Sepiolite grinding machine process flow

.jpg)

Sepiolite Processing Technology LZZG

The deep processing of sepiolite mainly includes ultrafine processing, activation, surface modification treatment and other methods Among them, ultrafine processing usually uses air 1984年1月1日 Sepiolite is used as deodorizer, dehydrant, neutralizer and decolorant in contact processes, where the oil is treated with sepiolite, and later filtered or in percolation processes Sepiolite: Properties and Uses ScienceDirectSepiolite is an inorganic clay material with stable high temperature resistance During the gradual heating process from low temperature to high temperature, the crystal structure of sepiolite Application And Properties Of Sepiolite Powder Hebei Yayang The optimal process parameters were obtained by taking the velocity gradient, rotational kinetic energy of dielectric sphere and wear amount of stirring mill as evaluation indexes The self Research on optimal process parameters of sepiolite spiral stirred

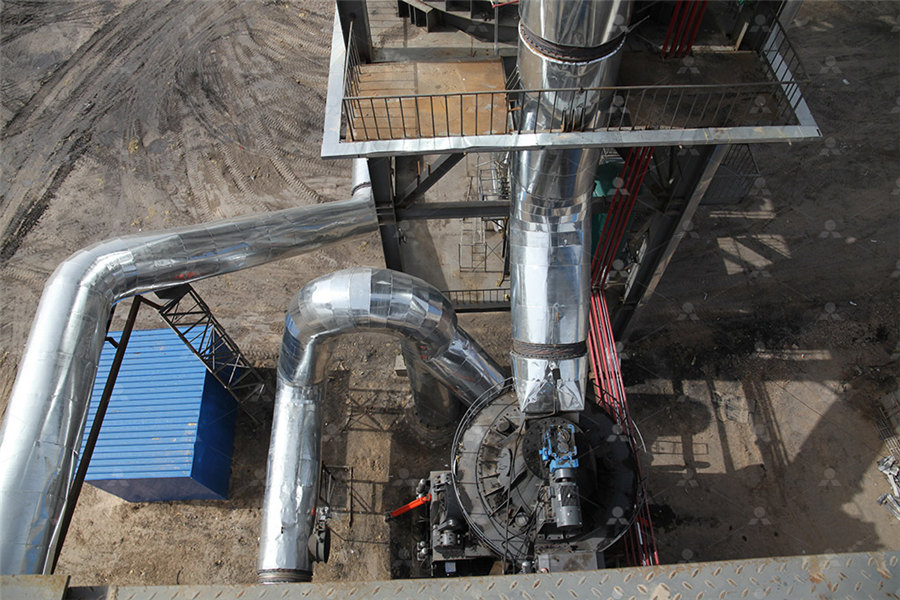

Sepiolite scrubbing machine beneficiation process LZZG

The use of scrubbing dispersion and centrifugal separation technology can achieve effective separation of sepiolite and associated talc, quartz, calcite, etc, and obtain a higher purity 2020年9月5日 Grinding combined with alkali activation proved a simple and effective method for boosting CO2sorption capacity of sepiolite to the level comparable to aminefunctionalized, acidactivated sepiolite sorbentsInfluence of Dry Milling on Phase Transformation of The grinding process of sepiolite generally consists of fine powder processing (20 mesh400 mesh)and ultrafine powder processing (400 mesh3250 mesh) STAGE 1: CRUSHING The SEPIOLITEgrinding millIn order to reduce the particle size and distribution width of sepiolite ore powder after grinding, a spiral stirring mill was developed based on laminated crushing theoryThe sepiolite grinding Research on optimal process parameters of sepiolite spiral stirred

.jpg)

Application And Properties Of Sepiolite Powder

Sepiolite is an inorganic clay material with stable high temperature resistance During the gradual heating process from low temperature to high temperature, the crystal structure of sepiolite DISCO delivers complete ultrathin grinding solutions that comprise four key elements: machine, grinding wheel, protective tape, and processing conditions TAIKO ® Process The TAIKO process is the name of a wafer back grinding process Grinding Solutions DISCO Corporation2013年5月9日 PDF Surface grinding is the most common process used in the manufacturing sector to produce smooth finish on flat surfaces This study was conducted by using surface grinding machine(PDF) Optimization of Process Parameters in Surface 2023年11月13日 Ultrafine grinding mill production line process flow The loader transports the crushed ore with a particle size of less than 500 mm to the firstlevel vibrating feeder, and intelligently adjusts the feeding speed through the variable frequency motor to ensure that large pieces of ore are transported smoothly and evenly to the secondlevel vibrating feederChina Hubei heavy calcium carbonate HGM100P ultrafine grinding

.jpg)

Chromium Processing Process Flow, Cases JXSC Machine

2019年8月23日 This Setup is a Rock Chrome ore processing plant, it is configured with raw material feeding, primary crushing, fine crushing, screening, ball mill grinding, and gravity separation to separate out and upgrade Chrome concentrate The chrome ore raw material stone is fed to the primary jaw crusher by a vibration feeder to feed rock chrome ore smoothly and Main Applications of Sepiolite powder process by Sepiolite grinding mill With the rapid development of China’s economy, the market demand After being processed by sepiolite grinding machine, it can be widely used in various industrial fields, such as architecture, ceramic technology, catalyst preparation, pigment synthesis, petroleum Application And Properties Of Sepiolite Powder Hebei Yayang 2011年1月1日 Figure 21 shows a twoway abrasive flow deburring process where pressure is being directed from top and bottom piston to abrasive media in the cylinder to push the abrasive back and forthAbrasive flow machining (AFM): An Overview ResearchGate2019年8月22日 The mainstream gold beneficiation process flow is generally crushing – grinding – gravity separation – flotation – chemical – smelting Gravity separation process and flotation are the most used gold mining methods around the world Gravity separationGold Processing Equipment, Process Flow, Cases JXSC Machine

Analyzing process parameters for industrial grinding circuit based

2023年9月1日 Based on the machine learning method, this study analyzed the full process parameters (ie, ball mill power, fresh ore feed rate, hydrocyclone feed pump power, hydrocyclone pressure, mill feed water flow rate, dilution water flow rate, and sump level) for industrial grinding circuitWe can say that the function of the grinding machine comes into play after the machining of a work piece by turning or milling machines The grinding machine provides high accuracy and fine surface finish with minimum tolerances The machining process is done by the abrasive action of the grinding wheel; the abrasives are embedded over the Grinding Machining Process : Complete Notes Mech4studySepiolite scrubbing machine beneficiation process September25,2024 Kaolin grinding production process The following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the mill (15mm50mm)Sepiolite scrubbing machine beneficiation process LZZGThe eggshell milling process is generally divided into two stages: crushing and grinding The equipment used includes a jaw crusher, eggshell powder making machine, bucket elevator, electromagnetic vibrating feeder, fan, analyzer, conveying pipeline, Eggshell Powder Making Machine

.jpg)

Bamboo Powder Making Machine

The bamboo milling process is generally divided into two stages: crushing and grinding The equipment used includes a jaw crusher, bamboo powder making machine, bucket elevator, electromagnetic vibrating feeder, fan, analyzer, Grinding is the common collective name for machining processes that utilize hard, abrasive particles as the cutting medium The grinding process of shaping materials is probably the oldest in existence, dating from the time prehistoric humans found that they could sharpen their tools by rubbing them against gritty rocksGrinding Processes SpringerLinkPDF On Jan 1, 2004, I Wilson published Special clays from attapulgite to sepiolite Find, read and cite all the research you need on ResearchGateSpecial clays from attapulgite to sepiolite ResearchGate2024年4月19日 Introduction to Grinder Machine Process Grinder machines are essential tools in the manufacturing industry, used to shape and finish metal, wood, and other materials with precision and accuracy They are versatile machines that can perform a variety of tasks, ranging from simple surface grinding to complex internal grinding operationsThe Grind: Understanding The Processes Of Grinding Machines

Sepiolite Clay Powder Grinder Milling Machines

2022年7月5日 80 mesh ~ 2500 mesh sepiolite processing technology, some use Raymond mill, some use ultrafine grinding mill, and some use a new type of mill for ultrafine powder vertical mill The following is a detailed introduction to two commonly used sepiolite grinder milling machine: Raymond mill and ultrafine grinding mill2019年8月26日 Quartz processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on WhatsAppQuartz Processing Equipment, Process Flow, Cases JXSC MachineProcess flow charts can offer several benefits for businesses, improving productivity and teamwork while eliminating unnecessary steps With Confluence Whiteboards, you can visualize and turn ideas into tasks Confluence brings everyone together in a connected workspace to move projects forwardProcess flow charts: Types, uses and benefits The Workstream2009年1月1日 Traditionally, the lowest operating cost was achieved by multistage, fully autogenous grinding since this eliminated the steel grinding media costs which may represent up to 50% of the grinding costProcessing of Magnetite Iron Ores–Comparing Grinding Options

.jpg)

What is Grinding? Process, Machine, Parts ElectricalWorkbook

2023年10月1日 Flow rate, velocity, pressure, physical, chemical and thermal properties of grinding fluid affects its effectiveness Advantages of Grinding It can be employed for materials, which are too hard to machine by other processes Better surface finish and smooth surfaces can be obtained The pressure required during grinding process is less1988年12月1日 The results show that the sepiolite framework is rather resistant to mechanical stress and its alteration by dry grinding occurs through three successive, overlapping processes: (i) thinning of Structural Alteration of Sepiolite by Dry Grinding ResearchGate2019年8月26日 Zircon processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on WhatsAppZircon Processing Equipment, Process Flow, Cases2021年4月14日 A HighSpeed Precision Bearing Internal Grinding Machine and Grinding Process This paper presents a research on the precision polishing of large bearing ring raceways by an abrasive flow machineA HighSpeed Precision Bearing Internal Grinding

.jpg)

Diamond Processing Equipment, Process Flow, Cases JXSC Machine

2019年8月23日 Main factors influencing diamond processing flow 1 raw ore mineral composition and their properties 2 disseminated grain size 3 ore argillization property 4 surrounding rock fragmentation 5 content of clay in raw ore 6 value minerals content 7 diamond processing plant scale 8 requirements of diamond concentrate Diamonds processing flowDownload scientific diagram Complete process flow for microgrinding tool fabrication using electroless plating technique [43] from publication: A comprehensive review of microgrinding Complete process flow for microgrinding tool fabrication using 2023年8月2日 The importance of wheat cleaning in the milling process is highlighted, along with technological advancements such as color sorting machines and debranning of wheat grains before grinding, which The Latest Innovations in Wheat Flour Milling: A Review2020年5月16日 In this study, selfoptimization of a grinding machine is demonstrated with respect to production costs, while fulfilling quality and safety constraints The quality requirements of the final workpiece are defined with respect to grinding burn and surface roughness, and the safety constrains are defined with respect to the temperature at the grinding surface Grinding Selfoptimizing grinding machines using Gaussian process

.jpg)

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Crushing Plant Flowsheet 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control2021年5月5日 The grinding machine is widely used to finish the workpiece Do you know why? Because the work removal rate is low between 025 to 05 mm (This can be advantages or disadvantages also for various types of works) Grinding Machine Parts and Function: The Grinding Machine Consists of Following Main Parts: Base or Bed; Column; Headstock Grinding Machine: Definition, Parts, Working Principle, Operation DISCO delivers complete ultrathin grinding solutions that comprise four key elements: machine, grinding wheel, protective tape, and processing conditions TAIKO ® Process The TAIKO process is the name of a wafer back grinding process Grinding Solutions DISCO Corporation

.jpg)

(PDF) Optimization of Process Parameters in Surface

2013年5月9日 PDF Surface grinding is the most common process used in the manufacturing sector to produce smooth finish on flat surfaces This study was conducted by using surface grinding machine2023年11月13日 Ultrafine grinding mill production line process flow The loader transports the crushed ore with a particle size of less than 500 mm to the firstlevel vibrating feeder, and intelligently adjusts the feeding speed through the variable frequency motor to ensure that large pieces of ore are transported smoothly and evenly to the secondlevel vibrating feederChina Hubei heavy calcium carbonate HGM100P ultrafine grinding 2019年8月23日 This Setup is a Rock Chrome ore processing plant, it is configured with raw material feeding, primary crushing, fine crushing, screening, ball mill grinding, and gravity separation to separate out and upgrade Chrome concentrate The chrome ore raw material stone is fed to the primary jaw crusher by a vibration feeder to feed rock chrome ore smoothly and Chromium Processing Process Flow, Cases JXSC MachineMain Applications of Sepiolite powder process by Sepiolite grinding mill With the rapid development of China’s economy, the market demand After being processed by sepiolite grinding machine, it can be widely used in various industrial fields, such as architecture, ceramic technology, catalyst preparation, pigment synthesis, petroleum Application And Properties Of Sepiolite Powder Hebei Yayang

.jpg)

Abrasive flow machining (AFM): An Overview ResearchGate

2011年1月1日 Figure 21 shows a twoway abrasive flow deburring process where pressure is being directed from top and bottom piston to abrasive media in the cylinder to push the abrasive back and forth2019年8月22日 The mainstream gold beneficiation process flow is generally crushing – grinding – gravity separation – flotation – chemical – smelting Gravity separation process and flotation are the most used gold mining methods around the world Gravity separationGold Processing Equipment, Process Flow, Cases JXSC Machine2023年9月1日 Based on the machine learning method, this study analyzed the full process parameters (ie, ball mill power, fresh ore feed rate, hydrocyclone feed pump power, hydrocyclone pressure, mill feed water flow rate, dilution water flow rate, and sump level) for industrial grinding circuitAnalyzing process parameters for industrial grinding circuit based We can say that the function of the grinding machine comes into play after the machining of a work piece by turning or milling machines The grinding machine provides high accuracy and fine surface finish with minimum tolerances The machining process is done by the abrasive action of the grinding wheel; the abrasives are embedded over the Grinding Machining Process : Complete Notes Mech4study

.jpg)

Sepiolite scrubbing machine beneficiation process LZZG

Sepiolite scrubbing machine beneficiation process September25,2024 Kaolin grinding production process The following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the mill (15mm50mm)