Cracked carbon black silica grinding mill

RECOVERED CARBON BLACK Hosokawa Alpine

2022年6月10日 ENERGYEFFICIENT RECOVERED CARBON BLACK FINISHING PRECISE CONTROL OF THE QUALITY AND TARGET FINENESS OF THE END PRODUCT HIGH 2024年11月18日 Through hightemperature cracking, the tires are split into oil gas, and carbon black The carbon black will be spirally cooled and transported to the bucket before the micro Carbon black powder grinding mill LIMING HEAVY 2022年9月30日 Recycling carbon black grinding mills (pyrolysis carbon black mills) include Raymond mills, pendulum mills, vertical mills, and ultrafine vertical mills If the rCB of 80325 Recovered Carbon Black rCB Processing Grinding Mill 2023年12月14日 At present, the refined cracked carbon black industry is in the development stage The high added value brought by ultrafine milling has made its industrial use increasingly widespread: mainly used as a key material for Türkiye Pyrolysis Carbon Black Grinding Line

Tire pyrolysis carbon black deep processing

2023年4月7日 The cracked carbon black is called coarse carbon black If you do not want to carry out further processing and refining, you can use a press to press the carbon black into carbon black balls The calorific value of carbon black 2024年6月14日 To address these challenges, FTM Machinery engineers have developed a carbon black ultrafine mill based on the Raymond mill Here are the mill's specifications: Material: Specifically designed for grinding non Carbon Black Processing: Turning Soot into 2024年7月16日 Carbon black is an important additive for rubber products, which is used to improve the physical properties of rubber, such as enhancing wear resistance, aging Carbon Black Grinding Mill for Fine Carbon Black Powder 2024年4月8日 The partial or total replacement of carbon black by silica fillers is initiated through various techniques for environmentfriendly, smart, and fuelefficient NR composites for high Recent advancements in silica filled natural rubber Springer

.jpg)

Review The past, present and future of carbon black as a

2020年2月20日 Carbon black is a reinforcing filler widely applied in the rubber elastomers manufacture This review is focused on the development of the life cycle of carbon black First, 2022年11月22日 A sustainable and green method is presented in this paper to produce highly oxidized carbon black using dry ball milling The mechanical energy by colliding milling balls is able to easily break and build chemical Green Oxidation of Carbon Black by Dry Ball 2020年2月20日 The production process of carbon black is not only energyconsuming, contributes to global CO 2 emissions significantly, but also utilizes nonrenewable feedstock, making it unsustainable The future of carbon black – the modification and the production of its substitutes from biomass and relevant materials were proposedReview The past, present and future of carbon black as a 2023年8月17日 Carbon Black Grinding Mill Equipment [] 1about carbon black grinding mill 11 the importance of carbon black grinding mill 12 carbon black grinding mill application 2carbon black grinding mill working principle 21 carbon black powder making flow 22 carbon black grinding mill working pcarbon black processing machine, tyre pyrolysis carbon black grinding

.jpg)

Precipitated silica grinding mill Clirik

2021年8月20日 The most common use (70%) of precipitated silica is as a pigment and reinforcing phase in automobile tires Precipitated silica also helps conduct heat away from the tread and belt area of the tire, reducing thermal damage and increasing tire life Precipitated silica particles are also employed in some radar absorbent materials and in photocopier and laser 2017年3月2日 Silica gel is a granular, vitreous, porous form of silicon dioxide made synthetically from sodium silicate Silica gel contains a nanoporous silica microstructure, suspended inside a liquidSilica Gel Powder Grinding Mill Silica gel is a granular, 2024年5月22日 Waste Tyre Pyrolysis Plant for Carbon black Application field:Waste Tyre Pyrolysis Plant to make pyrolysis carbon black, oil, fuel, etc Type:Waste Tyre Pyrolysis Plant for Carbon black Capacity:120 tone per furnace Live Chat Carbon black grinding mill/grinder mill Application field:Designed for carbon black super fine grinding, to solve the problem of cabon carbon black processing machine, tyre pyrolysis carbon black grinding Carbon black ultrafine grinding mill adopts a graded continuous grinding method to grind the material multiple times at the same time to truly realize ultrafine grinding +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Home;Carbon Black Ultrafine Grinding Mill

Fracture properties of silica/carbon blackfilled natural

2007年12月3日 Although much work has been done on crack properties in carbon blackfilled rubber, crack properties in silica/carbon blackfilled rubber have not been examined thoroughly [6] Here we report the crack growth properties of silica/carbon black NR vulcanizates EXPERIMENTAL 1 Formulation and Mixing2024年8月8日 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes Predominantly made from carbon steel, stainless steel, or alloy steel, steel balls are renowned for their high density and Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding 2020年8月28日 Heat conductivity, curing rate and fatigue crack growth properties of carbon blackfilled styrene butadiene rubber (SBR)/butadiene rubber (BR) blend that is frequently used in passenger car tire treads were simultaneously improved by a hybrid filler system of carbon black, high dispersible precipitated silica, modified layered silicate and ultralight mixed filler of Effect of mineral fillers on physicomechanical properties and heat 2020年11月10日 larger than the clustered carbon black particles, if left in there with the carbon black will significantly and adversely impact the tire manufacturing equipment as well as the final quality of the tire Reducing these grits using highspeed grinding mills, down to a size whereby they are rendered harmless, is the focus of this paperCarbon black: why quality matters hmicronpowder

R)8OC`6F[ZIB.jpg)

Amazoncouk: Large Black Pepper Mill

Ulsam Pepper Grinder 8 Inch Wooden Black Pepper Mill, Salt Grinder Refillable, Manual Large Peppercorn Grinder with Adjustable Thickness Ceramic Rotor for Kitchen Picnics 33 out of 5 stars 7 £849 £ 8 49Working principle of carbon black ultrafine powder grinding mill Carbon black ultrafine powder grinding mill mainly consists of main unit, classifier, powder collector, dust cleaner, blower, muffler, soundproof room, crusher, bucket Carbon Black Ultrafine Powder Grinding MillCarbon Black Powder Grinding Mill Finished Size: 1502500 mesh Processing Ability: 145 t/h Max Feeding Size: 1025 mm Application: Charcoal、Talc、Calcium Carbonate 、Limestone 、Kaolin、BentoniteCarbon Black Powder Grinding Mill in Uzbekistan2020年10月1日 The current study investigates the type of ratio for ball mill jars listed in Table 3 and [63,80,168,181,183] Different balltojar ratios can affect the milling kinetics, the size, and Silicon Powder Properties Produced in a Planetary Ball Mill

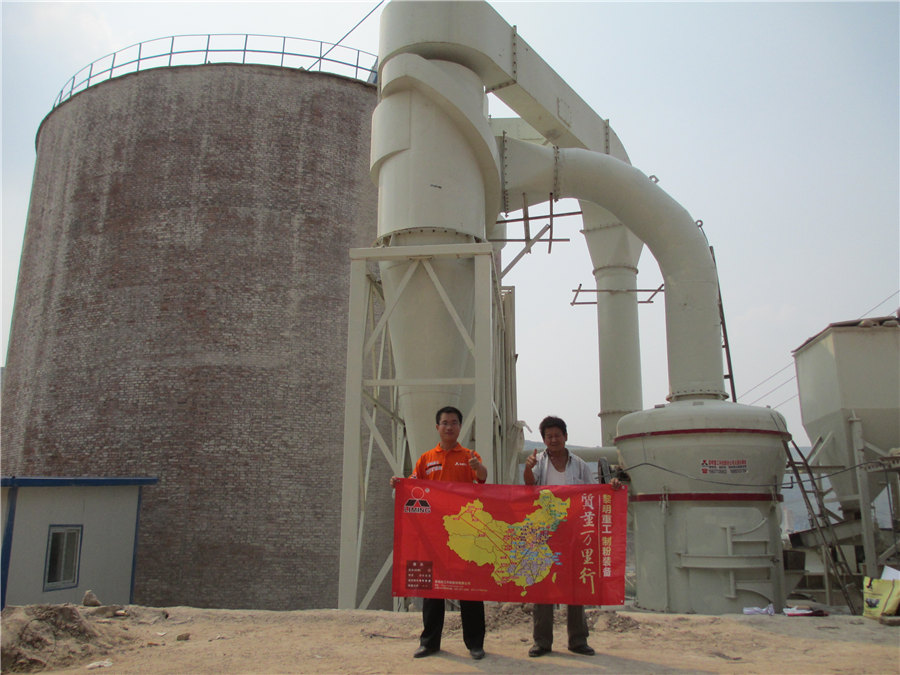

Carbon black grinding mill/grinder mill

2023年6月9日 When the carbon black grinding mill/grinder mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, 2022年4月18日 Synergistic effects of adding silica, as a secondary filler, to styrenebutadiene rubber composites highly filled with carbon black was investigated It was shown that there is a critical Carbon black/silica hybrid filler networking and its 2019年8月30日 The pyrolysis carbon black (CBp) from waste tires accounts for more than 35% of pyrolysis products Its poor reinforcing ability and low additional value limit heavily the wide application of Pyrolytic preparation and modification of carbon black recovered 2024年5月22日 And the carbon black also be widely used in various industrial fields such as rubber, plastics, inks, coatings, etcThe carbon balck grinding mill also is an energy conservation and environmental protection equipment , with the advancement of technology, modern carbon black grinding machines have also made significant improvements in energy Carbon Black Grinding Mill Equipment

.jpg)

(PDF) Development of a Cutting Force Prediction Model for Silica

PDF On Oct 8, 2019, Zhang Chong and others published Development of a Cutting Force Prediction Model for Silica/Phenolic Composite in Millgrinding Find, read and cite all the research you Good Quality Ce Iso Certificated Marble Talc Industrial Powder Pulverizer Scm Ultra Fine Grinding Mill Vibrating Ball Mill Machine for pyrite iron grinding High Quality Cement Ore Processing grinder Mill machine Price Mining Stone Wet / Dry Grinding Ball Mill Good Quality Traditional Stone Talc Raymond Vertical Coal Grinding Mill Machine For HGM grinding mill carbon black manufacturing process from 2021年9月30日 air in the Specialty Carbon Black powder by the binder or binder/additive until the complete wetting of the pigment is achieved The wetting process is infl uenced by viscosity, surface chemistry and porosity of the pigment • Dispersion: breaking Specialty Carbon Black agglomerates into aggregates • Stabilization of the Specialty Carbon Short Dispersion Guideline for Specialty Carbon Blacks in 2006年10月1日 Two different catalyst supports, carbon black (XC72R) and K20 (mesoporous carbon), were crushed and dispersed by mechanical milling using a bead mill The bead mill operated with 03μm zirconia Production of Carbonate and Silica NanoParticles in Stirred

On the Friction of Carbon Black and SilicaReinforced BR

2014年4月23日 Friction of carbon black and silicareinforced elastomers is studied experimentally and theoretically, using Persson’s model The effect of reinforcement fillers on elasticity was determined by dynamical mechanical analysis Carbon blackfilled samples have a higher Young’s modulus than the silicafilled compounds Silicafilled rubbers have a higher 2024年1月1日 Pyrolysis is a clean and lowcarbon thermochemical technology for waste tire management, which converts waste tires to highvalue alternative fuels (gas and liquid oil), carbon black, limonene, and monocyclic aromatic hydrocarbons [3, 4]Carbon black is an essential fine chemical product and primarily utilized as a reinforcing ingredient for tire manufacture [5]Carbon black production characteristics and mechanisms 2023年6月9日 The carbon black ball mill grinder machine is a device that destroys the raw materials to make the particles smaller after being mined or broken into small pieces As can be understood from its name, the carbon black ball mill is equipped with steel balls in a closed cylinder , Through the rotation of the cylinder, the steel ball falls from a high place and collides Ball Mill Grinder Machine For Carbon Black Powder2016年1月25日 A detailed study of the initiation of fatigue cracks in carbon black filled natural rubber is conducted Interrupted fatigue tests are performed and fatigued samples are observed with a scanning Fatigue crack initiation in a carbon blackfilled natural rubber

Recovered Carbon Black rCB Processing Grinding Mill

2022年9月30日 Recycling carbon black grinding mills (pyrolysis carbon black mills) include Raymond mills, pendulum mills, vertical mills, and ultrafine vertical mills If the rCB of 80325 mesh is processed within 20 tons in one hour, it is recommended to choose an economical pulverizer (Raymond mill, pendulum pulverizer) If you want to process more than 2023年8月23日 The KitchenGo Grinder is basic, with a glass peppercorn holder that screws onto a steel base containing a ceramic grinding mechanism We appreciated the large opening of the glass jar, which makes filling it a bit easier than some of the taller and narrower models The grind size adjuster is on the underside and produces a fine to semicoarse grind, but the dial's The Best 5 Pepper Mills Tested Rated GearLabThe key feature of Zenith’s carbon black grinding mill is its advanced grinding technology, which utilizes a combination of mechanical grinding and chemical purification processes This innovative approach ensures that the carbon black produced is of the highest quality, with a low impurity content and a uniform particle size distributionMalaysia’s Carbon Black Grinding Mill: Transforming Industry2021年8月31日 To produce ultrafine carbon black powder, you can use SBM carbon black ultrafine powder mills to grind carbon black raw materials The carbon black raw material is crushed and then enters the ultrafine grinder to be squeezed and ground by the grinding roller, with a fineness of up to 3000 mesh 3 Which industrial grinding mill is the best Carbon Black Ultrafine Powder Mill SBM Ultrafine Powder

Silica Gel Powder Grinding Mill Silica gel is a granular,

2017年3月2日 Silica gel is a granular, vitreous, porous form of silicon dioxide made synthetically from sodium silicate Silica gel contains a nanoporous silica microstructure, suspended inside a liquid2024年5月22日 Waste Tyre Pyrolysis Plant for Carbon black Application field:Waste Tyre Pyrolysis Plant to make pyrolysis carbon black, oil, fuel, etc Type:Waste Tyre Pyrolysis Plant for Carbon black Capacity:120 tone per furnace Live Chat Carbon black grinding mill/grinder mill Application field:Designed for carbon black super fine grinding, to solve the problem of cabon carbon black processing machine, tyre pyrolysis carbon black grinding 2024年8月8日 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes Ball Mill Success: A StepbyStep Guide to 2020年8月28日 Heat conductivity, curing rate and fatigue crack growth properties of carbon blackfilled styrene butadiene rubber (SBR)/butadiene rubber (BR) blend that is frequently used in passenger car tire treads were simultaneously improved by a hybrid filler system of carbon black, high dispersible precipitated silica, modified layered silicate and ultralight mixed filler of Effect of mineral fillers on physicomechanical properties and heat

.jpg)

Carbon black: why quality matters hmicronpowder

2020年11月10日 larger than the clustered carbon black particles, if left in there with the carbon black will significantly and adversely impact the tire manufacturing equipment as well as the final quality of the tire Reducing these grits using highspeed grinding mills, down to a size whereby they are rendered harmless, is the focus of this paperUlsam Pepper Grinder 8 Inch Wooden Black Pepper Mill, Salt Grinder Refillable, Manual Large Peppercorn Grinder with Adjustable Thickness Ceramic Rotor for Kitchen Picnics 33 out of 5 stars 7 £849 £ 8 49Amazoncouk: Large Black Pepper Mill2020年10月1日 The current study investigates the type of ratio for ball mill jars listed in Table 3 and [63,80,168,181,183] Different balltojar ratios can affect the milling kinetics, the size, and Silicon Powder Properties Produced in a Planetary Ball Mill 2024年7月2日 The performance of natural rubber (NR), a naturally occurring and sustainable material, can be greatly enhanced by adding different fillers to the NR matrix The homogeneous dispersion of fillers in the NR matrix is a key factor in their ability to reinforce As a novel method, wet mixing technology may effectively provide good filler dispersion in the NR matrix while Research Progress of Natural Rubber Wet Mixing

Development of a Cutting Force Prediction Model for Silica

2019年10月8日 A cutting force model was developed from silica/phenolic composites for millgrinding process The experimental was carried out on silica/phenolic material and found that the cutting force decreased significantly with the increase of cutting speed, whereas the same was found increased with the increase of feed rate and cutting depth By comparison of the 2023年6月9日 When the carbon black grinding mill/grinder mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, Carbon black grinding mill/grinder mill