Medium speed grinding of limestone

Investigation into the Fine Grinding of Limestone with a

In this study, we have performed experiments on the fine grinding of limestone with a SCmill, and investigated the effects of the grinding media size on the fine grindability of limestone under 2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research EnergyModel and Life CycleModel for Grinding Processes of Limestone 2003年3月5日 the grinding of limestone was studied as a function of additive type and dosage, polymer molecular weight, solids concentration and other operating variables alongJ Zheng C C Harris P Somasundaran Columbia grindability of limestone were investigated, as well as the wear of the grinding beads The fi ne grindability was evaluated through the mass of products below 1 μm measured using laser Eff ects of Operational Conditions on Fine Grindability

The onset of particle agglomeration during the dry ultrafine grinding

2015年11月1日 This study investigates structural and morphological changes in limestone particles ground in a planetary ball mill The grinding tests were carried out as a function of the This study examined the fine grinding of limestone using a bead mill and a circular stirred media mill Fine grinding characteristics of the bead mill using polysized grinding media with a Effect of Polysized and Monosized Grinding Media on 2014年1月10日 The dry grinding of limestone in a planetary ball mill was investigated as a function of the diameter of the grinding balls and the revolution speed of the mill The tests Particle size distribution and structural changes in limestone ground 2022年2月28日 Optimal grinding media size is determined based on input feed and desired product size After reaching the desired size, mineral particles continuously come out of the Grinding SpringerLink

制粉项目-2023.11.17.jpg)

Application of a Method for Measuring the

2022年11月15日 Through the new method, highenergy grinding was performed using a commercially available planetary mill on silicate materials such as limestone, feldspar, corundum, and quartz The effectiveness of the method 2024年7月17日 Materials entering the highspeed rotating impeller are centrifugally thrown outward, colliding with other materials, then repeatedly colliding and grinding between the impeller and casing before finally Types of Crushers: Choosing the Right One for 2018年7月15日 In this study, batch wet grinding studies were conducted in a stirred mill to evaluate the effect of the grinding media density, grinding media diameter, and stirrer tip speed on the ground Impact of grinding aids and process parameters on dry stirred media 2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research investigations have not yet been published on the EnergyModel and Life CycleModel for Grinding

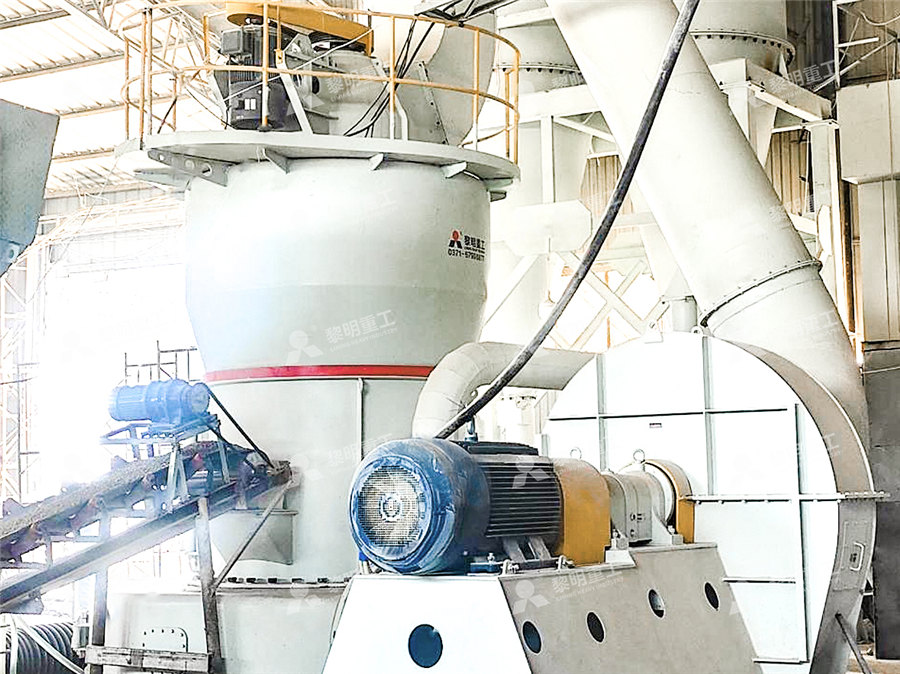

.jpg)

Grinding Technology of Limestone With Ball Mills

2014年7月12日 The document discusses grinding technology for limestone using ball mills It covers: 1 The properties and applications of limestone powder 2 Wet and dry grinding processes 3 Different types of grinding circuits including classical ball mill, airswept mill, birotator, and compound mill circuits 4 Details of mill internals such as ball charges and linings for or uniformsized) grinding media on the fine grindability of limestone Experiments were carried out under the operational conditions, including the rotor speed, the operating time, the mass of the grinding media, and the mass of the limestone sample Effect of Polysized and Monosized Grinding Media on Fine Grinding of Limestone in a Bead MillEffect of Polysized and Monosized Grinding Media on 2018年7月15日 The interactions between slurry, grinding media and mill structure are modelled by twoway couplings between the PFEM, the DEM and the FEM models The coupled model of the present study is used to predict the motion of slurry and grinding media, and to calculate the power draw during wet comminution in a pilot scale horizontal stirred media millImpact of grinding aids and process parameters on dry stirred media 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral

.jpg)

The effect of additives on stirred media milling of limestone

Journal of Materials Research and Technology, 2020 Grinding aids (GAs) have been an important advent in the comminution circuits Over the last few decades, in order to address the high energy consumption and scarcity of potable water for mineral processing, chemical additives have become a promising alternative2024年1月13日 Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGateThere are 7 types of limestone grinding mills available, each designed for specific purposes and applications A ball mill is a cylindrical device used to finely grind materials It consists of a7 Typs of Limestone Grinding Mills in 2023 Mediumout measurements on the fi ne grinding of limestone in a bead mill with a relatively high slurry concentration, and investigated the infl uence of various operational grinding conditions including rotor speed, operating time, mass of grinding beads and bead diameter on the fine grindability of limestone Moreover, the relationsEff ects of Operational Conditions on Fine Grindability

.jpg)

EnergyModel and Life CycleModel for Grinding Processes of Limestone

2022年5月22日 Normalized and weighted values in the wet grinding process in nanograms (Functional unit: 1 kg of limestone product Impact assessment method: CML 2001/Aug 20161997年5月30日 Semantic Scholar extracted view of "The effect of additives on stirred media milling of limestone" by Jie Zheng et al Skip to search Evaluated were the relationships of factors such as stirring speed and 1984; 115 PDF Save Effect of chemical additives on the dynamics of grinding media in wet ball mill grinding D Fuerstenau K The effect of additives on stirred media milling of limestone2022年4月20日 Medium and fine crushing: The coarsely crushed limestone is then subjected to medium and fine crushing We can choose impact crusher for equipment Some stones use cone crusher for secondary crushing, but the hardness of limestone is not high Then it is sent to the limestone grinding mill at a constant speed through a vibrating screen for Limestone crushing and grinding production line SBM 1997年5月30日 Since torque or energy consumption indicates 'fluidity' of media/ pulp during the operation, it can be concluded that PAA addition results in both 'fluidity' and grinding improvements, However il may be noted that an excessively high fluidity may result in less contact and interaction between media and particles, and thus in lower grinding The effect of additives on stirred media milling of limestone

.jpg)

Optimization of Ball Mill Grinding of a LimestoneType

2023年7月13日 ball mill (Table 1) with a constant speed of 735 rpm (908% of critical speed) Stainless steel balls ( =ρ 7800 kg/m 3) were used as a grinding media Grinding time varied in the range of 05–80 minutes Dierent sieves (√2 series) were used to determine the grinding eciency of the ground product2021年7月1日 The mass ratio of grinding aid/PTFE reached 4 for the production of ultrafine fine PTFE Therefore, the optimal conditions for ultrafine fine PTFE production were as follows: milling time of 3 h, grinding speed of 700 rpm, 10 mm grinding balls, and mass ratio of grinding aid (NH 4 Cl or CO(NH 2) 2)/PTFE) of 4Effect of grinding aids and process parameters on dry fine grinding 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget Overall Energy Use of Fine Grinding in Mineral Processing2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Limestone Grinding Mill That You Need To Know Mortar

.jpg)

Scaleup of Agitator Bead Mills Grinding Dispersing

2023年6月23日 grinding media, Kwade [12] defined the stress energy of the grinding media BE GM as a function of grinding media density ρ GM, grinding media diameter d GM and agitator peripheral speed v t (see Eq (2)) Through studies of the effect of the operating parameters grinding media density, agitator disk peripheral speed and grinding media size At the moment highquality limestone, exploited from deposits of various ages, is used for the production of lime sorbents used to reduce SO 2 emissions in Poland The research was aimed at assessing the efficiency of the mill for various grinding media types and feed particle size in order to determine its operating parametersAdjustment of limestone grinding in an electromagnetic 2023年7月4日 up by the highspeed airflow of the air ring at the edge of the grinding table, and the large particles directly fall on the grinding table for regrinding When the material in the airflow passes through the upper separator, under the action of the rotating rotor, coarse particles fall from the cone bucket to the grinding table for Roller Mill Springer2022年11月15日 Through the new method, highenergy grinding was performed using a commercially available planetary mill on silicate materials such as limestone, feldspar, corundum, and quartz(PDF) Application of a Method for Measuring the

.jpg)

Experimental study of clinker grinding in a ball mill and

2023年6月27日 of the grinding media inside the equipment using DEM are the rotation speed, the grinding media and clinker lling degree Experiments were performed varying the 94% (w/w) of limestone, 4% (w/w) of clays and 2% (w/w) of iron and aluminum oxides in a rotating oven operating at temperatures of about 1450 °C In this2021年9月10日 •Acceleration = agitator speed Media Size Test on Minizeta 50 % limestone slurry in water, 1 % Dispersant 580 Gram batched processed 140 160 16 25 mm Zirconium Silicate Beads 0406 mm Zirconium Silicate Beads 12 cir 15cir 12P 15P 40 kg/hr 50 kg/hr Fine Grinding Media Size MIXING DIFFERENT SIZES •In general, small media How to Choose the Correct GRINDING MEDIA PCI Mag2024年6月14日 The grinding process plays a crucial role in industry, allowing for the reduction of particle sizes of raw materials and substances to the required fineness—either as a finished product or for further technological processes The high demand for micro and nanopowders or suspensions is associated with the high energy consumption of the milling process Therefore, The Influence of the Grinding Media Diameter on Grinding2018年7月15日 The impact of the stress conditions inside the mill on the grinding result was examined by varying the media size d GM, grinding media density ρ GM and stirrer tip speed v tTherefore, three different kinds of grinding media materials as well as a number of media sizes were investigated in this study (see Table 1), while the grinding media filling ratio ϕ GM was Impact of grinding aids and process parameters on dry stirred media

Slurry rheology of limestone and its effects on wet ultra

2016年9月30日 Effect of various parameters on wet ultrafine grinding of limestone through slurry rheology in a stirred media mill Submitted to Powder Technology, 2004 Paper 4 Rheological behaviour in wet ultrafine grinding of limestone Submitted to O O R International Mineral Processing Congress in Istanbul, Turkey, September, 2006 v1999年11月1日 The number of captured particles depends among others on the solids concentration of the suspension and the size of the particles and can be evaluated by the ratio between the diameter of the active volume between two grinding media, d act, and the average distance between two particles in the suspension, yThe active volume between two grinding Determination of the most important grinding mechanism in stirred media 1 College of Resources and Environmental Engineering, Jiangxi University of Science and Technology, Ganzhou, China; 2 Jiangxi Key Laboratory of Mining Engineering, Jiangxi University of Science and Technology, Ganzhou, China; Grinding media have significant influence on the flotation of chalcopyrite and pyrite This effect is mainly related to the change in the surface Effect of Grinding Media on GrindingFlotation Behavior of2024年7月17日 Materials entering the highspeed rotating impeller are centrifugally thrown outward, colliding with other materials, then repeatedly colliding and grinding between the impeller and casing before finally Types of Crushers: Choosing the Right One for

.jpg)

Impact of grinding aids and process parameters on dry stirred media

2018年7月15日 In this study, batch wet grinding studies were conducted in a stirred mill to evaluate the effect of the grinding media density, grinding media diameter, and stirrer tip speed on the ground 2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research investigations have not yet been published on the EnergyModel and Life CycleModel for Grinding 2014年7月12日 The document discusses grinding technology for limestone using ball mills It covers: 1 The properties and applications of limestone powder 2 Wet and dry grinding processes 3 Different types of grinding circuits including classical ball mill, airswept mill, birotator, and compound mill circuits 4 Details of mill internals such as ball charges and linings for Grinding Technology of Limestone With Ball Millsor uniformsized) grinding media on the fine grindability of limestone Experiments were carried out under the operational conditions, including the rotor speed, the operating time, the mass of the grinding media, and the mass of the limestone sample Effect of Polysized and Monosized Grinding Media on Fine Grinding of Limestone in a Bead MillEffect of Polysized and Monosized Grinding Media on

.jpg)

Impact of grinding aids and process parameters on dry stirred media

2018年7月15日 The interactions between slurry, grinding media and mill structure are modelled by twoway couplings between the PFEM, the DEM and the FEM models The coupled model of the present study is used to predict the motion of slurry and grinding media, and to calculate the power draw during wet comminution in a pilot scale horizontal stirred media mill2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Journal of Materials Research and Technology, 2020 Grinding aids (GAs) have been an important advent in the comminution circuits Over the last few decades, in order to address the high energy consumption and scarcity of potable water for mineral processing, chemical additives have become a promising alternativeThe effect of additives on stirred media milling of limestone2024年1月13日 Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate

7 Typs of Limestone Grinding Mills in 2023 Medium

There are 7 types of limestone grinding mills available, each designed for specific purposes and applications A ball mill is a cylindrical device used to finely grind materials It consists of a