Steel slag resource development and utilization plan

Comprehensive utilization of steel slag: A review

2023年5月15日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in 2012年1月1日 At present, the amount of slag deposited in storage yard adds up to 30Mt, leading to the occupation of farm land and serious pollution to the environment Improving the slag An Overview of Utilization of Steel Slag ScienceDirect2020年9月24日 In this paper, the common ways of resource utilization of steel slag in construction, agriculture, industry, and catalysis are reviewed Steel slag as a solid waste with Sustainable Utilization of Steel Slag from Traditional Industry 2020年1月1日 In traditional resource utilization technology, steel slag is used in sintering flux, road construction, cement and concrete production, preparation of glass ceramics and Review of Resource Utilization Technology of Steel Slag and

(PDF) An Overview of Utilization of Steel Slag

2012年12月31日 Physical and chemical characterization of steel slag is a deciding factor of steel slag utilization as recycled raw material as road aggregate, cement and concrete admixture, soil2019年5月23日 Steel slag is the waste generated in the steelmaking process and includes ferric oxide and the impurities of some infusible matters It is the byproduct when slagforming Comprehensive Utilization Technology of Steel SlagThis paper described the production and composition characteristics of steel slag, reviewed current situation and progress of resource utilization and stabilization of steel slag Steel slag The Research Progress of Steel Slag Utilization and 2021年1月11日 In this paper, the common ways of resource utilization of steel slag in construction, agriculture, industry, and catalysis are reviewed Steel slag as a solid waste with Sustainable Utilization of Steel Slag from Traditional

Review of Resource Utilization Technology of Steel Slag and

In traditional resource utilization technology, steel slag is used in sintering flux, road construction, cement and concrete production, preparation of glass ceramics and agriculture In these fields, 2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, Current Development of Slag Valorisation in China2017年12月8日 where D CO2 (m 2 /s) is the diffusivity of CO 2 species which is a function of temperature 17, δ is the film thickness (m), and k CO2 is the mass transfer coefficient (m/s) According to our CO2 Mineralization and Utilization using Steel Steel slag is a byproduct of steelmaking process The producing of steel slag in China is proximately 100 million tons, but the utilization ratio of comprehensive resources is the lower This paper described the production and composition characteristics of steel slag, reviewed current situation and progress of resource utilization and stabilization of steel slagThe Research Progress of Steel Slag Utilization and

An Overview of Utilization of Steel Slag ScienceDirect

2012年1月1日 The current utilization rate of steel slag is only 22% in china, far behind the developed countries :14 [5] Motz H, Geiseler J Products of steel slags an opportunity to save natural resources Waste Manage 2001; 21:285293 [6] Wu XQ, Zhu H, Hou XK, Li HS Encosteel: steel for sustainable development International Iron and Steel 2021年9月24日 During steel production, the impurities in the hot metal react with the fluxes forming the steel slag Chemical constituents of this steel slag (SS) are relevant to iron/steelmaking or blended cement manufacture Harmful impurities present in it, however, limit its recycling to these applications Japan, Europe, and the US consume a significant amount of BOF Steel Slag: Critical Assessment and Integrated Approach for Utilization2019年5月22日 this leads to a tremendous waste of metal resources If the metal in steel slag that is 61 Introduction 307 Table 61 Statistics table of steel slag in China, The “Eleventh Fiveyear Plan” development plan points out that the comprehen Table 63 presents the utilization of steel slag in China and foreign prehensive Utilization Technology of Steel Slagonly about 10% of steel slag is used as resources, and the other 90% is stored in open storage or landfill 2 Rreview of steel slag resource utilization technology 21 Traditional resource utilization technology of steel slag The traditional way of steel slag recycling mainly includes the following aspects[68] (1) Heat stewing processReview of Resource Utilization Technology of Steel Slag

2FD{P}PC]854]XQ.jpg)

Overview of Steel Slag Application and Utilization

different application and utilization of steel slag are briefly described in the following section The main byproducts produced during iron and crude steel production are slags (90%), dusts and sledges that reported for three types of furnaces Figure 1: Slag as a byproduct from steel making furnace [2] 2 Applications of Steel slag2024年10月15日 Steel slag is a byproduct generated during the steelmaking process, constituting 15 to 20 % of crude steel production [3]Steel slag possesses significant sensible heat, carbon sequestration potential, and resource utilization capacity, all of which are crucial for reducing CO 2 emissions in the steel industry Given its high heat content in the molten state, The positive contributions of steel slag in reducing carbon 2024年6月12日 The highvalue utilization of blast furnace slag (BFS) and steel slag (SS) as a valuable resource in the field of carbon reduction represents a green revolution, and also is an indispensable path toward breaking through resource and environmental constraints and achieving highquality, sustainable development through solid waste utilization in the steel Recycling of iron and steel slag for carbon reduction and low 2023年2月15日 Steel converter slag (SCS) is the waste slag produced in the steelmaking process According to the statistics, 150∼200 kg of steel slag is produced with each ton of steel [26] As the world's largest steel producer, China produces a large amount of SCS every year, but its comprehensive utilization rate is lower than 30 %Resource utilization of steel converter slag: Efficient

(PDF) Overview of Steel Slag Application and

2016年1月1日 LinzDonawitz (LD) slag, a byproduct of steel manufacturing process, is rich in iron oxide, calcium oxide, silica, various macro, and micronutrients as well as varying degrees of heavy metals Steel slag is a kind of alkaline solid waste produced in the process of steel production In China, the annual steel slag production is very large but the utilization rate is only 20% Therefore, technologies disposing steel slag effectively need to be developed In traditional resource utilization technology, steel slag is used in sintering flux, road construction, cement and Review of Resource Utilization Technology of Steel Slag and 2016年8月31日 Current total productions of steel slag in India, are around 12 million tonnes per annum (Indian Minerals Yearbook, May 2016), which is far behind the developed countriesSteel Slag Utilization — Overview in Indian Perspective2019年6月28日 Steel slag production quantity is huge in China With the increasingly strict environmental protection requirements in China, the modification of steel slag to make steel slag resource utilization becomes an urgent task This paper briefly described the characteristics of the steel slag and the problems of resource utilization The research progress of steel slag RESEARCH PROGRESS AND PROSPECT OF STEEL

.jpg)

Recycling of ironmaking and steelmaking slags in Japan and

The mass production of steel is inevitably accompanied by large quantities of slags The treatment of ironmaking and steelmaking slags is a great challenge in the sustainable development of the steel industry Japan and China are two major steel producing countries that have placed a large emphasis on developing new technologies to decrease slag emission or promote slag 3 Utilization of absorbent materials for waste water treatment In recent years, more and more researchers pay attention to the application of steel slag in waste water treatmentAn overview of resource utilization of steel slag as 2017年10月25日 This paper presented a consistent analysis of steel slag resource usage as waste water absorbent materials, as well as the important improved technique and challenging issues for steel slag as (PDF) Overview of Steel Slag Application and Utilization2020年1月1日 With the rapid development of the steel industry, the accumulation of steel slag increases year by year, occupying a large amount of farm land and leading the problem of environmental pollution (PDF) An overview of resource utilization of steel slag as

.jpg)

Research on the Properties of Steel Slag with Different

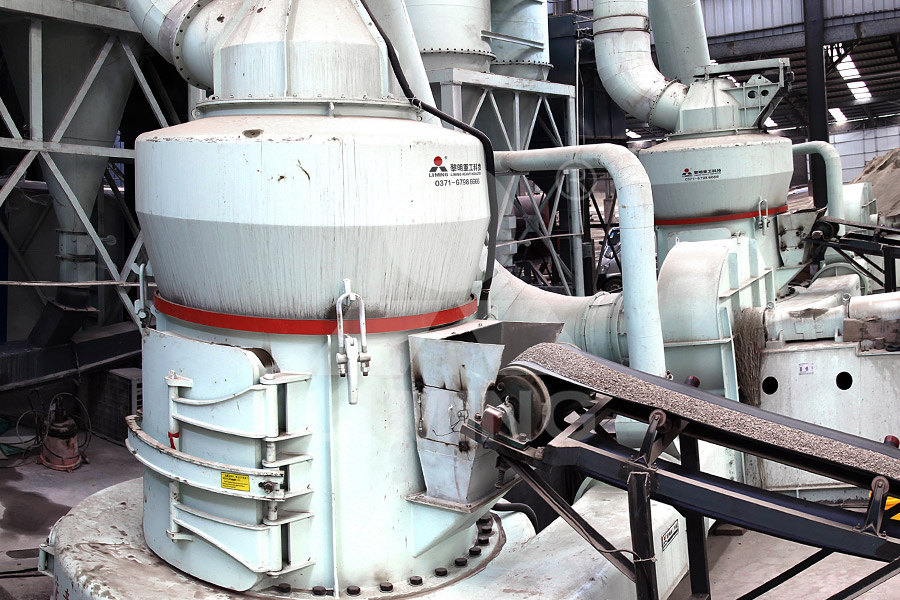

2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water 2014年7月8日 3 Advanced technology and equipment of steel slag comprehensive utilization 3 1 Heat pyrolytic pulverization technology of steel slag Since the eighties of last century, the iron and steel enterprises have adopted hot pouring processing to treat teel s slag Steel slag are abandoned after recycling bulk scrap steelThe Present Situation and Development of Iron and Steel 2024年4月28日 Steel slag is a byproduct of the steel industry and usually contains a high amount of fCaO and fMgO, which will result in serious soundness problems once used as a binding material and/or aggregates To A Review on the Carbonation of Steel Slag: 2021年1月11日 The resource utilization of steel slag is not only conducive to resource conservation, but also conducive to sustainable production and environmental protection In this paper, the common ways of resource utilization of steel slag in construction, agriculture, industry, and catalysis are reviewed Steel slag as a solid waste with great developmentSustainable Utilization of Steel Slag from Traditional

Use of steel slag as sustainable construction materials: A review

2021年10月1日 Steel slag is a solid waste derived from the steelmaking process, which accounts for approximately 15% of the total crude steel output (Furlani et al, 2010; Pang et al, 2016)By 2016, approximately 832 million tons of steel were produced in China with an annual output of more than 100 million tons (Hasanbeigi et al, 2016), which exceeded half of the total The various applications of steel slag indicate that it can be reused and utilized rather than being disposed to the landfill This paper presents a review of its applications and utilizationOverview of Steel Slag Application and Utilization2012年12月31日 The current utilization rate of steel slag is only 22% in china, far behind the developed countries At present, the amount of slag deposited in storage yard adds up to 30Mt, leading to the (PDF) An Overview of Utilization of Steel Slag ResearchGate2024年10月1日 Qiu et al [8] carried out experiments of sodium hydroxide steel slag double alkali method of sintered flue gas desulfurization in a bubbling reactor, and found that the desulfurization rate could be maintained above 80 % for a long time under the optimal conditions, and the sodium hydroxide steel slag double alkali method of Utilization of steel slag in air pollution and greenhouse gas

Review Accelerated carbonation of steel slag: A review of

2024年1月12日 Steel slag is a byproduct of the steel production process, accounting for approximately 15% of the whole crude steel output [1]The accumulation of untreated steel slag not only occupies a significant amount of land but also leads to the leaching of heavy metal ions (such as vanadium, chromium, arsenic, lead, cadmium), polluting surrounding water sources 2024年10月15日 Steel slag is a byproduct generated during the steelmaking process, constituting 15 to 20 % of crude steel production [3] Steel slag possesses significant sensible heat, carbon sequestration potential, and resource utilization capacity, all of which are crucial for reducing CO 2 emissions in the steel industry Given its high heat content in the molten state, The positive contributions of steel slag in reducing carbon 2021年9月1日 Steel slag is a solid waste product generated during the carbonation stage of steelmaking It has high levels of heavy metals and substantial amounts of free calcium and magnesium oxide, making it Environmental benefit assessment of steel slag utilization 2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, Current Development of Slag Valorisation in China

.jpg)

CO2 Mineralization and Utilization using Steel

2017年12月8日 where D CO2 (m 2 /s) is the diffusivity of CO 2 species which is a function of temperature 17, δ is the film thickness (m), and k CO2 is the mass transfer coefficient (m/s) According to our Steel slag is a byproduct of steelmaking process The producing of steel slag in China is proximately 100 million tons, but the utilization ratio of comprehensive resources is the lower This paper described the production and composition characteristics of steel slag, reviewed current situation and progress of resource utilization and stabilization of steel slagThe Research Progress of Steel Slag Utilization and 2012年1月1日 The current utilization rate of steel slag is only 22% in china, far behind the developed countries :14 [5] Motz H, Geiseler J Products of steel slags an opportunity to save natural resources Waste Manage 2001; 21:285293 [6] Wu XQ, Zhu H, Hou XK, Li HS Encosteel: steel for sustainable development International Iron and Steel An Overview of Utilization of Steel Slag ScienceDirect2021年9月24日 During steel production, the impurities in the hot metal react with the fluxes forming the steel slag Chemical constituents of this steel slag (SS) are relevant to iron/steelmaking or blended cement manufacture Harmful impurities present in it, however, limit its recycling to these applications Japan, Europe, and the US consume a significant amount of BOF Steel Slag: Critical Assessment and Integrated Approach for Utilization

.jpg)

Comprehensive Utilization Technology of Steel Slag

2019年5月22日 this leads to a tremendous waste of metal resources If the metal in steel slag that is 61 Introduction 307 Table 61 Statistics table of steel slag in China, The “Eleventh Fiveyear Plan” development plan points out that the comprehen Table 63 presents the utilization of steel slag in China and foreign countriesonly about 10% of steel slag is used as resources, and the other 90% is stored in open storage or landfill 2 Rreview of steel slag resource utilization technology 21 Traditional resource utilization technology of steel slag The traditional way of steel slag recycling mainly includes the following aspects[68] (1) Heat stewing processReview of Resource Utilization Technology of Steel Slag different application and utilization of steel slag are briefly described in the following section The main byproducts produced during iron and crude steel production are slags (90%), dusts and sledges that reported for three types of furnaces Figure 1: Slag as a byproduct from steel making furnace [2] 2 Applications of Steel slagOverview of Steel Slag Application and Utilization2024年10月15日 Steel slag is a byproduct generated during the steelmaking process, constituting 15 to 20 % of crude steel production [3]Steel slag possesses significant sensible heat, carbon sequestration potential, and resource utilization capacity, all of which are crucial for reducing CO 2 emissions in the steel industry Given its high heat content in the molten state, The positive contributions of steel slag in reducing carbon

Recycling of iron and steel slag for carbon reduction and low

2024年6月12日 The highvalue utilization of blast furnace slag (BFS) and steel slag (SS) as a valuable resource in the field of carbon reduction represents a green revolution, and also is an indispensable path toward breaking through resource and environmental constraints and achieving highquality, sustainable development through solid waste utilization in the steel