Calcite mill, selection, ore mill information

The Influence of Stirred Mill Orientation on Calcite Grinding

Based on grinding results from wet stirred milling, the stress energy in stirred media mills is mainly determined by the operating parameters of the tip speed of the stirrer and the size, density and Young’s modulus of the grinding media Besides the stress energy, the number of stress events also depends strongly on the 展开Optimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball Mill 226 ÇÜ Müh Mim Fak Dergisi, 33(3), Eylül 2018 1 INTRODUCTION The purpose of this experimental Optimization of Wet Grinding Parameters of Calcite Ore in Stirred 2022年1月1日 In this study, due to simplicity and potential usage, a Hardgrove mill was used to determine the kinetic breakage parameters of three different calcite samples with different The effects on the grinding parameters of chemical, morphological 2022年1月1日 Describing the petrographic and mineralogical properties and chemical composition of ores or minerals will assist in the selection and mathematical modeling of The effects on the grinding parameters of chemical, morphological

The effects on the grinding parameters of chemical, morphological

2022年1月1日 Most of the grinding plants for calcite are equipped according to the setups of tumbling mills such as ball mills However, it would be much more logical to replace such 2014年3月1日 Viscosity is a key parameter to control size reduction in a nanogrinding process This paper investigates the production of calcite suspensions by a wet grinding process in a Grinding of calcite suspensions in a stirred media mill: Effect of 2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid Effect of Operating Parameters on the Breakage Process of Calcite In this study, calcite (CaCO3) samples provided by Micron ’S Company (Ni ğde, Turkey) were used in the grinding tests, and their density was determined by using a helium pycnometer The Influence of Stirred Mill Orientation on Calcite Grinding

Wet Grindability of Calcite to UltraFine Sizes in Conventional Ball

2015年7月29日 The outcomes indicate that the wet grinding technique in conventional ball mill for calcite ore is effective to obtain ultrafine size products2014年1月1日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection Population balance model approach to ball mill 2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid mass fraction, grinding media size, media filling ratio, and grinding time have been investigated using a vertical type stirred media mill The results are evaluated on the basis of mean particle Effect of Operating Parameters on the Breakage Process of Calcite 2015年4月15日 The samples can be taken from adits, pits, trenches, etc, in the ore body or they can be crushed drill cores While it is helpful in anticipating variations in feed rates to know the grindability of the various ore types in a What Ore Testing is Required For Mill Selection

.jpg)

Impact of ball filling rate and stirrer tip speed on milling iron ore

2021年1月22日 Single magnetite, single calcite, and blended magnetitecalcite mixture at three weight ratios in four particle sizes were ground in a laboratory wet conical ball mill at four grinding time periodsThe CLRM Enhanced Roller Mill adjusts for calcite powder from 80 to 500 mesh, ideal for materials under Mohs 6 It is energy efficient The crusher is suitable for crushing all kinds of soft and hard ores with compressive strength not higher than Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill2022年5月5日 CLUM calcium carbonate vertical roller mill CLUM series ultrafine vertical roller mills can grind nonmetallic ores with Mohs hardness less than 7, up to 3000 mesh Among the finished powders it grinds, the content of fine powder is higher, and the content of 2um is higher With secondary powder selection functionCalcium Carbonate Grinding Mill Powder Modify SBM % 98824 0489 0388 0100 0065 0052 0022 0025 0020 0015 Grinding tests were carried out in a dry stirred ball mill both vertical and horizontal orientations with varyingThe Effect of Stirred Mill Orientation on Calcite Grinding

.jpg)

Monitoring ore loss and dilution for minetomill integration in

Despite the interest in investigating minetomill integration at individual gold mines (Bamber, 2008, p 5; Grundstrom et al, 2001), information on ore loss and dilution is relatively scarce as few reliable works have been documented that are applicable to conditions in South African gold mines (Onederra, 2004, p 1)The Influence of Stirred Mill Orientation on Calcite Grinding Serkan Cayirli1 Hasan Serkan Gokcen2 Received: 28 September 2020/Accepted: 7 April 2021 # Society for Mining, Metallurgy Exploration Inc 2021 Abstract The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientableThe Influence of Stirred Mill Orientation on Calcite Grinding2009年10月1日 Request PDF Batch Grinding in Laboratory Ball Mills: Selection Function The selection functions and the breakage distribution functions are based on the experimentallydetermined particle size Batch Grinding in Laboratory Ball Mills: Selection Function2014年10月27日 The outcomes indicate that the wet grinding technique in conventional ball mill for calcite ore is effective to obtain ultrafine size products Discover the world's research 20+ million membersWet Grindability of Calcite to UltraFine Sizes in Conventional Ball Mill

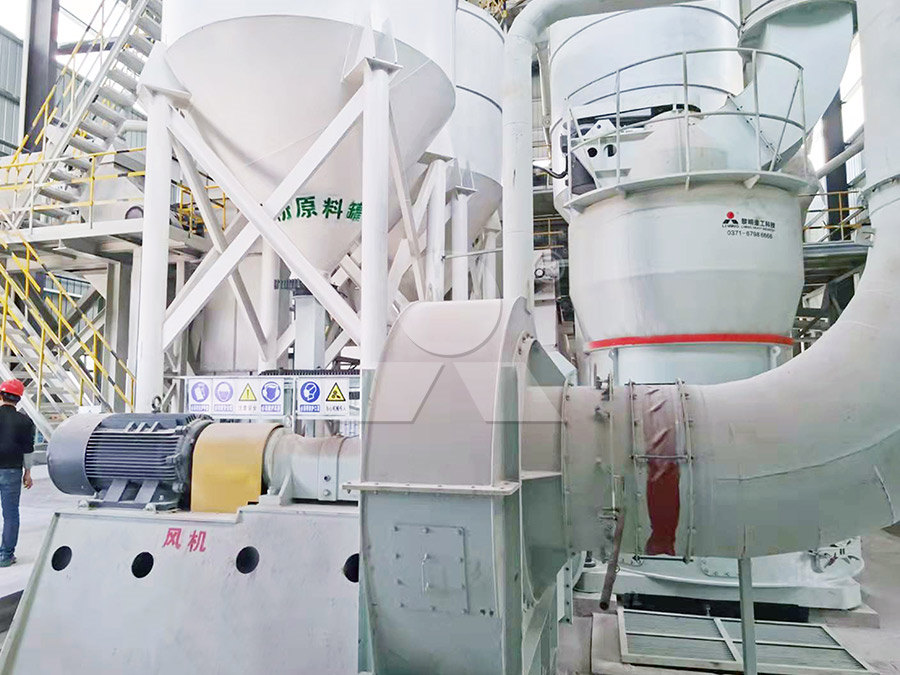

Vertical mill simulation applied to iron ores

2014年11月1日 The sample of coarse iron ore was characterized in laboratory tests carried out in a small batch ball mill Selection and breakage function parameters were determined from the laboratory tests2021年4月21日 The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill The experimental results were evaluated using stress intensity analysis The performance was also compared in terms of mill orientation The results showed that the d50 values decreased with The Influence of Stirred Mill Orientation on Calcite GrindingPDF On Jan 1, 2017, Serkan Cayirli and others published The Effect of Stirred Mill Orientation on Calcite Grinding Find, read and cite all the research you need on ResearchGateThe Effect of Stirred Mill Orientation on Calcite GrindingEquipment Selection Calcite Raymond mill Calcite 1200 mesh Mill Calcite Raymond mill Grinding customer site There are many customers onsite for materials such as calcite grinding machines, and they have a good reputation Please contact us for more details: +86 ( WhatsApp/WeChat) Calcite 1200 mesh MillNews Calcite milling machine

.jpg)

Optimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball Mill

2018年9月30日 Abstract This study focused on ultrafine grinding of calcite powder (CaCO3) using a vertical stirred ball mill The influences of various operating parameters such as stirrer speed (rpm), ball filling ratio (J), powder filling ratio (fc), solid ratio (wt%) and grinding time were studied under wet conditions2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill integration in The ideal calcite mill equipment For different processing needs, SBM Heavy Machine has developed a scientific calcite vertical roller mill selection configuration scheme, equipped with more reasonable vertical roller mill prices, helping each mill to create greater profits and gain greater social valuecalcite mill vertical roller millAs the HLMX 2500 Mesh Superfine Powder Grinding Mill works, the motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder The material moves to the edge of the dial due to the effect of HLMX 2500 Mesh Superfine Powder Grinding Mill

.png)

Ultimate End Mill Selection Guide: Choosing the Right Type of End Mill

2024年1月30日 End Mill Selection Guide When selecting an end mill for a specific machining task, it is crucial to consider several parameters that directly influence performance and results The choice of an end mill is dictated by the material being machined, the type of milling operation, the desired finish, and the machine’s capabilities2023年4月21日 Calcite ball mills have several uses in the building materials, chemicals, and mineral processing industries, as well as for grinding a wide range of ores and other materials In addition, according to the different loads used Calcite Processing SBM Mill Crusher2021年4月1日 Ultrafine grinding of calcite powder was studied under batch wet conditions in a laboratory stirred mill After grinding, the suspension was allowed to age at 30°C for 12 and 24 hThe Influence of Stirred Mill Orientation on Calcite GrindingFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, Ball mill is common used grinding plant in the industry, a wider selection Products: to improve the relevance of the collection Other Please specify: Help us improve: remainingOre mill, Ore grinding mill All industrial manufacturers

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 between the ball mill a nd rod mill showed that particles in a ba ll mill h ave a shorter residence time than in a rod mill [5 8] This is because balls offer less resistance to t he flow of 2022年4月8日 NO and SO2 are representative harmful gases generated in steel works, and iron ore sintering process accounts for more than 50 pct of total generation The current study investigated the effects of adding CaO and FeO, which are the components contained in raw materials to sinter mix on the formation of NO and SO2 The addition of CaO to sinter mix Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix There are five models of calcite grinding mill: HGM80, HGM90, HGM100, HGM125 and HGM1680L, both ultra fine grinding mill Finished production fineness: 250meshes2500meshes, 574 micronCalcite Grinding Mill2020年3月9日 Grinding of Calcite in a Stirred Media Mill Using the BoxBehnken Design Diler KatirciogluBayel Department of Mining Engineering, University of Nigde Omer Halisdemir, mill on the ultrafine grinding of refractory Au/Ag ores The grinding results were evaluated by d80 Following this study, Celep and Yazıcı [14] Grinding of Calcite in a Stirred Media Mill Using the BoxBehnken

Ball mill characteristics and test conditions Download Table

This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total 2014年3月1日 The determination of the specific energy depends among others on the mode of grinding operation For a grinding process in a circulating mode (multipasses), the specific energy can be determined as follows: (1) SE = ∫ 0 t N τ − N 0 d τ m P Where m P is the mass of the solid product, N(τ) is the power at the time τ and N 0 is the noload power If the grinding media Grinding of calcite suspensions in a stirred media mill: Effect of 2014年3月1日 Quartz and calcite are the representative gangue minerals exited in the hematite ores while the interactions between these gangue minerals are still unknown The roles of calcite slimes on the quartz flotation using corn starch as the depressant and dodecylamine (DDA) as the collector were studied though microflotation tests, zeta potential measurements and DLVO Grinding of calcite suspensions in a stirred media mill: Effect of 2014年1月1日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection Population balance model approach to ball mill

Effect of Operating Parameters on the Breakage Process of Calcite

2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid mass fraction, grinding media size, media filling ratio, and grinding time have been investigated using a vertical type stirred media mill The results are evaluated on the basis of mean particle 2015年4月15日 The samples can be taken from adits, pits, trenches, etc, in the ore body or they can be crushed drill cores While it is helpful in anticipating variations in feed rates to know the grindability of the various ore types in a What Ore Testing is Required For Mill Selection2021年1月22日 Single magnetite, single calcite, and blended magnetitecalcite mixture at three weight ratios in four particle sizes were ground in a laboratory wet conical ball mill at four grinding time periodsImpact of ball filling rate and stirrer tip speed on milling iron ore The CLRM Enhanced Roller Mill adjusts for calcite powder from 80 to 500 mesh, ideal for materials under Mohs 6 It is energy efficient The crusher is suitable for crushing all kinds of soft and hard ores with compressive strength not higher than Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill

.jpg)

Calcium Carbonate Grinding Mill Powder Modify SBM

2022年5月5日 CLUM calcium carbonate vertical roller mill CLUM series ultrafine vertical roller mills can grind nonmetallic ores with Mohs hardness less than 7, up to 3000 mesh Among the finished powders it grinds, the content of fine powder is higher, and the content of 2um is higher With secondary powder selection function% 98824 0489 0388 0100 0065 0052 0022 0025 0020 0015 Grinding tests were carried out in a dry stirred ball mill both vertical and horizontal orientations with varyingThe Effect of Stirred Mill Orientation on Calcite GrindingDespite the interest in investigating minetomill integration at individual gold mines (Bamber, 2008, p 5; Grundstrom et al, 2001), information on ore loss and dilution is relatively scarce as few reliable works have been documented that are applicable to conditions in South African gold mines (Onederra, 2004, p 1)Monitoring ore loss and dilution for minetomill integration in The Influence of Stirred Mill Orientation on Calcite Grinding Serkan Cayirli1 Hasan Serkan Gokcen2 Received: 28 September 2020/Accepted: 7 April 2021 # Society for Mining, Metallurgy Exploration Inc 2021 Abstract The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientableThe Influence of Stirred Mill Orientation on Calcite Grinding

.jpg)

Batch Grinding in Laboratory Ball Mills: Selection Function

2009年10月1日 Request PDF Batch Grinding in Laboratory Ball Mills: Selection Function The selection functions and the breakage distribution functions are based on the experimentallydetermined particle size