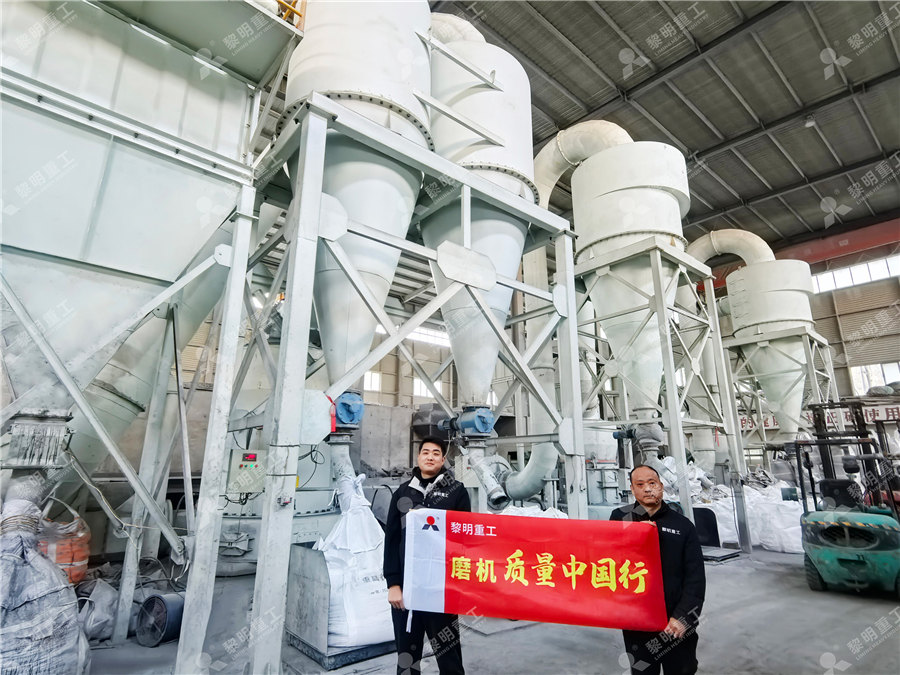

Lithium ore extraction lithium carbonate grinding and grinding system

.jpg)

Lithium extraction from hard rock lithium ores (spodumene,

2023年1月1日 The process flow is to convert lithium in ore into lithium sulfate by mixing roasting lithium mineral and excessive potassium sulfate (or calcium sulfate or a mixture of both), leach 2023年1月1日 Therefore, this paper presents a comparative life cycle assessment (LCA) to quantify the environmental impact of selected lithium production routes: brine (Chile), Comparative Life Cycle Assessment of Lithium Mining, Extraction2024年7月20日 This research introduces a process for the effective extraction and separation of lithium and sodium from the carbonate brine of Jieze Caka Salt Lake, utilizing trifluorinated βbiketone HBTA (4,4,4trifluoro1phenyl1,3 Lithium extraction from carbonaterich Salt Lake 2022年3月25日 Working with the lithium concentrate, SGS’ team uses a standardized flowsheet to produce high grade lithium products such as lithium carbonate or lithium hydroxide These Hard Rock Lithium Processing SGS

Lithium deportment by size of a calcined spodumene ore

2022年10月31日 The results showed that closedcircuit grinding resulted in 89% lithium recovery of the finest size fractions (− 06 mm) while opencircuit grinding led to 65% lithium recovery 2024年9月30日 In the last several decades, many techniques have been demonstrated and patented to process hardrock mineral spodumene The objective of this review is to present a thorough analysis of significant findings Aspects of Spodumene Lithium Extraction 2021年2月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies To address the low lithium content in leachate, it is feasible to develop solvent extraction or adsorption systems for lowlithium concentrations This would enable the enrichment of lithium Advances and promotion strategies of processes for extracting lithium

.jpg)

Critical Review of Lithium Recovery Methods:

2024年10月10日 We examine various lithium recovery methods, including conventional techniques such as hydrometallurgy, pyrometallurgy, and direct physical recycling, as well as emerging technologies like mechanochemistry, 2023年11月21日 extraction and filtering remove any unwanted minerals Sodium carbonate treatment converts the lithium chloride to lithium carbonate, which is then filtered and dried While startup costs can be high for lithium brine conversion and the process is somewhat slow, operational costs for this process are typically low Our advanced technologyLithium processing technology Complete solutions that The process flow of the sulfuric acid method lithium carbonate vertical roller mill production line is as follows: ① The spodumene or lepidolite ore is transformed and roasted, and after cooling, it is transported to the vertical roller mill for fine News Process Flow Of Lithium Carbonate 2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car Aspects of Spodumene Lithium Extraction

Lithium extraction from hard rock lithium ores (spodumene,

2023年1月15日 Lithium production in China mainly depends on hard rock lithium ores, which has a defect in resources, environment, and economy compared with extracting lithium from brine This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination methods, and analyzes 2018年8月19日 Lithium carbonate is then recovered from the solution through a series of evaporation and crystalization stages Pilot plants on the Lithium Nevada extraction processes showed a maxium lithium recovery of 915% Lithium extraction processes utilized at the Sonora project are based on sodium sulphate roasting Ore from the Sonora project is Lithium Extraction and Utilization: A Historical Perspective2022年3月25日 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content areHard Rock Lithium Processing SGS2020年6月22日 common to all spodumene processes as there is presently no operating method to convert ore directly into lithium carbonate due to the refractory nature of spodumene grinding Dense medium separation (DMS) will typically be used down to ~05 mm, but ~1 mm is a separation processes such as solvent extraction and ion exchange Lithium Lithium Ore Processing – an Overview of the Current and

Spodumene: The Lithium Market, Resources and Processes

2019年5月29日 This literature review gives an overview of the lithium industry, including the lithium market, global resources, and processes of lithium compounds production It focuses on the production of lithium compounds from spodumene minerals Spodumene is one of the most critical minerals nowadays, due to its high lithium content and high rate of extraction Lithium is 2021年2月1日 The solid phase formed as a result of decomposition, with a high degree of extraction of lithium from the ore contains a small amount of Li2O in its composition and therefore can be used in the Processing of lithium ores: Industrial technologies and case studies 2024年1月1日 In carbonate clay type lithium ore, Li mainly occurs in the interlayer of clay minerals represented by montmorillonite and exists in the form of Li + ion adsorption, which is called “adsorbed lithium"(Benson et al, 2017) Li in this occurrence state is generally extracted by activation roastingacid leaching processEfficient separation and extraction of lithium from lowgrade Regarding reserves, the globally confirmed lithium resources have significantly increased, totaling approximately 98 million tons Bolivia boasts the highest reserves, accounting for 2157 % of the global total, followed closely by Argentina and Chile (Fig 1 d) [6]Among these, salt lake brine resources make up 723 % of the reserves, while ores account for 203 %, with nearly 50 % of Advances and promotion strategies of processes for extracting lithium

.jpg)

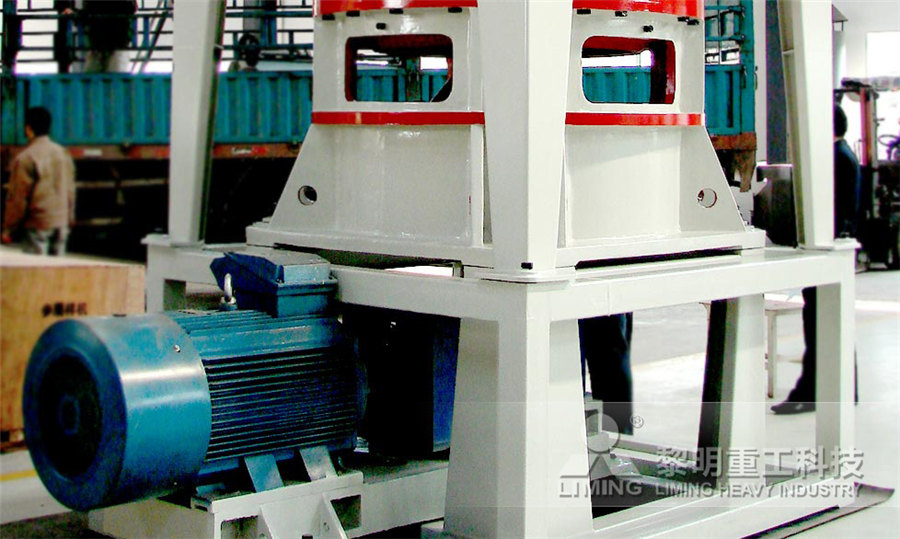

Ball Mill Is The Key To Grinding Lithium Ore

5 天之前 The general process of extraction is that after the lithium ores are broken into small pieces, they are then crushed and ground into finer particles by a lithium ore ball mill , and then use sulfuric acid roasting, sulfate roasting, PDF On Jan 1, 2022, Tianming Gao and others published Lithium extraction from hard rock lithium ores: technology, resources, environment and cost Find, read and cite all the research you need (PDF) Lithium extraction from hard rock lithium ores: Discover the different lithium extraction methods: exploring greener alternatives and the gamechanging technology of Lithium Harvest Australia's strength lies in its abundant lithium ore reserves, while Chile and Argentina harness the immense potential of their expansive continental brines, extracting lithium from vast underground brine Lithium Extraction Methods2021年12月1日 The current study aims to fill this gap by designing a cleaner production system for orebased lithium extraction in China, identifying the cleaner production level for this industry, and providing a basis for macroscopic management and policy implementation as the two are added to extract lithium carbonate and lithium hydroxide Sustainable production of lithium salts extraction from ores

.jpg)

Lithium extraction from carbonaterich Salt Lake brine using

2024年7月20日 China's salt lakes hold significant lithium reserves, yet the development of lowconcentration lithium resources from the carbonate brines in Tibet is a pressing matter Alkyl βdiketones extractants are capable of efficiently extracting lithium from alkaline solutions using an extraction method, but its optimized extraction prerequisite is an extreme alkaline solution with 2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage Ball Mill Is Indispensable For Lithium Ore Processing2019年1月15日 Lithium is a soft, silverwhite coloured, and the lightest alkaline metal with an atomic weight of 6939 Lithium compounds such as lithium carbonate, lithium hydroxide and lithium bromide are used in glass, ceramics, lubricant and grease manufacturing to improve extreme temperature resistance, in aluminium production, as catalysts in the pharmaceutical The beneficiation of lithium minerals from hard rock ores: A 2023年3月13日 Air is then bubbled through the mixture, causing the hydrophobic lithium minerals to rise to the surface and form a froth The froth is skimmed off and dried, producing a concentrate that contains about 67% lithium If you want to know more details about lithium ore flotation chemicals, you can browse 3 Types of Lithium Ore Flotation CollectorsLithium Ore Processing: An Overview You Must Know

.jpg)

Comparative Life Cycle Assessment of Lithium Mining, Extraction

2023年1月1日 This amount is equivalent to 7280 tons of lithium carbonate (LCE), based on the Zinnwald technical report [24] Extraction from geothermal and oilfield brines attempts to deploy direct lithium extraction (DLE) method, which may deploy sorption, ionexchange (IX), solvent extraction (SX), membrane technologies, or precipitation methods [2]2022年8月2日 It has been demonstrated in the literature that lithium extraction from differing resources is based on the generic mineral processing and extractive metallurgical techniques and resource typeA Review of Characterization Techniques and 2023年6月29日 The objective of this study is to describe primary lithium production and to summarize the methods for combined mechanical and hydrometallurgical recycling of lithiumion batteries (LIBs)Lithium Production and Recovery Methods: 2023年9月8日 There are two flotation processes for lithium ore: positive flotation and reverse flotation Lepidolite mostly uses positive flotation, while spodumene ore can be used for both positive and reverse flotation 11 Lithium ore positive The Most Effective Lithium Ore Processing

Comparative Life Cycle Assessment of Lithium Mining, Extraction

2023年4月20日 While many different lithium carbonate production routes have been developed, existing life cycle assessments (LCA) of lithium carbonate production from brines are mainly based on a single brine 2022年10月31日 The results showed that closedcircuit grinding resulted in 89% lithium recovery of the finest size fractions (− 06 mm) while opencircuit grinding led to 65% lithium recovery for the same Lithium deportment by size of a calcined spodumene ore2024年7月9日 Lithium ore is mainly used to extract lithium, which is widely used in batteries, ceramics, glass, lubricants, aerospace, medicine and other fields In recent years, due to the increasing demand for lithium batteries in electric vehicles and energy storage equipment, the mining and utilization of lithium ore has become more importantLithium Ore Grinding Mills SBM Ultrafine Powder Technology2023年2月1日 The present scenario has urged the necessity to beneficiate and extract lithium from the available resources judiciously Pegmatites constitute the second major economic resource of lithium, after brines, accounting for about 25% of global production [14]The lithiumbearing minerals, hosted by the pegmatite rocks, include spodumene, lepidolite, petalite, Recovery of lithium from spodumenebearing pegmatites: A

Ball Milling in Lithium Ore Processing: A Comprehensive Guide

2023年5月27日 The role of ball milling in lithium ore processing is to break down the lithiumcontaining minerals and release the lithium ions into the solution This is achieved through the mechanical grinding of the ore, which helps to increase the surface area of the material, making it easier for the leaching solution to penetrate and dissolve the Solventfree process, for obtaining lithium carbonate from brines of natural or industrial origin, or from ores and/or clays, comprising removing the contained boron by means of precipitation using a barium salt added to the natural or industrial brine or Licontaining ore or clay solution, in order to obtain a filtrate from which magnesium is removed in the form of magnesium hydroxide, and Lithiumextraction method for obtaining lithium carbonate 2024年2月3日 Mechanochemical approaches are one of the most promising alternative lithium extraction processes Milling αspodumene in a planetarystyle mill for only 30 min drastically reduces the particle size, increases surface area, destroys crystallinity, and cleaves OM (M = Li, Al, and Si) bonds [19, 20]Further, employing a conventional sulfuricacid roasting after Mechanochemical Extraction of Lithium from αSpodumene 2023年11月21日 extraction and filtering remove any unwanted minerals Sodium carbonate treatment converts the lithium chloride to lithium carbonate, which is then filtered and dried While startup costs can be high for lithium brine conversion and the process is somewhat slow, operational costs for this process are typically low Our advanced technologyLithium processing technology Complete solutions that

News Process Flow Of Lithium Carbonate

The process flow of the sulfuric acid method lithium carbonate vertical roller mill production line is as follows: ① The spodumene or lepidolite ore is transformed and roasted, and after cooling, it is transported to the vertical roller mill for fine 2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car Aspects of Spodumene Lithium Extraction 2023年1月15日 Lithium production in China mainly depends on hard rock lithium ores, which has a defect in resources, environment, and economy compared with extracting lithium from brine This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination methods, and analyzes Lithium extraction from hard rock lithium ores (spodumene, 2018年8月19日 Lithium carbonate is then recovered from the solution through a series of evaporation and crystalization stages Pilot plants on the Lithium Nevada extraction processes showed a maxium lithium recovery of 915% Lithium extraction processes utilized at the Sonora project are based on sodium sulphate roasting Ore from the Sonora project is Lithium Extraction and Utilization: A Historical Perspective

Hard Rock Lithium Processing SGS

2022年3月25日 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content are2020年6月22日 common to all spodumene processes as there is presently no operating method to convert ore directly into lithium carbonate due to the refractory nature of spodumene grinding Dense medium separation (DMS) will typically be used down to ~05 mm, but ~1 mm is a separation processes such as solvent extraction and ion exchange Lithium Lithium Ore Processing – an Overview of the Current and 2019年5月29日 This literature review gives an overview of the lithium industry, including the lithium market, global resources, and processes of lithium compounds production It focuses on the production of lithium compounds from spodumene minerals Spodumene is one of the most critical minerals nowadays, due to its high lithium content and high rate of extraction Lithium is Spodumene: The Lithium Market, Resources and Processes2021年2月1日 The solid phase formed as a result of decomposition, with a high degree of extraction of lithium from the ore contains a small amount of Li2O in its composition and therefore can be used in the Processing of lithium ores: Industrial technologies and case studies

Efficient separation and extraction of lithium from lowgrade

2024年1月1日 In carbonate clay type lithium ore, Li mainly occurs in the interlayer of clay minerals represented by montmorillonite and exists in the form of Li + ion adsorption, which is called “adsorbed lithium"(Benson et al, 2017) Li in this occurrence state is generally extracted by activation roastingacid leaching process