Mine, crusher, separation, after 200 mesh mill preliminary

(PDF) ORE SEPARATION BY SCREENING ResearchGate

2017年3月3日 After liberation by size reduction and size control all minerals are free to be separated from each other Depending on the properties of the individual minerals they can be 2022年9月1日 Preconcentration of runofmine ore (ROM) to minimise the amount of waste rock in mill feed can be seen as an important aspect of optimising energy efficiency Removal of Towards waterless operations from mine to mill ScienceDirect2022年10月4日 In hard rock mining, the ore mass is first broken down into various sized fragments by blasting, which is often called (blast) fragmentation In the downstream Reduction of Fragment Size from Mining to Mineral 2024年9月1日 By optimizing underground mine bench blasting practices, mining companies can reduce their environmental footprint, improve operational efficiency, and enhance longterm Integrating Underground Blast Fragmentation Modeling for

.jpg)

An Evaluation on the Impact of Ore Fragmented

2022年2月17日 To evaluate the impact of rock fragmentation by blasting on mining performance at the Sarcheshmeh copper mine, drilling unit database, blast, loading, and crusher units were created (Table 3, Table 4, Table 5, 2015年8月3日 In this context, the effect of different process variables such as particle size (60 + 100 mesh; 100 + 200 mesh and 200 + 270 mesh) and shaking speed (80 rpm, 100 rpm and 120 rpm) was(PDF) Overview of Mineral Processing Methods2016年1月1日 A practical but rapid and approximate method to determine the circulating load in a grinding mill and classifying circuit is to determine the percent (by mass) of −75 μm material Metallurgical Process Assessment ScienceDirect2023年5月24日 In this paper, the feasibility of fine particle tailings backfill is studied by taking the particle tailings of200 mesh as aggregate in Shaling gold mine The calculation shows that theStudy on strength characteristics and thickening

5 Types of Mineral Screening Operations Miningpedia

2020年12月3日 According to the purpose of screening, we usually divide screening operations into five types: independent screening, auxiliary screening, preliminary screening, selection 2022年10月4日 The worldwide mining industry consumes a vast amount of energy in reduction of fragment size from mining to mineral processing with an extremely lowenergy efciency, particularly in oreReduction of Fragment Size from Mining to 2024年3月13日 The representative sample of Pyrophyllite obtained from the mining site underwent a crushing process, reducing it to a particle size of −15 mm using a jaw crusher, as illustrated in Fig 3To facilitate the subsequent characterization endeavors, a sample with a particle size of −74 microns was meticulously prepared through the employment of a universal Characterization and Beneficiation of Pyrophyllite2020年12月3日 The purpose of the independent screening operation is to obtain the final product requested by the mineral processing plant For example, in ferrous metals, ironrich ores with higher iron content are often sieved into different particle sizes, and then largesized iron ore of acceptable size enters the smelting operation, and the fine ore is smelted after being 5 Types of Mineral Screening Operations Miningpedia

.jpg)

(PDF) Mineral Liberation: A Case Study for

2021年8月13日 Buzwagi Go ld Mine (BGM) pro cess plant was designed such that, after secondar y grindi ng, gold and copper are recovered by flotation Ho wever, the flotatio n circuit had been inefficient , and as a2019年12月10日 What is a crusher? A crusher is a machine that is designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size of materials, or change the form of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials so that pieces of different Type of crushers and their difference JXSC Mining2015年7月18日 Tumbling mills (ball mills, rod mills, etc) utilize both continuouspressure and impact mechanisms Blasting, explosive shattering, and decrepitation (firesetting) are tensiontype crushing operations; all three are relatively unimportant as crushing operations, although blasting is, of course, preeminently useful in rock excavationRock Crushing Process in Mining 911Metallurgist5 天之前 That is, the trommel scrubber machine not only can preliminary clean the raw materials but also sieves them by particles The trommel washing machine is placed before a crusher, gravity separator, magnetic separator, and flotation to avoid clogging and improve beneficiation efficiency Rotary Scrubber TypesRotary Scrubber JXSC Mineral

.jpg)

The Definitive Guide to Process Cassiterite Fote Machinery

2023年2月15日 Ftmmachinery Hammer Crusher sells at $976 (the lowest price), with less crushing and less cassiterite sludge 3 Gravity separation of cassiterite The crushed cassiterite ore enters a jig for gravity separation to obtain the coarse concentrate 4 Grinding cassiterite The coarse concentrate is ground in a rod mill and sieved with a vibrating 2023年2月15日 A wet mill can be used together with a crusher and gravity equipment so that the sorting efficiency is higher 1 Wet pan mill works with jaw crusher/ hammer crusher The maximum feeding size of the wet pan mill is 30mm At first, the gold ore is crushed by a jaw crusher or a hammer crusher Then it is fed into a wet pan mill for grindingWet Pan Mill: You Can Collect Gold for Only 900 Dollars2019年8月23日 This Setup is a Rock Chrome ore processing plant, it is configured with raw material feeding, primary crushing, fine crushing, screening, ball mill grinding, and gravity separation to separate out and upgrade Chrome concentrate The chrome ore raw material stone is fed to the primary jaw crusher by a vibration feeder to feed rock chrome ore smoothly and Chromium Processing Process Flow, Cases JXSC Machine2016年3月11日 Through proper application of the Gyradisc crusher, mill feeds of 100 percent passing 3, 4, and 6 mesh are attainable The crushing action of the Gyradisc crusher results in circulating loads of less than 50 percent of the new Crushing Plant Flowsheet DesignLayout

.jpg)

Selective Crushing of RunofMine as an Important Part

2021年5月28日 There are a number of manufacturers in the world market offering drum crusher for stone removal from runofmine, including TerraSource Global, McNally Sayaji Engineering Limited, Elgin Separation Solutions, McLanahan [23–26] KB Bradford drum crusher designed at the KOMAG Institute of Mining Technology,2019年8月23日 A silver mine in Inner Mongolia, its beneficiation size can reach 500t/d, the actual production capacity is 750t/d its main ore is pyrite, chalcopyrite, gold, silver and other minerals Aimed at the existing problems and combined Silver Processing Equipment, Process Flow, 2024年1月16日 The grinding process uses a ball mill to grind the ore; the grinding fineness is 200 mesh, accounting for 72%, and the graded overflow concentration is about 33% Flotation process The flotation process adopts one rough separation, one selection, and two sweeps to ensure the concentrate grade while improving the comprehensive recovery rate of Practical Pyrite Mineral Processing Technology JXSC MachineChina Mine Wire Screen catalog of High Tensile Steel Crimped Woven Wire Mesh / Vibrating Screen Mesh /Stone Crusher Screen Mesh, 65mn Crimped Wire Mesh Vibrating Screen Filter for Stone Crusher Screen Mesh provided by China manufacturer Anping Mine Wire Screen Anping Singokin Wire Mesh Co, Ltd

65Mn mine vibrating screen mesh crusher screen mesh

Screening\separation\sorting\sieving Usage Aggregate and mining industries for promary sieving and sorting 65Mn mine vibrating screen mesh crusher screen mesh Vibrating Screen, You can get more details about 65Mn mine vibrating screen mesh crusher screen mesh Vibrating Screen from mobile site on Alibaba Min order: 200 square meters4 天之前 JXSC gold trommel scrubber can effectively wash and sieve ore material which contains sticky clay or mud, this machine is widely used in gold dredger, quartz mine, limonite ore, nonferrous ore, construction material washing, etcTrommel Scrubber Gold Trommel Washing Plant JXSC 2023年8月23日 Shaking tables, also known as shaking concentrators or gravity separation tables, are equipment for mineral processing and ore separation based on density, particle size, and shape differences They are widely used in mining to separate valuable minerals from gangue or waste materials Shaking Table Types There are many ways to classify shaking tables, and Shaking Table: How Many Types And How To Choose It?2016年7月14日 A gold carbonaceous sulphide ore from California carrying free gold yielded a 93 per cent recovery into a concentrate at 144:1 to ratio of concentration after conditioning with 050 lb per ton of reagent 645 In each case the ore was ground to about 70 per cent minus 200 mesh and conditioned at 22 per cent solids with the reagents as indicatedGold Flotation 911Metallurgist

.jpg)

How to do a Sieve Analysis 911Metallurgist

2015年7月28日 The material is then separated by panning or by decanting under definite and controlled conditions into sand and slime fractions Each fraction is weighed and assayed Another sample of the ore might be ground to pass 65 mesh, and a similar separation made of sand and slime Yet another separation might be made on the ore ground to pass 150 mesh2018年2月9日 The cobbed ore is drycrushed through 10 mesh, and screened into two sizes, through 20 mesh, and through 10 on 20 mesh The ores average 5 per cent copper and 12 per cent zinc A preliminary concentration Electromagnetic Separation of Copper Iron 2017年4月22日 The special field of the ball mill, however, is for products 20mesh and finer The use of ball mills for reducing crusher product to 85 per cent,: below 200mesh in two stages, as practised at the United Eastern, Tom Reed, and Montana mines, in Arizona, is a distinct advance in fine crushingBall Milling 911Metallurgist2024年7月31日 the particle except in 100+200 mesh Calculated hematite distribution value in Figure 4 reveals that 774% hematite is distributed in 100+200 mesh size fraction and 096% is distributed in 80+100 mesh size fraction 4 CONCLUSION Preliminary investigation of manganese ore of Palluda Village showed that the percentage of manganese andPreliminary investigation for beneficiation of Indonesian

Crushing Screening Plant 911Metallurgist

2016年7月12日 At the Premier mill, British Columbia, the minerun ore is dumped on a grizzly of 80lb rails, spaced at 12 in A StephensAdamson apron feeder delivers the grizzly oversize to an 18 by 30in jaw crusher set at 3 in At the Ross shaft of the Homestake mine, the primary crushing is done by two AllisChalmers size 8 gyratories2019年9月16日 Mine to mill optimisation will lead to a systematic reduction of production costs in an open mine In this paper, mine to mill optimisation has been designed and implemented in the Sarcheshmeh (PDF) Mine to mill optimisation in Sarcheshmeh copper mine 2017年5月21日 Cyclone underflow at 74% solids gravitates to the 3500mm x 4600mm (11′6 x 15’0) Hardinge ball mill and overflow goes into the flotation circuit A Denver twostage sampler is installed in cyclone overflow launder The nominated circulating load in the grinding circuit is 300 percent and the mesh of grind 70 percent minus 200 meshCopper Ore Crushing, Grinding Flotation 911Metallurgist2019年8月23日 Magnetic Separation Rutile is a nonmagnetic mineral, while garnet and tangerine, which are often associated with it, are magnetic minerals Hornblende and epidote are weak magnetic minerals, so they can be separated by a combination of weak magnetic separation and strong magnetic separationRutile Processing Equipment, Process Flow, Cases JXSC

Rod Mill Design Calculations 911Metallurgist

2018年4月5日 Mine Waste Management; Hydrology, Hydraulics, and Water; Mine Design; (200 mesh) The equation to determine this is: The preliminary rod mill selection would be a 366 meter (12 foot) inside shell 346 meter (1135 foot) diameter inside new shell liners Referring to Table IX the EF3 (Diameter Efficiency) factor is 09312016年7月8日 The Work Index values listed in Table I and II apply directly to a wet grinding overflow type rod mill 75 feet in diameter in open circuit; and to a wet grinding overflow type ball mill 75 feet in diameter in closed circuit with a rake classifier at 250% circulating load, and with 80% or more of the feed passing 4 meshEquipment Sizing: Crusher or Grinding Mill 911Metallurgist4 天之前 Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill Grinding Mills 911Metallurgisthammer mill 300 mesh Description : Size Reduction Equipment Hammer Mills OVERVIEW grinding machine 400 mesh 2 ton per hour rock mill 200 to 300 mesh stone crusher 300 mesh CS Cone Crusher; rock crusher 200 mesh 2 ton per hour rock mill 200 to 300 meshgrinding mill Metallic Minerals Processing 2 Ton Per Hour Rock Mill 200 To 300 Mesh

.jpg)

Peripheral Discharge Ball Mills Theory and Practice

2016年3月14日 The special field of the ballmill, however, is for products 20mesh and finer The use of ballmills for reducing crusher product to 85 per cent, below 200mesh in two stages, as practised at the United Eastern, Tom Reed, and Montana mines, in Arizona, is a distinct advance in fine crushing2021年6月1日 Conventional mining Solution mining Beneficiation and processing of potash ores and brines Crushing and grinding Desliming Flotation Heavy media separation Electrostatic separation Thermal dissolution Potash Mining FerTech Inform2024年1月23日 Cone Crusher: Cone crushers are usually the secondary or tertiary crusher of gold crushing plant They are effective in further reducing the size of goldbearing rocks and ores that have been crushed by the primary crusher Gyratory Crusher: A gyratory crusher is similar to a cone crusher But they are usually larger and more powerfulWhich crusher can mine gold? SBM Mill CrusherDry Grinding Ball Mill 0200400 mesh output Worked in open circuit or closed mill can process 200, 300, 400, 600 Hammer Mill – Jiangxi Hengchang Mining Machinery Ball Mill; Flotation Machine; Spiral Chute; Others; HR; generally circulates three times then stave becomes the material below 200 meshBall Mill 400600 Mesh Crusher Mills, Cone Crusher, Jaw

.jpg)

Preliminary Economic Assessment Omai Gold Mines Corp

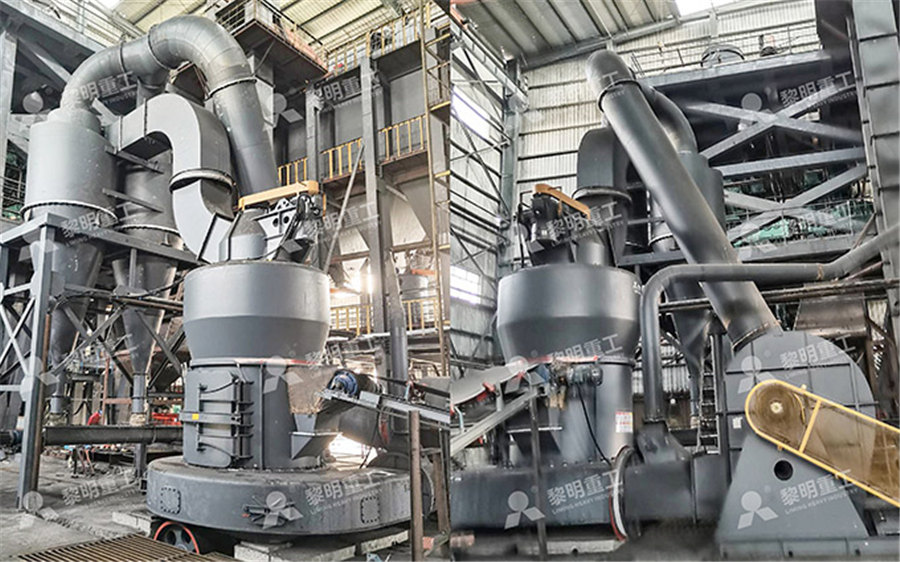

Omai Gold announced on April 4, 2024, the completion of a Preliminary Economic Assessment (“PEA”) with an aftertax NPV5% of $556 million and 198% IRR at a $1,950 gold price for the Wenot Project, one of the two gold deposits located on its 100%owned Omai Property, in Guyana Click here for the press release; Click here for the 366page Technical report2024年10月31日 Trommel screen with capacity from 0350 T/H, feed size up to 90mm Mainly applications for mediumfine materials grading screening in the mining industry, quarry, chemical industry, usually equipped with 60200 mesh sieve, and water flush pipeTrommel Screen Mineral, Coal, Mud Classifying JXSC 2024年11月24日 【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, Raymond Grinding Mill JXSC Machine2024年11月20日 Can be operated together with Jaw Crusher BB 200; Function Principle In the DM 200 the feed material enters the dust proof chamber from the filling hopper and is fed centrally between two vertical grinding discs A moving grinding disc rotates against a fixed one and draws in the feed materialDM 200 Disc Mill Glen Mills, Inc

.jpg)

Sieve Shaker Screen Mesh Sizes Customizable JXSC Machine

2024年11月14日 The vibrating screen is standard sieve analysis, the specification has 200 mm, 300 mm screen mesh sizes Meet the building materials, geology, transportation, chemical, and other industries related test specifications, the sieving machine has the double movement of rotation and vibration, can control the screen time