Heavy calcium powder secondary crushing

.jpg)

Cooperative stabilization of calcium carbonate powder, blast

2024年11月8日 The results manifested that the early shrinkage, dry shrinkage, and creep of calcium carbonate powderblast furnace slagbased white concrete (C20) were the lowest as content of calcium carbonate powder and blast furnace slag were 20 % and 10 %2024年10月31日 Heavy calcium powder particles become the core of cement hydration product growth, and promote cement hydration, so that the hydration products are tightly bound; heavy Study on properties of slag heavy calcium powder jcprorkr2024年8月15日 Heavy calcium carbonate using the crushing method, containing CaCO2 in more than 90% of the Whitehead with Raymond mill or other highpressure mill by crushing, The difference between heavy calcium carbonate and light calcium 2019年1月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and Concrete aggregates properties crushed by jaw and impact secondary crushing

China Hubei heavy calcium carbonate HGM100P ultrafine

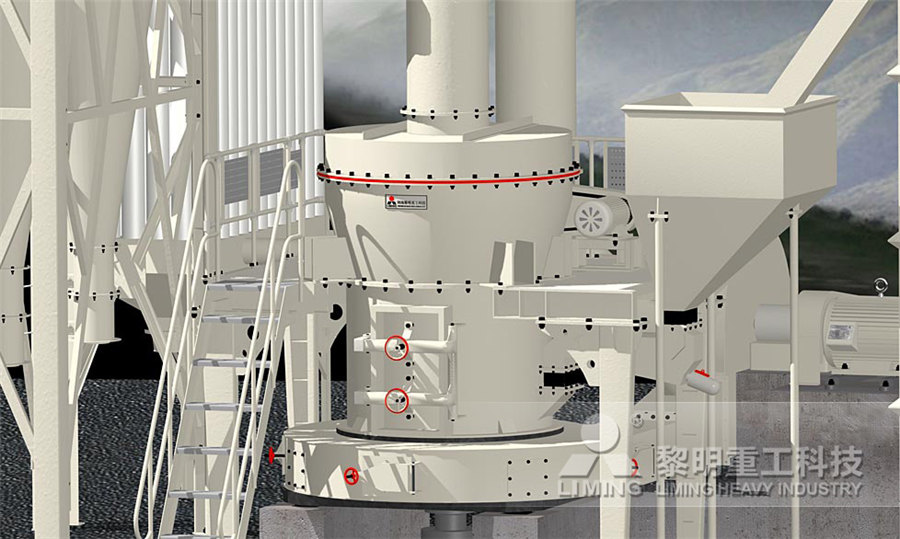

2023年11月13日 After selection, it enters the secondary hammer crusher again for further fine crushing The ore finally enters the bottom vertical elevator, which lifts the material to the top 2024年8月23日 Vertical mill + secondary classification, tertiary classification dry process is one of the main advances in the fine processing technology of heavy calcium carbonate powder in recent years Using vertical mill, ordinary heavy Heavy calcium carbonate dry production process 2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has Heavy calcium carbonate grinding, surface modification 2024年6月14日 Secondary Crushing: Further Size Reduction In the secondary crushing stage, the material undergoes further size reduction using an impact crusher The impact crusher is Ground Calcium Carbonate Production Plant In Sichuan

.jpg)

The solidification of heavy metal Pb2+contaminated soil by

The remediation of heavy metal Pb 2+contaminated soil by enzyme (urease)induced calcium carbonate precipitation (EICP) combined with biochar was studied The solidification efficiency The highefficiency heavycalciumpowder crusher disclosed by the utility model has the advantages that three gears meshed mutually are arranged in the crusher main body to crush Highefficiency heavycalciumpowder crusher Semantic 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the The Complete Guide to Primary Crushing, 2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more Calcium Carbonate Grinding Mill Powder

Highend calcium oxide ultrafine powder

2023年11月8日 Highend calcium oxide ultrafine powder milling equipmentHGM series 125 model production line, with excellent production capacity, helps customers achieve efficient production and high profits it enters the 2023年12月15日 Surface treatment of calcium carbonate powder involves modifying the surface properties of the particles to enhance their performance and compatibility with various applications The introduction Equipment and solutions for calcium carbonate powder 2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry Calcium carbonate milling process SBM Ultrafine Powder 2023年9月25日 The processing of ground calcium carbonate is simply the process of using crushing and grinding WIDELY USED IN THE PRODUCTION OF CALCIUM CARBONATE POWDER 04 The production line adopts internationally popular continuous production process: ball mill and amount of 500 ~ 1250 mesh products can be obtained through secondary CALCIUM CARBONATE POWDER

The solidification of heavy metal Pb2+contaminated soil by

The remediation of heavy metal Pb 2+contaminated soil by enzyme (urease)induced calcium carbonate precipitation (EICP) combined with biochar was studiedThe solidification efficiency of Pb 2+ reached 9841 % when the mass ratio of CaCl 2 /urea was 1:1 using EICP technology to remedy Pb 2+contaminated waterHowever, the formed precipitate was accompanied by 2024年8月15日 Calcium carbonate commonly known as limestone, stone powder, is an important building materials, in the industry is the raw material for firing lime and cement Mobile Secondary Crushing; Fine crushing and screening mobile station; Heavy calcium carbonate using the crushing method, containing CaCO2 in more than 90% of the Whitehead The difference between heavy calcium carbonate and light calcium 2023年12月16日 Roadway 10 had the highest coal powder mass of 344 g, followed by Roadway 7 with 222 g of coal powder The crushing energy of each section of the roadway was significantly higher than the transport energy This indicates that the gas expansion energy stored in the coal seam is used primarily for coal crushing under highpressure gas conditionsEnergy Evolution and Coal Crushing Mechanisms Involved in 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage

.jpg)

UltraFine grinding processing method and flow of heavy calcium powder

2024年10月13日 The ultrafine grinding of heavy calcium powder is essential to improve its application range and performance 1 Introduction Heavy calcium powder, also known as calcium carbonate, is a commonly used filling material in the industries of plastics, rubber, paper, paint, and pharmaceuticals The particle size of heavy calcium powder directly 2021年8月5日 Crushing stage: Large pieces of calcite are evenly fed into the crusher by the vibrating feeder for crushing, and the crusher is equipped with a processing dust removal machine The crushed calcite is sent to the second Calcite Industrial Ultrafine Powder GrinderAmong them, heavy calcium is refined by directly crushing calcite, limestone, chalk and shell by mechanical method, which has important applications in industrial production Raw material testing The particle shape of heavy Calcium Carbonate Powder Processing hc 2023年4月27日 3 Heavy calcium is made from natural ore crushing Light calcium is produced artificially It has a large amount of application in coatings 4 Heavy calcium is stable, but relatively light calcium is easy to settle 5 Light calcium is better at settling But the oil absorption is greater than heavy calcium The price is generally more The difference between calcium carbonate heavy and calcium

Customize Suitable Calcium Carbonate Plant DASWELL

2024年9月13日 The core part of calcium carbonate plant, the grinding mills of Daswell, whether ball mills with classifier or wet grinding mills, can produce ground calcium carbonate powder in various particle sizes from fine to ultra fine GCC powder Various calcium carbonate powder production capacity available According to customer’s needs, Daswell can 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder Raymond mill belongs to rolling and crushing The motor drives the grinding roller, and the centrifugal force is used to force the materials to squeeze, friction and shear at low speed, accompanied by intermittent impact crushing because of the low content of micro powder, the production capacity of superfine heavy calcium powder above 800 How To Select The Dry Process Production Line For Heavy Calcium 2022年2月15日 Limestone medium and fine crushing equipment, the crushed stone processed by jaw crushing needs to be sent to the impact crusher for secondary crushing The finished limestone stone has good particle shape and is cubic, Limestone crushing equipment configuration scheme

.jpg)

Limestone crushing technology and equipment SBM Ultrafine Powder

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and 2021年12月21日 About Lime Powder Lime powder is a white powdery substance with calcium carbonate as the main component The application range is very wide, the most common is calcium carbonate used in the construction industry, that is, industrial use The other is foodgrade calcium carbonate, which is widely used as a common calcium supplementLime Powder Making Machine2022年12月27日 The production of calcite powder is mainly divided into four steps: crushing, grinding, grading and powder collection +29 generally refers to ground calcium carbonate/ heavy calcium carbonate Calcite powder has a wide range of uses, usually used as a filler, widely used in artificial floor tiles, natural rubber, synthetic How To Make Calcite Powder? clirikchina2024年4月26日 White industrial grade heavy calcium carbonate powder (calcium carbonate) was formed by calcite, marble, and limestone [23], [24] Metakaolin was prepared from dehydration of kaolin (Al 2 O 3 2SiO 2 2 H 2 O) to generate anhydrous aluminum silicate at appropriate temperatures (600–900 °C) [25], [26] Calcium carbonate or metakaolin were Synergistic enhancement of industrial grade heavy calcium

Ground Calcium Carbonate Production Plant In Sichuan

2024年6月14日 4 Secondary Crushing: Further Size Reduction In the secondary crushing stage, the material undergoes further size reduction using an impact crusher The impact crusher is designed to crush the material into smaller pieces, typically less than 20 mm in size This step is vital for achieving the desired size before the grinding processHeavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the characteristics of wide source of raw materials, high whiteness, low oil absorption value, good applicability and low pricNews Calcium powder processing machinery and 2019年1月1日 Representative samples from two recycling plants were collected after primary impact crusher and secondary crushing were performed in a controlled laboratory condition through jaw and impact crushers The aggregates attained were characterized, demonstrating similar density, porosity, particle size distribution and content of attached cement Concrete aggregates properties crushed by jaw and impact secondary crushingAs an important inorganic nonmetallic industrial raw material, heavy calcium carbonate powder/ground calcium carbonate is widely used in papermaking, For the crushing and cleaning process, it can be seen from the above figure that the first crushing is performed by the jaw crusher, and then the second crushing is performed by the hammer How To Make High Quality Calcium Carbonate Powder

.jpg)

Cooperative stabilization of calcium carbonate powder, blast

2024年11月8日 Calcium carbonate powder (calcium carbonate) is a kind of dust solid waste, which is easy to cause Zhang et al [26] explored the synergistic enhancement of industrial grade heavy calcium carbonate, metakaolin, and white cement in white concrete The results show that 28 and its fineness modulus and crushing size were 25 and 5–25 mm 2024年9月14日 The heavy calcium produced by the ball mill production line can be used in papermaking, plastics, rubber, ink, chemical building materials, sealing materials, daily chemicals, etc Calcium carbonate powder mainly plays the role of filling, reducing the cost of the material, and at the same time improving the hardness and whiteness of the materialCalcium Carbonate Ball Mill Plant DASWELL2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process2021年12月20日 One of the most versatile materials, calcium carbonate, now has hundreds of other uses Many of these applications require crushing the rocks that contain calcium carbonate Manufacturing processes used to fabricate this concentrated powder allow numerous industries to utilize it to fabricate a wide array of products ConstructionCalcium Carbonate Manufacturing Process and Equipment

The Complete Guide to Primary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the 2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more Calcium Carbonate Grinding Mill Powder 2023年11月8日 Highend calcium oxide ultrafine powder milling equipmentHGM series 125 model production line, with excellent production capacity, helps customers achieve efficient production and high profits it enters the Highend calcium oxide ultrafine powder 2023年12月15日 Surface treatment of calcium carbonate powder involves modifying the surface properties of the particles to enhance their performance and compatibility with various applications The introduction Equipment and solutions for calcium carbonate powder

Calcium carbonate milling process SBM Ultrafine Powder

2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry 2023年9月25日 The processing of ground calcium carbonate is simply the process of using crushing and grinding WIDELY USED IN THE PRODUCTION OF CALCIUM CARBONATE POWDER 04 The production line adopts internationally popular continuous production process: ball mill and amount of 500 ~ 1250 mesh products can be obtained through secondary CALCIUM CARBONATE POWDERThe remediation of heavy metal Pb 2+contaminated soil by enzyme (urease)induced calcium carbonate precipitation (EICP) combined with biochar was studiedThe solidification efficiency of Pb 2+ reached 9841 % when the mass ratio of CaCl 2 /urea was 1:1 using EICP technology to remedy Pb 2+contaminated waterHowever, the formed precipitate was accompanied by The solidification of heavy metal Pb2+contaminated soil by 2024年8月15日 Calcium carbonate commonly known as limestone, stone powder, is an important building materials, in the industry is the raw material for firing lime and cement Mobile Secondary Crushing; Fine crushing and screening mobile station; Heavy calcium carbonate using the crushing method, containing CaCO2 in more than 90% of the Whitehead The difference between heavy calcium carbonate and light calcium

Energy Evolution and Coal Crushing Mechanisms Involved in

2023年12月16日 Roadway 10 had the highest coal powder mass of 344 g, followed by Roadway 7 with 222 g of coal powder The crushing energy of each section of the roadway was significantly higher than the transport energy This indicates that the gas expansion energy stored in the coal seam is used primarily for coal crushing under highpressure gas conditions2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage