Various machines for crushing large stones

.jpg)

What Machines Do Stone Crushing Plants Need? Fote

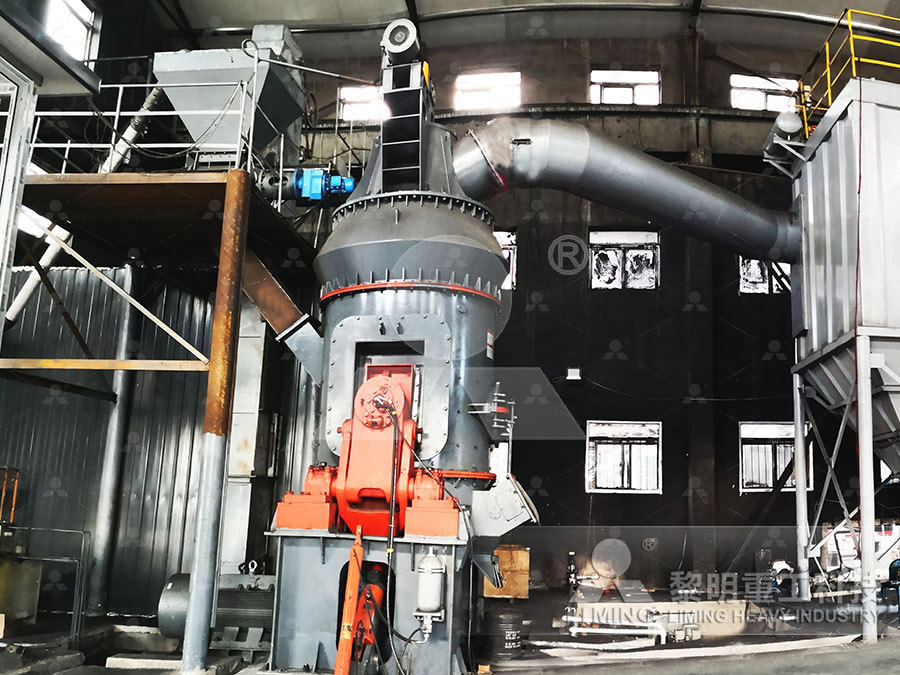

2024年10月14日 A stone crushing plant needs essential primary crushers like jaw and gyratory crushers as well as finecrushing equipment like impact crushers and ball mills Other critical heavyduty machines for the effective operation of Stone Crusher, also known as rock crusher, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust It utilizes a highpressure force to crush the rocks and is Stone Crusher Rock Crushing MachineA stone crusher is a type of stone crushing equipment designed to crush large rocks into smaller, more usable materials These machines use various mechanisms to achieve their goal, with some of the most common types being Stone Crushing Machine What is a Stone Crushing Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining operations Metso offering covers different gyratory crushers, jaw Crushers All crusher types for your reduction needs

Comparing Different Types of Stone Crushers

Stone crushers are heavyduty machines designed to crush rocks and minerals of various sizes, depending on the type of crusher With the everevolving technology, we have several kinds of crushers, each with its unique method Stone crusher machines are equipment designed to crush or break down large stones, rocks, and minerals into smaller pieces, gravel, or dust for various applications According to the customer’s final particle size requirements for Stone Crusher Machines In Philippines For Different Stone Crusher, also known as rock crusher, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust It utilizes a highpressure force to crush the rocks and is widely used in various industries such as construction, mining, metallurgy, and recyclingStone Crusher Rock Crushing MachineStone crushing and screening machines are used in large quarries and mines, processing stones to make them suitable for construction projects, infrastructure work, and other fieldsThese machines break down large and hard stones into desired sizes for use in various applications The primary use of stone crushing and screening machines includes quarries, infrastructure Crushing and Screening Machines CONMACH

Stone Crusher Machine Price: Factors, Range, and Ways to Save

2023年2月28日 Stone crusher machines are used in various industries for crushing different types of materials such as rocks, stones, and minerals These machines are an essential part of many construction and mining projects as they help in reducing the size of raw materials and making them usable for further processing Stone crusher machines come in For example crushed material for road base and fill The main kinds of crushing machines for secondary processing are discussed below Cone crushers Cone crushers are one of the main choices for secondary crushing A cone crusher is a powerful machine that is used in largescale industries for crushing various types of materials into smaller Types of Crushers: What You Need to Know Machinery Partner2023年2月28日 The shaft rotates at high speed and the hammers strike the material, causing it to break into smaller pieces The crushed material then exits through the bottom of the machine Gyratory Crushers Gyratory crushers are large machines used in the mining and construction industries to break down large rocks into smaller piecesA Comprehensive Guide to Understanding the Different Types of 2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before dischargeDolomite Sand Making Plant And Grinding Machine

The Ultimate Guide to Jaw Crushing Machines: Types More

2023年2月21日 Discover everything you need to know about jaw crushing machines, from the various types such as single and double toggle, hydraulic and portable models, to their working principles, advantages, and disadvantages This comprehensive guide also provides expert tips on maintenance and selecting the right machine for your specific applicationIt is made by crushing large rocks into smaller stones, which can be used for different projects or sold to the public However, not all crushed stone is created equal some types of stone are harder than others and require more crushing power and specific equipment for effective crushingThe Ultimate Guide on How to Crush Stone: Techniques and Wide application: capable of handling stones of various hardness and suitable for different engineering needs Large crushing ratio: capable of crushing large stones into small particles, with a crushing ratio of 46 Application Fields; Mining: It is the primary crusher machine for crushing hard rocks, ores, etcTypes And Applications Of SandMaking Equipment2023年2月15日 This type of crusher is often used in the crushing process of large and hard materials +86 ne 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, China A Guide to Types of Jaw Crushers for Crushing Rocks

HS Code : Crushing or Grinding Machines for Earth, Stones

These machines are designed to break down large rocks or minerals into smaller, more manageable sizes, making them easier to transport, process, and utilize in various industries HS Code specifically covers crushing or grinding machines used for this purpose2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, mining, Crushing it: A Comprehensive Guide to Stone Crusher 2023年2月22日 When buying a stone crusher machine, there are several factors to consider, such as the type of stone to be crushed, the required crushing capacity, the power supply, and the budgetIt’s also important to choose a reliable supplier with a good reputation for quality and service Other factors to consider include the machine’s size and weight, ease of operation BUYING GUIDE FOR STONE CRUSHER MACHINES AGICO2023年2月28日 Primary crushers are machines used to break down large rocks and stones into smaller pieces for further processing They are usually the first step in the crushing process and play a vital role in the mining and construction industries The primary function of a crusher is to reduce the size of the material for further processingPrimary vs Secondary Crushers: Understanding the Differences

How to Minimize Stone Crushing Plant Cost without Sacrificing

2023年2月23日 One of the most common types of equipment used in a stone crushing plant is a jaw crusher This type of machine is used for primary crushing of materials, and is ideal for crushing large rocks and stones A cone crusher is another popular choice for crushing stones2024年10月10日 It is made by crushing large rocks into smaller stones, which can be used for different projects or sold to the public However, not all crushed stone is created equal some types of stone are harder than others and require more crushing power and specific equipment for effective crushingThe Ultimate Guide on How to Crush Stone: Techniques and 2023年2月24日 A stone crusher machine is a powerful machine that is designed to crush large stones and rocks into Stone crushing machines have been used in the construction industry for many years These machines are designed to crush rocks and stones into smaller sizes that can be used for various construction purposes such as How much does a stone crusher machine cost?2023年2月24日 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects In this comprehensive guide, we explore the different types of crushed stone machines, their components, and how to operate them safely and efficientlyCrushed Stone Machines: The Key to HighQuality Building

.jpg)

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution Types of stone crusher machine Actually, for a crushing production line, the stone crusher philippines is the most crucial part So we provide various of stone crusher for our customers, including jaw crusher, cone crusher, The super Stone Crusher Machine Philippines for Crushing Types of rocks and their hardness After large rocks have been crushed into smaller stones, they can be separated by size using a screenerDifferent projects can call for different sizes of crushed stones so it may be important for you to How to Crush Stone: A Simple Guide Machinery PartnerEfficient, durable, and ideal for various crushing applications, explore the best stone crusher for your project (908) 3693340 info@kompletamerica Request Quote HomeStone Crusher Machine Efficient Crushing Solutions

The Ultimate Guide on How to Crush Stone: Techniques and

2024年10月10日 It is made by crushing large rocks into smaller stones, which can be used for different projects or sold to the public However, not all crushed stone is created equal some types of stone are harder than others and require more crushing power and specific equipment for effective crushingStone crushers in the Philippines are vital heavy equipment for crushing large stones into gravel or smaller pieces The crushing process The crushed stones are collected as they fall out of the machine and can be used in various projects including construction What are Mobile Crusher Philippines Multico Prime Power Inc2023年2月23日 The rock crusher machine is a gamechanger for the mining industry, enabling efficient and effective crushing of rocks for various applications Call Us Now: +86 : ne Home; Products Menu Toggle Mobile Crusher Menu Toggle Mobile Jaw Crusher; Crushing Equipment Menu Toggle Jaw Crusher The Rock Crusher Machine: A Revolutionary Equipment for Crushing Crushing stones is a crucial process that demands specific equipment and expertise It entails breaking down sizable stones into smaller, more manageable pieces, making them easier to handle or process This task is typically accomplished using specialized machines known as crushers, available in various sizes and typesTransforming Rocks into Fine Crushed Stone: Equipment Overview

FYEFEPS2HDZ49G5Z0[B.jpg)

Stone Crusher Plant for Sale Aimix Group

The quality of your mesin pemecah batu besar directly impacts your productivity Invest in stone crushers, conveyors, screens, and other machinery that can handle large volumes of stones Brands like AIMIX offer reliable solutions tailored to various needsStone crusher is a machine used to crush stones into smaller sizes These machines play an important role in various industries such as construction, mining, and the production of sand and gravel Pyramids also manufactures Bucket crushers, jaw crushers, Block making machine, Cement block machine, and various other productsStone Crushers Quarry Equipment Pyramids24 Oct 2024; A stone crushing plant is a complex industrial facility used for the processing of raw stones into various sizes of aggregates and other construction materials It is widely used in industries such as construction, mining, infrastructure, and road building The plant’s design and configuration depend on the type of rock, the production capacity, and the final product Typical Setup for a Stone Crushing PlantStone crusher machines are equipment designed to crush or break down large stones, rocks, and minerals into smaller pieces, gravel, or dust for various applications According to the customer’s final particle size requirements for Stone Crusher Machines In Philippines For Different

Stone Crusher Rock Crushing Machine

Stone Crusher, also known as rock crusher, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust It utilizes a highpressure force to crush the rocks and is widely used in various industries such as construction, mining, metallurgy, and recyclingStone crushing and screening machines are used in large quarries and mines, processing stones to make them suitable for construction projects, infrastructure work, and other fieldsThese machines break down large and hard stones into desired sizes for use in various applications The primary use of stone crushing and screening machines includes quarries, infrastructure Crushing and Screening Machines CONMACH2023年2月28日 Stone crusher machines are used in various industries for crushing different types of materials such as rocks, stones, and minerals These machines are an essential part of many construction and mining projects as they help in reducing the size of raw materials and making them usable for further processing Stone crusher machines come in Stone Crusher Machine Price: Factors, Range, and Ways to Save For example crushed material for road base and fill The main kinds of crushing machines for secondary processing are discussed below Cone crushers Cone crushers are one of the main choices for secondary crushing A cone crusher is a powerful machine that is used in largescale industries for crushing various types of materials into smaller Types of Crushers: What You Need to Know Machinery Partner

.jpg)

A Comprehensive Guide to Understanding the Different Types of

2023年2月28日 The shaft rotates at high speed and the hammers strike the material, causing it to break into smaller pieces The crushed material then exits through the bottom of the machine Gyratory Crushers Gyratory crushers are large machines used in the mining and construction industries to break down large rocks into smaller pieces2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before dischargeDolomite Sand Making Plant And Grinding Machine2023年2月21日 Discover everything you need to know about jaw crushing machines, from the various types such as single and double toggle, hydraulic and portable models, to their working principles, advantages, and disadvantages This comprehensive guide also provides expert tips on maintenance and selecting the right machine for your specific applicationThe Ultimate Guide to Jaw Crushing Machines: Types More It is made by crushing large rocks into smaller stones, which can be used for different projects or sold to the public However, not all crushed stone is created equal some types of stone are harder than others and require more crushing power and specific equipment for effective crushingThe Ultimate Guide on How to Crush Stone: Techniques and

Types And Applications Of SandMaking Equipment

Wide application: capable of handling stones of various hardness and suitable for different engineering needs Large crushing ratio: capable of crushing large stones into small particles, with a crushing ratio of 46 Application Fields; Mining: It is the primary crusher machine for crushing hard rocks, ores, etc