is added to regulate the setting time of Cement It slows down the initial setting, allowing enough time for proper placement of Cement and finishing of the concrete Cement Manufacturing Process: Know Wet Dry Grinding Gold Copper Ore Cement Gypsum Coal Limestone Ball Mill US$ 10000 / set 1 set (MOQ) Henan Hongji Mine Machinery Co, Ltd Henan Hongji Mine Machinery Co, Ltd Diamond Member Audited Supplier Henan, China Manufacturer/Factory Trading Company; ISO Limestone Grinding Mill MadeinChina

FYEFEPS2HDZ49G5Z0[B.jpg)

The Key Application Technology of Desulfurized Gypsum

(Grinding for 20min), grinding fly ash (grinding for 30min) The chemical properties of fly ash are shown in Table 1 The flue gas desulfurization gypsum adopts Zhengzhou Taixiang Thermal Power Co, Ltd, with a water content of 105%; it is dried in an oven at 60°C for use in the laboratory Table 1 Chemical composition of raw materialsalloy grinding balls ordinary carbon grinding balls stainless grinding balls Grinding balls specification Under normal circumstances, the diameter of the steel ball of the ball mill is between 20125mm, which is divided into large balls, medium balls and small balls, but the diameter of the steel ball used by the super large ball mill is 1301 Grinding Ball Ball Mill Balls For Sale Ball Mill MediaAir classification is a technique used to separate dry particles according to their size, density or aerodynamic shape RSG Inc manufactures air classifiers for all types of dry powders Small capacity machines start around 1 kg/hr for high density fine metal powders, food and pharmaceutical applicationsAir classifiers Dry grinding mills particle size analysisThe hammer mill, being a shorttime calcining system, grinds, dries, calcines and classifies the raw gypsum in a single step The resulting stucco is suitable for the production of plasterboard, gypsum fiberboard and gypsum wall blocks A hammer mill can process 100% moist FGD gypsum, 100% precrushed natural gypsum, or a mixture of bothCalcining processes for natural and synthetic gypsum

Gypsum Drywall Recycling JWC Environmental

Our Monster Industrial grinders easily grind down gypsum waste preparing it for recycling Watch this video to see how the Monster Industrial 7SHRED shred gypsum and drywall so it can be recycled! Related Resources Zero Waste Monster Learn More KCI Airport Gets a Handle on Lavatory Waste – Kansas City, MOFor slag grinding plant, ball mill generally causes problems of dust accumulation, low grinding efficiency and high grinding temperature The particle size and gradation distribution of the finished product are not as good as those of the vertical mill in the cement roller press grinding 3 Other cement equipmentSlag Grinding Plant GGBS Plant Slag Mill, Slag Cement 4 天之前 Gypsum; Iron and Steel; Marine Powder Handling; Fly Ash, Coal Handling and DirectFiring Mills for Power Plants; From grinding in our famous EM mill to pneumatic conveying, storage, mixing and packing, we have a solution whatever your requirements Dry Mortar Mixing Claudius Peters (CP) is a leading partner for the cement and Gypsum Claudius Peters2021年4月19日 Gypsum (C 0 G 100) is the softest material among the studied; however, it has a sharp feed PSD and low size, which can increase the resistance to grinding This is seen by gypsum’s initial fineness (n = 142), which has a narrower PSD than limestone (n = 070) The uniformities of the materials were very similar after being ground by the ball Resistance to Grinding and Cement Paste Performance of

Everything you need to know about

Normally, grinding aids are added in a 15% concentrated solution (1:7 grinding aid to water – helps the dispersal of grinding aid in mill), at approximately 225 Lb/Ton for medium fineness and 34 Lb/Ton for high fineness cement1996年4月1日 Dry grinding of gypsum (CaSO 4 2H 2 O) with hydrated minerals, such as talc, kaolinite or montmorillonite as an additive was conducted in a planetary ball mill in order to investigate the transformation of gypsum into its hemihydrate form (CaSO 4 1 2 H 2 O)This transformation of gypsum is accelarated by grinding and by the presence of hydrated mineralsMechanochemical changes in gypsum when dry ground with GRINDING AND CLASSIFYING In gypsum powder production, we stand by our customers by offering options of rotary kilns and vertical kilns, enabling them to achieve the best results GYPSUM BASED DRY MORTAR PLANTS CALCITE PRODUCTION PLANTS EXPANDED PERLITE PRODUCTION PLANTS Center Office +90 312 219 13 50GYPSUM TECHNOLOGIES – BaumakGrinding Natural Gypsum Preparation Gypsum Connecting Science and Technology ( Recentlyed No results found Tags Similarly, dry FGD gypsum may consolidate 共bridge兲 and resist mixing under certain conditions Kettle calciners operate most efficiently when the calcining mass is wellGrinding Natural Gypsum Preparation Gypsum

.jpg)

3 mins knowing Wet Grinding vs Dry Grinding: Which Grinding

2023年5月11日 What is dry grinding? Dry grinding refers to a type of grinding method that uses hard abrasives to process materials without the addition of any liquid medium Common dry grinding equipment includes ball mills, highpressure roller mills, and grinding machines Such as metal ores, coal, limestone, gypsum, etc Pharmaceutical preparation 2016年4月12日 A Open End, End Peripheral Discharge, CPD Rod Mills and Grate Discharge Ball Mills are particularly efficient for dry grindingSuch materials as limestone, cement clinker, gravel, phosphates, clays, gypsum, oil shale, terra cotta mixtures, coal and coke are economically reduced in size through their useDry Grinding Coke Grinding 911Metallurgist2022年3月1日 The efficiency of most grinding processes which are performed wet or dry is very low Dry grinding, in particular, is a difficult process in terms of material transportation since the particles are prone to form agglomerates and coating on the media and mill liners due to the static forces that occur during the grinding operation [1]Chemicals that are known as “grinding aids Analysis of grinding aid performance effects on dry fine 2016年12月19日 this mill offers the possibilities of grinding, drying, partly calcining as well as grinding, drying and complete calcining into beta hemihydrate plaster Due to the mill’s technical design, the first gypsum is fed into the mill and the grinding rollers are lowered The initial feed rate is lower than the nominal Below Figure 1 PFEIFFER GC mills type MPS for grinding, drying and

A Comprehensive Guide on the Uses of Gypsum in Cement

2024年8月20日 Gypsum, when dry, contains calcium (23%) and sulfur (17%) Uses of Gypsum in Cement Gypsum acts as a binding agent in the cement and controls various factors in it It is also used in the walls where fire protection is required since it has a natural fireresistance property Calcium sulfate also known as gypsum during grinding, can be