Asphalt brand new lime quicklime grinding mill

.jpg)

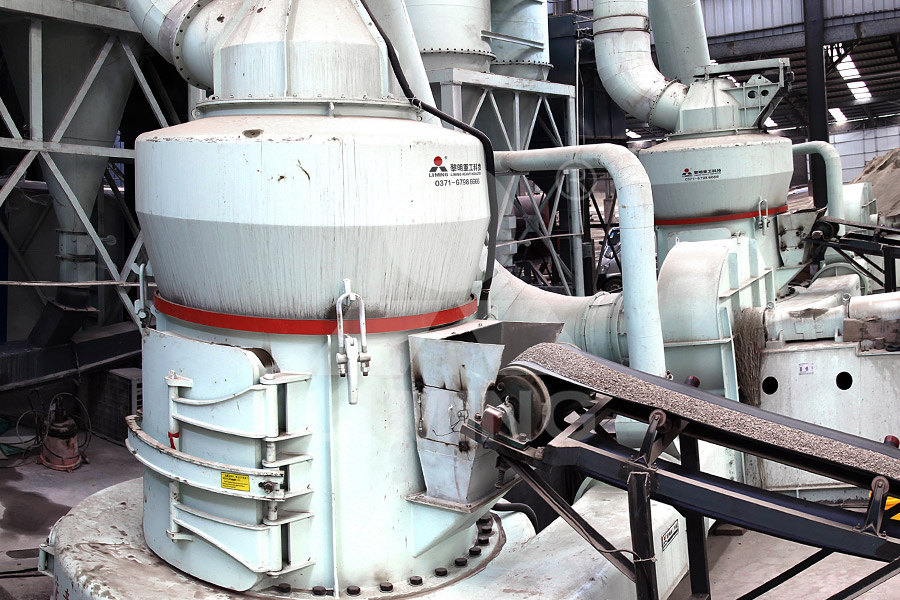

The Right Grinding Machines for Your Quicklime Industry

2024年10月30日 Offer tailored grinding mills for quicklime Wide application, highquality, energysaving and environmentally friendly2022年4月20日 After being calcined, limestone becomes calcium oxide CaO (commonly known as quicklime), which is generally in the form of lumps and is used in water quality treatment, asphalt improvement, desulfurization, building Limestone crushing and grinding production line 2023年12月8日 After calcining, limestone turns into calcium oxide CaO (commonly known as quicklime), which is generally in block form and is used in water treatment, asphalt improvement, desulfurization, building materials, Limestone crushing technology and equipment2023年6月28日 CaO (or quicklime) is made of limestone after calcination It is generally in block shape and used in water quality treatment, asphalt improvement, building materials, medicine, Limestone Grinding Mill mzenithmills

.jpg)

limestone grinding mill, limestone grinding machine,

2024年7月11日 Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked lime The main component of 2024年11月22日 Graymont is able to supply hydrated lime and limestone fillers for asphalt manufacturers from a number of Graymont sites across our network of plants In some cases, we are able to offer storage and logistics solutions for Lime in Asphalt Graymont2023年10月31日 Quicklime milling is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder quicklime processing plant, quicklime grinding machine, quicklime China Manufacturer Quicklime Grinding Cement Ball Mill for Sale US$3,2000011,20000: 1 Piece (MOQ)China Manufacturer Quicklime Grinding Cement Ball Mill for

制粉-10.25公众号.jpg)

Powder Grinder Equipment for Producing Lime Powder

2021年11月24日 CLUM superfine vertical roller mill can produce 3253000 mesh nonmetallic ore powder It can also be used to process hydrated lime and quicklime The industrial grinding mill has large output, intelligent operation, high efficiency and stability The finished powder produced is highend powder with high whiteness and good shape2024年10月8日 The vertical mill is integral to the quicklime production process After limestone is calcined in the lime kiln, the resulting quicklime is fed into the vertical mill for grinding The mill ensures that the quicklime meets the required fineness for various applications, such as in steelmaking, construction materials, and environmental treatmentVertical mill: The preferred equipment for quicklime production2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine How to do a good job of grinding in the lime 2023年6月28日 The benefits of using lime processing plants: Processing Slaking and grinding mills of the roller mounted or vertical type Grind performance to suit client process requirements Receival Intake of lime via bulk bag or pressurised vehicle Storage Single or multiple silos dependent upon site storage requirements WettingCase Study: LIMESTONE GRINDING QUICKLIME

Ball Mills Lime Systems

Whether you need a small labscale ball mill for testing or a large industrial ball mill for highcapacity grinding, we can accommodate your needs With our advanced technology and innovative design, our ball mills are designed to enhance your 2018年1月16日 Limestone is divided into quicklime and hydrated lime The calcining limestone turns into CaO which has the blockshaped appearance and is widely used in water conditioning, asphalt modify Limestone Grinding Mill 2018 LinkedIn2024年8月16日 both trials, the grinding process started with an efficient grinding period which ended after 125 s Figure 3: RMS acceleration signal assessed during 20 s grinding of 350 g of quicklime in the HPM 1500 disc mill The trials A F showed efficient grinding periods of at least 17 s duration (green dots) In C, D and E short periods ofRealtime monitoring of efficiency in quicklime grindingLimestone can be made into limestone powder by treatment of limestone crusher and limestone grinding mill Limestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, and after adding water treatment to get hydrated lime By mixing hydrated lime, lime slurry and lime paste can be Limestone Mill for Limestone Powder Grinding Limestone Crushing

News, conferences and events Pfeiffer

The Pfeiffer mill is designed to produce 35 tph of quicklime at a fineness of 10 % R 150 µm and will come equipped with a 200kW gearbox MPS mills have been used successfully for a great many years in works of the chemical, gypsum and lime industry where limestone, quicklime or gypsum are ground2013年5月1日 The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding of hydrated lime and the product Effect of ball mill grinding parameters of hydrated lime fine grinding 2023年6月1日 to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime Systems mills and all units have fully automated grease lubrication systems for the drive and idler shaft bearings Through an association with Nippon Eirich, Lime Systems hasCOMPLETE PLANT CAPABILITY LIME SYSTEMS LTDQuicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to mortar It can also be used as a drying or Quicklime preparation Gebr Pfeiffer

.jpg)

limestone grinding mill, limestone grinding machine,

2024年7月11日 Lime are divided into two kinds: quicklime and slaked lime The main component of quicklime is CaO, the general was massive, when it is with high purity, it is pure white; When it contains impurity, it looks pale gray or faint yellow It turns into slaked lime (hydrated lime) if getting wet The main ingredient is Ca (OH) 2The limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder Finenessquicklime In the past, the grinding of quicklime was extremely difficult, since quicklime generates a large amount of electrostatic charge upon being ground by a mill due to its inherently very high electric resistivity, and thereby the powders of quicklime deposit and solidify on the inner Wall or balls of the mill or aggregate themselves into granules, resulting in absorption of impulsive USA Method of grinding quicklime Google Patents2023年6月28日 the quicklime to a bucket elevator outside of the building The bucket elevator lifts the quicklime into the 100m3 silo for storage The quicklime is transferred out of the silo into the ball mill using bin activator, screw feeder, and vibrating conveyor Lime is then slaked via a ball mill (closed circuit) at a design rate of 11t/hVancouver LIME Transmin

Factors Affecting The Quality of Quicklime

2013年9月4日 The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln such as temperature, particle size of the limestone, rate of temperature rise, retention time, and CO2 concentration 2021年9月2日 Lime Lime is divided into quicklime and hydrated lime The main component of quicklime is calcium oxide (CaO), a white solid refractory and insoluble The limestone with high content of (CaO) is calcined in a ventilated lime kiln to above 900°C Quicklime is absorbent and can be used as a desiccant It is commonly used to prevent the regain of The difference between quicklime and hydrated lime2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder 2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is Lime/quicklime for metallurgy – how producing and

LIMESTONE GRINDING Bauermeister Size

Bauermeister mills can be used for grinding natural limestone as well as burnt lime to the desired particle size Hydrated lime reacts with carbon dioxide to create calcium carbonate This reaction (desired for mortar) rules out grinding 2024年11月25日 Limestone Used In Asphalt Mixing Plants CASES MORE 500,000 TPY Heavy Calcium Carbonate Grinding Plant VIEW MORE Quicklime Grinding Plant VIEW MORE 5TPH Clay Grinding Plant VIEW MORE 30TPH Coal Grinding Plant SBM Invites You to Join the Grand Event! READ MORE >> 2024 SBM Grinding Mill Quality Tour East China Station Grinding Mill, China Grinding Mill, Grinding PlantLime slaking is the process of converting quicklime to hydrated lime (CaO + H20 > Ca(OH)2) by mixing with water Lime slaking is an exothermic process which generates heat and creates steam Slaked or hydrated lime is often used in LIME SLAKING SYSTEMS Bulk Handling 2020年12月22日 Quicklime, CaO, and slaked lime, Ca(OH) 2 When calcium carbonate is heated strongly, it decomposes to give calcium oxide and carbon dioxide CaCO 3 (s) CaO(s) + CO 2 (g) Calcium oxide is traditionally known as quicklime If you add water to calcium oxide, you get calcium hydroxide (slaked lime) CaO(s) + H 2 O(l) Ca(OH) 2 (s)limestone, quicklime and slaked lime chemguide

HCM Quicklime Grinding Mills For Producing 2000 Mesh

2020年6月16日 quicklime production, quick lime manufacturer, quick lime superfine powder grinding mill When it comes to quicklime production of powder fineness 2000 mesh, it is highly suggested choose superfine 2024年11月22日 Zero Grind; Quicklime Dolomitic Quicklime; GBA; High Calcium Quicklime; Pulverized Quicklime; Graymont is able to supply hydrated lime and limestone fillers for asphalt manufacturers from a number of Graymont sites across our network of plants In some cases, we are able to offer storage and logistics solutions for mobile asphalt plants by Lime in Asphalt GraymontCage Mills for SuperFine Grind™ The new 75micron crusher targets agricultural lime, hydrated lime, quicklime, and other industrial applications to make products in the 40 mesh to 325 mesh range The HSI, asphalt crusher, specifically engineered for the asphalt industry, reduces RAP to the required size quickly and easily for further Stedman Machine Cage Mills for SuperFine Grind™2022年6月2日 Lime and limestone are used in large quantities as building materials and are also important raw materials for many industries Limestone can be directly processed into stone and fired into quicklime Lime has quicklime and slaked lime Crushing and grinding equipment is required in the limestone processing process YGM high pressure Raymond millLimestone grinding and processing equipmentNewsultramill

.jpg)

COMPLETE PLANT CAPABILITY LIME SYSTEMS LTD

2023年7月6日 to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime Systems mills and all units have fully automated grease lubrication systems for the drive and idler shaft bearings Through an association with Nippon Eirich, Lime Systems has2024年10月27日 Skip to main content Secondary menu Customer Portal; Main menu Products Chemical Limestone Dolomitic LimestoneQuicklime Graymont2021年11月24日 CLUM superfine vertical roller mill can produce 3253000 mesh nonmetallic ore powder It can also be used to process hydrated lime and quicklime The industrial grinding mill has large output, intelligent operation, high efficiency and stability The finished powder produced is highend powder with high whiteness and good shapePowder Grinder Equipment for Producing Lime Powder2024年10月8日 The vertical mill is integral to the quicklime production process After limestone is calcined in the lime kiln, the resulting quicklime is fed into the vertical mill for grinding The mill ensures that the quicklime meets the required fineness for various applications, such as in steelmaking, construction materials, and environmental treatmentVertical mill: The preferred equipment for quicklime production

.jpg)

How to do a good job of grinding in the lime

2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine 2023年6月28日 The benefits of using lime processing plants: Processing Slaking and grinding mills of the roller mounted or vertical type Grind performance to suit client process requirements Receival Intake of lime via bulk bag or pressurised vehicle Storage Single or multiple silos dependent upon site storage requirements WettingCase Study: LIMESTONE GRINDING QUICKLIME Whether you need a small labscale ball mill for testing or a large industrial ball mill for highcapacity grinding, we can accommodate your needs With our advanced technology and innovative design, our ball mills are designed to enhance your Ball Mills Lime Systems2018年1月16日 Limestone is divided into quicklime and hydrated lime The calcining limestone turns into CaO which has the blockshaped appearance and is widely used in water conditioning, asphalt modify Limestone Grinding Mill 2018 LinkedIn

.jpg)

Realtime monitoring of efficiency in quicklime grinding

2024年8月16日 both trials, the grinding process started with an efficient grinding period which ended after 125 s Figure 3: RMS acceleration signal assessed during 20 s grinding of 350 g of quicklime in the HPM 1500 disc mill The trials A F showed efficient grinding periods of at least 17 s duration (green dots) In C, D and E short periods ofLimestone can be made into limestone powder by treatment of limestone crusher and limestone grinding mill Limestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, and after adding water treatment to get hydrated lime By mixing hydrated lime, lime slurry and lime paste can be Limestone Mill for Limestone Powder Grinding Limestone CrushingThe Pfeiffer mill is designed to produce 35 tph of quicklime at a fineness of 10 % R 150 µm and will come equipped with a 200kW gearbox MPS mills have been used successfully for a great many years in works of the chemical, gypsum and lime industry where limestone, quicklime or gypsum are groundNews, conferences and events Pfeiffer2013年5月1日 The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding of hydrated lime and the product Effect of ball mill grinding parameters of hydrated lime fine grinding