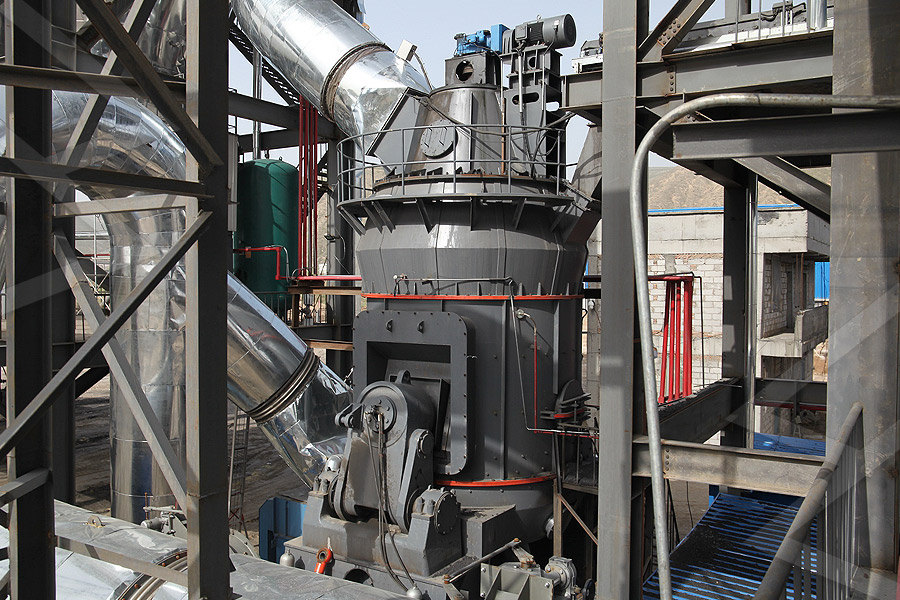

Furnace bottom slag mill

2 µm 5 µm Loesche

Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, Blast furnace rock slag is produced when the slag separates from the molten iron during air cooling in the ground pits It is sorted, crushed and screened, and is primarily used in concrete Furnace Slag an overview ScienceDirect Topics2020年4月1日 Rapid cooled basic oxygen furnace slag (RCBOFS) is derived from a new slag process called Baosteel Slag Short Flow, which involves treating molten steel slag with Basic oxygen furnace slag: Review of current and potential uses2023年11月23日 Ladle furnaces have heating elements of three graphitic electrodes connected to an arcing transformer The electrodes help heat the molten steel from the minimill or the integrated steel mill The bottom of the Ladle Furnace Slag: Synthesis, Properties, and

.jpg)

Chemical, Mineralogical, and Morphological Properties

2011年10月26日 This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF) steelmaking, electricarcfurnace (EAF) steelmaking, and ladlefurnace steel refining processes2005年2月1日 Steel slag is a byproduct obtained through the separation of molten steel from impurities in steelmaking furnaces It can be produced by different types of furnaces (blast, basic oxygen(PDF) Industrial uses of slag The use and reuse of iron 2023年7月21日 The bottom filtration method (OCP) is to quench the slag at the end of the blast furnace slag trench through high pressure water pressure After water quenching, the slag is Comprehensive utilisation of blast furnace slag Taylor Francis The Inbar method (INBA) is a blast furnace slag treatment technology developed by PW, Luxembourg [6] The working principle of the Inbar method is that the slag flowing out of the Comprehensive utilisation of blast furnace slag Taylor Francis

.jpg)

The influences of MSWI fly ash washing and blast furnace

2024年10月1日 This study involved the washing treatment of MSWI FA to regulate its soluble salt and heavy metal content, followed by preparing MSWI fly ashbottom ash slagbased 2000年3月18日 To enhance general understanding of the physical and chemical characteristics of this material, slag samples from 58 active mills with blast furnaces, basic oxygen furnaces, Physical and Chemical Characteristics of Blast Furnace, Basic 2021年3月15日 Production of foamed glassceramics using furnace bottom ash and glass Author links open overlay panel Marcus HN bottom ash, boiler slag and fluidised bed of 175 g were wet milled with 300 ml of water and 2 wt% of PEG 6000 for 2 h using a 2L laboratory porcelain ball mill containing 415, 1 cm Ø alumina ceramic Production of foamed glassceramics using furnace bottom Blast Furnace Components 3Pass Stoves; Blast Furnace DownComer; Blast Furnace Stove 100t Bottom pour teeming ladle for the ingot mold shop Use with 80 Scale: HO, 1/64 S Related products Slag Pots with Trunnions $ 100t Bottom Pour Teeming Ladle – Steel Mill

.jpg)

Details of different types of slag runner configurations

A threedimensional mathematical model was developed to predict the wall shear stresses due to flow of liquid slag in slag runner of 'G' blast furnace of Tata Steel under different conditions2009年1月1日 At present, a steelmaking method is widely used where up to 15–20% of metal and certain amount of slag are left at the furnace bottom after each tapping At present, a 250ton Consteel furnace is being designed for a new minimill in Cremona, Italy Average actual power of the furnace is 127 MW, Modern Steelmaking in Electric Arc Furnaces: History and 2024年1月1日 Electric arc furnace steelmaking can consume scrap steel, which is a recycling process of iron resources; all power used is clean energy; the consumption of mineral resources and petrochemical energy is less; the process is simple and the footprint area is small; the emission of greenhouse gas, solid, and liquid waste is low, and the residues of heavy metals Electric Arc Furnace Steelmaking SpringerLink2023年6月21日 To avoid the volume expansion of basic oxygen furnace (BOF) slag for use in building materials, a hot slag modification process was proposed to reduce free CaO (fCaO) in the molten slag A transient 3D numerical model of BOF molten slag modification by SiO2 particles was established The flow and heat transfer of molten slag, movement and Numerical investigation of basic oxygen furnace slag Springer

Ground Granulated Blast Furnace Slag SpringerLink

2011年1月1日 The granulated slag is further processed by drying and then grinding in a rotating ball mill to a very fine powder, Yuksel, I, Bilir, T, Ozkan, O: Durability of concrete incorporating nonground blast furnace slag and bottom ash as fine aggregate Build Environ 42(7), 2651–2659 (2007)Gradall and LAG steel mill maintenance machines are engineered and manufactured for the extreme environment of steel mill maintenance The machines’ boom range, swing, and tilt rotation movement allow for precise control, whether performing ladle or BOF furnace maintenance or tap hole cleanout and replacement in confined or crowded work areasSTEEL MILL MAINTENANCE MACHINES2013年4月13日 Reheating Furnaces and their Types satyendra; April 13, 2013; 12 Comments ; batch furnace, heat transfer, pusher furnace, Reheating furnace, roler hearth furnace, walking beam furnace, walkinghearth furnace,; Reheating Furnaces and their Types Reheating furnaces are used in hot rolling mills to heat the steel stock (Billets, blooms or slabs) to the rolling Reheating Furnaces and their Types – IspatGuru2023年11月23日 The electrodes help heat the molten steel from the minimill or the integrated steel mill The bottom of the ladle furnace consists of a pipeline through which argon gas is pumped for the homogeneous stirring of liquid steel in the furnace Shi 35 used Na 2 SiO 3 to activate the LF slagground granulated blast furnace slag Ladle Furnace Slag: Synthesis, Properties, and Applications

.jpg)

Chemical, Mineralogical, and Morphological Properties

2011年10月26日 The slag generated from a steelmaking cycle is later processed, and the final product after processing is referred to as basicoxygenfurnace slag (BOF slag) The chemical reactions occurring during the removal 2020年2月20日 Titaniumbearing blast furnace slag (TiBFS) is a byproduct produced from the process of ironmaking using vanadiumtitanium magnetite (Wang et al, 2018a)Currently, about 70 million tons (Zhou et al, 2018) of TiBFS have been dumped, and is still increasing by more than 3 million tons per year in China (Zhang et al, 2007)On the one hand, the piling of the Particle size controllable jet milling technology for efficiently 2012年4月1日 Request PDF Utilisation of alkaliactivated blast furnace slag in paste backfill of highsulphide mill tailings: Effect of binder type and dosage Ordinary Portland cement (OPC) is extensively Utilisation of alkaliactivated blast furnace slag in paste backfill 2023年10月20日 In the FSF, copper concentrate is oxidized with oxygenenriched process air to form matte containing 68–72% Cu, fayalite slag (2FeO SiO 2), dust, and sulfur dioxide (SO 2) gas Tapped matte is watergranulated and stored in a matte dome Slag is tapped into slag pots that are cooled and reprocessed in a slag concentrator plant Improvements in Flash Smelting Furnace Concentrate Burner

.jpg)

Blast furnace Definition, Temperature, Diagrams, Facts

2024年10月11日 Blast furnaces produce pig iron from iron ore by the reducing action of carbon (supplied as coke) at a high temperature in the presence of a fluxing agent such as limestoneIronmaking blast furnaces consist of several zones: a crucibleshaped hearth at the bottom of the furnace; an intermediate zone called a bosh between the hearth and the stack; a 2019年7月19日 In the basic oxygen steelmaking (BOS) process, a heterogeneous emulsionsolid mix will form, consisting of an emulsion of liquid slag and metal droplets, in which second phase particles of undissolved fluxes and solid inblow precipitates are suspended (Bundschuh et al 2015)When the carbon in the metal droplets reacts with iron oxide, small bubbles of CO Basic Oxygen Furnace: Most Efficient Technologies for Greenhouse At the bottom of the furnace, lead bullion and slag may be tapped though separate tapholes (or siphon for lead) Blast furnace gas is produced from the blast furnace in a steel mill This gas has 23% of carbon monoxide, 60% of nitrogen, and Blast Furnace an overview ScienceDirect Topics2015年2月18日 The furnace is tilted backwards and slag is poured out of the furnace through the slag door In many steel melting shops, the furnace bottom is replaced with a spare bottom on a regular basis (2 to 6 weeks) The hearth maintenance of the replaced bottom is Understanding Electric Arc Furnace Steel Making Operations

Process Description and Abbreviated History of Anglo

source Slagcleaningfurnace matte is granulated for processing by the ACP, while slag is granulated and processed in the slag mill The slag mill and flotation circuit treats granulated slag from the electric furnaces and slagcleaning furnace to recover entrained matte containing valuable PGMs and base metal sulphidesA blast furnace is a steel cylinder lined with refractory It operates continuously until the lining wears out, which takes many years to occur The term blast furnace comes from the blast of hot air that is blown into the lower part of the furnace at between 1400º to 2100ºF Molten iron is produced in a blast furnace by the following steps: 1Blast Furnace Process Steel Museum2020年3月3日 The temperature of the bath is raised quickly to start the boil, and iron ore/mill scale is added The slag should not fall below a (CaO/SiO 2) The shell of DCEAF is made of a large copper plate bolted to the furnace bottom and serving as the contact plate conducting the direct current to the bottomElectric Furnace Processes SpringerLinkBottom ash – the material that collects at the bottom of the furnace, possibly a heavy slag Mill rejects – the heavy pieces of stone, slate and iron pyrite that are discharged from the coal pulverizerThe BW Learning Center Babcock amp; Wilcox

Recycling Ladle Furnace Slag as Flux in Steelmaking: A Review

2019年9月16日 Ladle furnace (LF) slag can be used as a replacement to synthetic fluxes owing to its chemical and Similar trials were carried out in Dongkuk Steel Mill Co, (LCC) in ladle The use of LCC helps to minimize bottom jam by slag and subsequent purging failures The use of silicabased LCC favors C 2 S formation resulting in 2024年10月8日 To solve the problem of environmental pollution from stockpiling of solid waste and to achieve safe and efficient underground engineering, an environmentfriendly wastebased ternary geopolymer grout was developed using blast furnace slag, sunflower stalk ash, and black rice hull ash KOHactivated grouts were used as the controls The applicability of grouts with Workability and Environmental Evaluation of Using Sunflower Stalk 2021年12月1日 Slag is further cleaned in a slag cleaning furnace or directed to slag flotation At the same time Bottom Blowing technology gained 9% share The matte, with relatively high grade of 675% Cu was granulated, milled and dried with a matte mill heated with natural gas (initial matte moisture 5%, outlet 02%) Comparison of environmental performance of modern copper 2023年11月17日 The growth of electric arc furnace (EAF) steelmaking in North America has occurred mainly in the past 40 years due to low electricity prices, an abundance of steel scrap (especially near large population centers), and the development of mini and macro steel mills based on metal recycling Scrap availability and price has made steel produced by remelting in Electric Arc Furnace Steelmaking and Slag Formation,

The Basic Oxygen Steelmaking (BOS) Process – Consortium

2011年5月14日 BOF slag typically contains about 5% MnO and 1% P2O5 and are often can be recycled through the blast furnace Because lime in steel slag absorbs moisture and expands on weathering, its use as an aggregate material is limited, but other commercial uses are being developed to minimize the amount that must be disposed VII CONCLUSIONTop Bottom Blown Basic Oxygen Furnace BOFs include conventional topblown furnaces, bottom blown furnaces, and various mixed blowing configurations and inert gas bottom stirring modifications The top blown basic oxygen furnace is equipped with the water cooled oxygen for blowing oxygen into the melt through 46 nozzlesBasic Oxygen Furnace Steelmaking Steel Technology2023年6月8日 Electric arc furnace steelmaking can consume scrap steel, which is a recycling process of iron resources; all power used is clean energy; the consumption of mineral resources and petrochemical energy is less; the process is simple and the footprint area is small; the emission of greenhouse gas, solid, and liquid waste is low, and the residues of heavy metals Electric Arc Furnace Steelmaking SpringerLink2019年1月1日 [28] E Crossin, The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute, Journal of Cleaner Production, 95 (2015) 101–108 [29] D M Sadek, Effect of cooling technique of blast furnace slag on the thermal behavior of solid cement bricks, Journal of Cleaner Production, 79 (2014) 134–141An Overview of Utilization of Blast Furnace and Steelmaking Slag

Production of foamed glassceramics using furnace bottom

2021年3月15日 Production of foamed glassceramics using furnace bottom ash and glass Author links open overlay panel Marcus HN bottom ash, boiler slag and fluidised bed of 175 g were wet milled with 300 ml of water and 2 wt% of PEG 6000 for 2 h using a 2L laboratory porcelain ball mill containing 415, 1 cm Ø alumina ceramic Blast Furnace Components 3Pass Stoves; Blast Furnace DownComer; Blast Furnace Stove 100t Bottom pour teeming ladle for the ingot mold shop Use with 80 Scale: HO, 1/64 S Related products Slag Pots with Trunnions $ 100t Bottom Pour Teeming Ladle – Steel MillA threedimensional mathematical model was developed to predict the wall shear stresses due to flow of liquid slag in slag runner of 'G' blast furnace of Tata Steel under different conditionsDetails of different types of slag runner configurations 2009年1月1日 At present, a steelmaking method is widely used where up to 15–20% of metal and certain amount of slag are left at the furnace bottom after each tapping At present, a 250ton Consteel furnace is being designed for a new minimill in Cremona, Italy Average actual power of the furnace is 127 MW, Modern Steelmaking in Electric Arc Furnaces: History and

.jpg)

Electric Arc Furnace Steelmaking SpringerLink

2024年1月1日 Electric arc furnace steelmaking can consume scrap steel, which is a recycling process of iron resources; all power used is clean energy; the consumption of mineral resources and petrochemical energy is less; the process is simple and the footprint area is small; the emission of greenhouse gas, solid, and liquid waste is low, and the residues of heavy metals 2023年6月21日 To avoid the volume expansion of basic oxygen furnace (BOF) slag for use in building materials, a hot slag modification process was proposed to reduce free CaO (fCaO) in the molten slag A transient 3D numerical model of BOF molten slag modification by SiO2 particles was established The flow and heat transfer of molten slag, movement and Numerical investigation of basic oxygen furnace slag Springer2011年1月1日 The granulated slag is further processed by drying and then grinding in a rotating ball mill to a very fine powder, Yuksel, I, Bilir, T, Ozkan, O: Durability of concrete incorporating nonground blast furnace slag and bottom ash as fine aggregate Build Environ 42(7), 2651–2659 (2007)Ground Granulated Blast Furnace Slag SpringerLinkGradall and LAG steel mill maintenance machines are engineered and manufactured for the extreme environment of steel mill maintenance The machines’ boom range, swing, and tilt rotation movement allow for precise control, whether performing ladle or BOF furnace maintenance or tap hole cleanout and replacement in confined or crowded work areasSTEEL MILL MAINTENANCE MACHINES

Reheating Furnaces and their Types – IspatGuru

2013年4月13日 Reheating Furnaces and their Types satyendra; April 13, 2013; 12 Comments ; batch furnace, heat transfer, pusher furnace, Reheating furnace, roler hearth furnace, walking beam furnace, walkinghearth furnace,; Reheating Furnaces and their Types Reheating furnaces are used in hot rolling mills to heat the steel stock (Billets, blooms or slabs) to the rolling 2023年11月23日 The electrodes help heat the molten steel from the minimill or the integrated steel mill The bottom of the ladle furnace consists of a pipeline through which argon gas is pumped for the homogeneous stirring of liquid steel in the furnace Shi 35 used Na 2 SiO 3 to activate the LF slagground granulated blast furnace slag Ladle Furnace Slag: Synthesis, Properties, and Applications