Small steel slag micro powder production line

.jpg)

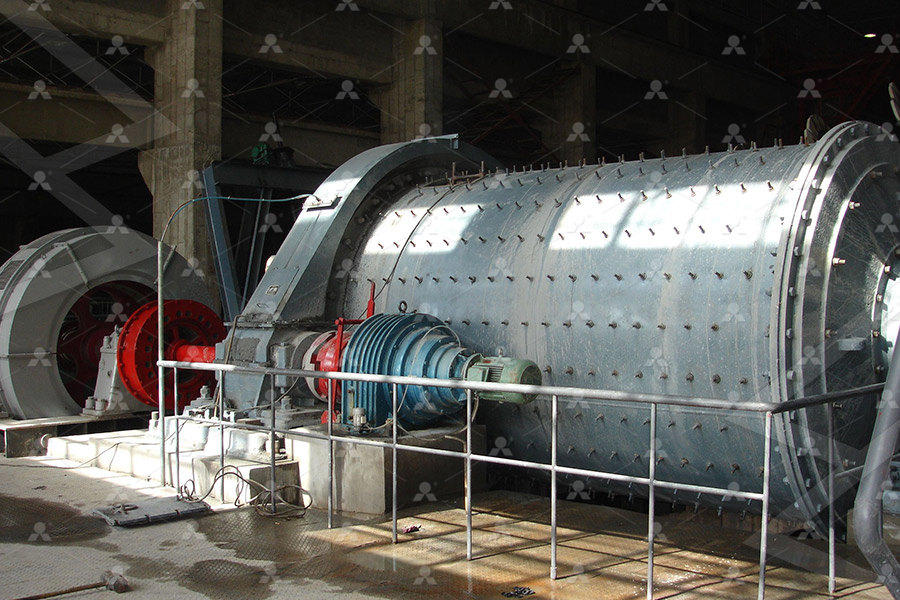

Milling production line of steel slag micro powder

The invention is characterized in that the milling production line is arranged according to a steel slag micro powder process flow; the milling production line mainly comprises a raw material A steel slag micropowder and production line technology, which is applied in the direction of recycling technology, can solve the problems of inconvenient installation and manufacturing, Milling production line of steel slag micro powder EurekaA steel slag fine powder and production line technology, applied in the direction of recycling technology, can solve the problems of low output, high investment cost, low energy utilization Milling production line of steel slag micro powder Eureka2024年1月2日 HCM ore powder vertical mill production line has reliable quality, high output and high efficiency, low energy consumption, low noise and environmental protection It is an ideal Slag micron powder process technology solution

.jpg)

Production process of steel slag micropowder Semantic

2011年3月17日 The invention relates to a production process of steel slag micropowder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and Slag/Steel scoria /Micro Powder Production LineChaoyang Jiantou Heavy Machinery Co, Ltd Welcome to the official website of Chaoyang Jiantou Heavy Slag/Steel scoria /Micro Powder Production LineChaoyang Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non Small Slag Powder Production regulus2024年8月30日 Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is less than 6% Superfine Slag Powder Production Line FTM Machinery

.jpg)

Analysis and multiobjective optimization of slag powder process

2020年11月1日 Optimal solution for slag powder production process is determined by proposed CTNSGAII algorithm Slag powder is a process with characters of multivariables, strongly 2024年3月28日 Steel slag micronized powder, granulated blast furnace slag, and cement were used as cementitious materials to prepare a foamed lightweight soil for roadbed filling to reduce the settlement and additional stress of the Features of Processes for Preparation and 2023年6月14日 To investigate the toughening effect and stress–strain relationship of steel fibrereinforced steel slag micropowder ultrahighperformance concrete (UHPC), nine sets of specimens with coarse aggregate Experimental Study on Axial Stress–Strain 2024年11月1日 Steel slag displays good reactivity, and its high calcium oxide and magnesium oxide content can be further enhanced using alkaliactivation technology, enabling its application as a geopolymer material [33], [34]The addition of micropowder materials can effectively fill the voids between the coarse and fine aggregates in concrete, enhancing Effect of electric furnace steel slag powder on the strength of

Modification of magnesium phosphate cement with steel slag powder

2024年8月9日 SSP and granulated blast furnace slag (GBFS) are the main bulk solid wastes generated by the steel industry [49], [50] SSP is an industrial byproduct rich in metal oxides (Fe 2 O 3, CaO, etc) with good electrical conductivity, generated at a ratio of 12–20 % of the total steel production [45], [51]2018年8月1日 The China Association of Metal Scrap Utilization first announced the production and utilization of steel slag in 2005 (2005); between 2005 and 2013, China’s steel slag production rose sharply along with an increase in its crude steel production The amount of steel slag reached 1013 million tons in 2013Steel slag in China: Treatment, recycling, and management2023年8月30日 The analysis of Table 9 shows that when the strength of the UHPC filled with steelslag micro powder increased from 120 MPa to 130 MPa, 140 MPa, 150 MPa, and 160 MPa, respectively, the ultimate flexural bearing capacity of the member increased by 16%, 32%, 49%, and 66%, respectively, and the rate of the increase in the flexural bearing Research on the Flexural Performance of Steel Pipe Steel Slag Powder 2020年9月28日 Due to the low hydration activity and poor volume stability, extensive steel slag utilization is restricted In this paper, the hydration process and microstructure of alkaliactivated materials with steel slag as a cementitious material and fine aggregate were studied The phase composition and micromorphology of hydration products were measured using XRD, NMR Hydration and Microstructure of Steel Slag as Cementitious

Comprehensive utilization of steel slag: A review

2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of 2019年5月23日 There is a large amount of randomness, and the incidence of “large ball hits small ball” occurs easily, leading to “over crushing” and agglomeration In 2005, a certain group in Shandong put of an assembly line of 600,000 tons of magnetic separation of steel slag into production, with the treatment of steel slag and steel slag powder Comprehensive Utilization Technology of Steel Slag2013年9月1日 The specific surface area of steel slag is generally between 300 and 500 m 2 /kg when it is used as a mineral admixture for cement or concrete production Some studies showed that, in this range, increasing the specific area of steel slag was beneficial to its activity [26], [27], [28]It is interesting to know the activity of steel slag with even higher specific surface areaCementitious properties of superfine steel slag ScienceDirectSteel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can Introduction To The Way Of Steel Slag Recycling

.jpg)

Steel slag recycling crushing and grinding production line

The dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%2023年6月28日 The utilization rate of steel slag in China is far behind that of developed countries The annual output of steel slag is still increasing, resulting in a large amount of accumulation, causing environmental pollution This paper Effects of Steel Slag Powder as A Cementitious 2021年8月1日 Steel slag micro powder is steel slag after special process grinding, is a byproduct in the process of steel production This paper studied the basic mechanical properties and crack control (PDF) Effect of Polyvinyl FiberSteel Slag Powder on Carbon dioxide sequestration using steel slag—modeling and experimental investigation Smitha Gopinath, Anurag Mehra, in Carbon Dioxide Sequestration in Cementitious Construction Materials, 2018 41 Introduction Steel slag is an industrial waste that is generated during the production of steel In the production of steel, oxides of metal impurities in the iron combine Steel Slag an overview ScienceDirect Topics

.jpg)

A Review on the Carbonation of Steel Slag: Properties,

2024年4月28日 Steel slag is a byproduct generated during the steelmaking process, with a production rate of approximately 10–15% of the crude steel quantity []Large amounts of steel slag have been produced annually in many regions []As a major steel producer in the world, crude steel production in China reached 101 billion tons in 2022 while producing more than 160 2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O 3, and MnO [3, 4]The major mineral components of steel slag are C 3 S, C 2 S, C 4 AF, RO phase, and freeCaO [5, Applications of Steel Slag Powder and Steel Slag Aggregate The invention belongs to a milling production line of steel slag micro powder The invention is characterized in that the milling production line is arranged according to a steel slag micro powder process flow; the milling production line mainly comprises a raw material hopper, a weighter, a belt conveyer, an iron remover, a metal detector, a threeway material dividing valve A, a Milling production line of steel slag micro powder2024年10月24日 In order to study the axial compression performance of steel pipe concrete short columns filled with steel slag micronized ultrahighperformance concrete (UHPC), this paper designs 27 steel pipe UHPC short columns for axial compression test and compares and analyzes the axial compression performance of the specimens in terms of the damage mode, Experimental Performance Study on Axial Compressive Load

Research on the Properties of Steel Slag with Different

2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water Typical morphology of steel slag [](a) BOF steel slag(b) EAF steel slag(c) LF steel slagBOF steel slag is the solid waste produced in the converter steelmaking process, and its discharge is approximately 100–150 kg per ton of BOF steel [20,21,22,23]BOF steel slag commonly has a grayishwhite appearance and a vesicular nature, with many noninterconnected pores []Application of Steel Slag as an Aggregate in Concrete Production2023年5月21日 The accumulation of steel slag and other industrial solid wastes has caused serious environmental pollution and resource waste, and the resource utilization of steel slag is imminent In this paper, alkaliactivated ultrahigh Effects of Steel Slag Powder Content and Curing 2023年8月25日 output of BOF steel slag accounts for about 70% of the total steel slag production [25] EAF steel slag is the byproduct of electric furnace steelmaking, the output of which is approximately 110 (PDF) Application of Steel Slag as an Aggregate

R)8OC`6F[ZIB.jpg)

Comprehensive utilization of steel slag: A review Request PDF

2023年3月1日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in industrial applications2024年9月20日 The improper treatment of steel slag (SS) will cause serious environmental problems Therefore, appropriate management and disposal practices are essential to mitigate the potential environmental risks This paper delineated the impact of steel slag on cementbased materials’ working performances The paper provides an exhaustive overview of the Influence of Steel Slag on Properties of CementBased 2023年11月15日 The limited cementitious activity of steel slag (SS) powder restricts its largescale utilization as a replacement material for Portland cement and even more so for inert iron ore tailings (IOT) The microIOT (MIOT) were utilized as additives to improve the compressive strength and hydration degree of a binary system containing SS and PCEnhancement mechanism of microiron ore tailings on 2011年6月1日 Electric arc furnace (EAF) steel slag, generated from carbon steel production process, is the most interesting from the asphalt technology point of view This paper aims to explore the feasibility Defining of EAF steel slag application possibilities in asphalt

Influence of steel slag on strength and microstructural

2024年7月20日 Geopolymer concrete (GC) utilizes industrial solid waste like steel slag, fly ash, and rice husk ash, offering a sustainable alternative to traditional cement By reducing reliance on cement, GPC helps mitigate carbon footprints and promotes ecofriendly construction practices With its significant commercial potential, GPC is poised to contribute to sustainable 2022年4月10日 Five fillers, including four SSP fillers, obtained by grinding different steel slag aggregates with an industrialized production line, and one conventional limestone powder (LP) filler, were evaluated The chemical compositions and micromorphologies of the SSPs were first characterized to evaluate the material homogeneity and gain insights Innovative use of industrially produced steel slag powders in 2020年4月20日 Waste steel slag is an industrial byproduct during the process of steelmaking, and its output approaches 15–20% of steel production [37], [38] In China, the annual steel slag output reaches about 100 million tons and the accumulated stockpile exceeds 1 billion tons [39] , [40] , but its comprehensive utilization rate is only about 20% Effectiveness of waste steel slag powder on the strength 2024年3月28日 Steel slag micronized powder, granulated blast furnace slag, and cement were used as cementitious materials to prepare a foamed lightweight soil for roadbed filling to reduce the settlement and additional stress of the Features of Processes for Preparation and

Experimental Study on Axial Stress–Strain

2023年6月14日 To investigate the toughening effect and stress–strain relationship of steel fibrereinforced steel slag micropowder ultrahighperformance concrete (UHPC), nine sets of specimens with coarse aggregate 2024年11月1日 Steel slag displays good reactivity, and its high calcium oxide and magnesium oxide content can be further enhanced using alkaliactivation technology, enabling its application as a geopolymer material [33], [34]The addition of micropowder materials can effectively fill the voids between the coarse and fine aggregates in concrete, enhancing Effect of electric furnace steel slag powder on the strength of 2024年8月9日 SSP and granulated blast furnace slag (GBFS) are the main bulk solid wastes generated by the steel industry [49], [50] SSP is an industrial byproduct rich in metal oxides (Fe 2 O 3, CaO, etc) with good electrical conductivity, generated at a ratio of 12–20 % of the total steel production [45], [51]Modification of magnesium phosphate cement with steel slag powder 2018年8月1日 The China Association of Metal Scrap Utilization first announced the production and utilization of steel slag in 2005 (2005); between 2005 and 2013, China’s steel slag production rose sharply along with an increase in its crude steel production The amount of steel slag reached 1013 million tons in 2013Steel slag in China: Treatment, recycling, and management

.jpg)

Research on the Flexural Performance of Steel Pipe Steel Slag Powder

2023年8月30日 The analysis of Table 9 shows that when the strength of the UHPC filled with steelslag micro powder increased from 120 MPa to 130 MPa, 140 MPa, 150 MPa, and 160 MPa, respectively, the ultimate flexural bearing capacity of the member increased by 16%, 32%, 49%, and 66%, respectively, and the rate of the increase in the flexural bearing 2020年9月28日 Due to the low hydration activity and poor volume stability, extensive steel slag utilization is restricted In this paper, the hydration process and microstructure of alkaliactivated materials with steel slag as a cementitious material and fine aggregate were studied The phase composition and micromorphology of hydration products were measured using XRD, NMR Hydration and Microstructure of Steel Slag as Cementitious 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review2019年5月23日 There is a large amount of randomness, and the incidence of “large ball hits small ball” occurs easily, leading to “over crushing” and agglomeration In 2005, a certain group in Shandong put of an assembly line of 600,000 tons of magnetic separation of steel slag into production, with the treatment of steel slag and steel slag powder Comprehensive Utilization Technology of Steel Slag

Cementitious properties of superfine steel slag ScienceDirect

2013年9月1日 The specific surface area of steel slag is generally between 300 and 500 m 2 /kg when it is used as a mineral admixture for cement or concrete production Some studies showed that, in this range, increasing the specific area of steel slag was beneficial to its activity [26], [27], [28]It is interesting to know the activity of steel slag with even higher specific surface area