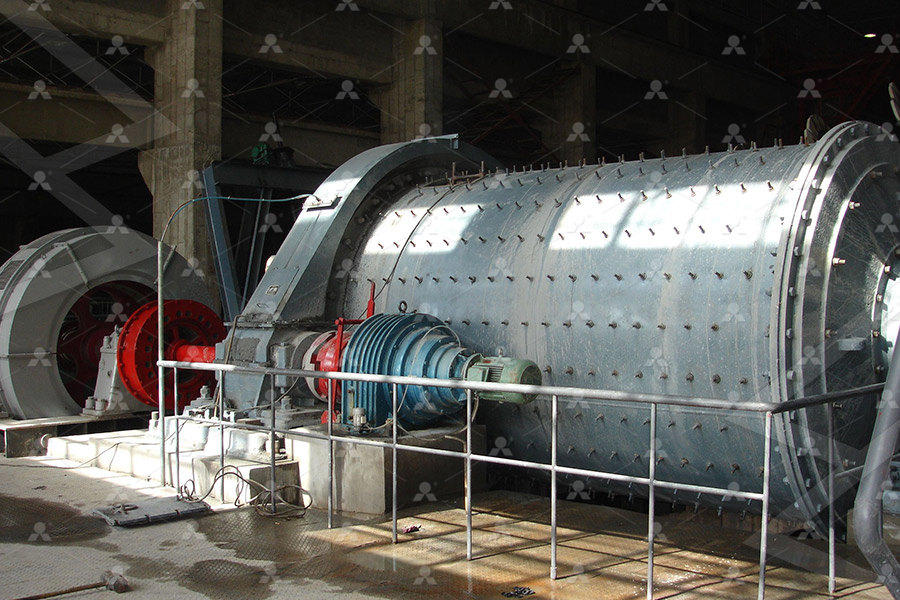

Shenhua Junneng coal preparation plant heavy medium workshop

.jpg)

The Shenhua coal direct liquefaction plant ScienceDirect

1999年5月1日 The preliminary feasibility study envisions construction of a 12,000 metric ton/day coal standalone liquefaction complex, with facilities for coal preparation, coal mixing, 1999年5月1日 Steam gasification of char from Shenhua coal direct liquefaction residue (DLR) was investigated in a fixed bed reactor The effect of temperature, mineral, liquefaction The Shenhua coal direct liquefaction plant Semantic ScholarBy the end of 2023, China Shenhua operated 35 intelligent coal mining faces and 61 intelligent roadway development working faces at underground coal mines There were 19 intelligent Company Profile2021年3月23日 Direct coal liquefaction is actually a process of coal hydrogenation at high temperature and high pressure with the action of catalyst Use of Shenhua direct coal Shenhua Coal Conversion Technology and Industry

.jpg)

Shenhua Coal to Liquids Plant, China Offshore Technology

2008年8月28日 The Shenhua Group Corporation, which is one of the world’s largest coal companies, began to construct the world’s first commercial direct coal liquefaction plant, 2004年4月1日 This paper presents the first indepth case study of China’s pioneering coal liquefaction project carried out in the Shenhua Group This project is of great potential Coal Liquefaction, Shenhua Group, and China’s Energy Security2014年9月12日 Process that suits the maceral characteristics of Shenhua coal is to control the reaction time of SDV and SDI in the same reaction system to avoid secondary pyrolysis of Research on the maceral characteristics of Shenhua coal and 2017年7月20日 On 12 June, I had the pleasure of visiting the world’s biggest single coaltoliquid (CTL) project, accompanied by Professor Yao Qiang, Tsinghua University, Professor Yu Visiting the world's biggest single coaltoliquid project in ICSC

[GYQ0R)ZQ]ESS4NJ.jpg)

Heavyweights in coal preparation ScienceDirect

2018年7月1日 Here, we look at two heavyweights in coal preparation, which reduced abrasion during the separation process, so decreasing the cost of maintenance Heavy medium 2021年8月27日 In the sevenfloor washing workshop of Shangwan Coal Preparation Plant, nearly no workers were seen, but only the roar of machines could be heard “With the remote Shendong Coal Group: Smart Coal Preparation Boosts High For the coal washability characteristics of that plant, a wateronly plant was shown to be more profitable than a heavy mediabased plant, although the latter provides better separation efficiencyFlowsheet of a modern coal preparation plant 2014年9月9日 The dense medium cyclone (DMC) process used in coal beneficiation plants is studied from a control system perspective Employing the dynamic model of the DMC process derived from mass flow balance Medium Density Control for Coal Washing

.jpg)

The Shenhua coal direct liquefaction plant Semantic Scholar

1999年5月1日 Semantic Scholar extracted view of "The Shenhua coal direct liquefaction plant" by A Comolli et al The effect of temperature, mineral, liquefaction catalyst and heavy oil Expand 22 Save Direct liquefaction techniques on lignite coal: A review Arif Ali Chen Zhao Environmental Science, Engineering Chinese Journal of Catalysis 2010年5月4日 Since it began operating, the plant has processed 42 million tons of raw coal The plant’s raw feed capacity is 600 tons per hour (tph) and the yield at the plant is approximately 43% plus or minus 3% The design of any new coal prep plant is governed by the raw coal washability of that particular mine’s seam collectionICG’s New Beckley Prep Plant Incorporates the Latest Coal There were 19 intelligent coal preparation plants 208 unmanned production vehicles worked in openpit coal mines Research, development and application were conducted for more than 200 sets of coal mine robots specialized in tunnelling, mining, coal transportation, safety control and rescue Performance rate of mediumterm and longterm Company Profile2016年10月22日 Panji coal preparation plant applies advanced and reliable separation circuit and equipment with China’s independent intellectual property rights such as gravityfed nondeslimed nonclassified three product heavy medium cyclone, fine coal heavy medium cyclone, jet flotation machine, inclined pipe thickener, and etcProcess Features of Panji Coal Preparation Plant SpringerLink

.jpg)

PERFORMANCE OPTIMIZATION OF A COAL

Performance Optimization of a Coal Preparation Plant Using Genetic Algorithms Vishal Gupta, Manoj K Mohanty, Ajay Mahajan Most of the coarse coal circuits make use of heavy medium processes 2023年11月22日 A new hybrid magnetic separator could improve recovery for heavymedia plants By Steve Fiscor, EditorinChief Eriez has been busy applying innovations in both magnetic circuit design and materials of construction to its line of wet drum magnetic separators The goal is to maximize magnetite recovery while operating with a minimum amount of wear and Advances in Magnetite Recovery Coal Age1 天前 (1) Crushing: The large pieces of coal are sent to the jaw crusher by the vibrating feeder for rough crushing, and the conveyor transports the coarsely crushed materials to the impact crusherThe impact crusher is suitable for medium or fine crushing to further dissociate clean coal (2) Screening: Thevibrating screen screens out three kinds of materials with different particle Coal Washing Process Plant JXSC Machinery2023年9月18日 Dense Medium Separation (DMS) stands as a cornerstone in the realm of mineral processing and ore beneficiation At its core, DMS leverages the inherent density differences between valuable minerals and gangue materials to achieve highly efficient separation This ingenious process relies on a dense medium—a suspension of finely ground The design and Performance of Dense Medium Separation Plants

.jpg)

A causal matrixbased method for key process

2018年6月1日 The implementation steps of CPKPIM are demonstrated in details through a case study in a heavy medium coal preparation plant Based on the total process criticality assessments, eleven key 2021年11月5日 Two prep plants were added (one active and one idle), seven active plants were listed as idle and six plants were removed Knowing that some prep plants may reopen and that permits remain active in some states, Coal 2021 US Prep Plant Census Coal Age2010年6月13日 The first thing to determine about a heavy media sump, regardless of whether it is for a coarse coal vessel or a heavy media cyclone circuit, is whether the sump level is set to rise or drop When the feed changes to a finer particle size, most parts of a coal preparation plant are heavily affected For an HMC circuit, the finer material An Evaluation of Heavy Media Control Methods Coal Age2023年9月27日 the heavy media coal separation process has been widely used in the coal separation process and has become the main meth od of coal separation, which h as m any advantages, s uch as h igh s o rtingAnalysis of Intelligent Control Strategy for Heavy Media Coal

The beneficiation of tailing of coal preparation plant by heavymedium

2018年9月17日 Densemedium cyclones have been used for beneficiation of fine particles of coal In this study, the usability of cyclones in the beneficiation of tailings of a coal preparation plant was investigated For this purpose, separation tests were conducted using spiral concentrator and heavy medium cyclones with the specific weight of medium 13–18 (g/cm3) 1999年5月1日 On September 22, 1997, Hydrocarbon Technologies (HTI) signed an agreement with Shenhua Clean Coal Technology Development, (SCCT) and China Coal Research Institute (CCRI) to execute a feasibility study for the construction of a Direct Coal Liquefaction plant in China, one of the major projects in China's ninth 5year planThe Shenhua coal direct liquefaction plant ScienceDirect2020年3月31日 In 2019, Industrial Resources designed and built an addition for a West Virginia coal preparation plant to increase its raw feed capacity from less than 900 tons per hour (tph) to more than 1,200 tph, a 35% to 40% increase It was clear that the existing preparation plant’s heavymedia cyclone circuit was heavily loaded, being pushed to Additional Heavymedia Cyclone Circuit Recovers More Coal2022年12月13日 The shortcomings of the density control system for heavy media suspension in the current coal preparation plant were introduced The intelligent control system of heavy media separation suitable for different coal quality characteristics in LinHuan Coal Preparation Plant was proposed The system was mainly composed of the following parts: relationship between ash Intelligent control of heavy media separation International

McArthur River Mine Heavy Medium Plant – The Benefits

2018年2月20日 availability In contrast to existing base metal heavy medium plants in Australia, the MRM Flow sheet utilised the principles in modern coal heavy medium cyclone plant design Since commissioning, the plant feed rate has been significantly increased and is now normally operated up to 540 t/h (dry basis)2023年10月27日 Operators add capacity to process future production By Steve Fiscor, EditorinChief Coal markets softened during the summer of 2023, but activity continues on a steady course for most coal producers Meanwhile, the medium and longterm outlook for demand remains strong, especially for metallurgical coal markets Those trends are reflected in Coal Age’s 2023 US Prep Plant Census Coal AgeThe national standard GB/T350542018, titled "Test Methods and Judgment Rules for Process Performance of Heavy Medium Cyclones for Coal Preparation," was issued General contracting for the construction of the largest coking coal preparation plant in China, "Shenhua Bayannur Energy Co, Ltd Coal Preparation Plant (12 million tons/year)"Beijing Guohua Technology Group2024年1月19日 22 Outperformance of heavy medium coal preparation technology Heavy medium coal preparation technology has been promoted as a common method because it can be adapted to different coal qualities COAL PREPARATION TECHNOLOGY: STATUS AND

.jpg)

(PDF) Valorization of South African Coal Wastes

2022年11月28日 In this work, dense medium separation studies of coal discards, using heavy liquids, resulted in three pooled fractions from typical South African coal waste discards from the Mpumalanga region In 2012, a single module heavy medium cyclone plant (HMP) was installed at the Glencore Zinc's (then Xstrata Zinc) McArthur River lead zinc mine The HMP formed the first part of the MRM Phase 3 Project to increase run of mine (ROM) capacity from 24 to 55 Mt/aThe purpose of the HMP is to remove liberated gangue from the crusher product at minimal loss of valuable McArthur River Mine Heavy Medium Plant The Benefits of This process has been used internationally in over 500 coal preparation plants Separates run of mine coal down to 025 mm and a top size as large as 4 inch (110 mm) using a 1500 mm diameter gravityfed 3product cyclone without desliming the raw coal Runofmine coal can be further separated down to 01 mm when combining the 3product heavy 3 Product Heavy Media Cyclone The Daniels Company2022年3月13日 Highefficiency deashing and desulfurization of fine coal is an inevitable trend in the comprehensive utilization of coal resources This work introducing heavymedium into the enhanced gravity Performance optimization and parametric evaluation of coal

An integrated heavy media cycloneflotation system for coal

1993年11月1日 Flotation was used to achieve improved separation of magnetite from the float and sink products obtained from heavy medium separation and to reduce the load of the medium cleaning circuit The investigation was carried out in two successive phases In the first phase, tests were performed on inplant samples from the Homer City Coal Prepation plant to 2019年8月29日 A full heavy medium preparation technique with a full closed circulation and full automation production is applied to all related coal preparation plants There are three major products of cleaned coal, cleaned mixed coal and Pingshuo mixed coal with over a dozen of coal products from the coal preparation plants中煤平朔集团有限公司 About PingshuoSemantic Scholar extracted view of "Recovery of Heavy Medium in Coal Washing Plant Using a Flat Plate Magnetic Separator and Optimization of Flow and Magnetic Fields" by C Shi et al Application of screening using a flipflow screen and shallow groove densemedium separation in a steam coal preparation plantRecovery of Heavy Medium in Coal Washing Plant Using a 2023年2月1日 Heavy medium coal washing technique can achieve deep coal desulfurization and ash reduction It is an important approach that can ensure clean and efficient utilization of coalRecovery of heavy medium in coal washing plant using a flat

Flowsheet of a modern coal preparation plant

For the coal washability characteristics of that plant, a wateronly plant was shown to be more profitable than a heavy mediabased plant, although the latter provides better separation efficiency2014年9月9日 The dense medium cyclone (DMC) process used in coal beneficiation plants is studied from a control system perspective Employing the dynamic model of the DMC process derived from mass flow balance Medium Density Control for Coal Washing 1999年5月1日 Semantic Scholar extracted view of "The Shenhua coal direct liquefaction plant" by A Comolli et al The effect of temperature, mineral, liquefaction catalyst and heavy oil Expand 22 Save Direct liquefaction techniques on lignite coal: A review Arif Ali Chen Zhao Environmental Science, Engineering Chinese Journal of Catalysis The Shenhua coal direct liquefaction plant Semantic Scholar2010年5月4日 Since it began operating, the plant has processed 42 million tons of raw coal The plant’s raw feed capacity is 600 tons per hour (tph) and the yield at the plant is approximately 43% plus or minus 3% The design of any new coal prep plant is governed by the raw coal washability of that particular mine’s seam collectionICG’s New Beckley Prep Plant Incorporates the Latest Coal

Company Profile

There were 19 intelligent coal preparation plants 208 unmanned production vehicles worked in openpit coal mines Research, development and application were conducted for more than 200 sets of coal mine robots specialized in tunnelling, mining, coal transportation, safety control and rescue Performance rate of mediumterm and longterm 2016年10月22日 Panji coal preparation plant applies advanced and reliable separation circuit and equipment with China’s independent intellectual property rights such as gravityfed nondeslimed nonclassified three product heavy medium cyclone, fine coal heavy medium cyclone, jet flotation machine, inclined pipe thickener, and etcProcess Features of Panji Coal Preparation Plant SpringerLinkPerformance Optimization of a Coal Preparation Plant Using Genetic Algorithms Vishal Gupta, Manoj K Mohanty, Ajay Mahajan Most of the coarse coal circuits make use of heavy medium processes PERFORMANCE OPTIMIZATION OF A COAL 2023年11月22日 A new hybrid magnetic separator could improve recovery for heavymedia plants By Steve Fiscor, EditorinChief Eriez has been busy applying innovations in both magnetic circuit design and materials of construction to its line of wet drum magnetic separators The goal is to maximize magnetite recovery while operating with a minimum amount of wear and Advances in Magnetite Recovery Coal Age

.jpg)

Coal Washing Process Plant JXSC Machinery

1 天前 (1) Crushing: The large pieces of coal are sent to the jaw crusher by the vibrating feeder for rough crushing, and the conveyor transports the coarsely crushed materials to the impact crusherThe impact crusher is suitable for medium or fine crushing to further dissociate clean coal (2) Screening: Thevibrating screen screens out three kinds of materials with different particle 2023年9月18日 Dense Medium Separation (DMS) stands as a cornerstone in the realm of mineral processing and ore beneficiation At its core, DMS leverages the inherent density differences between valuable minerals and gangue materials to achieve highly efficient separation This ingenious process relies on a dense medium—a suspension of finely ground The design and Performance of Dense Medium Separation Plants