Common faults and repair methods of ore mill

Inventory Of Common Faults And Solutions Of

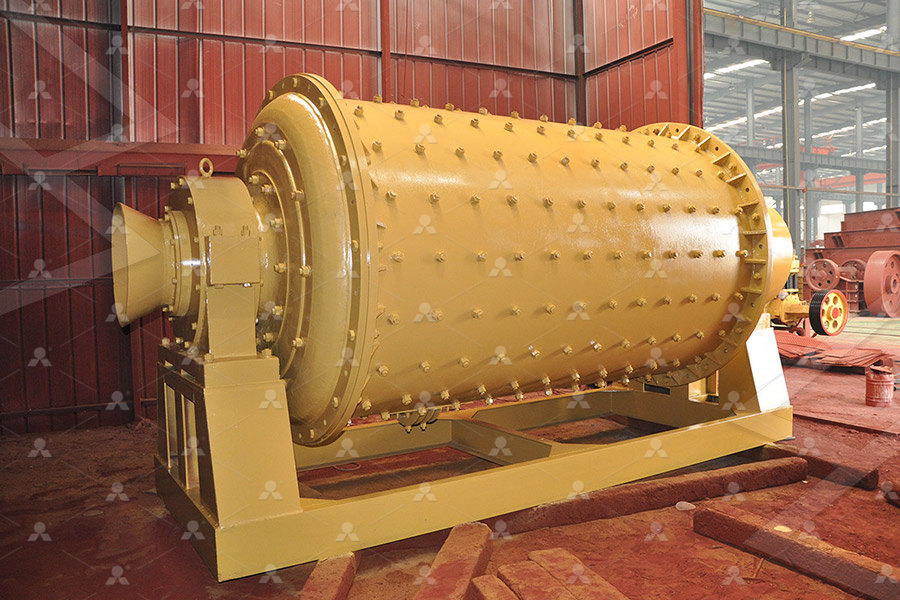

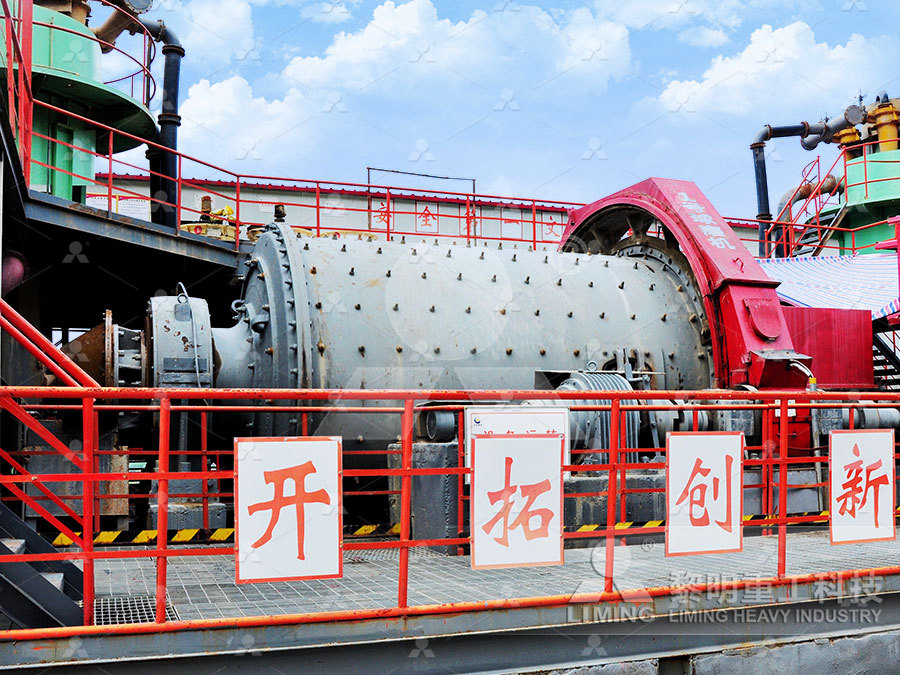

5 天之前 From excessive vibration to uneven grinding performance, our expert analysis will uncover the root causes behind these issues and provide effective solutions to have your mining ball mill running like a welllubricated machine in 2023年7月18日 The maintenance of the ball mill is of great significance in ensuring the normal operation of the equipment, extending the equipment lifespan, and improving production Ball Mill Maintenance Process and Methods MiningpediaThis study was aimed at increasing mine output and profit margin by controlling fragment size distribution, managing grade variability, and ensuring that broken ore reaches the mill plant timeously Movement of rock, ore loss, and dilution Monitoring ore loss and dilution for minetomill Solutions: check whether the oil pipe is blocked or leaking, and repair or replace the oil pipe in time, replenish the oil supply regularly, check whether the oil pump enters the air or leaks, and Common Faults and Solutions of Ball Mill Knowledge The

.jpg)

Review of control and fault diagnosis methods applied to coal mills

2015年8月1日 In this paper, fault detection techniques as applied to coal mills, are classified into four groups – quantitative methods, signal model based methods, qualitative methods, and 2022年8月28日 Researchers are finding new methods for better analysis of faults and reliability from traditional statistical methods to applying artificial intelligence With the advancement of Industry 40, the mining industry is A Review of Reliability and Fault Analysis 2024年6月13日 Common faults and treatment methods of Raymond Mill Summary: For industries such as mining development and daily chemical products, Common faults and treatment methods of Raymond Mill The following will explain the causes and solutions of the following Raymond powder mill failures 1 Powder leakage at the bottom of the mill Cause: There is a gap between the mainframe of 6 common faults and solutions of Raymond mill

.jpg)

Failure analysis of a ball mill located in a cement’s

2022年8月1日 The work herein presented analyses an existing failure in a ball mill of a cement production line The failure is recurrent and responsible for reducing the period between 2020年3月2日 Results show that stope HW stability improves when ore dip angle increases (ie, steeply dipping ore deposits) because the depth of relaxation zones and extent of failure Factors Influencing Stope Hanging Wall Stability and OreIn the dynamic world of rice milling, encountering operational challenges is inevitable This article delves into the realm of common faults that may arise in rice milling machine plants and provides effective troubleshooting methods Common Faults and Trouble Shooting Methods This maintenance method can repair and replace the equipment in advance, so as to avoid the occurrence of equipment failure However, because some potential hidden dangers can not be found and eliminated in the first time, the occurrence of equipment failure still exists Keywords boiler auxiliary machine; coal mill; fault; treatment methodAnalysis of Common Faults and Treatment Methods of

Nine common faults and solutions of rod mill News

2024年7月22日 Nine common faults and solutions of rod mill Jul 22, 2024 Rod mill is loaded by the cylinder body of the grinding body for the steel rods and named, rod mill is generally used in wet overflow type, can be used as a firstclass opencircuit grinding, widely used in artificial stone sand, mineral processing plant, chemical plant power sector2019年4月20日 2 Common Faults in Power Capacitors 21 Seepage Oil Leakage Capacitor leakage and oil leakage are common faults The reasons are manifold, such as improper handling methods, or the use of porcelain sleeves to cause cracks in the flange joints When connecting wires, damage to the porcelain bushing due to excessive force on the screw orCommon Faults and Treatment Methods of Power This maintenance method can repair and replace the equipment in advance, so as to avoid the occurrence of equipment failure However, because some potential hidden dangers can not be found and eliminated in the first time, the occurrence of equipment failure still exists Keywords boiler auxiliary machine; coal mill; fault; treatment methodAnalysis of Common Faults and Treatment Methods of 2024年2月7日 Research on Common Faults and Maintenance Methods of Computer Hardware Equipment Junning Lang 1,a,* 1 College of Network Engineering, Wuhu Institute of Technology, Wuhu, China a comparative replacement method, and software repair method Detailed steps and operation guidelines are also provided when analysing each maintenance Research on Common Faults and Maintenance Methods

(PDF) Factors Influencing Ore Recovery and Unplanned

2020年6月30日 Open stope mining is the most common mining method employed in underground, hard rock mines in Canada It is characterised by relatively small, single lift stopes (20,000 to 100,000 tonnes), and 2024年6月11日 Common Faults of Bending Machines and Troubleshooting Methods numberFaultPossible causes of the faultMethod of exclusion1The oil pump does not deliver oil or the oil supply is insufficientOil pump reverseChange to clockwise rotation directionCoupling Contact Us Disassemble the cylinder for inspection and repair Relief valve mon Faults of Bending Machines and Troubleshooting MethodsThe above are the 6 major faults that often occur in stone vibrating feeders and the corresponding solutions The vibrator should also pay attention to daily maintenance and maintenance during use, add grease to the bearing regularly and check whether the amplitude of the feeder and the surface temperature of the motor is in a normal stateSix common faults and solutions for vibrating feedersCommon Faults and Repair Methods of PCB Tag: PCB faults PCB repair Numerous do not recognize that the electronic devices, tools, as well as products they possess are built on a number of inner parts which function collaboratively to offer the essential performance and also functions they make use of A cellphone, for instance, is greater Common Faults and Repair Methods of PCB NEXTPCB

Review of control and fault diagnosis methods applied to coal mills

2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important 2023年5月12日 An introduction to common faults and repair methods of automobile engines Internal combustion engine and accessories, 2020(03), 162163 From automobile engine structure on its common failures (PDF) Research on Common Faults and 2023年2月14日 1 The rolling mill has thrown steel; 2 The cooling water of the rolling mill is all closed; 3 The CVC of the rolling mill moves to the roll changing position; 4 The AGC of the rolling mill is in the unloading position; 5 The positioning of the shaft head has been completed; 6 The main drive stops; mon Faults and Handling Methods of Rolling Mill Roll 8 Common Faults And Handling Methods For Conveyors Tel: +86735; Phone: +01; Email Complete Rice Mill Machine; Grain Dryer; Dust Collect System; Conveyor System; Hot Products Treatment method: Replace the roller, lift the well for repair, reduce the height difference at the drop point, or use shockproof rollers at 8 Common Faults And Handling Methods For Conveyors

Operation Analysis of a SAG Mill under Different Conditions Based on

2020年10月9日 In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the breakage process of the particles by controlling three 2022年12月5日 The common faults and repair methods of the electric kettle are described in detail below 1 The indicator light does not work and water cannot be boiled If the indicator light is not on, you need to check from two aspects One is that the power supply cannot be input normally, and the natural light of the electric kettle cannot be lit, and Common faults and repair methods of electric kettle2023年8月1日 Don't let common motor faults slow down your operations Get expert insights and troubleshooting tips on the 9 most common issues, and optimize your performance and safety today Troubleshooting 9 Common Motor Faults: Expert Methods and Tips To repair an open circuit, heat the affected part to the temperature allowed by the insulation Troubleshooting 9 Common Motor Faults: Expert Methods Hammer mill is the most common machine in a feed factory; its reliability directly determines the capacity and the normal operation of the followup process, so it is important for maintenance and repair personnel to analyze and deal with some common mechanical problems The hammer mill system mainly consists of a hammer mill and an engine Approaches for Common Mechanical Faults of Hammer Mills

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Here are two common extraction methods: a OpenPit Mining: Openpit mining is employed when the iron ore deposit is close to the surface or forms a large, easily accessible ore body In this method, largescale excavation machinery, such as excavators and haul trucks, is used to remove the overburden (surface material) and expose the ore deposit2023年7月22日 After the mill has been used for a period of time, the wearing parts should be repaired and replaced, and the continuous bolts and screws should be carefully checked before and after use 4 If the grinding roller has been used for more than 500 hours, the grinding roller must be mon Faults and Troubleshooting Methods of Raymond Mill 2024年10月29日 How to solve the common faults of horizontal sand mill? Oct 07, 2024 1 Blockage The inspection method for this type of fault is to remove the discharge screen and clean it with solvent or highpressure water gun 2 Wear of the rotor Whether the material is a disc rotor or a pin rotor, there will be wear The consequence of wear is the How to solve the common faults of horizontal sand mill?The study sorted out the types and causes of common faults in computer hardware equipment, and provided a detailed introduction to maintenance methods for these faults The study demonstrates through examples how to apply these maintenance methods to solve practical problems, aiming to provide reference for relevant researchResearch on Common Faults and Maintenance Methods of

.jpg)

Common Fault Diagnosis and Troubleshooting in

2020年5月15日 The Common Faults of Automotive AirConditioning and Refrigeration System and the it is necessary to find the leak point and repair it, whether it is refrigerant Tian Xiaohong, Bai Yongping A probe into the fault diagnosis and elimination method of automobile air conditioning system Science and Technology Outlook, vol 27, no 4, pp 2012年7月1日 Starter motor converts electrical energy through a battery into mechanical rotating energy These motors work under heavy load They produce big power in a short time and in a small volume(PDF) An overview of automobile starting system faults and 2023年3月21日 3 Empirical method Maintenance personnel understands the structure and working principle of each hydraulic component by mastering the hydraulic system theory of hydraulic presses, and on the basis of rich practical experience, conduct a comprehensive analysis of hydraulic press failures and make correct diagnoses mon Faults, Causes, and Maintenance Methods of 2023年5月4日 A hammer crusher is a kind of equipment for medium and fine crushing of medium hardness materials in the form of impact It processes gold ore, limestone, glass, coal, cement, gypsum, granite, dolomite, barite, etc Compared with other crushers, hammer mill has the advantages of onetime crushing, high production capacity, and easy maintenance Its 9 Hammer Crusher Common Faults and Solutions Fote

.jpg)

Common Faults On Crushing Machines Crusher Mills, Cone

The Common Problems and Solutions of Ball Mill processing The Common Problems and Solutions of Ball Mill Ball mill separating plant is widely used in dry way powder process of metallic and nonmetallic minerals, and powder Permanent magnet synchronous motors (PMSM) have been used in a lot of industrial fields In this paper, a review of faults and diagnosis methods of PMSM is presented Firstly, the electrical, mechanical and magnetic faults of the permanent magnet synchronous motor are introduced Next, common fault diagnosis methods, such as modelbased fault diagnosis, different signal Faults and Diagnosis Methods of Permanent Magnet Synchronous 2021年12月3日 Common faults and repair methods of voltage stabilizers Dec 03, 2021The power regulator is a power supply device that can automatically adjust the output voltage It can stabilize the unstable power supply voltage within the corresponding scale, and make various circuits, electrical equipment, etc work stably under normal voltage The Common faults and repair methods of voltage stabilizersIn the dynamic world of rice milling, encountering operational challenges is inevitable This article delves into the realm of common faults that may arise in rice milling machine plants and provides effective troubleshooting methods Common Faults and Trouble Shooting Methods

Analysis of Common Faults and Treatment Methods of

This maintenance method can repair and replace the equipment in advance, so as to avoid the occurrence of equipment failure However, because some potential hidden dangers can not be found and eliminated in the first time, the occurrence of equipment failure still exists Keywords boiler auxiliary machine; coal mill; fault; treatment method2024年7月22日 Nine common faults and solutions of rod mill Jul 22, 2024 Rod mill is loaded by the cylinder body of the grinding body for the steel rods and named, rod mill is generally used in wet overflow type, can be used as a firstclass opencircuit grinding, widely used in artificial stone sand, mineral processing plant, chemical plant power sectorNine common faults and solutions of rod mill News2019年4月20日 2 Common Faults in Power Capacitors 21 Seepage Oil Leakage Capacitor leakage and oil leakage are common faults The reasons are manifold, such as improper handling methods, or the use of porcelain sleeves to cause cracks in the flange joints When connecting wires, damage to the porcelain bushing due to excessive force on the screw orCommon Faults and Treatment Methods of Power This maintenance method can repair and replace the equipment in advance, so as to avoid the occurrence of equipment failure However, because some potential hidden dangers can not be found and eliminated in the first time, the occurrence of equipment failure still exists Keywords boiler auxiliary machine; coal mill; fault; treatment methodAnalysis of Common Faults and Treatment Methods of

Research on Common Faults and Maintenance Methods

2024年2月7日 Research on Common Faults and Maintenance Methods of Computer Hardware Equipment Junning Lang 1,a,* 1 College of Network Engineering, Wuhu Institute of Technology, Wuhu, China a comparative replacement method, and software repair method Detailed steps and operation guidelines are also provided when analysing each maintenance 2020年6月30日 Open stope mining is the most common mining method employed in underground, hard rock mines in Canada It is characterised by relatively small, single lift stopes (20,000 to 100,000 tonnes), and (PDF) Factors Influencing Ore Recovery and Unplanned 2024年6月11日 Common Faults of Bending Machines and Troubleshooting Methods numberFaultPossible causes of the faultMethod of exclusion1The oil pump does not deliver oil or the oil supply is insufficientOil pump reverseChange to clockwise rotation directionCoupling Contact Us Disassemble the cylinder for inspection and repair Relief valve mon Faults of Bending Machines and Troubleshooting MethodsThe above are the 6 major faults that often occur in stone vibrating feeders and the corresponding solutions The vibrator should also pay attention to daily maintenance and maintenance during use, add grease to the bearing regularly and check whether the amplitude of the feeder and the surface temperature of the motor is in a normal stateSix common faults and solutions for vibrating feeders