Resin roller mill equipment

Raymond® Roller Mills Coperion

The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersThe Ceramic Triple Rolling Mill system disperses, kneads, and mixes highviscosity fluids like paste and resin Note: For nonstandard specifications, we also make rollers with diameters of Ceramic Triple Roll Mill NORITAKE CO,LIMITEDHwa Maw established in 1972, mainly are produced the mixing and grinding equipments which serve the chemical industry in product's viscosity from low to very highHWA MAW MACHINE INDUSTRIAL CO, LTDOur mills offer a broad range of roll materials and concepts to meet all your applications, including cleanroom production to international standards Threeroll mills (triple mills) from Bühler provide reliability, high raw material yield and ThreeRoll Mills Grinding and Dispersing Bühler Group

.jpg)

High Capacity CE Certificated WaterAbsorbent Resin Roller Mill

High Capacity CE Certificated WaterAbsorbent Resin Roller Mill, Find Details and Price about WaterAbsorbent Resin Roller Mill WaterAbsorbent Resin Grinding Mill from High Capacity 2023年3月8日 FRANLI provides complete sets of resin manufacturing equipment and production lines, which are mainly suitable for the synthesis of various chemical resins, such as unsaturated polyester resin, phenolic resin, Resin Production Line Complete Manufacturing Find your roller mill easily amongst the 185 products from the leading brands (WAMGROUP, Brabender, LONGI, ) on DirectIndustry, the industry specialist for your professional purchasesRoller mill, Roller grinding mill All industrial manufacturersThe Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersRaymond Roller Mill airswept vertical ringroll

.jpg)

How to Select a Rolling Mill for Jewelry Making

2019年9月16日 A jeweler’s rolling mill is a machine consisting of two very smooth, highly polished, hardened steel rollers, mmounted in a strong, rigid frame Most jewelry studios are equipped with a manual rolling mill; however, Experience next generation milling technology with ROMIL – seamlessly combining proven technology with innovative features Its compact design makes it the ideal roller mill for both ROMIL Roller Mill by SWISCAWabash supplies Industrial Roller Mills and Raymond Equipment for Sale We have a huge These mills are capable of grinding an almost unlimited variety of materials including but not limited to synthetic resin, iron oxides, sulphur, Industrial Roller Mills Raymond Equipment for SaleBrowse the range of Roller Mills for sale from Post Equipment of Rock Valley, Iowa Delivery available to farms across the US Menu Farm Equipment Reel Feed Mixers; Vertical Feed Mixers; This roller mill is set up for high moisture corn and is rated for 4500 bu/hour! Ready to go! henkebuffalo2: Additional InformationRoller Mills for sale Post Equipment

Grain Roller Mills Automatic Equipment

Automatic's industrial grain roller mills produce precise particle size every time, even when it comes to high volume grain processing – as much as 15,000 bushels an hour for our hardestworking, highcapacity modelsThe Raymond® Roller Mill is an airswept vertical ring Phosphate Rock, Talc, Coal, Hydrated Lime, Petroleum Coke, Pigments, Phenolic Resins or similar materials Gallery; Downloads; Brochures Raymond Roller Mill Upgrades (16590 kB) RBS Research Development Center (19618 kB) Raymond Guide to Quality Equipment (28817 kB) Pulverizing Raymond® Roller Mills CoperionAutomatic Equipment is the nation’s leading provider of livestock roller mills, rotary mills, hammer mills, and other industrial grinding mills Farmers choose our grain processing equipment for beef, pork, dairy or poultry farming Get more from your grain with Automatic feed millsLivestock Roller Mills Grain Processing Equipment Automatic Equipment Machinery; Tools Disposables; Metallic Epoxy Kits; All Products addremove Paints addremove Resincoat Epoxy Resin Roller Sleeve is expertly crafted from thermobonded nylon stands resilient against chemicals that typically harm roller sleeves Hoyle Mill Road, Kinsley, WF9 5JB 0330 0570 695 Tools Disposables Resincoat

.jpg)

Grinding Mills and Pulverizers Selection Guide: Types, Features

Video credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuously2016年11月23日 For Laying Resin Bound, The Essential Resin Drive Tools You Will Need: A Forced Action Mixer A Wheelbarrow 16″ Trowel Plasterer’s Mixing Paddle Drill Transformer Spazzle/Rake Buckets White Spirit Cloths Gas Torch Gloves Duct Tape Chalk Roller Decorator’s Tray Rubber Spatula Stopwatch Plastic Sheeting If you are new to the Tools Of The Resin Drive Trade Resin Suppliers The Resin MillMill Powder Tech specializes in powder mixing technology, offering solutions from standalone machines to complete systems including conveying Over 80 years of experience on milling and mixing equipment manufacture, we are your reliable supplier View Detail Pin Mill PM Series View Detail Turbo Mill TM Series View Detail Impact Mill Powder Tech|Leader in Grinding Machine Equipment2023年3月8日 In the production of resin, the most used equipment is the chemical reactor, and the resin reactor can be divided into hightemperature resin reactors (150°C300°C) according to the reaction temperature ℃) and lowtemperature resin reactor (60℃150℃)The whole set of equipment of the resin production line includes a high tank, reaction kettle, dilution tank, oil Resin Production Line Complete Manufacturing Equipment

.jpg)

Resin Production Line, Plant and Equipment – SeFluid

Reactor is the core equipment of a resin production line A usual reaction kettle has a volume of 0510 cubic meters The body of reactor is a cylindrical body with jackets for heating or cooling, an oval bottom and several orifices on the Our selection of hammer and roller mill are designed to process ingredients efficiently and economically, while improving their absorption quality Find a dealer About us ; Buy Valmetal equipment 150 dealers across the world Hammer and Roller mill ValmetalPlanetary Ball Mill Located in Ceramics Lab (369) SOP: Across International PQN04 Planetary Ball MILL The Across International planetary ball mill is used when even finer particle sizes are necessary when compared to our rolling ball Processing Equipment gatech2024年6月7日 EPIC Powder's ring roller mill is ideal for producing ultrafine calcium carbonate powder with low investment and high efficiency Skip to content Home; The entire set of equipment operates under negative pressure, and the Ring Roller Mill Ultrafine calcium carbonate production equipment

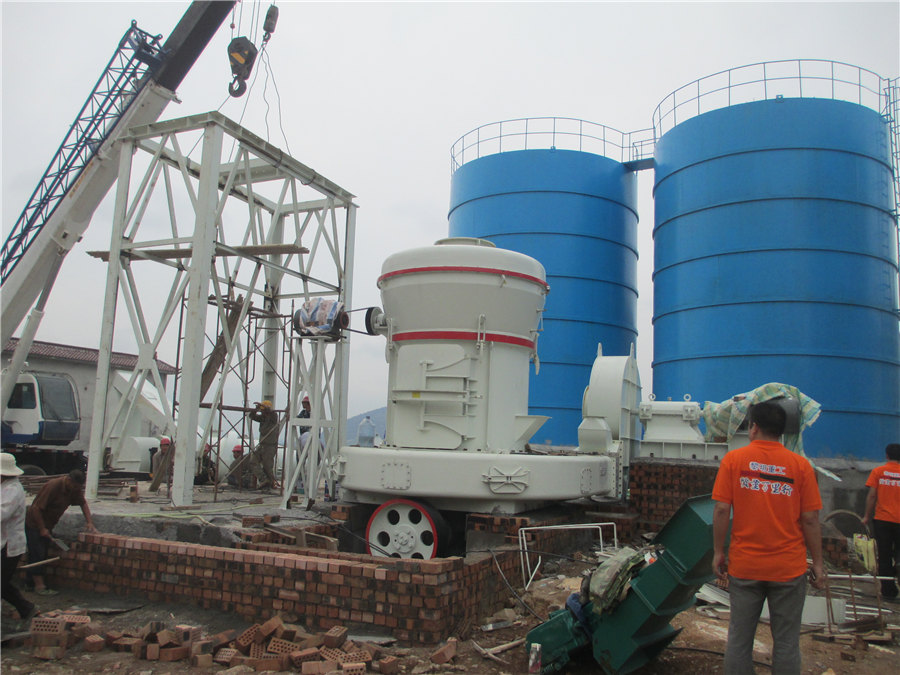

3M new material factory: Resin grinding mill production line

The second phase project with an annual output of 20000T purchased ALPA's equipment, and ALPA has provided five sets of high standard ultrafine grinding equipment Raw Material: Resin Capacity: 20000t/yResin Mill is the go to brand for resin bound products Installers can browse our range of resin materials and choose the perfect option for their customersResin Bound Surfacing Resin Bound Supplierequipment has been setting the standards in size reduction since 1887, The roller mill, when equipped with a variable speed mill drive, coke, pigments, phenolic resins or similar materials RAYMOND BARTLETT SNOW 2151 Fisher Drive Naperville, IL 60563 USA RAYMOND® ROLLER MILLS ThomasnetRoller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds Choose the roller mill that best fits your location's needs and gather more information by contacting companies through the form available belowRoller Mills Grain and Feed Equipment

Mill, Roller, Refiner Archives Loeb Equipment

Used Roller Mills and Refiner Mills for sale plus thousands of other items including Used Packaging Equipment and Used Processing EquipmentMini Grain Roller Mill – LGRM 2HP Grain Roller Mill Buy yourself a fully adjustable Grain Roller Mill to increase your stock and pets health The benefits of fresh rolled feed is well known and our Grain Roller Mills provide you with high quality, excellent durability and reliably milled grainLachys Mini Grain Roller Mill Farm Supplies Machinery EquipmentThe second phase project with an annual output of 20000T purchased ALPA's equipment, and ALPA has provided five sets of high standard ultrafine grinding equipment Raw Material:Resin Capacity:20000t/y3M new material factory: Resin grinding mill production lineShop our range of equipment machinery designed for use with our products Resincoat Epoxy Resin Roller Sleeve is expertly crafted from thermobonded nylon stands resilient against chemicals that typically harm roller sleeves Hoyle Mill Road, Kinsley, WF9 5JB 0330 0570 695 InformationEquipment Machinery Resincoat

Disperser, High Speed Mixers, Industrial Mixers, Abster Equipment

High Speed Dispersers are considered as most versatile equipment for paint production As the name suggests, the disperser range has been specifically designed to disperse, mix and homogenize products The process of dispersion is carried out by the centrally located shaft having Saw tooth impeller running at high speed (1000 to 1400 RPM)If your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders, air classifying mills, hammer mills, and lump breakers to meet all of your industrial processing needs We have been designing, manufacturing and creating innovative solutions for large and small customers all over the worldParticle Size Reduction Solutions Prater IndustriesAir Classifying Mill Rieco’s Air classifier Mill (ACM) is a mill with integrated grinding, classifying, conveying and collecting operations for achieving ultrafine grinding up to 810 micron which is highly suitable for Plastics and fiber grade applicationsPigment Grinding Systems Pigment Grinding Plant Manufacturers Triple Roller Mill TRM Mill, Resin plant manufacturer Hydraulic High Speed Disperser manufacturer Our Products High Speed Disperser; Ribbon Blender Mixer; Resin Plants; Sigma Mixer; Contact Us Abster™ Equipment 24/A, Laxmi Ind Estate, Amraiwadi, Ahmedabad , Gujarat, INDIA +91 +91Triple Roller Mill TRM Mill, Fine Grinding Mill, Manufacturers and

.jpg)

Stationary Roller Mills and Corn Crackers Horning

It was that need that spawned the Horning stationary roller mill Multiple options and nononsense engineering make these units a favorite of many happy owners Roll Adjustment in a Cinch Finetune the adjustment quickly with our innovative yet simple cinching adjustment on The choice of highenergy equipment will depend, primarily, on the viscosity of the mixture If it is an oil or resin vehicle with a viscosity of 10,000 cP or higher, the choice would probably be the roller mill For viscosities between 30010,000 cP in either aqueous or oilresin vehicles, the colloid mill could be used For viscosities fromPBCarbon Black 3044 US SPX FLOWHere is your One Stop Shop for Epoxy Resin, Fibreglass Materials, Resin Art Supplies Tools used in creative industries and marine repair Skip to content Home; Shop; Products River Table Resin; Fibreglass Roller $ 1250 Add to cart Sale! River Resin Premium 7kg Starter Kit $ 36000 Original price was: $36000 $ 32500 Current price Online Epoxy Resin Supplies Australia Wide ShippingIf you are in the market for dairy feeding equipment or beef feeding equipment, the RENN™ blower mill is built to handle high volumes of high moisture corn and corn silage Renn Auxiliary PTO Mill A RENN™ ROLLER MILL WITH THE AUXILIARY PTO OFFERS THE FLEXIBILITY OF ROLLING DIRECTLY INTO THE BAGGER, OR CAN BE DETACHED AND OPERATED AS Renn Roller Mills Stillwell Sales LLC

Industrial Roller Mills Raymond Equipment for Sale

Wabash supplies Industrial Roller Mills and Raymond Equipment for Sale We have a huge These mills are capable of grinding an almost unlimited variety of materials including but not limited to synthetic resin, iron oxides, sulphur, Browse the range of Roller Mills for sale from Post Equipment of Rock Valley, Iowa Delivery available to farms across the US Menu Farm Equipment Reel Feed Mixers; Vertical Feed Mixers; This roller mill is set up for high moisture corn and is rated for 4500 bu/hour! Ready to go! henkebuffalo2: Additional InformationRoller Mills for sale Post EquipmentAutomatic's industrial grain roller mills produce precise particle size every time, even when it comes to high volume grain processing – as much as 15,000 bushels an hour for our hardestworking, highcapacity modelsGrain Roller Mills Automatic EquipmentThe Raymond® Roller Mill is an airswept vertical ring Phosphate Rock, Talc, Coal, Hydrated Lime, Petroleum Coke, Pigments, Phenolic Resins or similar materials Gallery; Downloads; Brochures Raymond Roller Mill Upgrades (16590 kB) RBS Research Development Center (19618 kB) Raymond Guide to Quality Equipment (28817 kB) Pulverizing Raymond® Roller Mills Coperion

.jpg)

Livestock Roller Mills Grain Processing Equipment Automatic

Automatic Equipment is the nation’s leading provider of livestock roller mills, rotary mills, hammer mills, and other industrial grinding mills Farmers choose our grain processing equipment for beef, pork, dairy or poultry farming Get more from your grain with Automatic feed millsEquipment Machinery; Tools Disposables; Metallic Epoxy Kits; All Products addremove Paints addremove Resincoat Epoxy Resin Roller Sleeve is expertly crafted from thermobonded nylon stands resilient against chemicals that typically harm roller sleeves Hoyle Mill Road, Kinsley, WF9 5JB 0330 0570 695 Tools Disposables ResincoatVideo credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide: Types, Features 2016年11月23日 For Laying Resin Bound, The Essential Resin Drive Tools You Will Need: A Forced Action Mixer A Wheelbarrow 16″ Trowel Plasterer’s Mixing Paddle Drill Transformer Spazzle/Rake Buckets White Spirit Cloths Gas Torch Gloves Duct Tape Chalk Roller Decorator’s Tray Rubber Spatula Stopwatch Plastic Sheeting If you are new to the Tools Of The Resin Drive Trade Resin Suppliers The Resin Mill

Mill Powder Tech|Leader in Grinding Machine Equipment

Mill Powder Tech specializes in powder mixing technology, offering solutions from standalone machines to complete systems including conveying Over 80 years of experience on milling and mixing equipment manufacture, we are your reliable supplier View Detail Pin Mill PM Series View Detail Turbo Mill TM Series View Detail Impact 2023年3月8日 In the production of resin, the most used equipment is the chemical reactor, and the resin reactor can be divided into hightemperature resin reactors (150°C300°C) according to the reaction temperature ℃) and lowtemperature resin reactor (60℃150℃)The whole set of equipment of the resin production line includes a high tank, reaction kettle, dilution tank, oil Resin Production Line Complete Manufacturing Equipment