Slag mill type

2 µm 5 µm Loesche

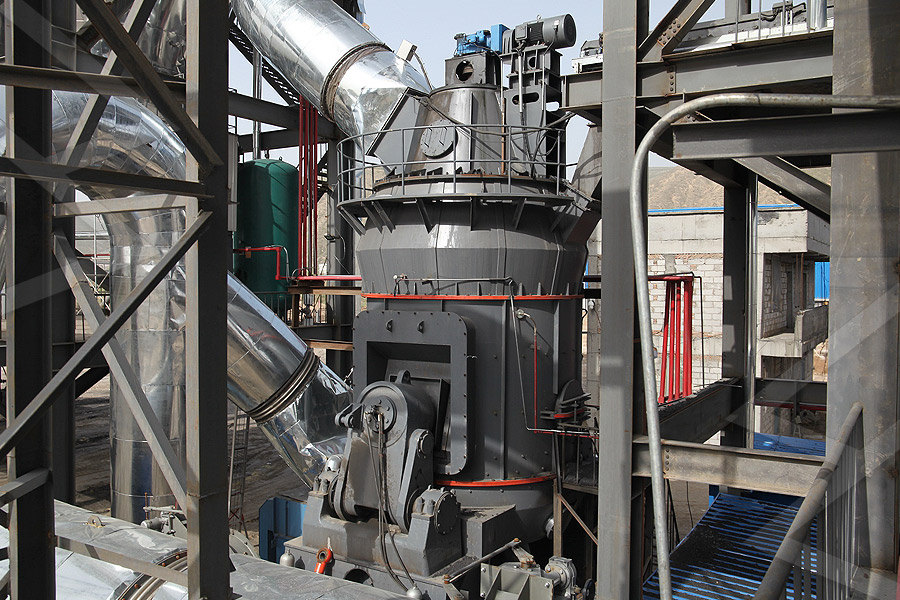

2017年8月11日 Loesche mills showed poor running behaviour of the mill owing to unsatisfactory formation of the grinding bed The application of this knowledge led to a patented solution in the form of a modified Loesche mill for fine grinding: LM – CS (cement/slag) In this mill 2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF) steelmaking, electricarc Chemical, Mineralogical, and Morphological Steel slag (SS) is a solid waste generated during the conversion of iron into steel in a basic oxygen furnace (BOF) or during the melting of scrap to make steel in an electric arc furnace Steelmaking Slag an overview ScienceDirect Topics2017年8月12日 steel slag combines all the advantages of conventional processes: • Efficient and costeffective metal recovery in the coarse range • Virtually 100% metal recovery down to Loesche Mills for Metal Recovery and Filler Production

(PDF) Iron and Steel Slags ResearchGate

2017年3月5日 The physicochemical properties of four different types of iron and steel slags, including blast furnace slag, basic oxygen furnace slag, electric arc furnace slag, and ladle furnace2023年11月23日 Ladle slag is a byproduct formed during the ladle refining stage of steel making It is a dusty material that has been considered industrial waste Technical advancements towards a sustainable industry led to the Ladle Furnace Slag: Synthesis, Properties, and 2013年3月13日 R MILL TRM series slag vertical roller mill(hereinafter named as “Slag VRM”)is specialized in slag grinding and developed on basis of TRM series raw grinding vertical roller TRM SERIES SLAG VERTICAL ROLLER MILL TRM 2015年3月17日 This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF) steelmaking, electricarcfurnace (EAF) Steel Slag: Chemistry, Mineralogy, and Morphology

.jpg)

Steel Slag—Its Production, Processing, Characteristics, and

2004年5月14日 Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper Up to date, the LOESCHE Mill type LM 352+2 is the sole vertical roller mill in this plant for cement grinding LOESCHE America to hold its 4th Annual Technical Seminar in South Florida This latest triumph involves the largest slag mill in Loesche Mining Technology2015年6月1日 Scientific interest in slag has been increasing steadily since the early 1990s The number of slag studies that are referenced in this paper by publication date is shown in Fig 1 (see Appendix A Summary of slag characterization references and type of data from each that was used in this paper, Appendix B Summary of slag application and reuse references for this Characteristics and environmental aspects of slag: A reviewIn addition to the vertical slag mill, other types of cement mill that can grind slag powder include: cement ball mill, pregrinding cement roller press, and cement roller press for final grinding For slag grinding plant, ball mill generally causes Slag Grinding Plant GGBS Plant Slag Mill, Slag

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit4 The new slag types All new steel production routes will produce new types of slags and specific slag/metal ratios, resulting total slag volumes, chemical and mineralogical composition and physical properties of the new liquid and solidified slags are yet unknown Thus, also their technical and environmental properties are still unknownThe steel production transformation process in Europe: New slag types Carbon dioxide sequestration using steel slag—modeling and experimental investigation Smitha Gopinath, Anurag Mehra, in Carbon Dioxide Sequestration in Cementitious Construction Materials, 2018 41 Introduction Steel slag is an industrial waste that is generated during the production of steel In the production of steel, oxides of metal impurities in the iron combine Steel Slag an overview ScienceDirect Topics2017年3月5日 Iron and steel mills are energy and materialintensive industries because they have Moreover, some types of steel slag may contai n a notable amount of heavy metals, such as As, Cd, and Hg (PDF) Iron and Steel Slags ResearchGate

.jpg)

Basics of slag production Article on the slag industry Global Slag

2011年10月27日 In tonnage terms, blast furnace slag is at present the main type followed by slags from the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) processes Various other processes such as external desulphurisation of steel may generate significant amounts of slag at some plants but overall they are only a small proportion of the total 2022年11月27日 This latest triumph involves the largest slag mill in the world, which already produces 255t an hour blastfurnace slag meal in Taiyuan, northern China In September 2011, LOESCHE was delighted by the order from the Taigang Group International Trade Co Ltd (China), which commissioned a LOESCHE vertical mill of the type LM 633+3 for grinding LOESCHE Hands Over the World’s Largest Slag MillIn the second quarter of 2014 over 300 vertical roller mills of this type were in operation or construction In the last four years, a further 100 mills were sold History The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical airswept grinding mills dates back to Ernst Curt Loesche’s inventionMore than 400 vertical roller mills for cement and granulated In September 2011, Loesche was commissioned for a vertical mill of the type LM 633+3 by the Taigang Group International Trade Co, Ltd (China) for its customers This was to be the largest slag mill in the world In March 2014, Loesche hands over world’s largest slag mill

Utilisation of alkaliactivated blast furnace slag in paste

2012年4月1日 The CPB samples of alkali activated neutral slag (NS) gained early strength consistently at a slower rate than that of acidic slag irrespective of the activator type Sodium hydroxide (SH)activated slag samples developed higher 28day strengths than sodium silicate (LSS)activated slag samples This study highlights that the alkali activated 2017年8月23日 Iron and steel mills are energy and materialintensive industries because they have Moreover, some types of steel slag may contain a notable amount of heavy metals, such as As, Cd, and Hg, which could cause severe environmental impacts [4] Worldwide iron and steel productions in 2014 were estimated to be 1190 and 1650 Mt, respectively [7 Chapter 11 Iron and Steel Slags Springer2007年2月1日 The first Polysius roller mill for slag grinding in China is in operation since 2002 in Anshan in the province of Liaoning The grinding plant of the Angang Group Slag Development Company is exactly the same size as the one which has been in operation since 1995 just a few hundred kilometres away in Korea The roller mill is a type RMS51/ Slag grinding with the Polysius Roller Mill in China2024年11月18日 Environmental Benefits of Slag Cement Slag cement is used in nearly all types of concrete construction: pavements; structures and foundations; mass concrete (ie, dams and retaining walls); and prestressed, dry cast and precast concrete products such as pipes, pavers, and blocks Today, slag cement is the best option for a concrete producer to use for the lowest Slag Cement Heidelberg Materials

【Slag】的中文翻译和相关专业术语SCIdict学术词典在线

2024年2月17日 【Slag】怎么翻译,它的中文翻译,汉语译词,【Slag】的相关专业术语翻译,来自SCIdict学术词典的解释和翻译,SCIdict是专为学术研究人员以及技术专家设计的中英专业术语词典,致力于为细分专业领域的翻译提供参照, 并同时促进各行各业人士的专业英语学习2005年2月1日 Steelmaking slag, an important metallurgical byproduct, is composed of a large amount of valuable components, including CaO, Fe t O, MnO, and MgO, all of which are required in the steelmaking (PDF) Industrial uses of slag The use and reuse of iron and 2011年3月11日 THE ESTIMATION OF SLAG PROPERTIES Ken Mills Department of Materials, Imperial College, London, UK kcmills@talktalk Short course presented as part of Southern African Pyrometallurgy 2011 There are several types of mathematical model namely (i) thermodynamic models (to establish the viability of the process and the optimum conditions) THE ESTIMATION OF SLAG PROPERTIES Pyro2020年4月1日 It can be categorized by either the process in which it was generated (basic oxygen furnace slag (BOFS), electrical arc furnace slag (EAFS), ladle refining slag (LFS)), or by the type of steel produced in said process (carbon steel slag or stainlesssteel slag) (Yi et al, 2012, Liu and Wang, 2017, Ndlovu et al, 2017) Countries such as Japan Basic oxygen furnace slag: Review of current and potential uses

.jpg)

mill Slag industry news from Global Slag

2018年12月20日 The mill is designed to produce Ordinary Portland Cement (OPC), Pozzolana Portland Cement (PPC), Portland Slag Cement (PSC) and slag cement types It is producing PPC at a capacity of 500t/hr at 3500 Blaine with 15% slagThe steel slag ball mill supports dry and wet grinding modes According to the different discharge modes, it can be divided into grate type and overflow type ball mill According to the shape of the barrel, there are three types of steel slag Steel Slag Ball Mill Quality Ball Bill Supplier 2016年1月17日 MSDS: Slag Page 3 of 6 Revised: 03/01/14 Section 4: FIRST AID MEASURES Eye Contact: Rinse eyes thoroughly with water for at least 15 minutes, including under lids, to remove all particles Seek medical attention for abrasions Skin Contact: Wash with cool water and a pH neutral soap or a mild skin detergent Seek medicalMSDS: Slag Material Safety Data Sheet2024年3月28日 The above analysis shows that the main elements of steel slag produced by different steel mills have similar mineral phases, CaO, and MgO mineral phases is performed using Jade software (version 60) on the XRD Research on the Properties of Steel Slag with

.jpg)

50 40 30 UBEマシナリー株式会社

2023年7月25日 Development of New Type Slag / Cement Mill Product Fineness of Slag / Cement powder is ultrafine (Dp50 = approx 10 15μm), and the occurrence of vibration can interfere with stable Mill operation The increase (improve) friction coefficient of material in the grinding area directly beneath the mill roller 2024年10月22日 The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3 2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials The compact and longlasting ATOX® Coal Mill has the capability to grind virtually all types of raw Vertical roller mills FLSmidth Cement2019年7月1日 Around 20 million tons of slag is produced annually in Europe, half of which is produced is BOS slag (Liu et al, 2016), meaning that large quantities of industrial byproducts are produced each yearOne obvious alternative to landfilling such byproducts would be to reutilize the slag in steelmaking or use for secondary applications (Joulazadeh and Joulazadeh, 2010)The recycling and reuse of steelmaking slags — A review

.jpg)

FOR CEMENT RAW MATERIAL loeschees

2017年8月11日 Aircooled blast furnace slag 1µm Iron oxide, Titanium 30µm oxide and Orthoclase Aircooled blast 5µm furnace slag Iron oxide (Fe2O ) 20µm Hydromagnesite + Calcite 2µm Loesche mill Type LM 464, Lengerich, Germany, 2003 3 1971 oduction of a modular system in mill construction: Intr2014年10月24日 The LOESCHE Mill Type LM 633+3 – proven technology for cement grinding The first LOESCHE mill of the type LM 633+3 commenced production back in 2009 in Nallalingayapalli, India and has Loesche hands over world’s largest slag mill – LM 633+32012年2月8日 Slag accounts for most of the residuals or byproducts of the steel manufacturing process and represents a not inconsiderable amount of energy waste and CO 2 emissions Energy recovery from steel mill slags is not actually performed because of the difficulty of the industrial implementation, but the actual demand and the incentives for new electricity Steel mill slags energy potential: the case of the steel factory Up to date, the LOESCHE Mill type LM 352+2 is the sole vertical roller mill in this plant for cement grinding LOESCHE America to hold its 4th Annual Technical Seminar in South Florida This latest triumph involves the largest slag mill in Loesche Mining Technology

.jpg)

Characteristics and environmental aspects of slag: A review

2015年6月1日 Scientific interest in slag has been increasing steadily since the early 1990s The number of slag studies that are referenced in this paper by publication date is shown in Fig 1 (see Appendix A Summary of slag characterization references and type of data from each that was used in this paper, Appendix B Summary of slag application and reuse references for this In addition to the vertical slag mill, other types of cement mill that can grind slag powder include: cement ball mill, pregrinding cement roller press, and cement roller press for final grinding For slag grinding plant, ball mill generally causes Slag Grinding Plant GGBS Plant Slag Mill, Slag The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills4 The new slag types All new steel production routes will produce new types of slags and specific slag/metal ratios, resulting total slag volumes, chemical and mineralogical composition and physical properties of the new liquid and solidified slags are yet unknown Thus, also their technical and environmental properties are still unknownThe steel production transformation process in Europe: New slag types

.jpg)

Steel Slag an overview ScienceDirect Topics

Carbon dioxide sequestration using steel slag—modeling and experimental investigation Smitha Gopinath, Anurag Mehra, in Carbon Dioxide Sequestration in Cementitious Construction Materials, 2018 41 Introduction Steel slag is an industrial waste that is generated during the production of steel In the production of steel, oxides of metal impurities in the iron combine 2017年3月5日 Iron and steel mills are energy and materialintensive industries because they have Moreover, some types of steel slag may contai n a notable amount of heavy metals, such as As, Cd, and Hg (PDF) Iron and Steel Slags ResearchGate2011年10月27日 In tonnage terms, blast furnace slag is at present the main type followed by slags from the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) processes Various other processes such as external desulphurisation of steel may generate significant amounts of slag at some plants but overall they are only a small proportion of the total Basics of slag production Article on the slag industry Global Slag2022年11月27日 This latest triumph involves the largest slag mill in the world, which already produces 255t an hour blastfurnace slag meal in Taiyuan, northern China In September 2011, LOESCHE was delighted by the order from the Taigang Group International Trade Co Ltd (China), which commissioned a LOESCHE vertical mill of the type LM 633+3 for grinding LOESCHE Hands Over the World’s Largest Slag Mill

.jpg)

More than 400 vertical roller mills for cement and granulated

In the second quarter of 2014 over 300 vertical roller mills of this type were in operation or construction In the last four years, a further 100 mills were sold History The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical airswept grinding mills dates back to Ernst Curt Loesche’s invention