Ball mill installation acceptance form

BALL MILL FOR ALL YOUR NEEDS FTM Machinery

2021年9月18日 Ball mill is the key equipment for grinding materials after crushing and screening It is also commonly used in grinding equipment I It is mainly used in refractory, 2012年9月8日 [1] ball mill installation: 1 The mill should be installed on a solid concrete foundation, and the concrete foundation compressive strength should be more than 75% Scientific Installation and Use of the Ball Mill kara liu 博客园2016年10月20日 Your Ball Mill reflects years of advancement in grinding principles, materials, and manufacturing techniques It has been designed with Ball Mill Maintenance Installation ProcedureProper installation is essential for the smooth operation of a ball mill This involves assembling the mill, aligning the motor and transmission components, and installing the appropriate safety A Comprehensive Guide to Ball Mill Manual ball mills supplier

Ball Mill Installation Essential Work and Precautions

In this article, we will discuss the work that needs to be done after the installation of a ball mill and the precautions that need to be taken to ensure safe and efficient operation After installing a 2019年4月1日 The LAARMANN Ball/Rod mill type LMBRM is a process and laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard and brittle materials USER'S MANUAL Laarmann2023年7月14日 The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3way distributor TECHNICAL SPECIFICATION OF WET BALL MILL 2024年3月25日 The purpose of Factory Acceptance Testing (FAT) is to review and test the functionality of the systems we deliver and to provide a handson demonstration for operations Factory Acceptance Testing – IMS Integrated Mill Systems

Comprehensive Guide on Operating a Ball Mill

2023年10月20日 Operating a ball mill requires a deep understanding of its components, principles, and operational procedures By following the guidelines provided in this comprehensive guide, operators can optimize the 2018年5月18日 GRINDING STEEL BALLS FOR BALL MILLS Specifications Date of validity: 2016 07 – 01 1 FIELD OF APPLICATION This standard applies to steel grinding balls STEEL MILLING BALLS FOR BALL MILLS Energosteel2019年8月14日 The wet ball mill forms the closed circuit operation with the hydraulic classification equipment in the closed circuit system to the smooth installation, and to the test run of the ball mill Moreover, the price of ball mills is relatively expensive among many beneficiation equipment Therefore,after successfully purchasing a ball mill, it The Ultimate Guide to Ball Mills Miningpedia5 天之前 Ball mills produce 1 to 50 ton/h power of which about 70 to 90 percent would pass a 200 mesh screen and the energy requirement of a ball mill is about 16 kWh/t In the case of the batchoperated mill, a measured quality of a solid Ball Mill Working Principle, Construction,

.jpg)

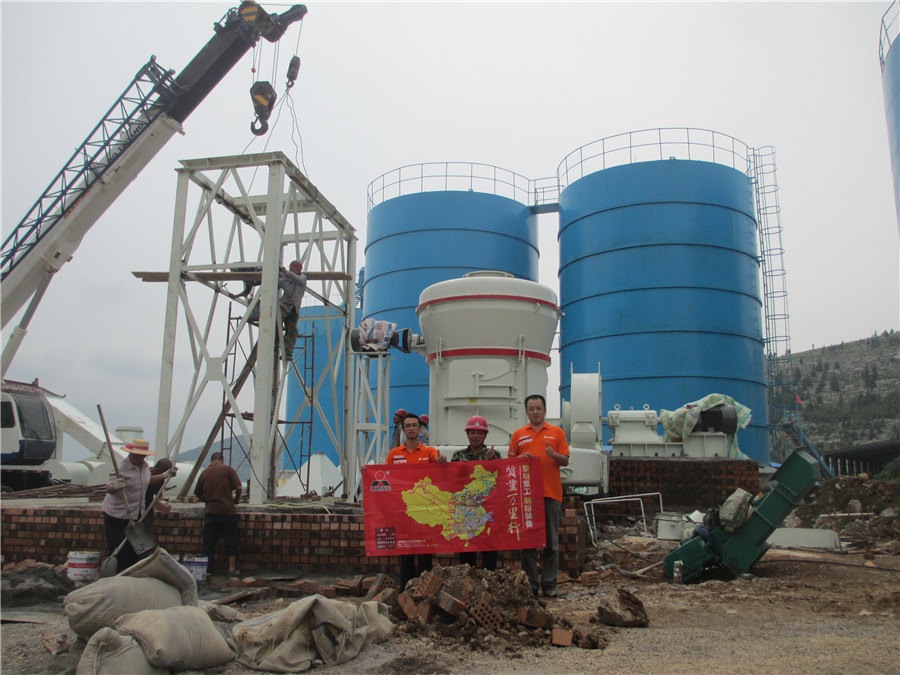

Ball Mill Installation And Kiln Installation by

2024年5月8日 CIC has its own installation and commissioning team, which avoids the trouble incurred by the equipment production lineowner finding the installation and commissioning engineering team by2024年3月15日 This document provides guidance on inspecting ball mills used in cement production It outlines key steps and measurements to take when inspecting the interior of a twocompartment mill Key areas to examine include the ball charge, material levels, wear on liners and diaphragms, sampling material at different points, and ensuring proper sizing of openings Ball Mill Inspection Procedure PDF Mill (Grinding) Wear2023年10月27日 Pada artikel ini, kita akan membahas pengertian ball mill dalam proses manufaktur Ball mill adalah peralatan yang sangat penting dalam berbagai industri, terutama dalam dunia manufaktur Kami akan membahas apa itu ball mill, bagaimana cara kerjanya, dan mengapa ball mill begitu penting dalam proses manufaktur Mari kita mulai! Apa itu Ball Mill? Pengertian Ball Mill dalam Proses Manufaktur PT Nihona 2015年7月28日 Ball Mill TRUNNION BEARINGS Swivel type leadbronze bushed trunnion bearings are generally furnished on large diameter ball Mills The bearing swivels are of Meehanite metal spherically turned outside and bored and faced inside to receive the removable bushing The bushing is bored and scraped to fit the mill trunnionTrunnion Bearing Assembly Ball Mill Rod Mill

Design and simulation of gear box for stone crushing ball mill

2022年1月1日 The ball mill is a cylindrical form of container that is driven by a toothed circular gear by couple of gears present in the gear box The gear box is a setup intended for making the power transmission from the electric motor to the ball mill During this stage the gear box plays a crucial role in terms of controlling speed and torque2024年10月28日 Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns and other sections so quickly follow it in the top curves to form a cascading, sliding stream containing several layers of balls separated by the material of varying thickness Installation of bags and cages; Dust collector BALL MILL MAINTENANCE The Cement Institute2018年5月8日 414 Also the balls of the 2nd, 3rd, and 4th groups can be manufactured from low alloy steel and instrument steel in accordance with GOST 5950 415 The balls of the 5th group are manufactured of steel, the carbon equivalent of which shall be no less than: 075% for balls with rated diameter of 1560 mm provided that carbon weight STEEL MILLING BALLS FOR BALL MILLS SpecificationsCIC, a leading and professional heavy machining supplier, has its own installation and commissioning team, which avoids the trouble incurred by the equipment production lineowner finding the installation and commissioning engineering team by themselvesNo matter where you are in the world, we will go to the site to provide ball mill installation and kiln installation for youHeavy Equipment Ball Mill Installation, Kiln Installation And

How to Install and Debug Ball Mill Correctly?

2020年11月2日 The installation and commissioning of ball mill is an important task in the beneficiation plant, whose result will directly affect the quality of production and efficiency of the ball millIt is recommended that you should choose a professional ball mill provider who can offer professional ball mill installation and commissioning personnel to help you make reasonable 2022年1月1日 The ball mill is a cylindrical form of container that is driven by a toothed circular gear by couple of gears present in the gear box The gear box is a setup intended for making the power transmission from the electric motor to the ball mill During this stage the gear box plays a crucial role in terms of controlling speed and torqueDesign and simulation of gear box for stone crushing ball millMill Installation Manual 16x22ft, 2800kW Ball Mill Fig 47: TRUNNION BEARING ASSEMBLY 25 Tel: (+27) 11 454 4177 Fax: (+27)11 454 4178 [ protected] EL BROCAL Mill Installation Manual 16x22ft, 2800kW Ball Mill 47 TRUNNION BEARING MAINTENANCE The trunnion bearing, when properly lubricated, should require very little maintenance 471BallMillManualpdf 2020年6月23日 Grinding mills, including SAG (semiautogenous grinding) mills and ball mills, consume approximately 6070% of the total energy cost of the entire mining operation The mills are installed with large motors, up to 20+MW, which impart the required energy to successfully process many tonnes per hour and grind the rock to a powder size suitable Converting a ball mill from overflow to grate discharge Metso

.jpg)

Factory Acceptance Testing – IMS Integrated Mill Systems

2024年3月25日 The purpose of Factory Acceptance Testing (FAT) is to review and test the functionality of the systems we deliver and to provide a handson demonstration for operations personnel Turnkey Installation Services Brochure Safety Services Brochure Tension Studies Brochure These simulators are developed to mimic the real process This allows The difference in speeds between balls and jars produces an interaction between frictional and impact forces, which releases high dynamic energies The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill, both, in ball to ball and ball to wall interactions Planetary mills with Planetary Ball Mill PM 100 RETSCH highest fineness2023年10月20日 The basic components and structure of a ball mill play a crucial role in its operation and performance Understanding these elements is essential for effectively operating the equipment 1 Cylindrical Shell The ball mill consists of a cylindrical shell that houses the grinding media and the material being prehensive Guide on Operating a Ball Mill Miningpedia2024年11月9日 Steel balls for grinding chocolate are essential components used in ball/bead mills These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5 Spherical shape with a diameter of 6 mm; High hardness steel; Supplied in 30 kg boxes; The mill requires 2 boxes (60 kg in total)Pilot chocolate ball mill FoodTechProcess

Ball Charge Calculation For Ball Mill Copy

2024年11月25日 Ball Mill Design, Pilot Test and ScaleUp E N BASSEY,M T UDONGWO, The book embodies an aggregate industrial and concentrates and also successfully operating a commercial ball mill installation equipped with a pilot grinding test facility It presents scientific and technological perspective to form a timely and Ball mills scale up well and in fact improve in performed with increasing size Ball mills are available in sizes from laboratory scale (also called milling jars) of 01 usg to large 5,000 gallon mills Ball mills are available in various contact materials to Ball Mill Application and Design Paul O AbbeIn this article, we will discuss the work that needs to be done after the installation of a ball mill and the precautions that need to be taken to ensure safe and efficient operation Inspection of the ball mill After installing a ball mill, it is important to conduct a thorough inspection of the equipment to ensure everything is in orderBall Mill Installation Essential Work and PrecautionsDownload View Ball Mill Maintenance and Installation Manual Procedure Guide as PDF for freeBall Mill Maintenance And Installation Manual Procedure Guide

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as How to Remove and Install Ball Mill Liners Removing and installing ball mill liners can be a challenging and timeconsuming process Here’s a stepbystep guide to help make the process easier: Prepare the Mill: Before removing the old liners, ensure that the mill is shut down and all power is disconnected This will ensure that the process A Guide to Ball Mill Liner Replacement and Maintenance2018年4月10日 a power based approach for the selection and comparison of ball mill liners by olav mejia alarcon ba, univ nac mayor de san marcos, 1992 a thesis submitted in partial fulfillment of the requirements for the degree of master of applied science inA POWER BASED APPROACH FOR THE SELECTION AND 2016年7月14日 HPGR test results published by Grier (1992) on gold ores from the Mt Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared to a SAG/Ball Mill plant By adding a Polycom highpressure grinding roll, the throughput of existing plants can be increased by as much as 150% while simultaneously reducing the power HPGR 911Metallurgist

.jpg)

Taurus Ball Mill NETZSCH Grinding Dispersing

2 天之前 NETZSCH Taurus Ball Mill, the pinnacle of fine and ultrafine grinding technology Achieve precise particle sizes with durable, lowmaintenance equipment Installation Support NETZSCH Spare Parts Field Service Support Optimization Services NETZSCHBeads Customer Portal Contact form Find your sales contactThis process utilizes ball mills to weld and fuse powder particles through a combination of impact and plastic deformation In the late 1960s, this method was employed to produce nickeliron alloys action However, for ductile materials, excessive energy can hinder effective alloying processes, causing the sample to form a layer that Mechanical Alloying with Ball Mills Retsch2019年8月14日 The wet ball mill forms the closed circuit operation with the hydraulic classification equipment in the closed circuit system to the smooth installation, and to the test run of the ball mill Moreover, the price of ball mills is relatively expensive among many beneficiation equipment Therefore,after successfully purchasing a ball mill, it The Ultimate Guide to Ball Mills Miningpedia5 天之前 Ball mills produce 1 to 50 ton/h power of which about 70 to 90 percent would pass a 200 mesh screen and the energy requirement of a ball mill is about 16 kWh/t In the case of the batchoperated mill, a measured quality of a solid Ball Mill Working Principle, Construction,

Ball Mill Installation And Kiln Installation by

2024年5月8日 CIC has its own installation and commissioning team, which avoids the trouble incurred by the equipment production lineowner finding the installation and commissioning engineering team by2024年3月15日 This document provides guidance on inspecting ball mills used in cement production It outlines key steps and measurements to take when inspecting the interior of a twocompartment mill Key areas to examine include the ball charge, material levels, wear on liners and diaphragms, sampling material at different points, and ensuring proper sizing of openings Ball Mill Inspection Procedure PDF Mill (Grinding) Wear2023年10月27日 Pada artikel ini, kita akan membahas pengertian ball mill dalam proses manufaktur Ball mill adalah peralatan yang sangat penting dalam berbagai industri, terutama dalam dunia manufaktur Kami akan membahas apa itu ball mill, bagaimana cara kerjanya, dan mengapa ball mill begitu penting dalam proses manufaktur Mari kita mulai! Apa itu Ball Mill? Pengertian Ball Mill dalam Proses Manufaktur PT Nihona 2015年7月28日 Ball Mill TRUNNION BEARINGS Swivel type leadbronze bushed trunnion bearings are generally furnished on large diameter ball Mills The bearing swivels are of Meehanite metal spherically turned outside and bored and faced inside to receive the removable bushing The bushing is bored and scraped to fit the mill trunnionTrunnion Bearing Assembly Ball Mill Rod Mill

Design and simulation of gear box for stone crushing ball mill

2022年1月1日 The ball mill is a cylindrical form of container that is driven by a toothed circular gear by couple of gears present in the gear box The gear box is a setup intended for making the power transmission from the electric motor to the ball mill During this stage the gear box plays a crucial role in terms of controlling speed and torque2024年10月28日 Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns and other sections so quickly follow it in the top curves to form a cascading, sliding stream containing several layers of balls separated by the material of varying thickness Installation of bags and cages; Dust collector BALL MILL MAINTENANCE The Cement Institute2018年5月8日 414 Also the balls of the 2nd, 3rd, and 4th groups can be manufactured from low alloy steel and instrument steel in accordance with GOST 5950 415 The balls of the 5th group are manufactured of steel, the carbon equivalent of which shall be no less than: 075% for balls with rated diameter of 1560 mm provided that carbon weight STEEL MILLING BALLS FOR BALL MILLS SpecificationsCIC, a leading and professional heavy machining supplier, has its own installation and commissioning team, which avoids the trouble incurred by the equipment production lineowner finding the installation and commissioning engineering team by themselvesNo matter where you are in the world, we will go to the site to provide ball mill installation and kiln installation for youHeavy Equipment Ball Mill Installation, Kiln Installation And