Anthracite crushing station with an output of 50 tons of calcium carbonate per hour

KEFID QUOTATION OF 50tph Crushing Plant PDF Scribd

This document provides a quotation for a 50 ton per hour stationary crushing line including: Background on raw materials and output sizes A flow chart and layout drawing of the There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 MetallurgistFIT™ Stations are focused on flexibility and speed for quick installation with three solutions: Primary gyratory stations, Jaw stations and Recrushing stations The capacities range from FIT™ mining crushing stations MetsoIt includes examples calculating screen effectiveness, power requirements for crushing using Bond's equation, and selecting the appropriate conveyor type and calculating power needs to Che 511A: Separation Processes and Intro To Particulate

Combining legacy and expertise Mining Crushing Stations

station is designed for stationary primary crushing applications Capacities range up to 4,000 tons per hour, 40 weeks (FCA) lead time and utilize our Superior™ MKIII crushing technology The Metso's Foresight™ semimobile primary gyratory (SMPG) station is a crushing plant made of steel The guiding principle is to reduce concrete works to the largest degree and build a Foresight™ mining crushing stations Metso2022年4月26日 Process simulation for crushing plants can be classified as either steadystate simulation or dynamic simulation The steadystate simulation models are based on (PDF) Optimization Capabilities for Crushing Plants ResearchGate2020年3月19日 A crusher’s maximum output is determined when the machine is at or close to full capacity during its peak performance Failing to maintain a full load can result in improper Selecting the right crusher for your operations Quarry

.jpg)

Optimal energy management for a jaw crushing process in deep

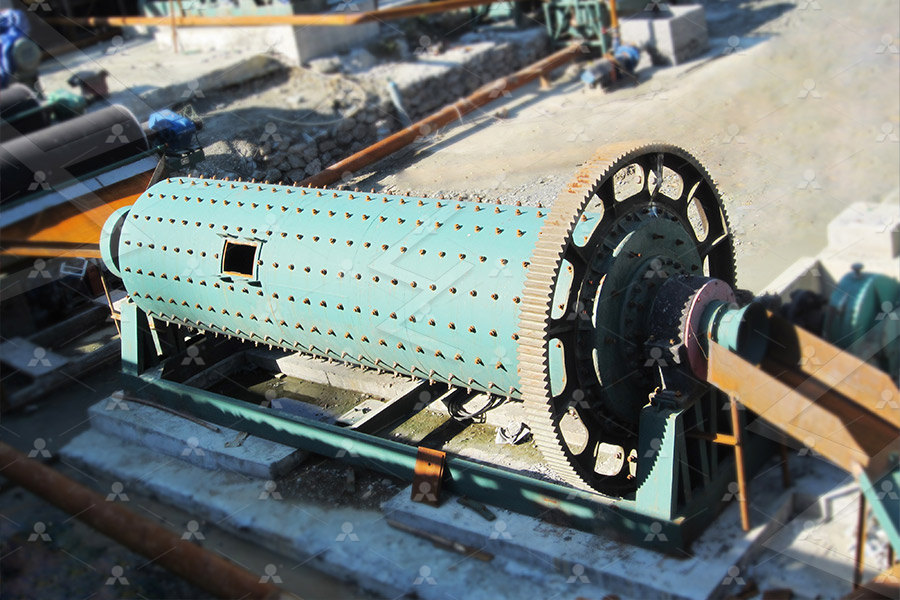

Due to the inefficiency of the jaw crushing machine, whose noload power consumption is between 40 and 50% of its rated power, the optimal switching control technique is shown to be 2023年5月29日 The cost of a ball mill with an output of 30 tons per hour can vary based on several factors The size and design of the mill, material of construction, motor power, and auxiliary equipment all How much does a ball mill with an output of 30 tons per hour2015年12月17日 The power consumption of a 42inch gyratory crusher is approximately 24 tons per horsepowerhour (29 t/kWh) Source: Arthur Taggart; Power consumption of a jaw crusher when idling is about 50% of full load, for a gyratory it is approximately 30% Source: Richard Taggart; The Crusher’s Rock BreakersRock Crushing Rule of Thumb 911Metallurgist2016年1月11日 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all Crusher Operating Costs: How to Optimize and Reduce

Heavy calcium carbonate grinding powder production line with

2022年6月27日 Installation site of heavy calcium carbonate grinding powder production line with an annual output of 200,000 tonsIn the whole ultrafine calcium carbonate prCoal Heating Encyclopedia ; The Volume of Anthracite Coal by Weight The Volume of Anthracite Coal by Weight Footer menu Home; Coal Forum; Fuel Comparison CalculatorThe Volume of Anthracite Coal by Weight Coalpail2022年9月12日 The peak volume of world acetylene production was more than 10 million tons per year which is synthesized in turn via the decomposition of calcium carbonate (ie, lime) and a source of carbon (eg, metallurgical coke or anthracite) in an electrical furnace at temperatures of 2000–2300°С The high temperatures of this Acetylene Production Technologies in the 21st Century: Main Anthracite also has higher ignition and ash fusion temperatures In the US, nearly all anthracite is mined in northeastern Pennsylvania and consumed in Pennsylvania and its surrounding states The only significant amount of anthracite is used for steam/electric production Anthracite currently accounts for only a small fraction of the total 12 Anthracite Coal Combustion US Environmental Protection

MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING

and sulphide ores The expected average output of 162 tons per hour of copper concentrates has never been attained since plant commissioning The major bottleneck has been established to be located around the crushing circuit of the Mowana production chain The major hypotheses of this research are that performance in a crushingOutput of up to 50 tons per hour: Wireless remote control system for all functions Tethered cable also included: Recommended loader bucket 24”36” 20” main conveyor belt: 54 gallon diesel fuel tank; 71 gallon hydraulic tank: Hydraulically folding main conveyor: Hydraulically adjustable jaws: Dust suppression: Vibratory grizzly feeder50TJ Tracked Jaw Crusher SMI Compact2021年1月15日 Furthermore, hematite (Fe2O3), calcium ferrite (CaO–Fe2O3), and compound calcium ferrite (CaO–SiO2–Fe2O3) were the major mineral phases, which were embedded with an interwoven structurePartial substitution of anthracite for coke breeze in iron ore PC800*1000 Output 3040 Tons Per Hour, Discharge Material Into 5mm Sand Mobile Stone Crusher Crushing Station US$9,5000011,00000 1 Piece (MOQ)PC800*1000 Output 3040 Tons Per Hour, Discharge Material

(PDF) The Characteristics of Limestone and Anthracite

2021年1月1日 The escalating demand for innovative solutions is driven by the challenges posed by water quality degradation and the pervasive impacts of climate change3 One hundred tons/hr of anthracite coal are to be moved horizontally a distance of 100 ft Select a conveyor of each of three classes listed, and calculate the power required to operate the system Choose the smallest conveyor that will do the job, a) Screw conveyor b) Flight conveyor c) Belt conveyor 4Solved 3 One hundred tons/hr of anthracite coal are to be Chegg2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2020年4月4日 Mobile crushing station; Accessories; Cooperation the working performance of the crushing equipment is stable, and the output is guaranteed at 500600 tons per hour The raw materials of the mine are: limestone, strength: about 100Mpa, obvious texture (shale), silicon and calcium content is about 20 ~ 25%; most of the Crusher equipment configuration of 600 tons per hour crushed

.jpg)

The advantages of ultrafine vertical mill in the processing and

2023年3月21日 Highend calcium carbonate production line with an annual output of 300,000 tons in Anhui, China Processing raw material: calcite Finished fineness: 1501250 mesh Annual output: more than 300,000 tons Finished product use: papermaking, coatings, building materialsThen v 1 v1 v 1 and v 2 v2 v 2 represent the “output per day” of mine #1 and mine #2, respectively Suppose the company operates mine #1 for x 1 x1 x 1 days and mine #2 for x 2 x2 x 2 days Write a vector equation whose solution gives the number of days each mine should operate in order to produce 150 tons of copper and 2825 kilograms A steam plant burns two types of coal: anthracite QuizletThe VYKIN 50JC is a compact midsized mobile tracked jaw crusher and can be used as an excellent concrete crusher It is best for crushing all types of material, such as crushing concrete, asphalt, rock, stone, limestone, pavers and more With a wide jaw inlet opening of 2675” x 17” and a production capacity of up to 50 tons per hour, the VYKIN 50 crusher is one of our most VYKIN 50JC Mobile MidSized Tracked Jaw Crusher VYKIN 2023年4月1日 The process was operated commercially in Høyanger, Norway, from 1928 to 1969, with an annual output of 17,000 tons and was subsequently closed for economic reasons [75] Significant research has been conducted recently in the framework of the ENSUREAL project for modernizing the Pedersen process to ensure zero waste production of alumina in Toward sustainable green alumina production: A critical review on

.jpg)

50 tons per hour iron ore crushing production line to mraliyu

2017年1月12日 1 50 T/H Iron Ore Crushing Production Line Date:Apr8,2015 my skype:evitalee55 whatsapp:0086 my : evita@hiimac welcome to my website! hiimac I:Quotation for 50 T/H Iron Ore Crushing Production Line Background: The Line is designed on the following basis: 1 Capacity : 50 t/h 2 Input size:250300mm 3 Express this output as a linear combination of two vectors, assuming that the plan burns x 1 tons of A and x 2 tons of B c To find how much heat the steam plant produces when it burns tons of anthracite and tons of bituminous coal, multiply the amount of anthracite by 276 and the amount of bituminous coal by 302, Solved A steam plant burns two types of coal: anthracite (A) Cheggmetallurgical coke with anthracite would reduce the carbon footprint by 652,000 tons of carbon dioxide equivalent per year This is roughly the same as the carbon footprints of 13,600 households, or of 77,000 motor vehicles This calculated reduction in carbon dioxide emission is for one blast furnace, producing 4000 tons of hot metal per day, inComparative Carbon Footprints of Metallurgical Coke and Anthracite 2017年9月11日 This study analyses the electromechanical performance of the crawler of a mobile crushing station Dynamics and electromechanical coupling models of the crawler in horizontal straight and steering conditions are established Meanwhile, a 1200t mobile crushing station, which is a virtual prototype, is established based on RecurDyn Results of Simulation analysis of electromechanical performance of

Environmentally friendly crushing station with an output of 300 tons

Environmentally friendly crushing station with an output of 300 tons per hourhttps://xcrusher/sitemapindexxml2016年2月26日 This curve shows approximately 29 percent of minus 3/4″ in the material as it comes from the crusher, or 29 tons of fines in each 100 tons of crusher output But, for the circulating load, we are only interested in that fraction of the crusher output which will pass the 3/4″ screen, which is 85 tonsCrushing Products Size and Shape What to Expect2016年10月7日 The total direct cost of crushing 2,000 tons in eight hours is generally about 3½d per ton, while in a smaller plant of half the hourly capacity it amounts to about 4d per ton This saving of ½d per ton is offset by the fact that the capital cost of the larger installation will be approximately 50% more than that of the smaller oneHow to Size of Crushing Plant 911Metallurgist2023年9月5日 Microwave energy and in situ stress cooperatively influence the permeability of coal reservoirs in microwaveassisted coalbed methane (CBM) extraction In this study, the combined influence of microwave energy and load on the failure characteristics of coal reservoirs was investigated using acoustic emission (AE) technology The failure characteristics of Loaded Failure Characteristics of Anthracite Derived from

.jpg)

A steam plant burns two types of coal: anthracite (A) and bi Quizlet

Find stepbystep Linear algebra solutions and the answer to the textbook question A steam plant burns two types of coal: anthracite (A) and bituminous (B) For each ton of A burned, the plant produces 276 million Btu of heat, 3100 grams (g) of sulfur dioxide, and 250 g of particulate matter (solidparticle pollutants) For each ton of B burned, the plant produces 302 million Btu, 6400 The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder Its output is generally 1 to 30 tons per hour The number of meshes refers to the number of holes on the screen per inch, and How to Choose a Calcium Carbonate Grinding Mill DASWELL2023年5月29日 The cost of a ball mill with an output of 30 tons per hour can vary based on several factors The size and design of the mill, material of construction, motor power, and auxiliary equipment all How much does a ball mill with an output of 30 tons per hour2015年12月17日 The power consumption of a 42inch gyratory crusher is approximately 24 tons per horsepowerhour (29 t/kWh) Source: Arthur Taggart; Power consumption of a jaw crusher when idling is about 50% of full load, for a gyratory it is approximately 30% Source: Richard Taggart; The Crusher’s Rock BreakersRock Crushing Rule of Thumb 911Metallurgist

Crusher Operating Costs: How to Optimize and Reduce

2016年1月11日 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all 2022年6月27日 Installation site of heavy calcium carbonate grinding powder production line with an annual output of 200,000 tonsIn the whole ultrafine calcium carbonate prHeavy calcium carbonate grinding powder production line withCoal Heating Encyclopedia ; The Volume of Anthracite Coal by Weight The Volume of Anthracite Coal by Weight Footer menu Home; Coal Forum; Fuel Comparison CalculatorThe Volume of Anthracite Coal by Weight Coalpail2022年9月12日 The peak volume of world acetylene production was more than 10 million tons per year which is synthesized in turn via the decomposition of calcium carbonate (ie, lime) and a source of carbon (eg, metallurgical coke or anthracite) in an electrical furnace at temperatures of 2000–2300°С The high temperatures of this Acetylene Production Technologies in the 21st Century: Main

12 Anthracite Coal Combustion US Environmental Protection

Anthracite also has higher ignition and ash fusion temperatures In the US, nearly all anthracite is mined in northeastern Pennsylvania and consumed in Pennsylvania and its surrounding states The only significant amount of anthracite is used for steam/electric production Anthracite currently accounts for only a small fraction of the total and sulphide ores The expected average output of 162 tons per hour of copper concentrates has never been attained since plant commissioning The major bottleneck has been established to be located around the crushing circuit of the Mowana production chain The major hypotheses of this research are that performance in a crushingMODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING Output of up to 50 tons per hour: Wireless remote control system for all functions Tethered cable also included: Recommended loader bucket 24”36” 20” main conveyor belt: 54 gallon diesel fuel tank; 71 gallon hydraulic tank: Hydraulically folding main conveyor: Hydraulically adjustable jaws: Dust suppression: Vibratory grizzly feeder50TJ Tracked Jaw Crusher SMI Compact2021年1月15日 Furthermore, hematite (Fe2O3), calcium ferrite (CaO–Fe2O3), and compound calcium ferrite (CaO–SiO2–Fe2O3) were the major mineral phases, which were embedded with an interwoven structurePartial substitution of anthracite for coke breeze in iron ore