Ore grinding machine rag use

High Pressure Grinding Rolls for Minerals AusIMM

In the diamond industry, the machines are used mainly for secondary and recrush duty In the iron ore industry, most of the machines are found in pellet feed applications However, there are a few notable examples where HPGRs are used for coarse iron ore grinding – in Chile, 2024年8月15日 These mineral processing plants utilize advanced equipment and technologies to perform crushing, grinding, flotation, magnetic separation, gravity separation, and other Mineral Processing Plants: What You Need to Know Fote MachineryEnduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron oreOur Dynamic HPGR Technology for Mineral Grinding Weir2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the Ore Grinding SpringerLink

Ultrafine Grinding in Contemporary Flow Diagrams for Mineral

2015年7月21日 This article discusses the range of application of ultrafine grinding for processing mineral raw materials and presents examples of the successful use of this technology in the 2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle Mineral Processing Equipment for Mining IndustryCustomized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Grinding Metso2023年7月27日 Rod grinding process is an ore grinding method which uses a long round metal rod as the grinding medium in a mill to smash the ore In the rod grinding process, when the Rod Grinding Process SpringerLink

Breakage process of mineral processing comminution machines –

2020年9月1日 Ore texture heterogeneity affects minerals breakage mode Shifting the particle breakage to nonrandom breakage mode improves liberation Microprocesses in breakage 2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed up to approximately Grinding Mills — Types, Working Principle Applications2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation Illite Ore Industrial Grinding Mill Machine SBM For this reason, tool grinding machines, circular grinders, surface grinders, bench grinders, etc, are essential for many stages of production for the industry and crafts At Surplex you will find a great variety of grinding machines and its Used Grinding Machines Industrial Metal Grinders

.jpg)

Occupations: Rag Grinder PastToPresentGenealogy

Grinding was one of the early processes in shoddy and mungo manufacturing Once the woollen rags were sorted, and the dust shaken out by a ‘ragshaker’ machine, they were spread in layers on the floor of the grinding room, and each layer sprinkled with olive or galipoli oil to facilitate the grinding process and reduce frictionSBM provides reliable and energysaving technologies and solutions, and its products cover ultrafine grinding mills, vertical mills, wet mills, coarse mills, crushers, powder surface coating machine, etcSBM Ore Ultrafine Grinding Mill2019年4月16日 LEARNING FROM OTHER INDUSTRIES; WHY THE VRM TECHNOLOGY IS A SERIOUS ALTERNATIVE FOR ORE GRINDING Any machine used for grinding or crushing consumes around 30 to 40% of the energy of a factory(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2018年7月30日 Remove the excess weld with a Norton Quantum3 inox or Norton Vulcan grinding wheel at a 3045° angle The grinding discs create a coarse surface finish so it’s a good idea to leave a small amount of weld on the surface TOP TIP: Combo Cut and Grind with one disc, maximum comfort and great alternative to regular grinding wheelsRAG – CuttingOff Grinding Norton Abrasives UK

.jpg)

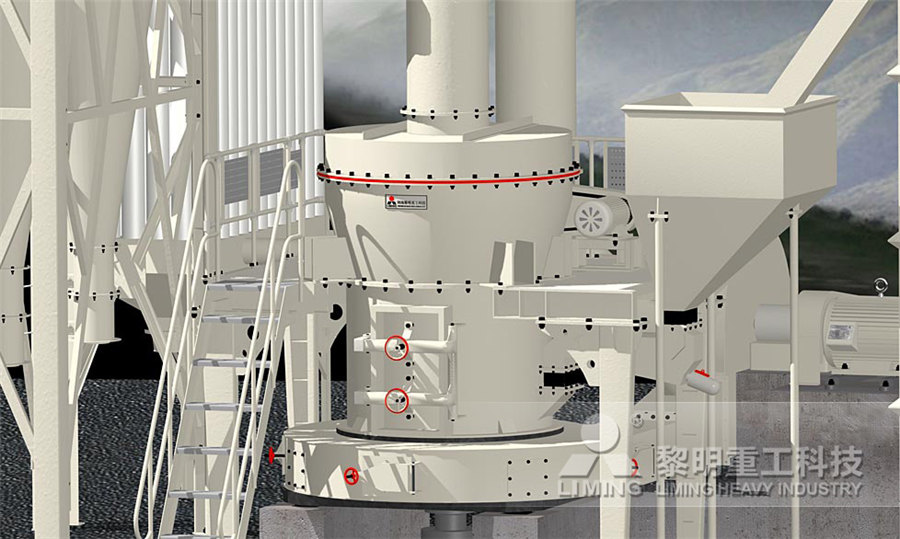

Ore Grinding Machines: Ball Mill, Rod Mil Grinding Media

Ore grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;The Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's lawUnderstanding the SAG Mill in Copper Ore Mining Process2015年3月15日 Furthermore, ore textures become more complex and the valuables are more finegrained, compared to ores of the last decades, requiring additional grinding for sufficient mineral liberation These trends may lead to a four times higher energy consumption for the comminution of the main metal ores in the year 2030 compared with today (Norgate and Research of iron ore grinding in a verticalrollermill2017年5月21日 The leading suppliers of SAG type mills are building up experience in the testing of ores, sizing of machines and in proper operation Grinding and Flotation Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the opencircuit 2600mm x 3960mm Copper Ore Crushing, Grinding Flotation 911Metallurgist

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Processing Machines Pretty new to create overall, but have a decent bit of it I've been working on an ore processing machine using the grinding wheels and bulk washing Have a decent bit set up but struggling with the rest Can I see what ore machines you guys have built!?Ore Processing Machines : r/CreateMod Reddit2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle The ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining, grinding, screening, crushing plantBall Mill JXSC Mineral

Iron Ore Pelletizing Process: An Overview ResearchGate

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate2023年4月23日 Harder ores have a larger grinding re sistance than soft ores ther efore, hard ores have lower breakage rates than soft ores Wear resistance depends on the stre ngth of the ore being ground [6 7 ](PDF) Grinding Media in Ball MillsA Review ResearchGate2012年6月1日 is charged with the starting material (ore, rock, etc) and the grinding media (balls), 52 the milling process takes place during rotation as a result of the transfer of kinetic Grinding in Ball Mills: Modeling and Process Controlcontrolled and manipulated in grinding mill circuits (Wei and Craig, 2009b) The three main elements in Fig 1 are the mill, the sump and the hydrocyclone The mill receives four streams: mined ore (MFS), water (MIW), additional steel balls (MFB) to assist with the breakage of ore and under ow from the hydrocyclone The ground ore in the mill mixesAnalysis and validation of a runofmine ore grinding mill circuit

(PDF) A Method of Ore Blending Based on the Quality of

2021年5月31日 ore’s composition, the particle size of the ore, and the grinding time When comparing Machines to Classify Dephosphorization in BOF Steelmaking Metals 2020, 10, 25 [CrossRef] 23Main machines in ore grinding process are Iron ore mill equipment The most common Iron ore mills in mining are ball mill, raymond mill and high pressure suspension mill The selection of is according to customers’ requirements and Iron ore grinding plant for ores milling process SBM2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to Grinding Machines: Types and Selection PrinciplesJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

The effects of ore blending on comminution behaviour and

2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a 2024年10月25日 Dasen Mining is a professional ore mining machinery, equipment manufacturer, supplier and mining solution provider for gold ore, copper ore, tungsten ore, tin ore, tantalum ore, chrome ore, manganese ore, iron ore, zircon ore, leadzinc ore etcDasen: all in one ore mining machinery, equipment, solution Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study A Jankovic and W Valery Metso Process Technology Innovation, PO Box 1028, Eagle Farm Qld, 4009, Australia ABSTRACT:Efficiency of the comminution operations is traditionally assessed based on operating cost and energy consumption(PDF) Reducing Grinding Energy and Cost Magnetite Iron Ore 2022年6月29日 The grinding drum of the gold rolling machine is of the ferrule type It is a gold machine for ore dressing of small and medium enterprises in mining areas Ф1200, Ф1100, Ф1000, Ф900, Ф850 are available for users to choose gold Structural design: The gold rolling machine must first be able to ensure a solid structure, How to use and maintain the gold ore wet pan mill

Effect of different parameters on grinding efficiency and its

2016年11月22日 Fundamentals of grinding mechanism As a material removal process, grinding process is similar to other cutting processes in many respects, such as materials are removed in forms of chips (Chen, Citation 2009; Rowe, Citation 2009)However, grinding has its distinctness from other machining processes2020年3月28日 The grinding product t10 is negatively correlated with the feed sizes of ore when the grinding force is applied to the ore At the same time, it has a simple positive linear relationship with the Development of a Novel Grinding Process to Iron Ore Pelletizing 2023年10月17日 Factors for choosing a suitable ore powder grinding mill 1 Raw material characteristics: Different raw materials have different hardness, humidity and grinding and crushing properties, and the corresponding ore powder grinding mill needs to be selected to meet the processing requirements 2 Production capacity: Determine the required processing How to choose a suitable ore powder grinding mill?2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation Illite Ore Industrial Grinding Mill Machine SBM

Used Grinding Machines Industrial Metal Grinders

For this reason, tool grinding machines, circular grinders, surface grinders, bench grinders, etc, are essential for many stages of production for the industry and crafts At Surplex you will find a great variety of grinding machines and its Grinding was one of the early processes in shoddy and mungo manufacturing Once the woollen rags were sorted, and the dust shaken out by a ‘ragshaker’ machine, they were spread in layers on the floor of the grinding room, and each layer sprinkled with olive or galipoli oil to facilitate the grinding process and reduce frictionOccupations: Rag Grinder PastToPresentGenealogySBM provides reliable and energysaving technologies and solutions, and its products cover ultrafine grinding mills, vertical mills, wet mills, coarse mills, crushers, powder surface coating machine, etcSBM Ore Ultrafine Grinding Mill2019年4月16日 LEARNING FROM OTHER INDUSTRIES; WHY THE VRM TECHNOLOGY IS A SERIOUS ALTERNATIVE FOR ORE GRINDING Any machine used for grinding or crushing consumes around 30 to 40% of the energy of a factory(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

.jpg)

RAG – CuttingOff Grinding Norton Abrasives UK

2018年7月30日 Remove the excess weld with a Norton Quantum3 inox or Norton Vulcan grinding wheel at a 3045° angle The grinding discs create a coarse surface finish so it’s a good idea to leave a small amount of weld on the surface TOP TIP: Combo Cut and Grind with one disc, maximum comfort and great alternative to regular grinding wheelsOre grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;Ore Grinding Machines: Ball Mill, Rod Mil Grinding MediaThe Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's lawUnderstanding the SAG Mill in Copper Ore Mining Process2015年3月15日 Furthermore, ore textures become more complex and the valuables are more finegrained, compared to ores of the last decades, requiring additional grinding for sufficient mineral liberation These trends may lead to a four times higher energy consumption for the comminution of the main metal ores in the year 2030 compared with today (Norgate and Research of iron ore grinding in a verticalrollermill

Copper Ore Crushing, Grinding Flotation 911Metallurgist

2017年5月21日 The leading suppliers of SAG type mills are building up experience in the testing of ores, sizing of machines and in proper operation Grinding and Flotation Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the opencircuit 2600mm x 3960mm