calcined gypsum powder process flow

Calcination Processes Gypsum: Connecting

The preparation of natural and synthetic gypsum prior to calcination, such as drying and grinding The various calcination methods for βhemihydrate and αhemihydrate are reviewed, such as batch kettle, continuous kettle, submerged 2016年12月19日 One option is direct calcining in a Pfeifer vertical roller mill of the type MPSGC (Fig 2) In this process, the gypsum is dried and ground to the required fineness of the plaster Grinding and calcining of gypsum with Pfeiffer grinding The factors such as the type and purity of kaolinite, limestone, gradation of the limestone, concentration of gypsum, calcined clay, limestone ratio, clinker content, watertobinder ratio,Flowsheet of calcination process Download Scientific Diagram2022年6月15日 When gypsum is heated at about 150– 160 °C, it loses approximately threequarters of its water in a partial dehydration process and becomes hemihydrate gypsum Gypsum Products Springer

Flow diagram of the manufacturing gypsum and

The produced gypsum composites were experimentally investigated to study the synergistic effect of zeolite (natural and calcined) and shell powders (egg, conch, cuttlebone and scallop) on the2021年11月1日 The results show that the obtained hemihydrate gypsum mixing with water can prepare highperformance building gypsum after the FGD gypsum adding 3–5 wt% of CaO is Preparation of highperformance building gypsum by calcining FGD gypsum 2021年3月3日 When gypsum is heated at about 150–160 °C, it loses approximately threequarters of its water in a partial dehydration process and becomes hemihydrate gypsum Gypsum Products SpringerLink2023年5月22日 First, the gypsum raw material to be calcined is sent to the silo, and then sent to the calciner by the feeder for calcination Under the action of mechanical dispersing force and hot air generated by the gas, the material Gypsum calcination process MECRU Heavy

.jpg)

Influence of calcination temperature on hydration behavior,

2023年2月27日 In the case of gypsum calcined at 300–400 °C, originally containing 75–90 wt% anhydrite II, it took 3 and 6 days, respectively, to obtain complete hydration Gypsum calcined at 500 and 600 °C did not hydrate completely even after curing at 100 % RH for 8 days and samples still contained > 40 and 70 wt% anhydrite II, respectivelyGypsum Board production flow "Tiger Board" is produced in the factory automated production line Let's see the manufacturing process Molding process Calcined “gypsum” is mixed with water to make a slurry (muddy Gypsum Board production flow YOSHINO 2024年8月27日 Gypsum powder grinding line process flow Gypsum rock crushing process The gypsum rock blocks after mining are large in volume, and their sizes are uneven, often accompanied by impurities, so they need to be finely screened with the help of multistage crushers to meet the requirements of subsequent grinding operationsGypsum Powder Production Line Hongji Mining Machinery2024年6月15日 The phase changes of gypsum were considered to be sufficiently understood for a long time However, due to the increasing importance of gypsum recalcination (connected with the planned closure of thermal power plants resulting in a lack of FGD gypsum) and new detailed research associated with it, gaps in the current knowledge have been discovered This paper New insight into the phase changes of gypsum Springer

Innovative gypsum processing at GIPS AD Global Gypsum

2013年5月21日 Auxiliary equipment is needed for hot gas generation, product dust collection from the system air stream and for air flow supply The mill design is based on hot gas inlet temperatures of up to 650°C, which allow low airflow volumes Calcined gypsum from a technical process is not a pure gypsum hemihydrate, but also consists of waterfree 2020年4月14日 The comparison of mortar flow (050 w/c) of reference cement, blended cement mixtures with 30% calcined clay at different temperatures and blended cement with rotary kiln calcined clay (same raw kaolin from Beihai) can be seen in Fig 8 It shows that the blended cement with 740–780 °C suspension CC performs good workability with around 190 Research and Design of Suspension Calcining Technology 2024年9月23日 After chosen by the screening machine the gypsum powder that meet the degree of fineness will be calcined in the hot oil calcinator and the gypsum powder that can’t meet it will be returned to the grinder and regrind The qualified gypsum powder will sent to the warehouse or to the board production line Process Flow DiagramGypsum Powder Production Line AmuliteCalcination in a rotary kiln is a direct, longtime calcining process During the process, the phases of the CaSO 4 x H 2 O system can be optimally adjusted Rotary kilns are used for the calcining natural gypsum In this process, precrushed natural gypsum is Calcining processes for natural and synthetic gypsum

.jpg)

Gypsum calcination process MECRU Heavy Industry

2023年5月22日 First, the gypsum raw material to be calcined is sent to the silo, and then sent to the calciner by the feeder for calcination Under the action of mechanical dispersing force and hot air generated by the gas, the material undergoes processes such as dispersion, drying, calcination and strong highspeed homogenization Calcined gypsum is 2021年4月30日 Natural gypsum can be mined in over 85 countries around the world, including Canada, the United States, and Mexico Gypsum rock is mined or quarried, crushed, or ground into a fine powder The calcined gypsum becomes the base for gypsum plaster, gypsum boards, and other gypsum products Another type of gypsum is synthetic gypsumDifferent Types of Gypsum, Uses and FAQs The Architects 2021年9月27日 Calcined Gypsum Powder produced by the domestic industry and imported from the subject countries are comparable in terms of essential product characteristics such as physical chemical characteristics, manufacturing process technology, functions uses, product specifications, pricing, distribution marketing and tariff classification of DGTR investigation reveals dumping of ‘Calcined Gypsum Powder’The produced gypsum composites were experimentally investigated to study the synergistic effect of zeolite (natural and calcined) and shell powders (egg, conch, cuttlebone and scallop) on the Flow diagram of the manufacturing gypsum and

Calcined Gypsum Powder

Calcined Gypsum Powder Manufacturer In India and other countries, we are wellknown calcined gypsum powder manufacturers Despite limited resources, we produce highquality gypsum casting powder quickly A calcined gypsum powder plant does not require much time Sand cement plaster takes around 2021 days to solidify, dry, and settle2024年4月12日 The stockpiling of phosphogypsum is a waste of land resources and also causes serious pollution to natural resources such as water and atmosphere This paper explores the mechanism of efficiently modified phosphogypsum and constructs a model and evaluation system for heavy metal leaching and migration transformation The modified phosphogypsum is used Highly efficient modified phosphogypsum building gypsum powder A process for preparing calcined gypsum (stucco) which comprises treating a mass of calcined gypsum by adding, with thorough blending, small portions of an aqueous solution of ligno sulfonate; allowing the treated stucco to heal; and optionally drying the healed stucco and further optionally grinding the healed stucco If the treated calcined gypsum is not to be used shortly USA Process for preparing calcined gypsum and gypsum 2019年4月6日 The pulverized Gypsum was calcined in a vessel of some type, likely ceramic The resulting product, eventually many hundred of years later, named Plaster of Paris, provided this early man with a medium for making cast objectsGypsum Calcining 911Metallurgist

.jpg)

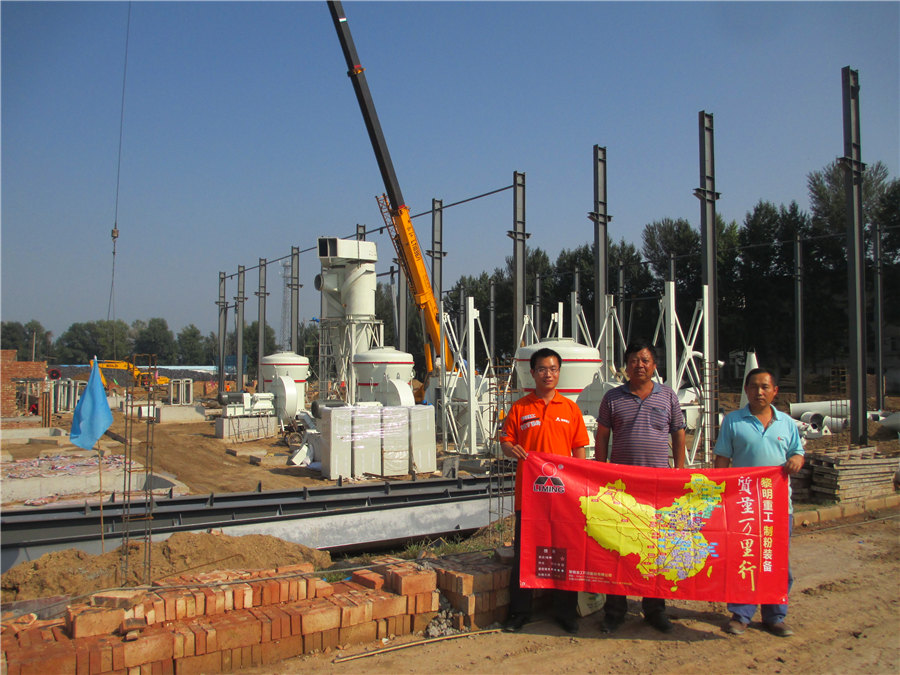

CLIRIK gypsum grinding mill for gypsum powder production process

2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) through a special mill and heating and calcining at a certain 2024年1月30日 The chemical formula of gypsum is CaSO 4 ․2H 2 O Gypsum is known as calcium sulfate dihydrate due to the presence of two molecules of water When gypsum is subjected to calcination then it produces calcium sulfate hemihydrate, well known as plaster of Paris (POP) The formula of plaster of Paris is CaSO 41/2H 2 O The Calcination Calcination: Definition, Process, Examples, and Applications2015年5月13日 The calcined gypsum–lime–metakaolin–water system and its subsystems consisting of two and three components are analyzed using the isothermal heat flow calorimetry, differential scanning calorimetry, and thermogravimetry The hydration heat development in the initial hydration phase up to several hours is monitored in a common way, on the samples Application of isothermal calorimetry and thermal analysis 2020年9月29日 The application has been filed by M/s Saint Gobian India Pvt Ltd (SGIPL), who is the major producer (53%) of the Calcined Gypsum Powder or Gypsum plaster in India M/s Saint Gobian India Pvt Ltd further submitted that in the present case producers of the subject goods are from fragmented industry consisting of a large number of small Antidumping investigation on imports of Calcined Gypsum Powder

.jpg)

Study on the system of calcined desulfurization gypsum

2023年12月10日 Note: desulfurization gypsum in the table is desulfurization gypsum calcined at 800 ℃; SO3 is calculated according to sulfate content in desulfurization gypsum and Al 2 O 3 is calculated Gypsum Powder We are one of the Best Gypsum Powder Manufacturers Suppliers of Natural, Fine, Organic, micronized, calcined, universal, Water Resistant, Agriculture, POP, White, Gypsum Plaster Powder for food, Plants, Gypsum Powder Suppliers in India, Gypsum Usually, in the process, the temperature is also regulated Calcination of bauxite and gypsum involving the removal of water of crystallisation in the form of water vapour Decomposition of volatile components from raw petroleum Calcination Definition, Examples, Process, Gypsum Board Manufacturing Process Drywall Plaster Throughout the gypsum board manufacturing process chalklike powder called land plaster called stucco 4 Calcine System The land plaster is heated in large kettles to remove most of the water from the plaster ©2010 GeorgiaPacific Gypsum LLC water rehydrates the stucco 8 Board Line The board travels diagram for manufacturing process of gypsum powder pdf

FGD Gypsum Production Process

Mineralogically identical to natural gypsum, FGD gypsum, or synthetic gypsum, is produced from gas captured within emission control systems at coal fired electric utilities An emission that would compromise air quality, sulfur dioxide (SO2) gas, is the primary contribution coal makes to FGD gypsum Utilities that produce panelgrade synthetic gypsum beneficially reuse FGD sludge Classification of Gypsum Gypsum usually refers to two kinds of minerals: raw gypsum and anhydrite Raw Gypsum is calcium sulfate dihydrate ((Ca (SO 4) 2H 2 O), also known as gypsum dihydrate, gypsum or gypsum, composition CaO (326%), SO 3 (465%), H2O+ (209%), monoclinic system, crystal is platelike, usually dense block or fiber, white or gray, red, brown, What is Gypsum How Gypsum is Processed MC2024年7月2日 This study concentrated on producing limestone calcined clay calcium sulfoaluminate cement by replacing portland cement in limestone calcined clay cement with calcium sulfoaluminate cement, with the goal of increasing the early strength of limestone calcined clay cement The mineralogy and microstructures of hydrating pastes were investigated using Characterization of Limestone Calcined Clay Cement Made 2022年9月27日 The extensive usage of concrete and ordinary Portland cement has generated 5~8% of annual global CO2 emissions, causing serious environmental problems To reduce such environmental impact, researchers have made significant efforts to develop alternative materials that may partially or entirely replace the ordinary Portland cement, such as limestone calcined A Review on Hydration Process and Setting Time of Limestone Calcined

.jpg)

Study on the system of calcined desulfurization gypsum

Study on the system of calcined desulfurization gypsum aluminate cement slag powder cement Xiong Zhang1, Hao Ren1, Tao Ji1, Gaoyu Liao1,and Yongjuan Zhang1,* 1 Institute of Building Materials, Tongji University, Shanghai , China Abstract In this study, by adding a small amount of calcined desulfurization gypsum and aluminate2023年10月31日 Currently the world's most popular desulfurization process is limestonegypsum method But there is one big problem in the past, the fineness of the powder should be reach D90=325 mesh Introduction to Gypsum Powder Production Flow Gypsum stone is crushed into particles of less than 30mm in diameter, and the particles are grinded in the Gypsum Powder Production Line sbmmill2023年2月27日 In the case of gypsum calcined at 300–400 °C, originally containing 75–90 wt% anhydrite II, it took 3 and 6 days, respectively, to obtain complete hydration Gypsum calcined at 500 and 600 °C did not hydrate completely even after curing at 100 % RH for 8 days and samples still contained > 40 and 70 wt% anhydrite II, respectivelyInfluence of calcination temperature on hydration behavior, Gypsum Board production flow "Tiger Board" is produced in the factory automated production line Let's see the manufacturing process Molding process Calcined “gypsum” is mixed with water to make a slurry (muddy Gypsum Board production flow YOSHINO

Gypsum Powder Production Line Hongji Mining Machinery

2024年8月27日 Gypsum powder grinding line process flow Gypsum rock crushing process The gypsum rock blocks after mining are large in volume, and their sizes are uneven, often accompanied by impurities, so they need to be finely screened with the help of multistage crushers to meet the requirements of subsequent grinding operations2024年6月15日 The phase changes of gypsum were considered to be sufficiently understood for a long time However, due to the increasing importance of gypsum recalcination (connected with the planned closure of thermal power plants resulting in a lack of FGD gypsum) and new detailed research associated with it, gaps in the current knowledge have been discovered This paper New insight into the phase changes of gypsum Springer2013年5月21日 Auxiliary equipment is needed for hot gas generation, product dust collection from the system air stream and for air flow supply The mill design is based on hot gas inlet temperatures of up to 650°C, which allow low airflow volumes Calcined gypsum from a technical process is not a pure gypsum hemihydrate, but also consists of waterfree Innovative gypsum processing at GIPS AD Global Gypsum2020年4月14日 The comparison of mortar flow (050 w/c) of reference cement, blended cement mixtures with 30% calcined clay at different temperatures and blended cement with rotary kiln calcined clay (same raw kaolin from Beihai) can be seen in Fig 8 It shows that the blended cement with 740–780 °C suspension CC performs good workability with around 190 Research and Design of Suspension Calcining Technology

Gypsum Powder Production Line Amulite

2024年9月23日 After chosen by the screening machine the gypsum powder that meet the degree of fineness will be calcined in the hot oil calcinator and the gypsum powder that can’t meet it will be returned to the grinder and regrind The qualified gypsum powder will sent to the warehouse or to the board production line Process Flow DiagramCalcination in a rotary kiln is a direct, longtime calcining process During the process, the phases of the CaSO 4 x H 2 O system can be optimally adjusted Rotary kilns are used for the calcining natural gypsum In this process, precrushed natural gypsum is Calcining processes for natural and synthetic gypsum2023年5月22日 First, the gypsum raw material to be calcined is sent to the silo, and then sent to the calciner by the feeder for calcination Under the action of mechanical dispersing force and hot air generated by the gas, the material undergoes processes such as dispersion, drying, calcination and strong highspeed homogenization Calcined gypsum is Gypsum calcination process MECRU Heavy Industry 2021年4月30日 Natural gypsum can be mined in over 85 countries around the world, including Canada, the United States, and Mexico Gypsum rock is mined or quarried, crushed, or ground into a fine powder The calcined gypsum becomes the base for gypsum plaster, gypsum boards, and other gypsum products Another type of gypsum is synthetic gypsumDifferent Types of Gypsum, Uses and FAQs The Architects