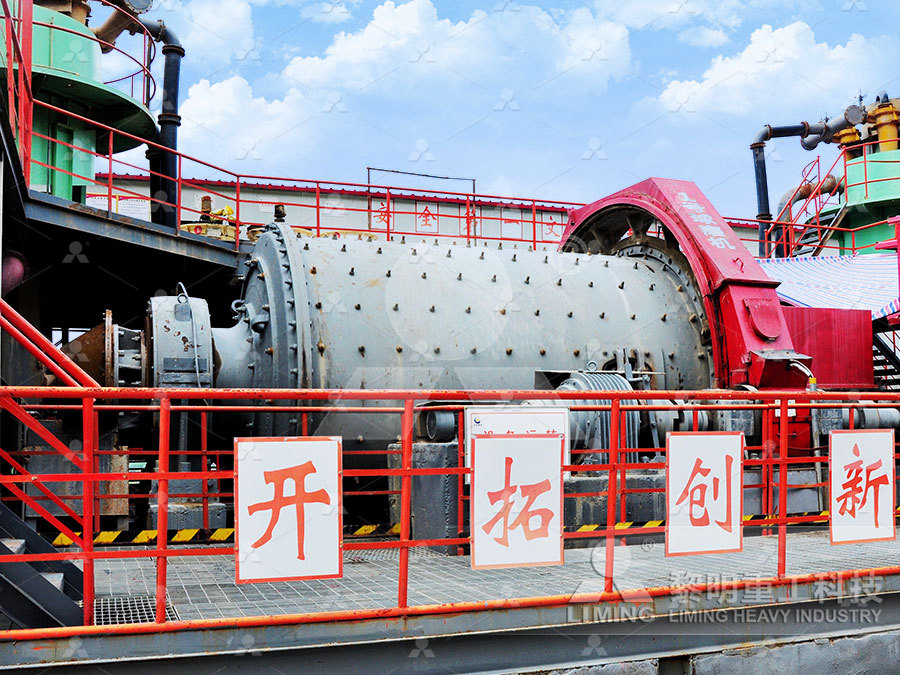

1800 square cobalt ore lithium ore grinding high calcium stone powder making machine

Geometallurgy of cobalt ores: A review ScienceDirect

2021年1月1日 This paper starts by reviewing the main geometallurgical properties of cobalt ores, with a particular focus on ore mineralogy which exerts a significant control over ore 2021年5月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies 2023年1月1日 The process flow is to convert lithium in ore into lithium sulfate by mixing roasting lithium mineral and excessive potassium sulfate (or calcium sulfate or a mixture of both), leach Lithium extraction from hard rock lithium ores (spodumene, 2021年2月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies

Lithium deportment by size of a calcined spodumene ore

2022年10月31日 The results showed that closedcircuit grinding resulted in 89% lithium recovery of the finest size fractions (− 06 mm) while opencircuit grinding led to 65% lithium recovery 2022年7月28日 The results showed that the noncalcined ore required 173 times more energy for grinding than the calcined ore ie W i (ie BBMWI) for the noncalcined ore was 449 kWh/t Effect of calcination on coarse gangue rejection of hard rock SGS Minerals Services has experience with complete flowsheet development to recover high grade lithium products from hard rock lithium minerals SGS offers a multidisciplinary team Hard Rock Lithium Processing SGSThe Pineer froth flotation process enables sustainable and costeffective spodumene/lithium ore recovery Comes from one supplier, responsible for the whole package Provides mechanical Lithium Ore Flotation Plant Pineer Mining Machinery

(PDF) Geometallurgy of cobalt ores: A review ResearchGate

2021年1月1日 This paper starts by reviewing the main geometallurgical properties of cobalt ores, with a particular focus on ore mineralogy which exerts a significant control over ore 2019年8月23日 Lithium is an element valuable for the production of glass, aluminum products, and batteries It is mined from ores of petalite (LiAl (Si2O5)2, lepidolite K (Li,Al)3 Lithium Processing Equipment, Process Flow, Cases JXSC Machine2024年4月26日 Cobalt deposits including stratiform sedimenthosted CuCo deposits, NiCo laterite deposits, magmatic NiCuCoPGM sulphide deposits, and hydrothermal Co deposits And the cobalt mining steps mainly include Cobalt Resources Overview and Mining JXSC Mineral2022年12月28日 In the process of raw ore processing, must use grinding, grinding and other machinery Cobalt ore is a kind of metal, its hardness is higher than the general ore, generally to choose 2~3 stages of crushing equipment The crushing and grinding process of cobalt ore can refer to the crushing and grinding process of lithium oreNew energy cobalt extraction frontend crushing grinding process

Stone Powder Making Machine

① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill China Stone Grinding Machine wholesale Hms1800 Manual Stone Grinding Machine for Marbl Granite Slab US$ 25003500 / Piece Hlmjx12c 12 Heads Quartz Stone Auto Low Price High Pressure Stone Fine Powder Grinding Machine US$ / Set 1 Set (MOQ) Henan Shanky Machinery Co, LtdStone Grinding Machine MadeinChina2023年4月23日 Nickel ore refers to the naturally occurring rocks or minerals that contain significant amounts of nickel Nickel is a chemical element with the symbol Ni and atomic number 28 It is a silverywhite metal with a relatively high melting point and excellent corrosion resistance Nickel is commonly found in the Earth's crust, but it is typically extracted from its Nickel (Ni) Ore Properties, Formation, Minerals, Deposits2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?

)D`ERF`389RMI4.jpg)

How to Extract Cobalt from Ore? Mining Pedia

2023年12月8日 Cobalt, an essential metal in various industries, is primarily extracted from its oresThe process of extracting cobalt from ore involves several steps, each playing a vital role in obtaining this valuable element This article will provide a comprehensive guide on how to extract cobalt from ore, highlighting the key processes and techniques involvedCobalt hexammine chloride solution is decomposed in caustic to make Co(OH) 3, which is converted into Co 3 O 4 for reduction in hydrogen to make extra fine cobalt metal powder Submicron cobalt metal powders are made via thermal decomposition of cobalt oxalate, CoC 2 O 4 2H 2 O ( BacoCarles, Arnal, Poquillon, Tailhades, 2008 ; Gingerich McClintic, 1980 )Cobalt Ore an overview ScienceDirect Topics2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environment and cost Tianming Gao, Na Fan, Wu Chen, Tao Dai(PDF) Lithium extraction from hard rock lithium ores: technology 2021年2月1日 Lithium mica and spodumene (Dessemond et al, 2019;Su et al, 2020), as representatives of lithium ore resources are usually recovered by the sulfuric acid method (Rioyo et al, 2022; Yelatontsev Processing of lithium ores: Industrial technologies and case studies

.jpg)

Powder Grinding Mills Engineered by FTM Fote

Whether soft rock, hard rock, nonmetallic minerals, or coal, FTM Machinery can provide costeffective grinding solutions Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, 2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while Lithium extraction from hard rock lithium ores (spodumene, Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] highquality ore grinding equipment, and perfect service the SBM Ultrafine Powder Technology Industrial Download scientific diagram Leaching behaviour of cobalt: (a) high cobalt ore; (b) high copper ore; (c) low cobalt ore with mica; (d) low cobalt ore without mica from publication: UV/visible Leaching behaviour of cobalt: (a) high cobalt ore; (b) high copper ore

(PDF) Lithium Mining, from Resource Exploration to Battery Grade

2021年10月7日 The paper discusses the process of lithium mining, from resource exploration to the production of batterygrade lithium saltsFind Cobalt Ore stock images in HD and millions of other royaltyfree stock photos, Beautiful blue stones square background image Square shape 2024 Mining of Coal, Tantalum, Nickel, Cobalt, lithium Dump Truck and Excavator Worker mining Coal, metal Tantalum and silver Mining business, Mineral ResourcesCobalt Ore royaltyfree images Shutterstock2021年1月1日 Due to its low concentration in ores, cobalt is usually considered to be a companion metal which is of limited economic interest The bulk of global cobalt production emanates as a byproduct of extraction of commodities such as copper (~55%), nickel (~35%), and arsenic (Azevedo et al, 2018, Smith, 2001)The only exceptions, which represent a small Geometallurgy of cobalt ores: A review ScienceDirect2023年9月11日 Lithium Ore Ball Mill Types Lithium resources are mostly extracted from pegmatite ores and salt lake brine Extracting lithium from brine is simple, with a high recovery rate, low cost, and little environmental pollution However, currently, lithium resources in salt lake brine are gradually depleted Extracting lithium from pegmatite ores has Ball Mills for Lithium Ore JXSC Machine

Lithium Ore Beneficiation Process Overview JXSC Machine

It is an indispensable raw material for modern hightech products Lithium Ore Beneficiation Equipment Lithium ore beneficiation equipment includes crushers, ball mills, jigs, flotation machines, and auxiliary equipment to form a complete production line Lithium Ore Beneficiation Methods 1 Manual Selection MethodA typical run of mine ore can contain 12% Li2O, while a typical spodumene concentrate is suitable for future lithium battery production We Pineer has experience with complete flowsheet development to recover highgrade lithium concentrate powder from hard rock lithium mineralsLithium Ore Flotation Plant Pineer Mining Machinery2022年12月23日 These articles are all about cobalt ore You can learn more graphite ore mining knowledge +86 ; xlyin@xinhaimining; Follow us; Home; About; Products Mineral Processing Solution; Mining Machines; Crushing Machines; Screening Machines; Grinding Machines; Classifying Machines; Magnetic Fushan hightech industrial Cobalt Ore Mining Knowledge Mining Pedia2021年5月1日 The role of lithium in chemical and nuclear industries could hardly be overestimated (Babenko et al, 2007)World lithium consumption in 2019 was estimated as ~58∙10 3 tons, with an increase of 18% compared with the previous year (National Minerals Information Center, 2020)Nevertheless, excluding the USA, worldwide lithium production in 2019 Processing of lithium ores: Industrial technologies and case

Quantification of Lithium and Mineralogical Mapping

2022年2月16日 For example, lithium has been quantified using a highthroughput ELEMISSION instrument, with high accuracy in spodumene minerals, which are raw material for Liion battery materials manufacturing [6]2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical lithium ores, primarily spodumene and brine, into highpurity batterygrade precursors We systematically examine the study findings Transformations of Critical Lithium Ores to BatteryGrade MDPI803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content areHard Rock Lithium Processing SGS2023年5月14日 3 Advantages of Lithium Ore Flotation Machine 1) High Efficiency The lithium ore flotation machine is designed to separate lithium from other minerals in the ore It uses the principle of selective attachment of air bubbles to the surface of the lithium mineral particles, allowing them to float to the surface and be collectedFlotation Machine for Lithium Ore: Efficient Separation and

[GYQ0R)ZQ]ESS4NJ.jpg)

Lithium Ore Mining Process JXSC Mineral

1 Lithium Flotation Processing Applicable minerals: Lithium ores have industrial value, especially lithium ores in finegrained disseminated form Main process: Common lithium ore flotation methods include forward and reverse flotation Positive flotation method: After the lithium ore is finely ground (avoid overgrinding that may cause mud formation), add a strong alkali for flotationNickel and Cobalt Production Michael S Moats, William G Davenport, in Treatise on Process Metallurgy: Industrial Processes, 2014 226 Cobalt from Central African Copper–Cobalt Ores While most cobalt (~ 50%) is produced as a coproduct from the processing of nickel/ cobalt ores, a significant amount of cobalt (~ 35%) is produced from Central African copper–cobalt oresCobalt Ore an overview ScienceDirect Topics2023年5月27日 They are also relatively inexpensive and readily available However, steel balls can cause contamination of the lithium ore due to the presence of iron This can be a significant issue, especially if the lithium ore is intended for use in hightech applications such as batteries 2) Ceramic beadsBall Milling in Lithium Ore Processing: A Comprehensive Guide3 Cobalt ore flotation After grinding, the qualified cobalt ore powder is sent to the flotation machine for flotation, and a suitable collector agent is added to obtain highgrade cobalt concentrate 4 Cobalt ore drying The cobalt concentrate recovered by flotation contains a certain amount of waterCobalt Mining Process JXSC Mineral

Cobalt Resources Overview and Mining JXSC Mineral

2024年4月26日 Cobalt deposits including stratiform sedimenthosted CuCo deposits, NiCo laterite deposits, magmatic NiCuCoPGM sulphide deposits, and hydrothermal Co deposits And the cobalt mining steps mainly include 2022年12月28日 In the process of raw ore processing, must use grinding, grinding and other machinery Cobalt ore is a kind of metal, its hardness is higher than the general ore, generally to choose 2~3 stages of crushing equipment The crushing and grinding process of cobalt ore can refer to the crushing and grinding process of lithium oreNew energy cobalt extraction frontend crushing grinding process① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill Stone Powder Making MachineChina Stone Grinding Machine wholesale Hms1800 Manual Stone Grinding Machine for Marbl Granite Slab US$ 25003500 / Piece Hlmjx12c 12 Heads Quartz Stone Auto Low Price High Pressure Stone Fine Powder Grinding Machine US$ / Set 1 Set (MOQ) Henan Shanky Machinery Co, LtdStone Grinding Machine MadeinChina

Nickel (Ni) Ore Properties, Formation, Minerals, Deposits

2023年4月23日 Nickel ore refers to the naturally occurring rocks or minerals that contain significant amounts of nickel Nickel is a chemical element with the symbol Ni and atomic number 28 It is a silverywhite metal with a relatively high melting point and excellent corrosion resistance Nickel is commonly found in the Earth's crust, but it is typically extracted from its 2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?2023年12月8日 Cobalt, an essential metal in various industries, is primarily extracted from its oresThe process of extracting cobalt from ore involves several steps, each playing a vital role in obtaining this valuable element This article will provide a comprehensive guide on how to extract cobalt from ore, highlighting the key processes and techniques involvedHow to Extract Cobalt from Ore? Mining PediaCobalt hexammine chloride solution is decomposed in caustic to make Co(OH) 3, which is converted into Co 3 O 4 for reduction in hydrogen to make extra fine cobalt metal powder Submicron cobalt metal powders are made via thermal decomposition of cobalt oxalate, CoC 2 O 4 2H 2 O ( BacoCarles, Arnal, Poquillon, Tailhades, 2008 ; Gingerich McClintic, 1980 )Cobalt Ore an overview ScienceDirect Topics

.jpg)

(PDF) Lithium extraction from hard rock lithium ores: technology

2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environment and cost Tianming Gao, Na Fan, Wu Chen, Tao Dai2021年2月1日 Lithium mica and spodumene (Dessemond et al, 2019;Su et al, 2020), as representatives of lithium ore resources are usually recovered by the sulfuric acid method (Rioyo et al, 2022; Yelatontsev Processing of lithium ores: Industrial technologies and case studies