Marble production calcium powder process

.jpg)

Synthesis and characterization of precipitated calcium

2024年3月29日 CaCl 2 solution and Ca (OH) 2 slurry, both prepared from marble waste (MARWAS), were carbonated with CO 2 gas in the presence of cetyltrimethylammonium bromide (CTAB), sodium dodecyl sulfate (SDS), Teepol610s, Triton X100, and Tween80 as the 2023年5月1日 The potential of CaObased sorbents using waste and natural geological materials (two wastes of marble powders and four limestones) for CO 2 capture through the Calooping process using wastes of marble powders and 2019年12月1日 The results presented here indicate the potential application of inexpensive waste marble powder as an alternative to commercial sorbent used in calcium looping (CaL) Recycling wastederived marble powder for CO2 capture2024年2月1日 Even if the marble industry produces large amounts of waste marble powder (WMP) during the cutting and polishing processes, with losses reaching 30–50% (Rana et al, Use of waste marble powder for the synthesis of novel calcium

.jpg)

Suitability of marble powders in production of high strength

2023年11月7日 This paper presents the effect of two locally sourced waste marble powders Kadapa marble powder (KMP) and Bethamcherla marble powder (BMP) as partial 2016年7月5日 The main goal and innovative idea addressed in this study consists of investigating if solid wastes WMP from marble producer sources can be used as possible inexpensive and effective solid materials to be used as Waste Marble Powders as Promising Inexpensive 2021年6月23日 The use of wastes of marble powder (WMP) and dolomite as sorbents for CO2 capture is extremely promising to make the Calooping (CaL) process a more sustainable and ecofriendly technologyBlending Wastes of Marble Powder and 2024年9月11日 To address these issues, this study introduces a novel approach involving the chemically converted waste marble powder (CCWMP) treatment of soil In this process, Effective Utilization of Waste Marble Powder by Chemical

The Treatment of Natural Calcium Materials

2024年2月20日 Two sources of calcium derivative compounds were tested, waste marble powder (WMP) and dolomite The SAS micronization of the derivate calcium acetate was carried out at 60 °C, 200 bar, a 05 mL min−1 flow rate of 2019年12月1日 Experimental CaL tests were carried out in a fixed bed reactor using natural CaObased sorbent precursors, such as WMP, dolomite and their blend, under mild and Recycling wastederived marble powder for CO2 capture2024年10月23日 Dolomite marble powder is added in sizes from 100250 microns In the coating industry (paints), marble powder calcium carbonate is an essential material, as it forms from 30 – 40% of the paint components and is Marble Powder Calcium Carbonate BMS 2024年4月7日 This production process gives artificial stone a certain degree of hardness, sturdiness and wear resistance, while also enabling customization of various colors and textures Artificial stone is a stone substitute made from What Is Artificial Marble? Marble George

What is Marble Powder? What is it Used For?

2024年7月30日 Marble powder is also known as limestone and calcium carbonate In nature, marble powder is mainly found in old rocks and seashells Marble powder, which is used intensively in industry, can also be used in paint 2024年11月7日 In the paint industry, calcium carbonate marble powder is a basic material because it is composed of 3040% of the paint components and is preferred over calcium carbonate powder because of its crystallinity In the paint manufacturing process, powders are colorants and adhesives for forming sticky, stable highflow materials The particle size Marble Powder Calcium Carbonate BMS FACTORIES2024年1月13日 Keywords: precipitated calcium carbonate, waste marble powder, whiteness Introduction Limestone is a common type of sedimentary rock in the earth crust which primarilyPRECIPITATED CALCIUM CARBONATE PRODUCTION, 2024年9月11日 Lime stabilization remains the most commonly adopted method to improve expansive soil; however, lime production has drawbacks such as depleting natural resources, high energy consumption, and substantial greenhouse gas emissions To address these issues, this study introduces a novel approach involving the chemically converted waste marble powder Effective Utilization of Waste Marble Powder by Chemical

.jpg)

Effect of surface area on rates of reaction chemguide

2020年11月18日 Core Chemistry 14 16 The effect of surface area on the rates of chemical reactions This page uses the reaction between marble chips and dilute hydrochloric acid to investigate the relationship between the rate of reaction and the surface area of the marble chipsDOI: 101016/jpsep201910005 Corpus ID: ; Recycling wastederived marble powder for CO2 capture @article{Nawar2019RecyclingWM, title={Recycling wastederived marble powder for CO2 capture}, author={Azra Nawar and Hosein Ghaedi and Majid Ali and Ming Zhao and Naseem Iqbal and Rashid Atta Khan}, journal={Process Safety and Environmental Protection}, Recycling wastederived marble powder for CO2 captureManufacturer of Marble Powder Marble Sand Powder, White Marble Powder offered by Golden Micro Chemicals, Thane, Maharashtra Production Capacity: 300 TON; Delivery Time: 57 days; Packaging Details: 50 KG PP Bag; Yes! I am Interested Calcium Powder Get Best Quote China Clay Powder Get Best Quote Hydrous Kaolin Clay Get Best QuoteMarble Powder Marble Sand Powder Manufacturer from 2024年8月21日 In conclusion, mixers are indispensable equipment in the Calcium Carbonate Manufacturing Process, ensuring the production of highquality calcium carbonate efficiently and effectively Their role in achieving consistency, reducing processing time, enhancing productivity, enabling customization, and ensuring quality control is paramountThe Ultimate Guide Calcium Carbonate Manufacturing Process

[PDF] Precipitated calcium carbonate production, synthesis

Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other industries In the present paper, precipitated calcium carbonate (PCC) has been produced from waste marble powder (WMP) by the CalcinationDissolutionPrecipitation (CDP) method Calcination, dissolution and precipitation experiments Fig 1 SEM image of the waste marble powder (WMP) The calcinationsdissolutionprecipitation (CDP) method was utilized for the production of precipitated calcium carbonate (PCC) The experimental flow sheet and evaluated parameters for the production are given in Fig 2 and Tables 2–4, respectivelyPRECIPITATED CALCIUM CARBONATE PRODUCTION, 2024年1月2日 Concrete, an indispensable cornerstone of the construction industry, presents a formidable environmental challenge owing to the substantial carbon dioxide (CO2) emissions incurred during the production of cement However, in light of the construction sector’s vital economic and social contributions, it becomes imperative to harmonize it with environmental Influence of recycled concrete, marble, glass, and limestone powder 2022年6月11日 Marble powder as an adsorbent As the main constituent of WMP is dolomite, principally calcium and magnesium carbonates, the positively charged Ca + and Mg + ions present in dolomite possess an affinity toward negative ions They hence can be employed as an adsorbent for anionic adsorbates (Mehta et al 2016)Table 2 presents different adsorbents Green calciumbased photocatalyst derived from waste marble powder

Synthesis and characterization of precipitated calcium

2024年3月29日 CaCl2 solution and Ca(OH)2 slurry, both prepared from marble waste (MARWAS), were carbonated with CO2 gas in the presence of cetyltrimethylammonium bromide (CTAB), sodium dodecyl sulfate (SDS), Teepol610s, Triton X100, and Tween80 as the surface modifiers in a semibatch foambed reactor (FBR) to synthesize ultrafine or submicron 2024年2月20日 The potential of the supercritical antisolvent micronization (SAS) technique was evaluated for the production of CaObased particles with a size and a physical structure that could enable high performance for CO2 capture through the calcium looping process Two sources of calcium derivative compounds were tested, waste marble powder (WMP) and dolomiteThe Treatment of Natural Calcium Materials Using the 2013年1月17日 Fillers can be silica, calcium carbonate etc Fillers and resin are mixed, followed by curing and molding to yield marble Various techniques like slip casting, isostatic pressing, dry casting are also used to cast marble The real marble look is simulated using pigments, chips etc Onyx is another compound similar to marble but with moreRECENT DEVELOPMENTS IN SYNTHETIC MARBLE Download Table Physical properties of marble powder from publication: Influence of limestone waste as partial replacement material for sand and marble powder in concrete properties Green Physical properties of marble powder Download Table

.jpg)

Environmental, Energy, and Water Footprints of Marble

2022年7月7日 wastewaterproducing production chains by which around 70% of valuable minerals in freshwater are lost through withdrawal, processing, and refining [9] Marble industries dispose of their wastes in fine powder, which is one of the leading environmental concerns worldwide [9] The mining process produces 40% of the marbleLimestone is a naturally occurring and abundant sedimentary rock consisting of high levels of calcium and/or magnesium carbonate and/or dolomite (calcium and magnesium carbonate), along with minerals Lime production begins by extracting limestone from quarries and mines Sizing Limestone enters a primary crusher to break the rockHow Lime is Made2019年12月15日 of natural stone processing waste: solid and semiliquid or slurry (Almeida et al, 2007) In fact during the marble cutting process by gang saws, water is used as a coolant and the powder flows along with it as waste marble slurry Depending on the kind of process involved, the sludge generated is equal to between 2030% ofRECOVERY AND REUSE OF MARBLE POWDER BY 2013年4月1日 Marble powder is a byproduct obtained during the quarrying process from the parent marble rock; which contains high calcium oxide content of more than 50%(PDF) EFFECT OF THE LIME CONTENT IN

Comprehensive Knowledge About Marble

2023年10月12日 Marble’s chemical makeup is also influenced by environmental conditions including temperature, pressure, and the presence of other minerals and liquids during the creation process For instance, in addition to calcium 2024年11月4日 Calcium carbonate (marble powder) is extensively used in various industries such as marble, chalk, and limestone production It is also utilized in PVC manufacturing and is a beneficial molecule in ceramic production The similarity between the chemical composition of marble and limestone, coupled with the very fine particle size of marble Marble Powder Bumer Stone2024年7月11日 Marble Marble, also known as marble, is a recrystallized limestone with the main component CaCO3 Limestone softens under high temperature and high pressure and recrystallizes to form marble when the minerals are changed There are many colors, usually with obvious patterns and many mineral particles The Mohs hardness is between 25 and 5marble grinding machine, marble grinding mill, marble powder 2024年4月25日 The carbothermic process, employed by BASF in Germany between 1940 and 1960, provided an alternative route to calcium carbide production, but it has since been abandoned 1 Physical Properties of Calcium Carbide The raw materials for calcium carbide production, known as the “burden” in the electrothermic furnace, play a crucial role in Calcium Carbide: Properties, Production and Uses

artificial marble manufacturing process Utand Stone

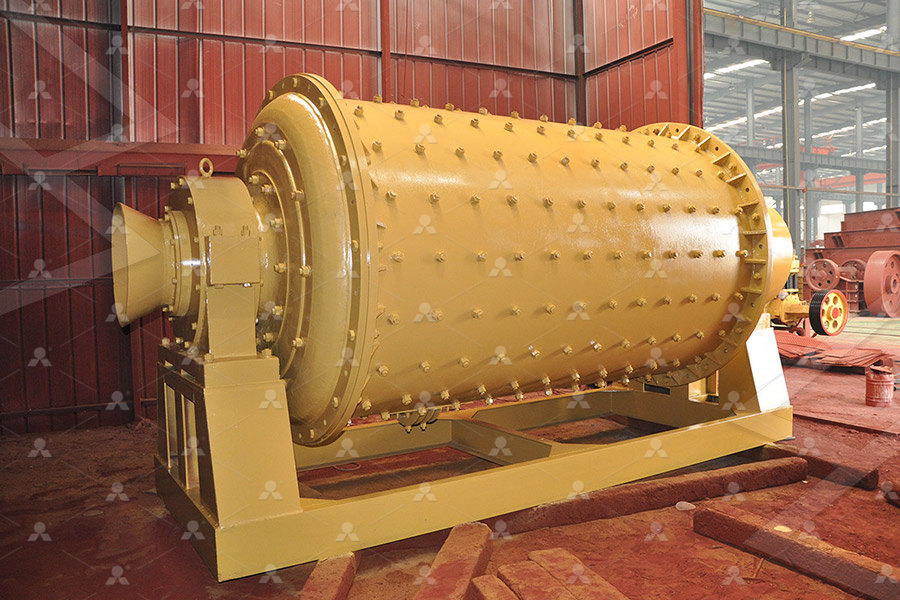

2016年12月8日 Utand artificial marble production process 1 Ingredients: mix 5 to 100 mesh white diamond or rosin jade powder and superfine calcium carbonate powder to obtain mixture a; 2 The mixture B was obtained by adding pigment to mixture a and stirring for 5 to 20 minutes;2024年9月13日 In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, storage bins, grinding mill, dust collectors, classifiers and other equipmentHow to Choose a Calcium Carbonate Grinding Mill DASWELL2019年9月26日 As for the quartz powder, a grinder mill is used for crushing the pure, lumpy quartz to produce a fine powder 3) Supplying Of Quartz When it comes to the manufacturing process of engineered quartz stone, the process starts with the manufactured quartz materials selection It could be any quartz product such as quartz sand or quartz granulesQuartz Stone Manufacturing Process: Everything You Need 2024年10月23日 Dolomite marble powder is added in sizes from 100250 microns In the coating industry (paints), marble powder calcium carbonate is an essential material, as it forms from 30 – 40% of the paint components and is Marble Powder Calcium Carbonate BMS

What Is Artificial Marble? Marble George

2024年4月7日 This production process gives artificial stone a certain degree of hardness, sturdiness and wear resistance, while also enabling customization of various colors and textures Artificial stone is a stone substitute made from 2024年7月30日 Marble powder is also known as limestone and calcium carbonate In nature, marble powder is mainly found in old rocks and seashells Marble powder, which is used intensively in industry, can also be used in paint What is Marble Powder? What is it Used For?2024年11月7日 In the paint industry, calcium carbonate marble powder is a basic material because it is composed of 3040% of the paint components and is preferred over calcium carbonate powder because of its crystallinity In the paint manufacturing process, powders are colorants and adhesives for forming sticky, stable highflow materials The particle size Marble Powder Calcium Carbonate BMS FACTORIES2024年1月13日 Keywords: precipitated calcium carbonate, waste marble powder, whiteness Introduction Limestone is a common type of sedimentary rock in the earth crust which primarilyPRECIPITATED CALCIUM CARBONATE PRODUCTION,

.jpg)

Effective Utilization of Waste Marble Powder by Chemical

2024年9月11日 Lime stabilization remains the most commonly adopted method to improve expansive soil; however, lime production has drawbacks such as depleting natural resources, high energy consumption, and substantial greenhouse gas emissions To address these issues, this study introduces a novel approach involving the chemically converted waste marble powder 2020年11月18日 Core Chemistry 14 16 The effect of surface area on the rates of chemical reactions This page uses the reaction between marble chips and dilute hydrochloric acid to investigate the relationship between the rate of reaction and the surface area of the marble chipsEffect of surface area on rates of reaction chemguideDOI: 101016/jpsep201910005 Corpus ID: ; Recycling wastederived marble powder for CO2 capture @article{Nawar2019RecyclingWM, title={Recycling wastederived marble powder for CO2 capture}, author={Azra Nawar and Hosein Ghaedi and Majid Ali and Ming Zhao and Naseem Iqbal and Rashid Atta Khan}, journal={Process Safety and Environmental Protection}, Recycling wastederived marble powder for CO2 captureManufacturer of Marble Powder Marble Sand Powder, White Marble Powder offered by Golden Micro Chemicals, Thane, Maharashtra Production Capacity: 300 TON; Delivery Time: 57 days; Packaging Details: 50 KG PP Bag; Yes! I am Interested Calcium Powder Get Best Quote China Clay Powder Get Best Quote Hydrous Kaolin Clay Get Best QuoteMarble Powder Marble Sand Powder Manufacturer from

.jpg)

The Ultimate Guide Calcium Carbonate Manufacturing Process

2024年8月21日 In conclusion, mixers are indispensable equipment in the Calcium Carbonate Manufacturing Process, ensuring the production of highquality calcium carbonate efficiently and effectively Their role in achieving consistency, reducing processing time, enhancing productivity, enabling customization, and ensuring quality control is paramount