Sulfur rare earth ore grinding machinery process

Unlocking Potential: Rare Earth Elements

2023年11月9日 Rare earth elements are typically found in dispersed deposits and often mixed with other minerals, making their extraction and separation difficult and expensive FTM Machinery has a professional team that can 2024年9月1日 The treatment of common rare earth resources can be divided into three main stages: the frontend process of extracting rare earth elements from the ore phase, the Review of rare earth extraction and product preparation 2024年4月1日 Rare earth elements (REEs) are irreplaceable materials supporting lowcarbon technology and equipment, and their commercial demand and strategic position are becoming Recent process developments in beneficiation and metallurgy of rare 2024年6月1日 Strategies like extracting rare earth elements and making geopolymers from tailings were explored Techniques like bioleaching and mechanical activation can improve A review on complex utilization of mine tailings: Recovery of rare

Mineral Processing of Rare Earth Ores SpringerLink

2020年3月26日 About 95% of the world’s rare earth production comes from bastnaesite, monazite, and xenotime minerals In many instances, rare earth minerals are found in 2020年11月16日 Preleaching processing comprised threestage crushing of the ore to c 1/2 in (c 127 mm) size before grinding by utilizing a rod mill and two ball mills with cyclone Toward Closing a Loophole: Recovering Rare Earth Elements 2012年5月21日 – Reduction = for high purity rare earth alloys • Smelting (metallothermic reduction) is the most widely used method where reductants react in a furnace with oxidants Rare Earth Elements: A Review of Production, Processing, 2021年5月23日 One combined treatment of raw material (ore, concentrate, and waste bearing rare earth) contains a combination of pyrometallurgical operations (thermal decomposition of the obtained precipitate) and hydrometallurgical Advances in Understanding of the Application of

Mineral Processing and Extractive Metallurgy of

2015年12月25日 Mineral processing (sometimes called mineral dressing or ore dressing) is the preparation of ore from the stage that the material is brought out of the mine (also called “run of mine” or “asmined”) through the production of 2014年9月17日 Sulfur mining takes place in countries such as Poland, Russia, Ukraine, United States and Turkmenistan Ijen, a quiet but active volcano in East Java, Indonesia contains a one kilometer wide crater lake; a well known site of Sulfur Mining Processing: What to Know2015年8月31日 The escalating demand of rare earth metals (REMs) in various applications and their continuous depleting ores have laid emphasis to produce metals from their complex resources by developing energy (PDF) Process development to recover rare earth metals 2023年9月10日 Bioleaching exhibits high potential for the processing of lowgrade complex mineral resources With the development of the economy and an increase in demand, rare earth elements (REEs) in secondary resources, Bioleaching of Rare Earth Elements: Perspectives

.jpg)

Rare Earth Magnets: Manufacturing and Applications

2023年12月29日 One of the most important and wide range of applications for rare earth (REs) containing materials is the production of permanent magnets Since the 1960s, this class of magnets has given designers and engineers the ability to increase performance, reduce the size of devices and even create applications that would not be possible with other magnet materials1 天前 Savona Equipment is your source for new, used, and reconditioned Ore Mineral Processing Plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, recycling, mining, and treatment facilities Our inventory includes complete gold processing plants, silver processing Gold and Silver Ore Processing and Recovery Plants for Sales Rare 2019年8月23日 Sulfur attaches to metal ions, creating a number of significant sulfide ore minerals such as galena (lead sulfide), pyrite (iron sulfide), chalcocite (copper sulfide), and sphalerite (zinc sulfide) Mined sulfur is mostly from salt domes or bedded depositsSulfur Processing Equipment, Process Flow, Cases JXSC Machine2023年11月30日 Dear Colleagues, Rare earth elements (REEs), also known as “industrial vitamins”, are of immense importance They are widely used in the production of magnets, alloys, catalysts, batteries, medical equipment and superconductors, etc REEs are made up of 17 elements including lanthanide elements (La, Ce, Pr, Nd Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Minerals Special Issue : Recent Developments on the Leaching Process

.jpg)

A review on the cracking, baking and leaching processes of rare earth

2017年8月1日 A review on the cracking, baking and leaching processes of rare earth element concentrates 741 Table 2 REE concentrate cracking methods Process Temperature and resi dence time Status Remarks Operating plants or concentrate origin Ref Alkaline cracking with sodium hydroxide 4 h at 150 and 120 ºC where the dosage of sodium hydroxide is 50 wt 2024年4月1日 Rare earth elements (REEs) are irreplaceable materials supporting lowcarbon technology and equipment, and their commercial demand and strategic position are becoming increasingly prominent With the continuous depletion of rare earth (RE) resources, developing highefficiency beneficiation and ecofriendly metallurgical processes has attracted Recent process developments in beneficiation and metallurgy of rare 2020年11月16日 The demand for rare earth elements (REE) has increased significantly over the last decade, with global rare earth oxide (REO) production increasing markedly over the last 2 years from 132,000 t in 2017 to 210,000 t in 20191 This production increase is drive by the need for REE in hightechnology equipment, particularly in the lowcarbon energy industry, but also Toward Closing a Loophole: Recovering Rare Earth Elements 2020年8月1日 Treating ore with chlorination metallurgy is a kind of metallurgical process of comprehensive recovery and utilization of ore resources by means of chlorination metallurgy The main reason is that the affinity of the metal to sulfur is smaller than that of the metal Kinetics in chlorinating mixed rare earth oxides reaction process by Mechanism and application of the ore with chlorination

.jpg)

Grinding Rare Earth Magnets into Shape

2023年4月6日 Producing rare earth magnets like neodymium or samarium cobalt requires numerous steps before the product can be magnetized and shipped After the rare earth ore is discovered, mined, processed, and refined, 2019年8月8日 The leaching processes and mechanisms of weathered crust elutiondeposited rare earth (RE) ores with ammonium sulfate were investigated for their high efficiency and low consumption exploitation The leaching process is a typical reversible heterogeneous ion exchange reaction in liquid–solid systems The raw ore and leached tailings were analyzed by Leaching Process and Mechanism of Weathered Crust 2020年9月23日 Primary economical deposits of rareearth elements (REEs) are exhausting all over the world, and it has become necessary to find new sources and methods for their extraction In addition, increasing the application of REEs in modern technological society has increased its demand globally One of the important movements to compensate for the future shortages of A Review of RareEarth Elements Extraction with Emphasis 2018年3月15日 The third is the leaching process that uses equipment with industrial grade agitators and mixers and contains a leaching solution and allows the valuable material to leach from the ore into solutionThe Basics of How Ore Processing and Recovery Plants Work

.jpg)

Rareearth element Processing Ores Britannica

2024年11月21日 Rareearth element Processing Ores: All rareearth ores contain less than 10 percent REO and must be upgraded to about 60 percent in order to be processed further They are first ground to a powder and then separated from the other materials in the ore body by various standard processes that include magnetic and/or electrostatic separation and flotation 2019年7月12日 Rare earth metals are used extensively in hightech production of objects for many branches of industry (smart phones, cosmetic lasers) including the military complex (optical instruments, navigation systems, radar) []Provision of the country’s industry with rare earth metal (REM) is an important condition for modernization of all branches of industryRare Earth Metal Extraction from Apatite Ores Metallurgist2012年6月11日 Mechanochemical sulfidization of a mixed sulfide/oxide copper ore by cogrinding with sulfur and additives including Mg(NO3)2 and Fe(NO3)3 salts and iron, aluminum and magnesium powders was Mechanochemical Sulfidization of Lead Oxides by Grinding with Sulfur 2019年11月1日 Mechanochemical sulfidization of a mixed sulfide/oxide copper ore by cogrinding with sulfur and additives including Mg(NO3)2 and Fe(NO3)3 salts and iron, aluminum and magnesium powders was Mechanochemical Sulfidization of a Mixed OxideSulphide Copper Ore

(PDF) A Review of Rare Earth Mineral Processing Technology

2017年9月10日 The purpose of this paper is to comprehensively review and summarize the rare earth processing routes, the mostly employed rare earth separation methods, supply and demand of rare earth around the Complex sulphide ores represent considerable reserves and resources in base non ferrous metals, in precious metals, and in sulphur Some of their essential characteristics, which allow a general presentation of the complexity of their processing options, from the ore to the pure metals or finished products, have already been presented by the author (1,2)Complex Sulphide Ores: Processing Options SpringerLink2018年4月1日 The FM process has been successfully applied in the industrial production of the Dalucao rare earth ore located in Sichuan, China The average rare earth oxide (REO) grade of the obtained rare earth concentrate was 65% in the latest 12month production run with an average recovery of 55%Flotationmagnetic separation for the beneficiation of rare earth 2019年7月12日 Rare earth metals (REM) after sulfuric acid treatment of apatite ore are partly (15–20%) transferred into extraction phosphoric acid (EPA) solution(PDF) Rare Earth Metal Extraction from Apatite

.jpg)

8 Types of Gold Ore Properties and Ways to Process

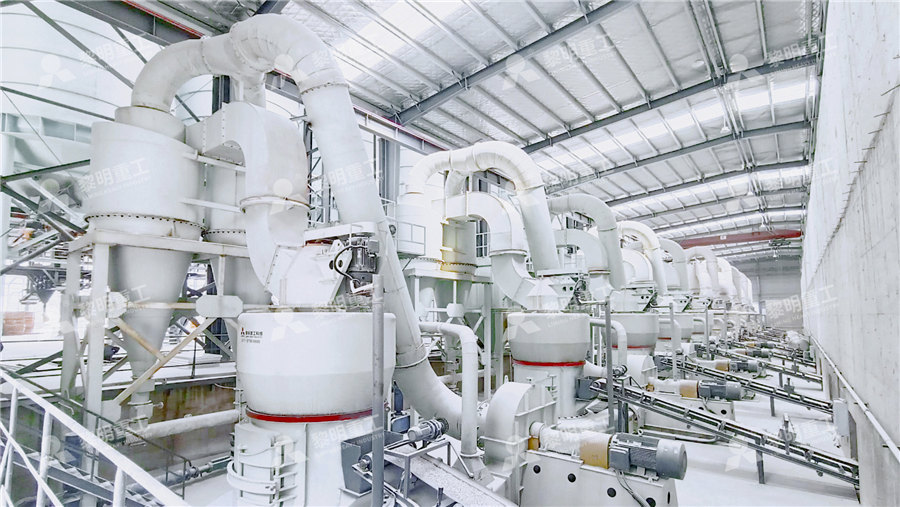

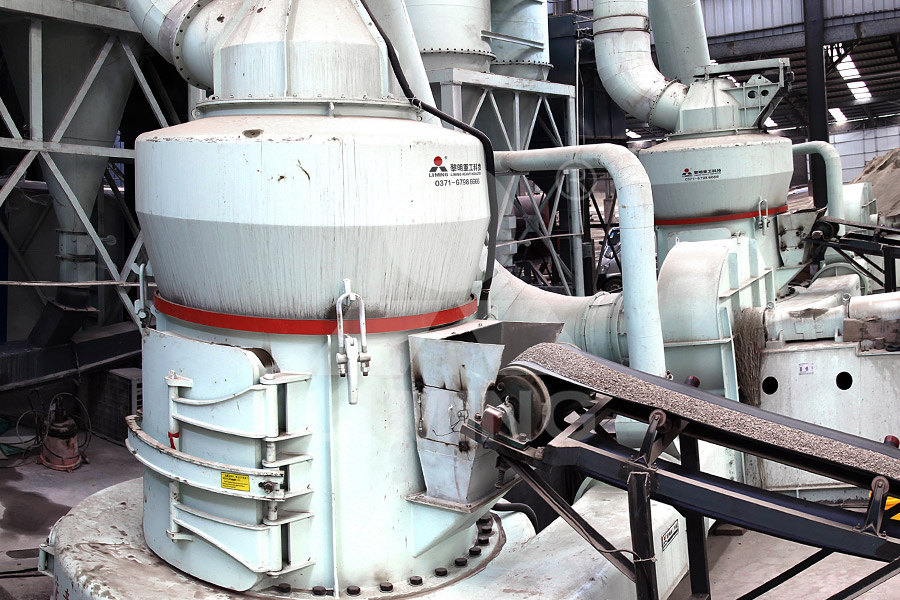

2023年6月12日 4 Recover the gold from tailings with a flotation machine so as to obtain highgrade gold ore concentrate 2 Silvergold ore It is the principal sulfide of gold (usually pyrite) and decomposes to gold metal and elemental sulfur, illustrating the "nobility" of gold and grind the granite ore into smaller piecesThe application relates to a process for rare earth extraction and thorium removal from monazite or bastnasite bearing ores or ore beneficiation and industrial waste containing a variable amount of rare earth elements as oxides, phosphates, carbonates or sulfates, comprising (i) controlled mixture between sulfuric acid and the material containing rare earth and (ii) water leaching System and process for selective rare earth extraction with sulfur 2020年8月12日 Zhengyuan is China grinding machine manufacturer Designed with totallynew machine structure, optimized machinery size, uniquely designed machinery parts, and simplified production process, wet ultrafine grinding machine has higher performance We offer ball mill, impact mill, jet mill and powder processing equipment Our superfine grinding equipment suits Wet Ultrafine Grinding Machine,Ball Mill,Jet Mill,China Grinding 2020年1月15日 Rare earthbearing gypsum tailings from the fertilizer industry are a potential source for an economically viable and sustainable production of rare earth elements Large quantities are generated inter alia in Catalão, Brazil, as a byproduct in a fertilizer production plant Hitherto, the gypsum has been used as soil conditioner in agriculture or was dumped Extraction of Rare Earth Elements from PhosphoGypsum

Material and Energy Requirement for Rare Earth Production

2013年8月21日 The use of rare earth metals (REMs) for new applications in renewable and communication technologies has increased concern about future supply as well as environmental burdens associated with the extraction, use, and disposal (losses) of these metals Although there are several reports describing and quantifying the production and use of REM, there is still a 2020年3月1日 Mechanochemical sulfidization of a mixed sulfide/oxide copper ore by cogrinding with sulfur and additives including Mg(NO 3) 2 and Fe(NO 3) 3 salts and iron, aluminum and magnesium powders was investigated for the first time Also, the influence of sulfidization during the wetmilling process was examined on the separation efficiency and recovery of copper in Mechanochemical sulfidization of a mixed oxidesulphide copper ore 2023年8月8日 A rare earth beneficiation plant is a facility designed to separate and purify rare earth elements from their ores The process typically involves crushing, grinding, and separating the ore into What is a rare earth beneficiation plant? LinkedIn2014年9月17日 Sulfur mining takes place in countries such as Poland, Russia, Ukraine, United States and Turkmenistan Ijen, a quiet but active volcano in East Java, Indonesia contains a one kilometer wide crater lake; a well known site of Sulfur Mining Processing: What to Know

.jpg)

(PDF) Process development to recover rare earth metals

2015年8月31日 The escalating demand of rare earth metals (REMs) in various applications and their continuous depleting ores have laid emphasis to produce metals from their complex resources by developing energy 2023年9月10日 Bioleaching exhibits high potential for the processing of lowgrade complex mineral resources With the development of the economy and an increase in demand, rare earth elements (REEs) in secondary resources, Bioleaching of Rare Earth Elements: Perspectives 2023年12月29日 One of the most important and wide range of applications for rare earth (REs) containing materials is the production of permanent magnets Since the 1960s, this class of magnets has given designers and engineers the ability to increase performance, reduce the size of devices and even create applications that would not be possible with other magnet materialsRare Earth Magnets: Manufacturing and Applications1 天前 Savona Equipment is your source for new, used, and reconditioned Ore Mineral Processing Plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, recycling, mining, and treatment facilities Our inventory includes complete gold processing plants, silver processing Gold and Silver Ore Processing and Recovery Plants for Sales Rare

Sulfur Processing Equipment, Process Flow, Cases JXSC Machine

2019年8月23日 Sulfur attaches to metal ions, creating a number of significant sulfide ore minerals such as galena (lead sulfide), pyrite (iron sulfide), chalcocite (copper sulfide), and sphalerite (zinc sulfide) Mined sulfur is mostly from salt domes or bedded deposits2023年11月30日 Dear Colleagues, Rare earth elements (REEs), also known as “industrial vitamins”, are of immense importance They are widely used in the production of magnets, alloys, catalysts, batteries, medical equipment and superconductors, etc REEs are made up of 17 elements including lanthanide elements (La, Ce, Pr, Nd Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Minerals Special Issue : Recent Developments on the Leaching Process 2017年8月1日 A review on the cracking, baking and leaching processes of rare earth element concentrates 741 Table 2 REE concentrate cracking methods Process Temperature and resi dence time Status Remarks Operating plants or concentrate origin Ref Alkaline cracking with sodium hydroxide 4 h at 150 and 120 ºC where the dosage of sodium hydroxide is 50 wt A review on the cracking, baking and leaching processes of rare earth 2024年4月1日 Rare earth elements (REEs) are irreplaceable materials supporting lowcarbon technology and equipment, and their commercial demand and strategic position are becoming increasingly prominent With the continuous depletion of rare earth (RE) resources, developing highefficiency beneficiation and ecofriendly metallurgical processes has attracted Recent process developments in beneficiation and metallurgy of rare

Toward Closing a Loophole: Recovering Rare Earth Elements

2020年11月16日 The demand for rare earth elements (REE) has increased significantly over the last decade, with global rare earth oxide (REO) production increasing markedly over the last 2 years from 132,000 t in 2017 to 210,000 t in 20191 This production increase is drive by the need for REE in hightechnology equipment, particularly in the lowcarbon energy industry, but also