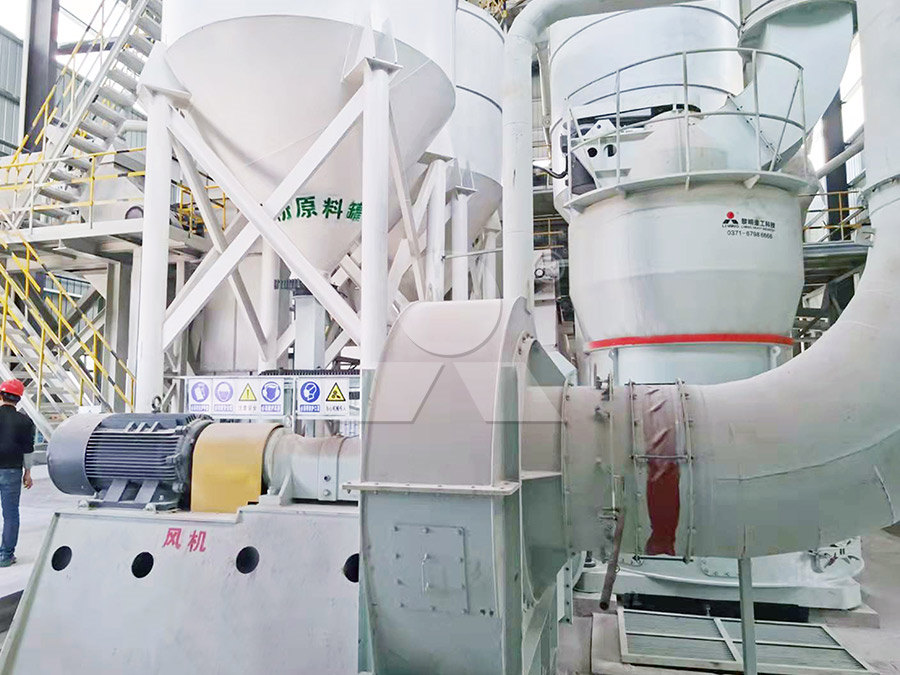

Iron powder processing and crushing

.jpg)

金属材料の粉末技術~鉄粉~ JSTAGE

In this paper, the details of production process of iron powders containing alloyed steel powders in JFE steel, which produces both reduced and water atomized iron powders, are described In 2004年1月27日 This has been for long the most widely used method for the production of iron powder Selected ore is crushed, mixed with carbon, and passed through a continuous furnace Powder Metallurgy – Powder Processes (Solid State There are four main processes used in powder production: solidstate reduction, atomization, electrolysis, and chemical In solidstate reduction, selected ore is crushed, typically mixed with carbon, and passed through a continuous furnaceMaking Metal Powder MPIF2017年8月27日 The Production of Iron Powder The various methods used to manufacture iron powder are as follows: 1 Reduction (a) Carbon reduction of ore concentrates (b) Hydrogen Iron Powder: ProductionCharacteristicsFabrication

Iron Ore Processing, General SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and 2024年5月18日 For this reason, this paper investigates the properties and characteristics of ultrafine iron powder prepared by hydrogen reduction Highpurity ultrafine iron powder was Production of ultrafine iron powder by lowtemperature 2022年7月30日 To avoid differences in the sintering properties of the same iron ore powder due to different particle sizes, this study carried out the assimilation, liquid phase fluidity indices, and binding phase strengths of several iron ore Study on the Basic Characteristics of Iron Ore 2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct Comminution and classification technologies of iron ore

.jpg)

Iron Ore Sintering: Process: Mineral Processing and Extractive

2017年3月24日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents, and solid fuel (coke) The 2004年1月27日 This has been for long the most widely used method for the production of iron powder Selected ore is crushed, mixed with carbon, and passed through a continuous furnace where reaction takes place leaving a cake of sponge iron which is then further treated by crushing, separation of nonmetallic material, and sieving to produce powderPowder Metallurgy – Powder Processes (Solid State 2024年1月19日 The obtained iron powder is sent to a dryer for drying to obtain iron fine powder Australia, Brazil, China, India, Russia, South Africa and Canada are all countries with rich iron ore resources in the world These regions are home to large iron ore deposits and provide the majority of the world's iron ore supplyHow to process iron ore SANDMINE2022年11月17日 Copper–iron alloys are used as structural, electrical contact, and elastic materials and those for the protection against electromagnetic waves They have wide prospects for applications in electronics and in the manufacture of semiconductors, automotive parts, and medical equipment Conventional methods for producing Cu–Fe alloys by melting and for The Influence of Rolling Processing on the Structure and

.jpg)

Crushing Mineral Processing 911Metallurgist

2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separation2024年5月18日 Ultrafine iron powder is widely used due to its excellent performance Hydrogen reduction of finegrained highpurity iron concentrate to prepare ultrafine iron powder has the advantages of low energy consumption, pollutionfree, and low cost The hydrogen reduction of highpurity iron concentrates, characterized by the maximum particle size of 643 μm when the Production of ultrafine iron powder by lowtemperature 2018年6月21日 In contrast to the direct reduced iron process, the blast furnace process can be operated on a large scale After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually processed During pelletizing, ore powder is rolled into iron ore green pellets in rotating drums together with water Iron ore mining and dressing tecscience5 天之前 The product fineness of bentonite powder processing equipment Raymond mill is generally around 325400 mesh With the development of technological progress, the demand for finer powder products is increasing Improve the ability to capture fine powder and reduce pollution to the surrounding environmentBentonite Processing Methods And Required Equipment

.jpg)

Iron Ore Processing JXSC Mineral

2024年11月22日 Iron Ore Dressing The iron ore dressing process is aimed at the processing of iron ore materials, which is divided into crushing and screening, grinding and classification, separation, and dehydrationCrushing and screening refers to the crushing and screening of iron ore to ensure that the particle size of crushed ore can provide ore that meets the requirements 2023年4月7日 Magnetite is an important iron ore, so how to extract iron? Magnetite processing requires crushing, grinding, beneficiating, and drying 2 After drying and dehydration in a dryer, the dried iron concentrate powder is obtained Through the above process, the magnetite processing plant can obtain more than 65% of highquality iron ore How to Recover Iron from Magnetite: 4 Methods and Stages2022年1月1日 Additionally, iron ore processing facilities often receive ores from various sources (such as satellite pits) with different qualities These ores may be treated by different processing routes and/or blended to meet product specifications Some examples of different iron ore crushing and screening flowsheets are provided below:Comminution and classification technologies of iron ore2022年1月23日 Additionally, when the downstream process involved grinding mills, the fines created from highspeed crushing circuit were a benefit to the comminution process In general, if the feed material, application parameters, and downstream process match with the capabilities of a highspeed impact style crusher, this is the crusher type to usePhysical Bauxite Processing: Crushing and Grinding of Bauxite

Iron ore crushing equipment and process flow

2022年8月17日 Iron ore crushing process In the iron ore crushing process, the feeder, first crushing, secondary crushing, screening, fine crushing and dry selection are generally used For the sake of economy, generally the finer the 2023年9月5日 2 Preparation Methods of Metal Powder: 21 Physicochemical Methods 211 Reduction Method The reduction of metal oxides and salts is a widely used method for powder preparation Solid carbon can be used to Metal Powder Preparation Methods and 2021年8月27日 1 A hard brittle layer of pure metal which is subsequently milled to obtain powder (eg iron powder) 2 A soft, spongy substance which is loosely adherent and easily removed by scrubbing 3 A direct powder deposit from the electrolyte that collects at the bottom of the cell Factors promoting powder deposits are, high current density, low metalPowder metallurgy – basics applications IIT Guwahati2023年11月15日 EARTHTECHNICA CO, LTD Taking full advantage of our promising technologies for 'CRUSHING, GRINDING AND SEPARATION', we are globally developing four businesareas consisting of Crushing grinning, Recycling, Powder processing and Casting products to meet the customer needsEARTHTECHNICA CO, LTD

.jpg)

A novel approach to enhance decrepitation temperature and

2024年7月24日 Utilizing ultrafine iron ore concentrate for pellet production can expand domestic iron ore resources in China and promote the utilization of lowgrade ores However, a challenge arises with the low decrepitation temperature and reducibility in the preparation process of ultrafine iron ore concentrate pellets To address the challenge, a novel approach was 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding processThe GP (singlecylinder) hydraulic cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines The copper powder of 012mm sieved by the vibrating screen is evenly sent to the ball mill for grinding, and sieved by the spiral classifier Ball MillCopper Ore Processing Solution Eastman Rock Crusher2014年1月1日 PM has its origins in Egypt 3,000 years ago where a crude form of iron powder forming was practiced Modern industrial PM mass production arose in the nineteenth century, making copper coins, medallions, ingots, and tungsten wires that needs to be reduced to as fine as 30 mm by crushing/grinding Similar processes develop in ball/vertical Powder Processing of Bulk Components in Manufacturing

82: Mining and Ore Processing Geosciences LibreTexts

Media Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 2024年6月13日 The copper ore powder after flotation is fed into the dryer for drying, and finally, copper concentrate is obtained Copper Ore Crushing Equipment Jaw crusher: Used for primary crushing and processing large Copper Introduction And Ore Crushing JXSC Iron processing Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by Iron processing Ores, Smelting, RefiningIron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense Iron processing Definition, History, Steps, Uses,

Crushing and grinding process of copper ore Crusher Plant

Cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines Solid structure, stable performance, automatic control, easy operation, integration of thin oil lubrication Stage 2: Grinding The 012mm copper powder sieved by the vibrating screen is evenly sent to the ball mill for 2024年1月23日 Those machines are suitable for gypsum powder processing Users can also choose suitable grinding machine equipment according to their own needs Eastman is a professional mining equipment manufacturer with 38 years of rich experience in the mining construction industry We can also provide lab equipment 700tph Iron Ore Crushing PlantGypsum Powder Grinding And Processing Plant Equipment2024年5月9日 The strong magnets will attract the fine iron ore powder Iron particles are drawn to and taken by the magnets This magnetic separation technique is effective for highquality ores, such as magnetite A magnet is used to attract magnetic iron particles and the waste rock is discarded Through this process, we get concentrated iron ore powderIron Ore Mining Essentials: Key to Steel Production JXSC2024年8月7日 Types of Mineral Processing Equipment Crushing Equipment: Essential in mineral processing, crushing breaks down large ore blocks into smaller, manageable pieces for further processing Primary crushing is the reduction of significant ore particles into smaller bits using jaw crushers Key types include Jaw Crushers, which handle large rocks Mineral Processing Equipment for Mining Industry

.jpg)

(a) Iron ore powder from crushing plant waste and (b) charcoal powder

A production of pig iron has been conducted from crushing plant waste The process of preparing pig iron was using hot blast cupola (HBC) furnace which was injected with charcoal powder to improve 2016年11月1日 A production of pig iron has been conducted from crushing plant waste The process of preparing pig iron was using hot blast cupola (HBC) furnace which was injected with charcoal powder to improve (PDF) The production of pig iron from crushing plant waste using hot This has been for long the most widely used method for the production of iron powder Selected ore is crushed, mixed with carbon, and passed through a continuous furnace where reaction takes place leaving a cake of sponge iron which is then further treated by crushing, separation of nonmetallic material, and sieving to produce powderPowder Manufacture – EPMA Association2004年1月27日 This has been for long the most widely used method for the production of iron powder Selected ore is crushed, mixed with carbon, and passed through a continuous furnace where reaction takes place leaving a cake of sponge iron which is then further treated by crushing, separation of nonmetallic material, and sieving to produce powderPowder Metallurgy – Powder Processes (Solid State

.jpg)

How to process iron ore SANDMINE

2024年1月19日 The obtained iron powder is sent to a dryer for drying to obtain iron fine powder Australia, Brazil, China, India, Russia, South Africa and Canada are all countries with rich iron ore resources in the world These regions are home to large iron ore deposits and provide the majority of the world's iron ore supply2022年11月17日 Copper–iron alloys are used as structural, electrical contact, and elastic materials and those for the protection against electromagnetic waves They have wide prospects for applications in electronics and in the manufacture of semiconductors, automotive parts, and medical equipment Conventional methods for producing Cu–Fe alloys by melting and for The Influence of Rolling Processing on the Structure and 2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing 911Metallurgist2024年5月18日 Ultrafine iron powder is widely used due to its excellent performance Hydrogen reduction of finegrained highpurity iron concentrate to prepare ultrafine iron powder has the advantages of low energy consumption, pollutionfree, and low cost The hydrogen reduction of highpurity iron concentrates, characterized by the maximum particle size of 643 μm when the Production of ultrafine iron powder by lowtemperature

Iron ore mining and dressing tecscience

2018年6月21日 In contrast to the direct reduced iron process, the blast furnace process can be operated on a large scale After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually processed During pelletizing, ore powder is rolled into iron ore green pellets in rotating drums together with water 5 天之前 The product fineness of bentonite powder processing equipment Raymond mill is generally around 325400 mesh With the development of technological progress, the demand for finer powder products is increasing Improve the ability to capture fine powder and reduce pollution to the surrounding environmentBentonite Processing Methods And Required Equipment2024年11月22日 Iron Ore Dressing The iron ore dressing process is aimed at the processing of iron ore materials, which is divided into crushing and screening, grinding and classification, separation, and dehydrationCrushing and screening refers to the crushing and screening of iron ore to ensure that the particle size of crushed ore can provide ore that meets the requirements Iron Ore Processing JXSC Mineral2023年4月7日 Magnetite is an important iron ore, so how to extract iron? Magnetite processing requires crushing, grinding, beneficiating, and drying 2 After drying and dehydration in a dryer, the dried iron concentrate powder is obtained Through the above process, the magnetite processing plant can obtain more than 65% of highquality iron ore How to Recover Iron from Magnetite: 4 Methods and Stages

Comminution and classification technologies of iron ore

2022年1月1日 Additionally, iron ore processing facilities often receive ores from various sources (such as satellite pits) with different qualities These ores may be treated by different processing routes and/or blended to meet product specifications Some examples of different iron ore crushing and screening flowsheets are provided below: