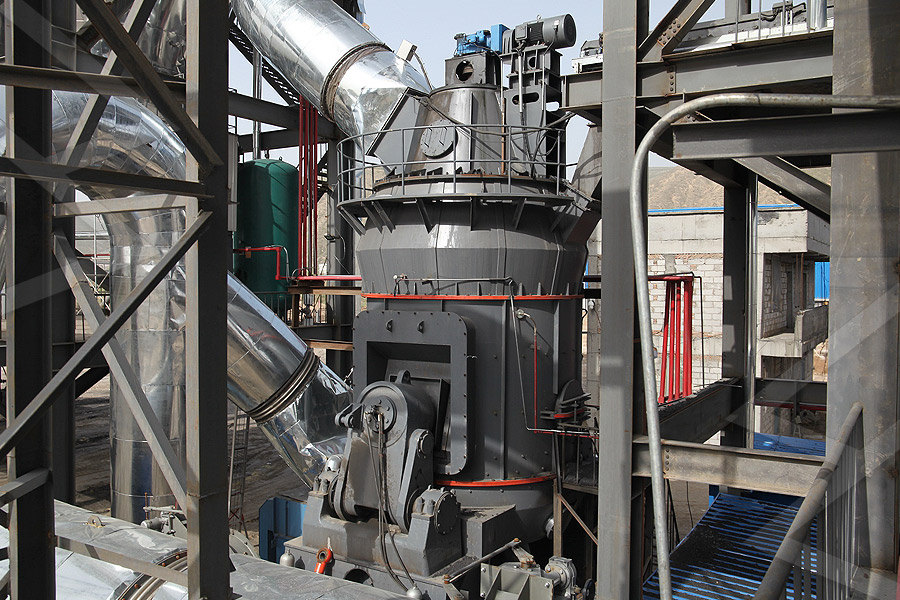

Kobelco domestic 200 mesh coal powder mill

.jpg)

Iron Unit Field|KOBELCO Kobe Steel, Ltd

Highpurity granular iron "Iron Nugget" is produced by utilizing low grade iron ore and noncoking coal This process enables low investment and reduced environmental burden KOBELCOPelletizing System (KPS) can produce 2024年10月13日 The production of 200 mesh coal powder requires the selection of an appropriate vertical mill that meets the specific requirements of the application The choice of Choosing the right vertical mill for 200 mesh coal powder 2 天之前 Whether for mixing or sheeting, KOBELCO mills offer a multitude of features that will provide long life and precise material control Fixed and variable friction ratios permit Mills – Kobelco Stewart Bolling, Inc KSBI2024年10月13日 A 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh coal powder mill/coal powder preparation

Prospects for Coalbased Direct Reduction Process

2011年1月6日 Kobe Steel has developed coalbased direct reduction (DR) technologies, the FASTMET, FASTMELT and ITmk3 processes, which reduce carbon composite agglomerates We, Kobe Steel, Ltd, have supplied many rolling mills worldwide Based on the advanced knowhow and experiences with many reference, we can offer you a wide range of products and Steel Mills KOBE STEEL, LTDLimestone sand powder preparation in India Output size:2040, 4070, 70140 mesh fine graded sand and 200 mesh fine powderLM220M, coal mill, 200 mesh, D85, 45tph2024年5月21日 Material : coal Output size : 200mesh Feeding sizes : 30mm Capacity : 2025T/H Equipment : LM1700 Vertical MillKefid 200 mesh pulverized coal preparation project in

.jpg)

200 Mesh Coal Powder Vertical Grinding Mill In Lime Rotary

We are Vertical Coal Mill manufacturer provide 200 Mesh Coal Powder Vertical Grinding Mill In Lime Rotary Kiln Production Line Hefei Hengcheng Industrial Equipment Technology Co, LtdCoal pulverizers increase the crosssectional area and dryness fraction of coal prior to it entering a furnace Pulverized coal ignites more efficiently than raw lumps of coal, thus the overall efficiency of the furnace increases if it is fired Vertical Grinding Mill (Coal Pulverizer) Explained2024年8月22日 1800 rpm primary air fan, and four mill outlets supplying pulverized coal to one of the three horizontal rows of (4) dualfuel burners When operating at boiler MCR, each mill had a coal throughput of approximately 53,000 #ffir Specified product fineness was 70% thru 200 mesh and 98% thru 50 mesh Diminishing supply of the original Kansas coalWorldProven Coal Pulverizer Technology Debuts in the A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

A Comparison of Three Types of Coal Pulverizers

2024年8月22日 Mill Speed Capacity Desired Coal Properties Feed Size Total Moisture Grindability (HGI) Abrasiveness Prod Fineness thru 200 Mesh Standard Screen Typical Air to Coal Ratio at 100% Mill Load Specific Power @ 100% Mill Load Typical Conditions CrusherDryer Mill PA Fan Total StartUp Time NoiseMill Only Approx Dimensions Mill Dia (D)2024年3月7日 The fineness of coal which gives the measure of pulverizing is maintained to a level of 75% though 200 mesh and less than 1 to 2% over 50 mesh The mill outlet temperature of coalair mixture is maintained between 65 to 90 degree centigrade in the case of low and medium volatile coal In the case of high volatile coal, while the lower limit Boiler Performance and Mill Outlet Temperature Bright 2020年9月29日 cinnamon (ground) 70 to 200 clay 01 to 2 coal dust 1 to 100 coffee (ground) 5 to 400 concrete dust 3 to 100 dust (household) 005 to 100 dust mites 100 to 300 eye of a needle 1230 flour (wheat milled) 25 to 212 gelatin powder 5 to 90 giardia cysts 8 to 14 ginger (ground) 25 to 40 200 No 200 200 Mesh 00500 00020 00750 00030 MESH and MICRON SIZES Industrial Spec2015年8月7日 The present work investigates the grinding characteristics of PC blend with coal in a laboratory ball mill to meet an industrial tube mill conditions 0% leads to a decrease in −200 mesh Grinding Characteristics of Coal and Petroleum Coke/Coal

200 Mesh Coal Powder Activated Carbon for Refinement

2024年11月17日 200 Mesh Coal Powder Activated Carbon for Refinement Organic Solvents US$1,04000 124 Tons US$1,02000 2549 it have to be milled in ball mill before put into storehouse Besides, ordinary activated carbon which made through physical method (Steam, CO2 and mix of gases Our laboratory was built in 2014 These years, with technical 180200: 250280: 325355: The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, energysaving capabilities, and ability to produce fine and ultrafine powders Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including Vertical Roller Mill SBM Ultrafine Powder TechnologyThis Coal Powder Making Plant in Bhutan utilizes our CLRM1300 Raymond grinding mill to achieve 80400 mesh coal powder production with high capacity The customer celebrated the factory’s commencement with prayers for a SBM Ultrafine Powder Technology Industrial 2 天之前 Whether for mixing or sheeting, KOBELCO mills offer a multitude of features that will provide long life and precise material control Fixed and variable friction ratios permit processing of many different compounds or polymers Our mills are available in various sizes and can be custom built for your application Options include:Mills – Kobelco Stewart Bolling, Inc KSBI

coal grinding mill, coal pulverizer machine, coal

2024年7月11日 2 After the break, particle size suitable materials are transferred to the European version of the Tshaped device or mediumspeed Tshaped grinding mill, LM milling machines and other coal milling equipment; 3 Coal The whole grinding line is used for processing coal to 200 mesh, our technicians configure one set of LM150M in order to meet customers demand for production MTW European Type Grinding Mill for limestone powder making Output size:200mesh > Limestone production line in Vietnam > LM vertical roller mill for limestone powder making LM150M Coal mill , 200mesh D90 25tphLIMING HEAVY Our vertical coal mill is designed to enhance the process, maximizing energy efficiency Home; Products compact equipment, low dust emission, and efficient combustion of coal powder Working Principle Fineness of pulverized coal (200 mesh pass %) 80: Coal moisture content (%) ≤1: Main motor Power (kW) 55: 110: 132: 180: 250250: 315 HighEfficiency Vertical Coal Mill Enhancing Coal 2011年1月6日 coalbased DRI Out of the global DRI production of 685 million tonnes in 2008, the production of coalbased DRI occupies 176 million tonnes, which equates to 257% of the total1) Most coalbased reduction processes including SL/RN2) employ rotary kilns Pellets, or lumpore, mixed with coal are/is charged into the rotary kilns2) and heatedProspects for Coalbased Direct Reduction Process

.jpg)

Steel Powder|KOBELCO Kobe Steel, Ltd

In 1970, Kobe Steel was the first in Japan to commence the manufacturing and sale of atomized steel powder In the years since, the properties of steel powder have been recognized across various fields including automotive components, and steel powder has become widely used for powder metallurgy, environmental applications (contaminated soil, and water purification) 2016年5月3日 68% passing 200 mesh On average, the pipes were about 65% passing 200 mesh, short of our standard of 75% minimum passing 200 mesh on a mass weighted average basis The actual data are shown in Figure 6 Coal pipe F9 on pulverizer B was the only pipe that met the original plant fuel specification guarantee ofPulverized Coal Pipe Testing and Balancing Storm 2015年11月1日 The coal mill grinds the raw coal into fine powder and hot air entering the mill dries and carries the pulverized coal to the burners of the furnace Maffezzoni (1986) emphasized that coal mills are the primary cause of slow load following capability and regular plant shutdowns A major problem in plant’s load control is the inability of the A unified thermomechanical model for coal mill operationFuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200mesh (74μm) screen Figure 2 shows a particlesize distribution from a bowlmill grinder typically used in power plants A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200mesh screen, which is equivalent to 70% Pulverized Coal Boiler an overview ScienceDirect Topics

Design and Modify of Mill Discharge Valve Using

2019年8月1日 High performance bowl mills of bowl size 80" are used for pulverizing the coal to required fineness of about 70 microns coal powder This coal powder is fed to boiler through steel pipes called If your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders, air classifying mills, hammer mills, and lump breakers to meet all of your industrial processing needs We have been Fine Grinders, Hammer Mills, and More for Phrase one: raw material crushing Coal blocks will be crushed to 15mm50mm fineness by crusher Phrase two: drying and grinding 1Coal material with low moisture will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding The hot air in the mill will dry the coal This will reduce drying cost 2For high Coal Mill Manufacturers Powder Making Machine Price2024年10月13日 Coal crusher: A coal crusher, such as a jaw crusher, cone crusher, or impact crusher, is used to break the coal into smaller pieces with a maximum size of about 2030 mm Coal mill: A coal mill, also known as a pulverizer, is used to grind the crushed coal to a fine powder with a particle size of around 200 mesh (75 μm)What equipment is required for the preparation and production of 200

DM 200 Disc Mill Glen Mills, Inc

2024年11月20日 Thanks to its robust design, the Disc Mill DM 200 can be used under rough conditions in laboratories and pilot plants, as well as online for the quality control of raw materials The powerful DM 200 requires only a few minutes to achieve the desired grind size2021年6月1日 This was mainly due to the sparseness of coarse coal powder, leading to a low probability of coal powder larger than 200 μm to be captured by the measurement system Although the obvious difference of PCF for mill D and B can be revealed with SAD directly, R 90 results and distribution curves were still with deviations comparing to the sieving Online measurement of pulverized coal fineness on a 300 2024年10月13日 3 Coal Grinding and Milling System: Mills: Typically ball mills or vertical roller mills, used to grind the coal to a fine powder The coal is dried and ground to a particle size typically between 70% passing through a 200mesh screen (0074 mm) Classifiers: Equipment to separate the ground coal into different particle sizes, ensuring the Complete set of coal powder preparation equipmentFind your powder mill easily amongst the 104 products from the leading brands (Fritsch GmbH, NETZSCH, BOHLE, ) on DirectIndustry, the industry specialist for your professional purchases 200 kg/h 1,200 kg/h Motor power: 30 kW metallurgy chemistry etc Suitable materials: Coal powder the air swept mill is suitable for coal grinding Powder mill, Powder grinding mill All industrial

Ball Mill Hammer Mill Indonesia Mesh 200 Crusher Mills,

ball mill mesh 200 – mining application hammer mill indonesia mesh 200 – Crusher South Africa 2 ton per hour rock hammer mill 200 to 300 mesh Hammer Mill Indonesia Mesh 200,200mm Hammer Mill Suppliers 2024年8月22日 1800 rpm primary air fan, and four mill outlets supplying pulverized coal to one of the three horizontal rows of (4) dualfuel burners When operating at boiler MCR, each mill had a coal throughput of approximately 53,000 #ffir Specified product fineness was 70% thru 200 mesh and 98% thru 50 mesh Diminishing supply of the original Kansas coalWorldProven Coal Pulverizer Technology Debuts in the A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics2024年8月22日 Mill Speed Capacity Desired Coal Properties Feed Size Total Moisture Grindability (HGI) Abrasiveness Prod Fineness thru 200 Mesh Standard Screen Typical Air to Coal Ratio at 100% Mill Load Specific Power @ 100% Mill Load Typical Conditions CrusherDryer Mill PA Fan Total StartUp Time NoiseMill Only Approx Dimensions Mill Dia (D)A Comparison of Three Types of Coal Pulverizers

Boiler Performance and Mill Outlet Temperature Bright

2024年3月7日 The fineness of coal which gives the measure of pulverizing is maintained to a level of 75% though 200 mesh and less than 1 to 2% over 50 mesh The mill outlet temperature of coalair mixture is maintained between 65 to 90 degree centigrade in the case of low and medium volatile coal In the case of high volatile coal, while the lower limit 2020年9月29日 cinnamon (ground) 70 to 200 clay 01 to 2 coal dust 1 to 100 coffee (ground) 5 to 400 concrete dust 3 to 100 dust (household) 005 to 100 dust mites 100 to 300 eye of a needle 1230 flour (wheat milled) 25 to 212 gelatin powder 5 to 90 giardia cysts 8 to 14 ginger (ground) 25 to 40 200 No 200 200 Mesh 00500 00020 00750 00030 MESH and MICRON SIZES Industrial Spec2015年8月7日 The present work investigates the grinding characteristics of PC blend with coal in a laboratory ball mill to meet an industrial tube mill conditions 0% leads to a decrease in −200 mesh Grinding Characteristics of Coal and Petroleum Coke/Coal 2024年11月17日 200 Mesh Coal Powder Activated Carbon for Refinement Organic Solvents US$1,04000 124 Tons US$1,02000 2549 it have to be milled in ball mill before put into storehouse Besides, ordinary activated carbon which made through physical method (Steam, CO2 and mix of gases Our laboratory was built in 2014 These years, with technical 200 Mesh Coal Powder Activated Carbon for Refinement

.jpg)

Vertical Roller Mill SBM Ultrafine Powder Technology

180200: 250280: 325355: The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, energysaving capabilities, and ability to produce fine and ultrafine powders Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including