What is the slope of Raymond mill conveyor

.jpg)

Conveyors Maximum Inclination vs Product

2010年11月25日 Maximum conveyor slopes for various materials: Use this chart to estimate the inclination or slope angle of a conveyor Measure the horizontal run and the vertical rise of the conveyor Draw the lines in the chart to 2022年5月16日 To start, you’ll need to understand the primary categories of conveyors and the key differences between them Gravity systems are powered either by gravity (items sliding down a slope) or by human assistance (workers Powered Conveyors vs Gravity Conveyors: Which 2024年1月29日 Calculating the slope of a gravity conveyor is a critical aspect of conveyor design in terms of the maximum angle of belt conveyor, directly influenced by gravity and material characteristics A wellcalculated slope Rise and Decline: Maximum Angle of Belt Conveyor2022年12月7日 Roller Chain Conveyors or Apron Chain Conveyors are used to transfer heavy bulk materials from one point to another This manual for practical application indicates the Chain Conveyors Practical Calculations PDHonline

Dimensioning of belt conveyors (waste as conveyed

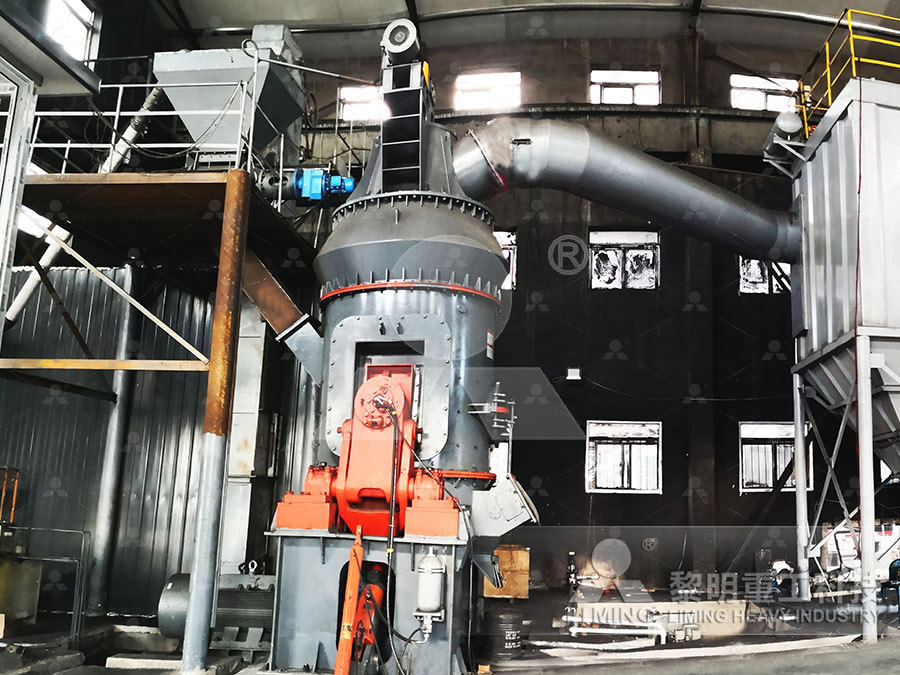

2018年1月19日 We recommend for normal operating conditions to use a filling r atio of 80% (factor 08) in the calculation an angle of surcharge of 10° is to be used for biowaste and 2020年6月16日 Raymond mill has been widely used in highfine pulverization processing of nonflammable and nonexplosive materials, such as quartz, talc, marble, limestone, dolomite, 4 steps to help you understanding the Raymond Mill2024年11月21日 Find conveyor equipment calculators to help figure specs Conveyor Lift Stockpile Volume Conveyor Horsepower Maximum Belt Capacity Idler SelectorConveyor Calculators ALL Superior Industries2022年7月7日 Raymond Mills are commonly airswept vertical Roller Mills with an integral classification system that simultaneously dries, pulverizes and classifies clays, minerals and Raymond Mills SolidsWiki

.jpg)

Conveyor belt according gradient angles KENKI

2018年1月12日 Types of conveyor belt differ according to angles of slope during conveying There are mainly four reference angles as the followings and all of them are for rubber conveyor belt with ship bottom shapes These angles are 2024年1月29日 The conveyor slope angle is a vital factor in conveyor design, directly impacting the maximum angle of inclination Careful consideration of the material properties and behavior at various angles is essential for designing Rise and Decline: Maximum Angle of Belt Conveyor2021年12月29日 Raymond mill is a threedimensional structure, covers an area of small, systematic strong, from the rough processing of raw materials to transport to powder and packaging, can become an independent production system the main business scope: a variety of dry mix mortar production lines, including sand dryers, cement silos, belt conveyors Raymond Mill : The Ultimate FAQ Guide Dry Mortar PlantThe screw conveyor has a spiral blade on a shaft inside a chute, with bearings at both ends and a drive unit at one end, featuring top and bottom openings Clirik Raymond Mill Successfully Installed in Kyrgyzstan; HGM80 Roller Mill For Grinding Glass Powder; Clirik Mill Achieves Calcite Micro Powder Grinding Production; Contact UsScrew Conveyor Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill

Slope Formula What is Slope Formula? Equation, Examples

The slope formula is used to calculate the inclination or steepness of a line It finds application in determining the slope of any line by finding the ratio of the change in the yaxis to the change in the xaxis The slope of a line is defined as the change in the "y" coordinate with respect to the change in the "x" coordinate of that lineSlope angle of a conveyor can be calculated using the height difference between start and end point of a conveyor and also the length of conveyor Slope angle will determine the height of each legs along the conveyor Slope angle is different according to the type of product moved, the type of conveyor and the belt type usedMinimum and Maximum Slope Angle on a Conveyor2019年12月19日 The conveyor doesn’t vibrate, so it doesn’t require installation with vibration isolation media In some cases, depending on the belt type and conveyor length, the drive pulley can be located at either end of the conveyor and the conveyor can operate in reverse While a short belt conveyor can be started and stopped frequently, stopping aBelt and vibratingtrough conveyors: Some guidelines 2024年11月21日 Find conveyor equipment calculators to help figure specs Conveyor Lift Stockpile Volume Conveyor Horsepower Maximum Belt Capacity Idler SelectorConveyor Calculators ALL Superior Industries

.jpg)

How to Choose the Proper Vibratory Conveyor for Your

2023年8月8日 Mechanical conveyor systems are a critical component of material handling, ofering an eicient and costefective method of transporting substances between and within processing centers Although many systems rely on simple conveyor belts, rollers, or chains, other methods are available for applications with more particular requirements2023年9月14日 Screw conveyors are mainly divided into tubular screw conveyors, Ushaped screw conveyors, shaftless screw conveyors and shaft screw conveyors The shaft tube type screw conveyor has an inclination angle of up to about 45°, and the shaft Ushaped screw conveyor has a maximum inclination angle of about 20°30°What is the maximum tilt angle of the screw conveyor?2023年9月5日 Conveyors play an indispensable role in many aspects of bulkhandling and reliability is paramount They can also be a considerable overhead The conveyor belt market is extremely competitive, something signified by How to Establish the True Cost of Conveyor Belts 2018年9月30日 For different types of Raymond mills, the difference in performance is due to structural differences, but the specific working principle is similar, and the working principle is the same What is the working principle of Raymond Mill? LinkedIn

(PDF) INSTALLATION OF HIGH CAPACITY BELT CONVEYOR

2023年10月12日 The present Indian annual demand of 120 Mt is expected to go up to 310 Mt by the end of this century Although the major share of this is expected to come from opencast mines, underground coal 2023年4月11日 PALABORA'S MAIN SLOPE BELT Lawrence K Nordell, Conveyor Dynamics, Inc (USA) Johan J Van Heerden, Palabora mining Company (RSA) ABSTRACT: Hard rock conveyor belt life cycle cost is set by the belt's cover wear life Little is published that identifies means of increasing belt life by reducing the belt cover attrition mechanismsTECHNICAL INNOVATION'S EXTEND LIFE OF cvdyn2023年5月6日 Uses of Conveyor Belts in Paper Mills and Industries The use of conveyor belts in paper mills and industries is diverse They are used in the following ways: Transportation of raw materials such as wood chips, pulp, and paper rolls to different stages of production; Transportation of finished products such as boxes of paper to the storage areaConveyor Belts in Paper Mills and Industries: A 2022年5月16日 Chute Conveyors Perhaps the simplest gravity conveyor, a chute operates much like a playground slide: items slide down a low friction surface, from the high end of a slope to the low end Powered Conveyor Systems As the name suggests, powered conveyor systems use power to propel goods along a conveyor linePowered Conveyors vs Gravity Conveyors: Which Do You Need? Raymond

Incline Conveyor Lengths Calculator Spaceguard

Spaceguard Ltd Unit 15A Bergen Way Hull East Yorkshire HU7 0YQ 07835 01482 Spaceguard Ltd is a company registered in England and Wales Company number: The Conveyor is adaptable for both standalone and integrated use, designed to create horizontal or inclined systems It operates efficiently across a wide temperature range, from 20°C to +40°C, and is capable of handling materials with temperatures up to 50°C Clirik’s European Coarse Powder Mill is used in industries like metallurgy Belt Conveyor Grinding Mill,Raymond Mill,Ball Mill,Ultrafine MillCement conveyor refers to a belt conveyor in cement plant, which is necessary accessory equipment in the cement production line A belt conveyor is a kind of material handling equipment with strong adaptability, applied for conveying bulk density less than 167t / m³, it is mostly used for powder, granular, small lump materials, and bagged materials, such as sand, ore, coal, Cement Conveyor Belt Conveyor In Cement Plant AGICO2024年11月26日 The objective shared by incline conveyors and steep incline conveyors – to convey bulk solids on an incline – often presents confusion in determining which type of conveyor is best for a given application While both Incline Conveyors Vs Steep Incline Conveyors

.jpg)

Incline And Maximum Angle Belt Conveyor

2024年3月14日 Angle belt conveyor diagrams serve as a blueprint, providing invaluable insights into the conveyor’s architecture: Path Illustration: Diagrams delineate the conveyor’s trajectory, clearly marking the ascent from the 4 天之前 Spiral classifiers are the main classification equipment for various mineral processing plant It is mainly used for ore classification, separation, screening, desliming, and dewatering in sandwashing operations The spiral Spiral Classifier JXSC Machinery2024年4月2日 Each type represents a specific approach in roller conveyor design, tailored to solve distinct challenges in material transport and handlingFrom gravity conveyors that rely on the natural force of gravity to advanced 24v powered conveyors that offer unparalleled control and efficiency, the choice of system depends on a thorough understanding of the operational Roller Conveyor Design Principles: Applications And Raymond mill is a common type of cement mill used in cement plant and lime calcination plant, and generally apply for the production of mineral powder or coal powder, such as the fine powder processing of raw ore, gypsum, coal and other materials Why choose Raymond mill from AGICO? AGICO Cement is one of leading raymond mill suppliers in China, we can offer any Raymond Mill, Raymond Mill For Sale For Cement and Lime

.jpg)

What Are the Key Advantages of Using a Raymond Mill?

2024年11月11日 Here are some key advantages of using a Raymond mill: 1 High Efficiency: Raymond mills are known for their high efficiency in grinding materials to a fine powderThe design minimizes energy The production of heavy calcium powder is mainly divided into three steps: crushing, grinding, and weathering of heavy calcium carbonate The specific crushing process is: crushing by jaw crusher, impact crusher or hydraulic cone crusher, and then enter the Raymond mill The powder machine is grinded, and the machine is separated and processed for powder selection and powder What is the output of Raymond Mill?23 小时之前 FEECO’s steep incline conveyors permit the transportation of bulk materials at inclines ranging from 18 degrees to 90 degrees, while still maintaining the feed and discharge properties of a standard belt conveyor (incline conveyors up to 18° are also available)Steep Incline Conveyors FEECO International IncAdvantages of Raymond mill 1 Raymond mill has a threedimensional structure and occupies a small area It can form a series of independent spaces for feeding, crushing, grinding, conveying, packaging, etc, reducing labor, infrastructure, time and other costs by 30,000 to 50,000 yuanDolomite Raymond Mill SBM Ultrafine Powder Technology

Report on: Gravity Roller Conveyor Design ResearchGate

2023年8月18日 horizontal plane, but at times a gentle slope is given to these conveyors to aid motion of the loads An inclination of 15% to 3% ensures that the load will roll by gravity2024年1月29日 The conveyor slope angle is a vital factor in conveyor design, directly impacting the maximum angle of inclination Careful consideration of the material properties and behavior at various angles is essential for designing Rise and Decline: Maximum Angle of Belt Conveyor2021年12月29日 Raymond mill is a threedimensional structure, covers an area of small, systematic strong, from the rough processing of raw materials to transport to powder and packaging, can become an independent production system the main business scope: a variety of dry mix mortar production lines, including sand dryers, cement silos, belt conveyors Raymond Mill : The Ultimate FAQ Guide Dry Mortar PlantThe screw conveyor has a spiral blade on a shaft inside a chute, with bearings at both ends and a drive unit at one end, featuring top and bottom openings Clirik Raymond Mill Successfully Installed in Kyrgyzstan; HGM80 Roller Mill For Grinding Glass Powder; Clirik Mill Achieves Calcite Micro Powder Grinding Production; Contact UsScrew Conveyor Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill

Slope Formula What is Slope Formula? Equation, Examples

The slope formula is used to calculate the inclination or steepness of a line It finds application in determining the slope of any line by finding the ratio of the change in the yaxis to the change in the xaxis The slope of a line is defined as the change in the "y" coordinate with respect to the change in the "x" coordinate of that lineSlope angle of a conveyor can be calculated using the height difference between start and end point of a conveyor and also the length of conveyor Slope angle will determine the height of each legs along the conveyor Slope angle is different according to the type of product moved, the type of conveyor and the belt type usedMinimum and Maximum Slope Angle on a Conveyor2019年12月19日 The conveyor doesn’t vibrate, so it doesn’t require installation with vibration isolation media In some cases, depending on the belt type and conveyor length, the drive pulley can be located at either end of the conveyor and the conveyor can operate in reverse While a short belt conveyor can be started and stopped frequently, stopping aBelt and vibratingtrough conveyors: Some guidelines 2024年11月21日 Find conveyor equipment calculators to help figure specs Conveyor Lift Stockpile Volume Conveyor Horsepower Maximum Belt Capacity Idler SelectorConveyor Calculators ALL Superior Industries

How to Choose the Proper Vibratory Conveyor for Your

2023年8月8日 Mechanical conveyor systems are a critical component of material handling, ofering an eicient and costefective method of transporting substances between and within processing centers Although many systems rely on simple conveyor belts, rollers, or chains, other methods are available for applications with more particular requirements2023年9月14日 Screw conveyors are mainly divided into tubular screw conveyors, Ushaped screw conveyors, shaftless screw conveyors and shaft screw conveyors The shaft tube type screw conveyor has an inclination angle of up to about 45°, and the shaft Ushaped screw conveyor has a maximum inclination angle of about 20°30°What is the maximum tilt angle of the screw conveyor?