Cracking carbon black crushing plan, processing materials

.jpg)

Prospect and challenges of producing carbon black from oil

2023年9月1日 In producing highquality carbon black, the processing of initial feedstock must be carried out to facilitate handling and feeding to the carbon black plant Oil palm biomass with 2024年5月1日 Methane (CH 4) cracking is emerging as a bridge technology for hydrogen (H 2) production fostering the transition from current carbonintensive production processes (eg Turquoise hydrogen and carbon materials production from 2022年7月18日 The study encompasses a comprehensive analysis of existing carbon black manufacturing methodologies, emphasizing key parameters such as feedstock selection, reactor design, and process(PDF) Production of Carbon Black ResearchGate2017年8月25日 at increasing the output of thermal gasoil on a thermal cracking plant by altering the process conditions without changing the crackingunit flowsheet failed to give positive Increasing the yield of carbon black feedstock on a

(PDF) Carbon black and hydrogen production

2020年4月20日 It presents the Carbon Black and Hydrogen Process (CBH Process) as an alternative option for hydrogen generation at large scale facility, suitable for supplying large amounts of2017年8月27日 from a catalytic cracking unit, these gas oil cuts representing raw material for feedstocks in carbonblack production The catalytic cracking was conducted in two regimes, a Catalytic gas oils used as raw material for carbonblack2023年4月13日 Carbon Black is obtained by incomplete combustion or thermal cracking of hydrocarbonrich raw materials Orion Engineered Carbons uses various processes to Handling of carbon black Orion2015年12月18日 Allothermal cracking of methane is a suitable and ecofriendly way to simultaneously produce hydrogen and carbon black The economic viability of the process Full article: Influence of temperature and pressure on carbon black

.jpg)

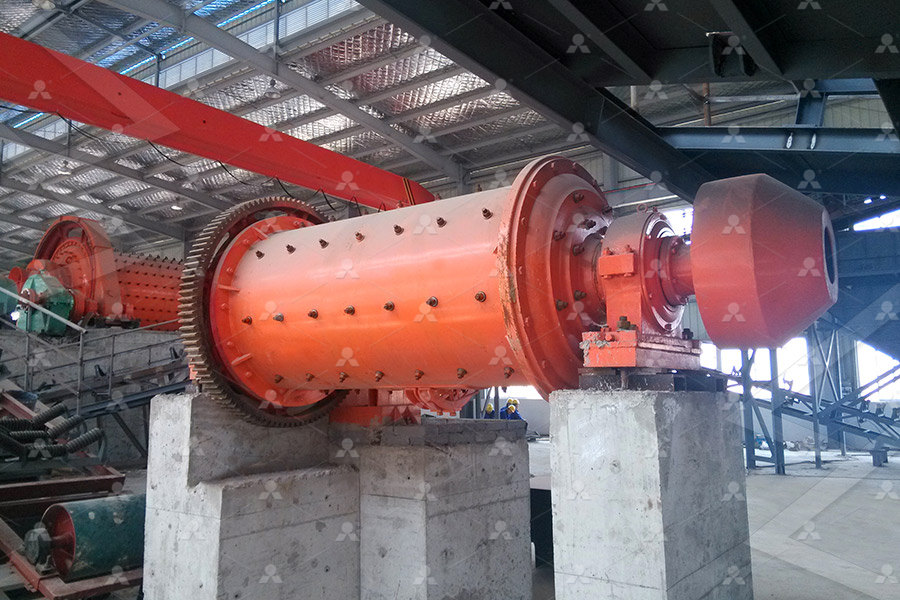

CAMC Horizontal Cracking Carbon Black Deep Processing

process flow 1 Cracking: Using continuous cracking equipment under high temperature and catalyst action, crude carbon black is cracked in negative pressure and some corresponding 2021年5月19日 The internal gelation process using previously boiled hexamethylenetetramineurea was used in exploratory study to produce CeO2–ZrO2 microspheres, which can serve as a simulant for ceramic (PDF) The effect of washing process on the cracking of ZrO 2 2020年4月20日 CBH Process refers to a plant with hydrogen thermal plasma reactor able to decompose Hydrocarbons (HC's) into Hydrogen (H2) and Carbon Black (CB), a cleaner technology than its competing (PDF) Carbon black and hydrogen production 2022年4月26日 The optimization capabilities for crushing plants comprise a system solution with the twofold application of 1) Utilizing the simulation platform for identification and exploration of operational (PDF) Optimization Capabilities for Crushing

.jpg)

A Practical Finite Element Modeling Strategy to Capture Cracking

2021年1月21日 The proposed modeling strategy aims at providing reliable predictions of flexural responses of RC members with a focus on concrete cracking behavior and crushing failure, which serve as the 2020年5月6日 Stress corrosion cracking is a phenomenon associated with a combination of tensile stress, corrosive environment and, in some cases, a metallurgical condition that causes the component to premature failures The fractures are often sudden and catastrophic, which may occur after a short period of design life and a stress level much lower than the yield stress It Stress Corrosion Cracking Behavior of Materials IntechOpen2021年8月31日 Carbon blacks of different finenesses have different application ranges, so it is necessary to process carbon black raw materials to obtain the required carbon black powder Stage 1: broken The raw carbon black ore is crushed into small particles by the jaw crusher and then sent to the storage bin by elevatorCarbon Black Ultrafine Powder Mill SBM Ultrafine Powder 2022年9月1日 The rubber material on a tyre is mostly distributed on the tread and sidewalls The rubber blends used vary depending on the desired application but often contain varying proportions of polyisoprene (natural rubber), and synthetic rubbers, such as polybutadiene and styrenebutadiene rubber (SBR) (SangiovanniVincentelli Martin, 2001)The use of carbon Material recovery and recycling of waste tyresA review

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface2018年8月6日 Coconut shell is a raw material for producing carbon black, which is useful as an alternative material for absorbing and attenuating electromagnetic interference (Karmankar, 2016) (PDF) EXTRACTION OF CARBON BLACK FROM THE COCONUT SHELL Materials 2021, 14, 506 3 of 26 described in detail [22,23] Therefore, it is important for the research community to evaluate the existing approaches [2,24,25] for assigning the bond–slip A Practical Finite Element Modeling Strategy to Capture 2022年3月21日 Significant academic research and moderate commercial process innovation on rareearth element (REE) processing have been underway for decades The last several years have seen exponential growth in research due to growth in demand of REE that is threatened by supply risks and environmental obstacles The REE industry appears to be at the intersection Processing the ores of rareearth elements MRS Bulletin

.jpg)

Carbon Black SP Global

Thermal Cracking Catalytic and Thermal Cracking Catalytic or Thermal Cracking Fluid Coking Thermal Cracking and Coking Furnace Process for Carbon Black Raw Material Cost in Carbon Black Production Cost of Carbon Black Plants Adjusted to CE Cost 2024年1月5日 The above micromodels were used for quasistatic cracking simulations of quasibrittle materials using the FEM [23, 43, 44] and SBFEM [27], and good simulation results were obtained Concretelike materials are highly ratedependant under dynamic loading In addition, the effects of the strain rate were not instantaneous [9] When the strain Simulation of the dynamic cracking of brittle materials using 2023年9月28日 The carbon black material used as reinforcing filler in tires was recovered by vacuum pyrolysis at a temperature of 500°C and a total pressure of 20 kPa(PDF) Mechanical properties of pyrolysis carbon black in 2016年10月1日 However, some polymer composites comprising of certain filler materials like carbon particles, carbon fibres and nanotubes could render the polymer matrix opaque resulting in incompatibility with OCT imaging [162] With the advancement of OCT technique, several other OCT techniques have been developed in addition to classic OCT, such as Cracks, microcracks and fracture in polymer structures:

.jpg)

3D modelling of carbon black formation and particle

2003年1月1日 The most stable materials are the carbon blacks having the highly ordered graphitic structure, prepared in thermal plasma process by hydrocarbons cracking These materials present a low surface 2001年3月1日 An original plasma process for carbon black and hydrogen synthesis is presented A pilot scale (100 kW) reactor is developed to obtain new carbon black grades from hydrocarbon crackingCarbon Black processing by thermal plasma Analysis of the 2016年3月11日 Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of Crushing Plant Flowsheet DesignLayout 911Metallurgist1999年7月12日 There was no shortage of theories regarding the cause of the problem Degradation during processing and attack by ultraviolet radiation were ruled out by the melt flow test The raw material typically was produced in the range of 5 to 6g/10 minutes; no molded part exceeded 66g/10 minutesThe Materials Analyst, Part 22:Stress cracking: How to avoid

.jpg)

Optimization Capabilities for Crushing Plants Chalmers

minerals processing is to maximize material ore throughput below a target size fraction for the subsequent process The operation of a crushing plant is complex and suffers variabilities during the process operation, resulting in a drive for optimization Procedure Place about a 2 cm 3 depth of mineral wool in the bottom of the boiling tube and gently press it in place with a glass rod Drop about 2 cm 3 of liquid paraffin on to the wool, using a dropping pipette Use enough paraffin to Cracking hydrocarbons in liquid paraffin with a 2022年6月1日 Other carbon materials, eg carbon black and carbon molecular sieves, can be also prepared from coal and its derivatives Wang group [112, 113] prepared carbon black from coal tar via chemical looping pyrolysis The particle size of asprepared carbon black was between 20 and 50 nm, and the yield reached 535%Synthesis, modification strategies and applications of coal 2024年11月7日 Discover a toptier waste tire cracking carbon black deep processing line for all your carbon black needs Highquality equipment for efficient production : jinghuapowder@163; Phone: +86(WhatsApp/Wechat) Battery New Material; Fine Chemical Material; Superhard Functional Material; Nonmetallic Mineral Material; China Waste Tire Cracking Carbon Black Deep Processing

TechType: Carbon Black Process ppPLUS

2024年6月30日 Carbon Black Process Details Lamp Black Process This method obtains carbon black by collecting soot from fumes generated by burning oils or pine wood This process is the oldest way to produce carbon black (formerly from oil lamps) and has been used since antiquity BC, and is not suitable for mass production2024年3月1日 Next, a brief overview of the mechanism of catalytic methane cracking for hydrogen production and the characteristics of the generated carbon as a byproduct are presented Finally, the catalytic cracking of methane in molten media or solid materials and the research trend were prospectedMethane catalytic cracking by solid materials and molten Carbon Black Processing Plant Main applications and production process of the carbon black processing machine: The carbon black from waste tyre pyrolysis after processed is characterized as N220, N330, N660, with composite structure It has both excellent high reinforcement and a wide range of generalpurpose properties, which is a reinforcing Carbon Black Processing Plant/Machine for Sale Beston 2022年10月1日 The material composition of passenger car tires is usually based on higher content of synthetic rubber and carbon black in comparison to truck tires Therefore, the performance properties of passenger car tires (eg low rolling resistance, improved skid resistance, good wear, etc) [30] are higher than truck tires At the same time, waste Waste tire rubberbased materials: Processing

(PDF) Stress Corrosion Cracking Behavior of Materials

PDF On May 6, 2020, Alireza Khalifeh published Stress Corrosion Cracking Behavior of Materials Find, read and cite all the research you need on ResearchGate2016年3月24日 Electrochemical hydrogen charging and permeation techniques were used to characterize hydrogen distribution, trapping, and diffusion in X60 and X60 sour service (X60SS) pipeline steels The results obtained contribute to better understanding of hydrogeninduced cracking (HIC) SEM observations illustrated that all HIC cracks were formed at the center of HydrogenInduced Cracking Assessment in Pipeline Steels 2023年1月1日 Pyrolysis of hydrocarbons refers to any thermally induced decomposition of hydrocarbon feedstocks in the absence of oxygen Industrial interest in this process is longlasting and historically covers many areas such as the thermal decomposition of natural gas to produce carbon black (Halloran, 2008; SánchezBastardo et al, 2021a), the production of ethylene Catalytic and noncatalytic chemical kinetics of hydrocarbons cracking 2021年5月19日 The internal gelation process using previously boiled hexamethylenetetramineurea was used in exploratory study to produce CeO2–ZrO2 microspheres, which can serve as a simulant for ceramic (PDF) The effect of washing process on the cracking of ZrO 2

.jpg)

(PDF) Carbon black and hydrogen production

2020年4月20日 CBH Process refers to a plant with hydrogen thermal plasma reactor able to decompose Hydrocarbons (HC's) into Hydrogen (H2) and Carbon Black (CB), a cleaner technology than its competing 2022年4月26日 The optimization capabilities for crushing plants comprise a system solution with the twofold application of 1) Utilizing the simulation platform for identification and exploration of operational (PDF) Optimization Capabilities for Crushing 2021年1月21日 The proposed modeling strategy aims at providing reliable predictions of flexural responses of RC members with a focus on concrete cracking behavior and crushing failure, which serve as the A Practical Finite Element Modeling Strategy to Capture Cracking 2020年5月6日 Stress corrosion cracking is a phenomenon associated with a combination of tensile stress, corrosive environment and, in some cases, a metallurgical condition that causes the component to premature failures The fractures are often sudden and catastrophic, which may occur after a short period of design life and a stress level much lower than the yield stress It Stress Corrosion Cracking Behavior of Materials IntechOpen

Carbon Black Ultrafine Powder Mill SBM Ultrafine Powder

2021年8月31日 Carbon blacks of different finenesses have different application ranges, so it is necessary to process carbon black raw materials to obtain the required carbon black powder Stage 1: broken The raw carbon black ore is crushed into small particles by the jaw crusher and then sent to the storage bin by elevator2022年9月1日 The rubber material on a tyre is mostly distributed on the tread and sidewalls The rubber blends used vary depending on the desired application but often contain varying proportions of polyisoprene (natural rubber), and synthetic rubbers, such as polybutadiene and styrenebutadiene rubber (SBR) (SangiovanniVincentelli Martin, 2001)The use of carbon Material recovery and recycling of waste tyresA review2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist2018年8月6日 Coconut shell is a raw material for producing carbon black, which is useful as an alternative material for absorbing and attenuating electromagnetic interference (Karmankar, 2016) (PDF) EXTRACTION OF CARBON BLACK FROM THE COCONUT SHELL

.jpg)

A Practical Finite Element Modeling Strategy to Capture

Materials 2021, 14, 506 3 of 26 described in detail [22,23] Therefore, it is important for the research community to evaluate the existing approaches [2,24,25] for assigning the bond–slip