Specifications and models of steel ball coal mill

STEEL MILLING BALLS FOR BALL MILLS Specifications

2018年5月8日 The balls of 3rd and 4th groups are manufactured of steel with carbon equivalent of no less than 075% and carbon weight percentage of no less than 060% provided that the required hardness is availableThere are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high Grinding in Ball Mills: Modeling and Process Control2016年8月1日 A duplex inlet and outlet ball mill pulverize system model is established by considering the effect of raw coal moisture on the dynamic characteristic of the mill The EKF Modeling and control of ball mill system considering coal moisture2017年8月12日 Loesche designs, plans and constructs everything from individual machines to turnkey drygrinding installations for all solid fuels Loesche is certified in accordance with EN LOESCHEMILLS

.jpg)

Modeling and simulation of ball mill coalpulverizing system

Abstract: The paper presents a mathematical model and its Matlab/Simulink realization for ball mill coalpulverizing system (BMCPS) Based on the analysis of mass and energy balance, the 2018年5月18日 GRINDING STEEL BALLS FOR BALL MILLS Specifications Date of validity: 2016 07 – 01 1 FIELD OF APPLICATION This standard applies to steel grinding balls STEEL MILLING BALLS FOR BALL MILLS Energosteel2019年10月1日 Cause Analysis of Congested Pulverized Coal Dropping of Pulverized Coal Feeder in Storage Pulverizing System and Solutions; Quantitative characterization of Optimization and transformation of 300MV units steel ball coal mill 2023年6月10日 coal mill is an important component of a steam power plant which grinds precrushed raw coal particles of size 1020 mm to fine particles of size less than 150 μm using Mathematical validation and comparison of ball tube

.jpg)

A statistical analysis and optimization of Indian coal

2022年5月10日 Grinding of coal up to μm size is indispensable to achieve its maximum calorific value and better combustion A systematic experiment, as well as modeling of grinding of 2021年6月9日 The ball mill control and optimization system under consideration provides accomplishment of the following functions: Measurement and calculation of the actual values AUTOMATION AND OPTIMIZATION OF COAL GRINDING Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements In a cement ball mill, generally, φ50100mm steel balls are used Ball Mill Grinding Media Steel Balls for Ball Mills 2021年2月15日 This study analyzes the dynamic characteristics of duplex inlet and outlet ball mill direct firing pulverizing system A mass and energy balancebased model is built by thermodynamic analysis(PDF) System dynamics model of output of ball

.jpg)

Modeling and simulation of ball mill coalpulverizing system

The paper presents a mathematical model and its Matlab/Simulink realization for ball mill coalpulverizing system (BMCPS) Based on the analysis of mass and energy balance, the physical models for all controlrelated subprocesses of BMCPS are developed respectively Then the integrated dynamic mathematic model is constructed with Matlab/Simulink Validation using 2016年8月1日 Fig 1 shows the structure of a duplex inlet and outlet ball mill The system is equivalent to two parallel cylinders joined together in one ball mill to achieve high milling efficiency Milling work is carried out by the collision, squeezing and grinding of the steel balls inside the mill The working principle described as follows [10]Modeling and control of ball mill system considering coal moisture 2020年8月13日 UMseries Coal Mill Models with details of structural dimension, product throughputs and driving power (approx Values) Roller Arrangement A B H Flow Sheet of Coal / Petcoke Grinding AMCL Machinery Limited Corporate Office: 2, Red Cross Place (HNGIL), Kolkata WB Head Office: 202, Ackruti CentreVERTICAL ROLLER MILLS AMCL2024年8月22日 Ball Tube Mill The Ball Tube Mill (BTM) is a cylindrical lowspeed grinding mill It consists of a steel barrel, lined with cast abrasionresistant liners and partially filled with hardened steel balls Coal and preheated primary air enter one or both ends of the mill from a crusher/dryer or feeder As the mill rotates, the balls cascade andA Comparison of Three Types of Coal Pulverizers

Setpoint optimization and control of coalpulverizing

2009年5月25日 Stable control of a coalpulverizing system with balltube mill usually cannot be hold due to some disturbances, such as coal hardness and steel ball wearing, etc A hierarchical structure with a direct control layer and a setpoint optimization layer is applied to this typical system Based on steadystate gain models of different operating points, a grid search method 2017年2月13日 Ball Mill Specifications AllSteel Shells and Heads BallRod Mills have heavy rolled steel plate shells which are arc welded inside and outside to the steel heads or to rolled steel flanges, depending upon the type of mill The double welding not only gives increased structural strength, but eliminates any possibility of leakageBall Mills 911Metallurgist2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding2017年2月13日 Ball Mill Specifications AllSteel Shells and Heads BallRod Mills have heavy rolled steel plate shells which are arc welded inside and outside to the steel heads or to rolled steel flanges, depending upon the type of mill Ball Mills 911Metallurgist

Calculate and Select Ball Mill Ball Size for

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation2021年6月29日 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement The research focuses on the mill speed as well as air classifier speed effect on the two Effects of Mill Speed and Air Classifier Speed on 10×10 marcy ball mill specifications, ball mill technical Get price and support, find the working site in your country ! Introduction Ball mill is suited for milling various kinds of minerals and other materialsBall Mill Technical Specifications Crusher Mills

The Role of Ball Mill Steel Balls JXSC Mineral

2022年11月9日 With the continuous use of ball mill equipment, the quality of ball mill steel balls has also become a key point The varieties specified in the national standard include chemical composition, mechanical properties, Cast ball specifications, and inspection methods, etc Good quality grinding balls should have the following properties:DOI: 101016/jpowtec201909062 Corpus ID: ; Wet and dry grinding of coal in a laboratoryscale ball mill: Particlesize distributions @article{Bu2020WetAD, title={Wet and dry grinding of coal in a laboratoryscale ball mill: Particlesize distributions}, author={Xiangning Bu and Yuran Chen and Guangxi Ma and Yujin Sun and Chao Ni and Guangyuan Xie}, Wet and dry grinding of coal in a laboratoryscale ball mill: 2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls and 60% big balls (PDF) Effects of Ball Size Distribution and Mill Speed and 2020年5月1日 The main aim of this study is to improve the processing capacity of the largescale ball mill Taking a Φ549 × 883 m ball mill as the research object, the reason for the low processing capacity of the ball mill was explored via process mineralogy, physicochemical analysis, workshop process investigation, and the power consumption methodEnhancing the capacity of largescale ball mill through

Grinding in Ball Mills: Modeling and Process Control

There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media with sizes of the balls ranging from 10 to 150 mm in diameter [30]2011年6月1日 The paper presents a mathematical model and its Matlab/Simulink realization for ball mill coalpulverizing system (BMCPS) Based on the analysis of mass and energy balance, the physical models for Modeling and simulation of ball mill coalpulverizing system2024年1月10日 Ore discharge method Ball mills can be divided into overflowtype and gridtype, while rod mills are classified into overflowtype and opentype rod mills Among ball mills, the commonly used ones are gridtype ball mills Ball Mill VS Rod Mill: Difference Selection2020年3月31日 A switch from ball mills to Vertimill® boosts Miaogou Iron Mine’s transformation Challenge: The mine’s original grinding circuit consisted of ball mills exclusively Due to downturn in the iron steel industry, Miaogou’s concentration costs were exceeding the price of iron concentrate, putting significant pressure on company’s operationsMetso Vertimills

What are Mill Balls Made of? ball mills supplier

The type and quality of the mill balls used in the process play a significant role in determining the efficiency and effectiveness of the milling process Understanding Mill Ball Materials 1 Steel Balls Steel balls are the most common type of mill balls used in ball milling processes They are made of steel and come in different sizes and 2014年4月1日 Input variables Intermediate variables Output variables; A P 1 (%) – A1 feeder actuator position: M c (kg) – mass of coal in mill: T out (°C) – mill outlet: A P 2 (%) – A2 feeder actuator position: M pf (kg) – mass of pulverized coal in mill: Temperature: T in (°C) – primary air temperature inlet the mill: W c (kg/s) – mass flow rate of raw coal into the mill: ΔP Out (mbar A new modelbased approach for power plant Tubeball mill 2011年3月1日 They are used to pulverize raw coal into fine powder of desired temperature and fineness Although there are plenty of coal mines in China, the quality of raw coals varies greatly Therefore, ball mill coalpulverizing systems are widely used to grind various raw coals The flowchart of ball mill coalpulverizing system is shown in Fig 1 This Multiple models and neural networks based decoupling control of ball Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldReliable Coal Pulverizers and Mills » Babcock Wilcox

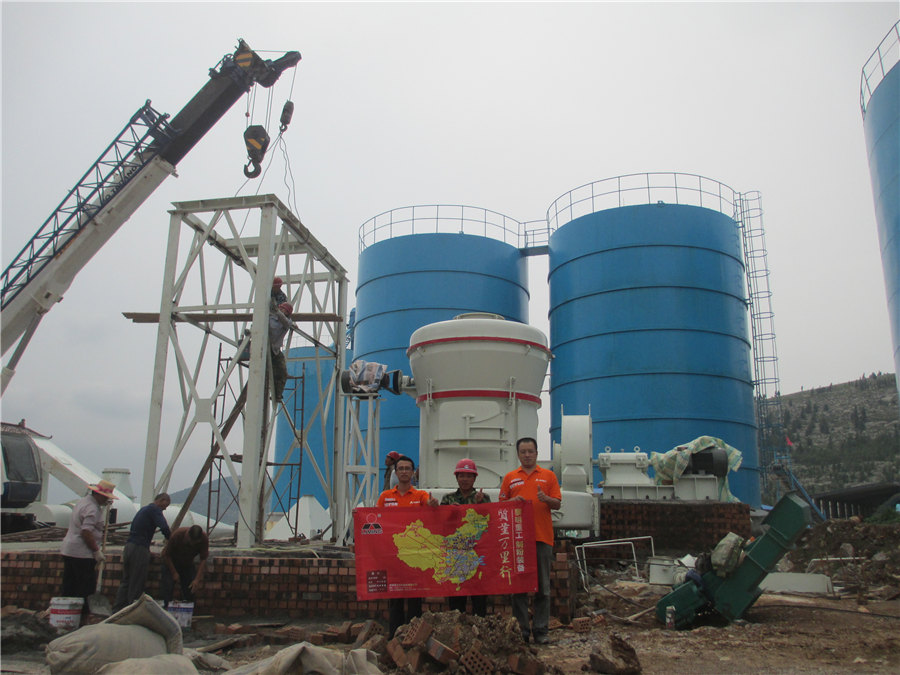

Optimization and transformation of 300MV units steel ball coal mill

2019年10月1日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before modificationTransform the pulverizing system and optimize the run mode of the pulverizing system by comprehensive treatmentSo we can control the pulverizing unit consumption under Coal water slurry ball mill (CWS ball mill) is the key equipment for coal water slurry fuel production, which is commonly used in coal water slurry power plant Coal water slurry ball mill is grinding equipment specially used for coal water slurry production Its specifications, structure and working conditions must meet the requirements of coal water slurry production scale, Coal Water Slurry Ball MillMTZ Steel ball coal mill Environmental Protection Equipment Crushing Equipment Rotary Cut Crusher Steel Scrap crushing complete equipment Grinding Equipment MLT desulfurization vertical roller mill and also the manufacturer to produce the coal mills with various kinds, specifications and types in the world Our company has Coal Mill北方重工The company’s cement ball mill has 31 specifications and models with a cylinder diameter ranging from 22m to 42m, and the supporting motor is 380KW to 3530KW a ball mill made of stainless steel will cost more than one made of Ball Mill In Cement Plant Selling Various Types

Ball Mill Grinding Media Steel Balls for Ball Mills

Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements In a cement ball mill, generally, φ50100mm steel balls are used 2021年2月15日 This study analyzes the dynamic characteristics of duplex inlet and outlet ball mill direct firing pulverizing system A mass and energy balancebased model is built by thermodynamic analysis(PDF) System dynamics model of output of ball 2010年7月14日 focuses on tubeball coal mill and mill condition monitoring Compared with the vertical mills, tubeball mills are more complex in structure and have a much higher grinding capacity The modeling procedure adopted in the paper is different from the work reported in [2], [3], [7], [8], and [9] The mathematicalMathematic Modeling and Condition Monitoring of The paper presents a mathematical model and its Matlab/Simulink realization for ball mill coalpulverizing system (BMCPS) Based on the analysis of mass and energy balance, the physical models for all controlrelated subprocesses of BMCPS are developed respectively Then the integrated dynamic mathematic model is constructed with Matlab/Simulink Validation using Modeling and simulation of ball mill coalpulverizing system

Modeling and control of ball mill system considering coal moisture

2016年8月1日 Fig 1 shows the structure of a duplex inlet and outlet ball mill The system is equivalent to two parallel cylinders joined together in one ball mill to achieve high milling efficiency Milling work is carried out by the collision, squeezing and grinding of the steel balls inside the mill The working principle described as follows [10]2024年8月22日 Ball Tube Mill The Ball Tube Mill (BTM) is a cylindrical lowspeed grinding mill It consists of a steel barrel, lined with cast abrasionresistant liners and partially filled with hardened steel balls Coal and preheated primary air enter one or both ends of the mill from a crusher/dryer or feeder As the mill rotates, the balls cascade andA Comparison of Three Types of Coal Pulverizers2009年5月25日 Stable control of a coalpulverizing system with balltube mill usually cannot be hold due to some disturbances, such as coal hardness and steel ball wearing, etc A hierarchical structure with a direct control layer and a setpoint optimization layer is applied to this typical system Based on steadystate gain models of different operating points, a grid search method Setpoint optimization and control of coalpulverizing 6 天之前 DOVE Rod Mills are supplied in a wide range of capacities and specifications DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr – 20 Kg/Hr) DOVE Rod Mill also referred to as steel rod mill shape is similar to DOVE Ball Mill, and is characterized by the use of steel Rods Rod Mills Grinding Mills DOVE