How to process clay into production

.jpg)

How to Process Natural Clay 10 Easy Steps

2024年2月3日 The process of turning raw, earthy clay into a workable and moldable substance involves a series of essential steps, from harvesting and refining to preparing the clay for artistic endeavors Understanding the 2024年3月29日 When we’re ready to make a batch of clay, we chip off hunks of it, weigh out the proper amount, and incorporate it into our recipe Since we use the wild clay at 25 percent, it How to Process Clay for Pottery Tips for Digging Clay by 2015年9月10日 Clays usually are transported by truck from the mine to the processing plants, many of which are located at or near the mine For most applications, clays are processed by 1125 Clay Processing US EPA2020年7月13日 To process a starting clay, subtracting or adding material to it, means choosing possible alternatives preferentially evaluated on the basis of the stages of manufacture process and not necessarily related to vessel use Ceramic technology: how to recognize clay

Finding and Processing Your Own Natural Clay

In this instructable, I will show you how to find your own clay, straight from the ground and refine it like it was done since prehistoric times To put it in simple terms, clay is essentially just small particles of stone It can be put into three Mix 1 ½ ounces of bread yeast in 2 cups of warm sugar water to activate the yeast and add it to the clay bucket Mix it together with an electric drill and a paddle mixer This also increases the plasticity Cover the bucket with a lid In the Studio: Processing Natural Clays2020年7月13日 Optical microscopy and electron microscopy provide the main contribution to identifying most of the processing practices on the clay, whereas bulk methods provideCeramic technology: how to recognize clay 2020年7月8日 The production process of pieces with red ceramic comprises several steps that can be divided into four major stages, namely, extraction and preparation of raw materials, Clay Ceramic Materials: From Fundamentals and Manufacturing

.jpg)

Tips for Foraging and Processing Your Own Clay

Ready to try out wild clays in your own work? Here are some tips for getting started with foraging for local materials then processing and testing them Start simple: Backyards of friends and family may have limited geologic diversity 2 天之前 Manufacturers use different kinds of clay to make various ceramics The process is almost the same for all ceramics First, the clay is made flexible with water and some other chemicals Then they are given the desired shape How Are Ceramics Made? (Step By Step Process) 2023年9月28日 Step 7: Cut and Wedge Clay Once the clay has reached a suitable consistency, carefully cut it into manageable pieces using a wire cutter Begin the wedging process by folding and compressing the clay to remove air How to Recycle Clay Explained in 10 Easy Steps 2008年8月17日 times the clay was dug, the bricks were made and the kilns set or drawn by manual labour with help from animal power About 100 years ago, the first effective machines for brick production appeared, and the trend towards mechanisation of clay winning, making and handling operations has continued at an increasing pace to the present dayPart 1 CLAY BRICK MANUFACTURE

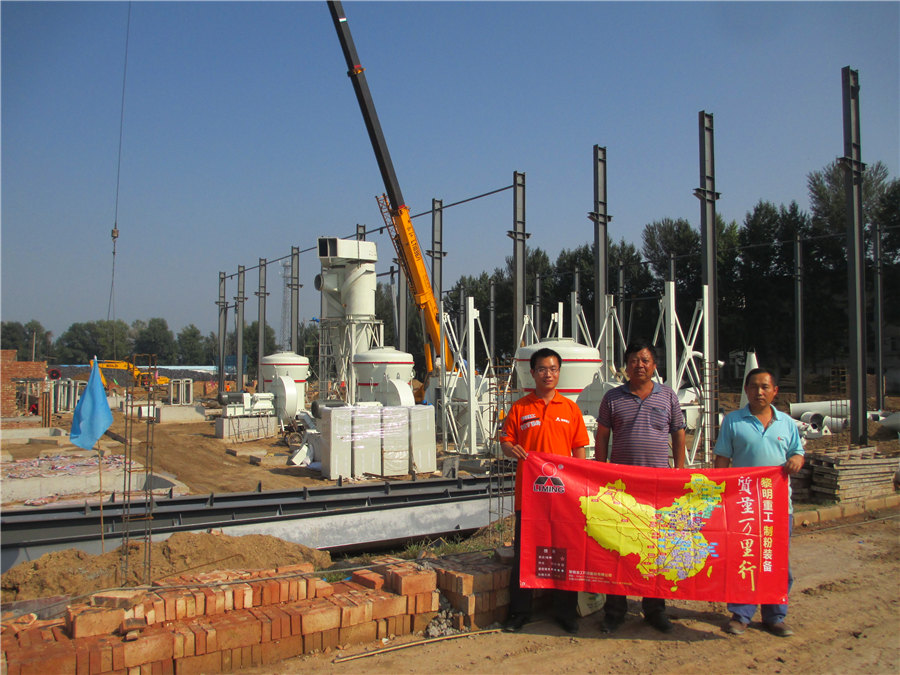

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年5月27日 Bentonite clay production process features ore mining, sodium activation (if required), drying, milling, classifying, pelleting, etc Grinding and drying are key steps Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodiumbased bentonite Step 4: Grind the sodium bentonite to 200 mesh with a Raymond mill Step 5 Now, the rectangular strips coming out the opening are cut by wires to get required thickness of brick So, these are also called wire cut bricks Now these raw bricks are ready for the drying process Dry clay machines Dry clay machines are more time saving machines We can put the blended clay into these machines directly without temperingManufacturing of Bricks for Masonry Construction – Methods and Process2024年1月25日 Cooling and Unloading the Clay Bricks Once the firing process is complete, the clay bricks are then left to cool down Once they are cold enough, they are unloaded and stacked into piles ready for the distribution process At this stage, the manufacturers will also carry out a quality inspection to ensure all of the fired bricks are up to How It’s Made: Clay Bricks Masonry Magazine2024年11月11日 The wooden casing of a pencil is usually made from cedar or other softwoods The wood is cut into thin panels and shaped into a cylindrical form 2 Graphite and Clay The lead of a pencil is composed of graphite and clay, both naturaloccurring and malleable minerals The graphite is mixed with clay to make it stronger and more durable 3 PaintDetailed Guide on How Pencils are Made: The Production Process

.jpg)

The Brick Making Process How Bricks Are Made Block

When you look into creating bricks, it's pivotal to know that various production methods demand specific types of equipment to achieve the desired quality and efficiency The extrusion method, which produces the majority of bricks, utilizes machinery that thoroughly mixes clay or shale with water before forcing the mixture through a die to form 2023年11月2日 Pottery clay is made through a manufacturing process that involves excavating clay soil from the earth's surface, breaking it down into smaller particles, Menu; for; reaching high temperatures and transforming the clay into durable ceramic objects Porcelain is commonly used in the production of highend dinnerware, figurines, How Is Pottery Clay Made: From Raw Materials to Finished 2023年1月31日 Mining, processing, shaping, drying, and firing are the steps in the production of dry clay Mining And Processing Clay extraction and processing: Clay is normally removed from the earth by openpit mining, and it is subsequently processed into a fine powder Clay is extracted from the earth, often by openpit mining, and processed by being Molding and Shaping: A Guide to the Various Stages of Clay2024年2月25日 Integrating Clay into Lesson Plans: Clay can be seamlessly integrated into various subjects: Art: Obvious but essential, for teaching sculpture, Start by kneading the clay to make it pliable This process, called ‘wedging’, Creating with Clay in Your Classroom, HowTo

.jpg)

Recent advances in lithium extraction from lithiumbearing clay

2023年3月1日 The current common process for producing LiOH is through the indirect reaction between Li 2 CO 3 and Ca(OH) 2 By contrast, the direct production of LiOH from Libearing clay minerals may be a more economically viable method (Tadesse et al, 2019) In this case, the treatment of lepidolite using hydroxide seems to be a feasible method since 2018年10月25日 Here's my full answer for the process diagram task below The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes IELTS Writing Task 1: process diagram answerGraphite, clay, wood, rubber, and metal combine to create pencils The lead is created by combining graphite and clay, and it is then carefully carved and put together into wooden panels To ensure the production of highquality pencils, the manufacturing process requires precise stages such as glueing, stacking, cutting, and quality checkingThe Best StepbyStep Guide To The Pencil Manufacturing Process 2020年7月13日 The manufacturing sequences of ceramic production comprise the selection, preparation and manipulation of clay by the eventual addition of various types of temper to make the material workable Ceramic technology: how to recognize clay processing

How to Harvest Clay 10 Easy Methods (2024) Potteryhow

2024年1月18日 However, they can also be useful for harvesting clay on a smaller scale In this section, we will discuss the basics of how to use a pug mill to harvest clay 9 Dry Processing Dry processing involves drying out the clay and then grinding it into a fine powder2024年11月16日 Stage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller How Cement is Made Cement Manufacturing Process2020年5月26日 Wet processing of clay Outside of dry processing – crushing, sieving and pulverizing into a powder – you can also choose to wet process your clay This is also known as the wet extraction method This is the more timeconsuming approach, though it is much easier on your muscles Let the clay and the water do the work instead of youHow To Harvest Clay For Pottery Natural Building Rural 2021年5月1日 Process flow diagram for the processing of lithium slags from lithiumthermal production of REE, adapted from Kulifeev et al (2006) Industrial schemes for the complex processing of brines usually require sources with lithium content 300–500 mg/L and based mainly on evaporation with sequential crystallization ( Garret and Laborde, 1981 )Processing of lithium ores: Industrial technologies and case

The Firing Process for Making Ceramics The Spruce Crafts

2019年10月26日 Firing is the process of bringing clay and glazes up to a high temperature The final aim is to heat the object to the point that the clay and glazes are "mature"—that is, that they have reached their optimal level of melting To the human eye, pots and other clay objects do not look melted; the melting that occurs is on the molecular level2019年11月21日 This process is called wedging, and I will say a bit more about how to wedge your clay later 4) Air Drying Here’s what you can do if your clay is too sticky Clay dries out quite quickly when it is left in the open air Take How to Prepare Clay for Pottery Pottery Tips by 2020年8月21日 Lithium production from clay sources is expected to become commercially viable, though perhaps not until 2022 Lithium is a metal commonly used in batteries like the rechargeable ones found in laptops, cellphones, and Commercial Lithium Production and Mining of 2023年5月9日 • Brick is made of clay or shale formed, dried and fired into manufacturing process These variations are addressed by a durable ceramic product ASTM standards • There are three ways to form the shape and size of a • The method used to form a brick has a major impact on brick: extruded (stiff mud), molded (soft mud) and dry its textureManufacturing of Brick Brick Industry Association

The Six Basic Stages Of Clay And Ceramic Production Explained

2022年9月29日 Here are the six basic stages of clay production explained: Slip Clay Stage Of Clay Slip clay is clay with added water to make it a liquid or a paste This clay is often used to pour into a mold so that the mold can dry The clay used for a mold can be known as slip casting, as the clay is poured into the mold to mold a shape2023年3月28日 StepbyStep Process of Slipcasting Let’s dive into the slipcasting process and explore how you can create your own ceramic art 1 Prepare Your Model The first step is to create a model of the object you want to slipcast This can be sculpted from clay or made from another material, such as wood or plaster The model serves as the basis The Beauty of Slipcasting: A StepbyStep Guide to Transforming Clay Brickmaking improvements have continued into the twentieth century Improvements include rendering brick shape absolutely uniform, lessening weight, and speeding up the firing process For example, modern bricks are seldom solid Some are pressed into shape, which leaves a frog, or depression, on their top surface Others are extruded with How brick is made material, production process, 2023年8月25日 Summary: Introduction This experimental project aimed to reproduce the Hellenistic (fourththird century BC) Greek pottery production process The project was conducted by the authors, Francesca Tomei, PhD graduate in Archaeology at the University of Liverpool, and Juan Ignacio Jimenez Rivero, a ceramist specializing in replicating ancient pottery technology, Experimenting with the Ancient Greek Pottery Production Process

.jpg)

Your Guide to the 6 Stages of Clay Pottery Beginners

2023年11月18日 In this form, clay can be recycled If you mess up a piece, don’t fret! You can take one of two steps: Form a “rainbow” with your wet clay; Spread it on a piece of plaster to dry a bit Once some of the moisture is out, you can rewedge and try again! Shield your creations from premature cracks by ensuring a slow, moistureregulated 2023年3月2日 The final step in processing clay is forming it into desired shapes This can be done using a variety of techniques, such as handbuilding, throwing on a potter’s wheel, or using molds Handbuilding is the simplest of these techniques and involves using your hands to shape clay into desired formsHow to Process Clay Explaine in 8 Effective Steps 2024🧱Learn the stepbystep process for crafting clay bricks! Find tips on drying, firing, and preventing cracks, plus discover the key materials and techniques for quality bricks🏗️ Place the clay mixture into these molds and press it down firmly This step is important to remove any air bubbles, which can weaken the brick's structure How to Make Clay Bricks: The Ultimate Guide to Brick 2 天之前 Manufacturers use different kinds of clay to make various ceramics The process is almost the same for all ceramics First, the clay is made flexible with water and some other chemicals Then they are given the desired shape How Are Ceramics Made? (Step By Step Process)

.jpg)

How to Recycle Clay Explained in 10 Easy Steps

2023年9月28日 Step 7: Cut and Wedge Clay Once the clay has reached a suitable consistency, carefully cut it into manageable pieces using a wire cutter Begin the wedging process by folding and compressing the clay to remove air 2008年8月17日 times the clay was dug, the bricks were made and the kilns set or drawn by manual labour with help from animal power About 100 years ago, the first effective machines for brick production appeared, and the trend towards mechanisation of clay winning, making and handling operations has continued at an increasing pace to the present dayPart 1 CLAY BRICK MANUFACTURE2023年5月27日 Bentonite clay production process features ore mining, sodium activation (if required), drying, milling, classifying, pelleting, etc Grinding and drying are key steps Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodiumbased bentonite Step 4: Grind the sodium bentonite to 200 mesh with a Raymond mill Step 5 How to Dry, Grind and Granulate Your Bentonite Clay?Now, the rectangular strips coming out the opening are cut by wires to get required thickness of brick So, these are also called wire cut bricks Now these raw bricks are ready for the drying process Dry clay machines Dry clay machines are more time saving machines We can put the blended clay into these machines directly without temperingManufacturing of Bricks for Masonry Construction – Methods and Process

How It’s Made: Clay Bricks Masonry Magazine

2024年1月25日 Cooling and Unloading the Clay Bricks Once the firing process is complete, the clay bricks are then left to cool down Once they are cold enough, they are unloaded and stacked into piles ready for the distribution process At this stage, the manufacturers will also carry out a quality inspection to ensure all of the fired bricks are up to 2024年11月11日 The wooden casing of a pencil is usually made from cedar or other softwoods The wood is cut into thin panels and shaped into a cylindrical form 2 Graphite and Clay The lead of a pencil is composed of graphite and clay, both naturaloccurring and malleable minerals The graphite is mixed with clay to make it stronger and more durable 3 PaintDetailed Guide on How Pencils are Made: The Production Process When you look into creating bricks, it's pivotal to know that various production methods demand specific types of equipment to achieve the desired quality and efficiency The extrusion method, which produces the majority of bricks, utilizes machinery that thoroughly mixes clay or shale with water before forcing the mixture through a die to form The Brick Making Process How Bricks Are Made Block 2023年11月2日 Pottery clay is made through a manufacturing process that involves excavating clay soil from the earth's surface, breaking it down into smaller particles, Menu; for; reaching high temperatures and transforming the clay into durable ceramic objects Porcelain is commonly used in the production of highend dinnerware, figurines, How Is Pottery Clay Made: From Raw Materials to Finished

.jpg)

Molding and Shaping: A Guide to the Various Stages of Clay

2023年1月31日 Mining, processing, shaping, drying, and firing are the steps in the production of dry clay Mining And Processing Clay extraction and processing: Clay is normally removed from the earth by openpit mining, and it is subsequently processed into a fine powder Clay is extracted from the earth, often by openpit mining, and processed by being