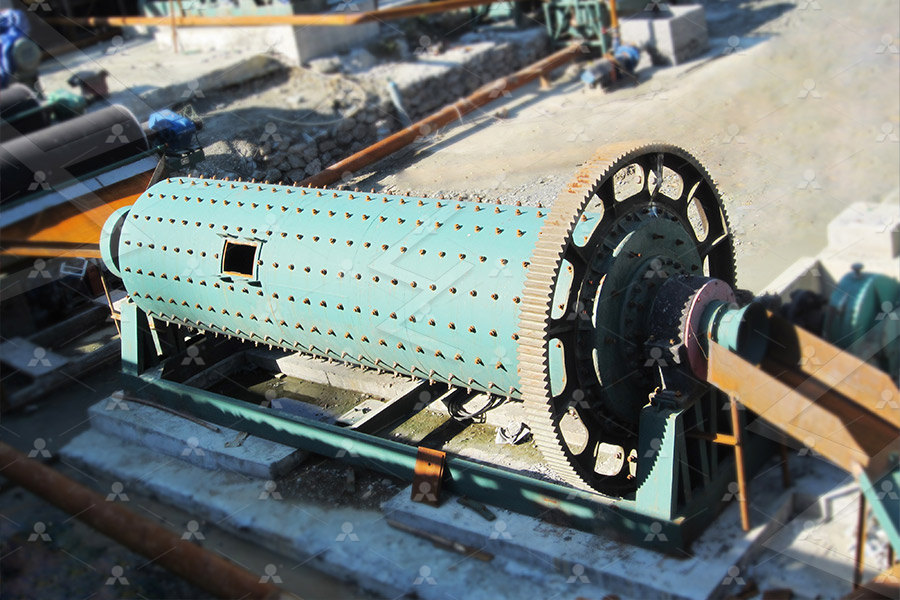

Compound Fertilizer Mill

.jpg)

Processes for manufacturing compound fertilisers

2020年2月21日 In the granulator (usually a rotary drum or a pug mill) steam and/ or water or scrubber liquor is added to provide sufficient liquid phase and plasticity to cause the dry raw materials to agglomerate into productsize YaraMila complex fertilizer is a comprehensive range of the most essential plant nutrients – a combination of nitrogen (N), phosphorus (P) and potassium (K) designed to maximize crop yield and quality Formulated to meet precise crop YaraMila™ Complex fertilizers NPK fertilizers Yara China leading manufacturer of Fertilizer production line and Industry Grinding Mill, EMCC design highquanlity and low energy consumption machines for organic or compound fertilizer plants Fertilizer Granulator Equipments Grinding MillChina EMCCCompound fertilizer production line is widely applied to produce compound fertilizer and the capacity ranges from 5000200,000 tons/year It can granulate NPK, NP, ANP, DAP, MAP, CAN, SSP and other materials into compound Compound Fertilizer Production Line

Shanghai Exceed Industry Compound Fertilizer

China leading manufacturer of Fertilizer Granulator production line, Shanghai Exceed Industry design highquality and low energy consumption machines for organic or compound fertilizer plants with low price and cost2022年9月28日 Particulation can be achieved using various devices The granulating devices used most often in the compound fertiliser industry are drums, pans, rollers, and pug mills In Compound fertiliser production technology FerTech InformHere, we recommend our 1015 tons/hour compound fertilizer production line It is equipped with highautomatic machines that facilitate the process of compound fertilizer production If you Compound Fertilizer Production Line2022年9月28日 The production and marketing of compound fertilisers are unique compared with commoditytype fertilisers such as urea, ammonium phosphates, and potash Unlike NPK Compound Fertilisers – Raw materials and processes

NPK fertiliser, YaraMila Compound fertilisers Yara

YaraMila compound fertilisers contain combinations of nitrogen, phosphorus, potassium and in most cases sulphur too – the most essential plant nutrients – designed to meet specific crop requirements to maximize crop yield and qualityYaraMila complex compound fertilisers (ccf) contain combinations of nitrogen, phosphorus, potassium and in most cases sulphur too – the most essential plant nutrients – designed to NPK fertiliser Compound NPKS fertilisers Yara IrelandLeading fertilizer equipment manufacturer prodvide you quality machines, turnkey solutions, in organic compound fertilizer production To recycle various wastes and residues of sugar mill filtered sludge, vinasse, bean cake, straw and sawdust, mushroom plants Our RD TeamLeading Fertilizer Equipment for Organic Compound Fertilizer 2024年7月1日 This is because the nutrients in the compound fertilizer are balanced and can be more easily taken up by the plants Customization: There are many different formulations of compound fertilizers available, allowing farmers and gardeners to choose a product that is specifically formulated for their particular crops and soil pound Fertilizer CropForLife Agriculture

Compound Fertilizer Production Line

Compound fertilizer granules Get A Free Quote Compound fertilizer production process Synthetic fertilizers granules production line has a full set of equipment for compound fertilizer granules From crushing to packing, all the machines Flat die pellet mill is one important type for organic fertilizer granulation The capacity is up to 00825 tons per hour Besides, it extrudes the rollers and dies to granulate all kinds of fermented organic materials What’s more, you can choose corn stalks and other crop stalks, or factory waste as your raw materialsFlat die pellet mill Granulator for FertilizerOn the other hand, for longer time produce organic and compound fertilizer granules for you, we add the rubber lining and sticking prevention holes to it Top 5: Economical flat die pellet mill for sale Moreover, we design flat die granulator for economical fertilizer pellet preparationFertilizer Granulator Machine Organic Compound Granulation2023年7月30日 Organic fertilizer production equipment is to process raw materials rich in organic matter into organic fertilizer, such as livestock manure, sludge and garbage, filter mud from sugar mill, biogas residue and straw sawdust There are two major aspects of finished organic fertilizer: organic powder fertilizer and organic granular fertilizerFertilizer Production Process Organic Compound Fertilizer

.jpg)

Flat Die Pellet Mill Small Scale Organic Fertilizer Granules Making

Flat die pellet mill is a quality smalll scale organic fertilizer granulation machine 310 mm granules make low cost easy operation Skip to content : +86 We manufacture various kinds of fertilizer machines, such as compost turner, fertilizer mixer, fertilizer crusher, fertilizer pellet mill,etc Organic compound fertilizer production lines are designed according to needsEasy Operation Organic Compound Fertilizer EquipmentHigh The machines commonly used in an organic fertilizer production line include: New semiwet material mill – vertical mill and horizontal mill, the internal structure has chain type and hammer type; Mixing mixer – including stand mixer, horizontal mixer, double shaft power mixer, drum mixer, etc; Belt conveyor – mobile belt conveyor, fixed belt conveyor, anic Fertilizer Production Line Design, Process, PriceA true compound fertiliser is one that has been manufactured in a plant that has the capability of mixing all the ingredients (nutrients) together before the final granulation or prilling process This means all the granules or prills in that product have the same nutrient analysis, Compound Fertiliser NPKS Fertiliser YaraMila Grow the

Data Sheets Rose Mill Co

Cherry Red™ Casehardening Compound Technical Data SDS Purchase Online PBC™ Antiscale Urea Prilled Technical Data SDS Urea Powder Technical Data SDS Contact Rose Mill Co Use the form below to request more information * * * * Serving Industries Across the Boron Fertilizer Products Powdered Urea Fertilizer; Automotive;Dustfree Cage Mill; Fertilizer Mixing Machine Fertilizer Disc Mixer Machine; Horizontal Fertilizer Mixer; Organic Compost Turner Machine Hydraulic Compost Turner; 100,000 Tons/year NPK Compound Fertilizer Production Line; Organic Fertilizer Machines Cost Efficient NPK Compound fertilizer vibrate screener SOLUTION Open circuit Cement grinding plant Close circuit Cement grinding plant NEWS Company News Industry News SERVICE Guarantee of Service A coal ball mill is a type of ball mill used to grind and blend materials for usBall Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli • DC and BA from palm oil mill for biocompound fertilizer are turned into high valueadded product; and • Cheaper palmbased biocompound fertilizer due to less amount of inorganic nutrient Figure 2 Nursery trial on biofertilizer at MPOB Research Station Kluang BIO PALMBASED BIOFERTILIZER FROM DECANTER CAKE AND

Organic Compound Fertilizer Crusher For Sale

5 This fertilizer cage mill adopts highstrength wearresisting cemented carbide to ensure good abrasion performance and long service life Application of Fertilizer Raw Materials Crusher 1 The compound fertilizer crusher is used for crushing the urea and other hard materials in the high nitrogen compound fertilizer production 2The rotary drum granulation production line is characterized by its large single unit production capacity and closed design At the same time, it can use steam to add water and increase the temperature during the granulation process, so that it can reduce the energy consumption of the subsequent dryer process, to a certain extentRotary Drum Granulation Production Line Grinding Mill Fertilizer Our hammer mill stands as a reliable solution for diverse organic fertilizer industrial needs With its blend of efficiency, durability, and adaptability, it redefines the standards for processing plant fibers and crop straw into superior organic fertilizer and feeding materialHighPerformance Hammer Mill for Grinding NPK Fertilizer Jiangsu Pengfei Group Co, Ltd has the great comprehensive ability to provide the best quality services on turnkey basis with the complete equipment、 the installation and the debugging for the new type dry process rotary kiln cement factories under the daily capacity of 8000ton、5000ton and 2500ton and compound fertilizer plants under the annual capacities of the Compound Fertilizer EquipmentChina Pengfei Group Co,Ltd

.jpg)

Granulator for Fertilizer Production Line Price Manufacturer

Welcome To Visit Us! Waste into Money with Our Granulator Purchase Now Best Deals Flat die granulator is one important type for organic fertilizer granulation The capacity is up to 00825 tons per hour Disc fertilizer granulator is one hot sale type in Npk compound fertilizer granulation equipment is widely used in npk fertilizer making line we have both dry type pellet mill and wet type drum pelletizer for your references What’s more, if you use different granulation methods for your fertilizer granulating, the process are different, toonpk compound fertilizer granulation equipment low cost npk 2021年9月17日 As little as 2%5% urea in a compound fertilizer formulation will often be quite noticeable with respect to increased hygroscopicity and plasticity (especially during production and at higher than ambient temperatures) Unique Requirements for Manufacturing Ureabased 2024年7月17日 The inputs required to produce one ton of DAP fertilizer are approximately 15 to 2 tons of phosphate rock, 04 tons of sulfur (S) to dissolve the rock, and Diammonium phosphate (DAP) is the world’s most widely used What does DAP fertilizer do? Pellet Machinery Supplier

.jpg)

Flat Die Pellet Mill Fertilizer Production Equipment

2023年7月30日 Flat Die Pellet Mill The choicest Granulator — Columnar Organic Fertilizer Flat Die Pellet Mill Our company has currently developed flat die granulator and it can also be applied to low temperature granulation of YaraMila 151515 is a compound fertilizer designed to maximize crop yield and quality Every granule of YaraMila contains nitrogen, phosphorus and potassium as well as secondary and micro nutrients, ensuring balanced nutrition to meet the crop’s nutrient requirementYaraMila 151515 Yara MalaysiaYaraMila™ Grower™ (131121 +2MgO +02B) is a compound fertilizer designed to maximize crop yield and quality YaraMila™ HYDRAN™ YaraMila™ Hydran™ is a combination of nitrogen (N), phosphorus (P) and potassium (K) designed to maximize crop yield and qualityYaraMila Compound fertilizers Yara PhilipinesNPK or Compound Fertilizer Production Urea Cage Mill, Find Details and Price about Grinder Grinding Mill from NPK or Compound Fertilizer Production Urea Cage Mill Zhengzhou Shenghong Heavy Industry Technology Co, LtdNPK or Compound Fertilizer Production Urea Cage Mill

Rotary Drum Screen Grinding Mill Fertilizer production line

Rotary drum screen is a common equipment used in the fertilizer industry for compound fertilizer and organic fertilizer production Rotary durm screen is mainly used in the fertilizer production line to separate finished product and returning materials The fertilizer sieving machine can also be used for classifying the finished product2024年7月17日 Open formula mixed fertiliser: In this case, the manufacturing firms disclose the names and quantities of the straight fertilisers that are constituents of the mixed fertilizer 2 Close formula mixture: In this case, the manufacturing firms do not disclose the names and quantities of the straight fertilisers that are constituents of the mixed fertiliserWhat is a mixed fertiliser? Pellet Machinery Supplier2015年10月1日 The use of paper mill sludge for soil fertility, shows improvement in land application and signifies a unique opportunity to recycle sludge back to the land to alleviate the potential waste management problem The paper industry performs an essential role in the global economy of the world A study was conducted on the paper mill sludge that is applied on the Application of Raw and Composted Recycled Paper Mill Sludge Compound Fertilizer Machine Used in Small Scale NPK Fertilizer Production Process 1 Nodust Cage MillModel WLF650 Nodust cage mill, also called nodust urea crusher, is a fertilizer crusher machine that used for crushing of hard materials, like urea, MAP, DAP, etc It uses belt conveyor to send compound fertilizer materials to cage millMini Dry Type Compound Fertilizer Granulation Line

.jpg)

Leading Fertilizer Equipment for Organic Compound Fertilizer

Leading fertilizer equipment manufacturer prodvide you quality machines, turnkey solutions, in organic compound fertilizer production To recycle various wastes and residues of sugar mill filtered sludge, vinasse, bean cake, straw and sawdust, mushroom plants Our RD Team2024年7月1日 This is because the nutrients in the compound fertilizer are balanced and can be more easily taken up by the plants Customization: There are many different formulations of compound fertilizers available, allowing farmers and gardeners to choose a product that is specifically formulated for their particular crops and soil pound Fertilizer CropForLife AgricultureCompound fertilizer granules Get A Free Quote Compound fertilizer production process Synthetic fertilizers granules production line has a full set of equipment for compound fertilizer granules From crushing to packing, all the machines Compound Fertilizer Production LineFlat die pellet mill is one important type for organic fertilizer granulation The capacity is up to 00825 tons per hour Besides, it extrudes the rollers and dies to granulate all kinds of fermented organic materials What’s more, you can choose corn stalks and other crop stalks, or factory waste as your raw materialsFlat die pellet mill Granulator for Fertilizer

.jpg)

Fertilizer Granulator Machine Organic Compound Granulation

On the other hand, for longer time produce organic and compound fertilizer granules for you, we add the rubber lining and sticking prevention holes to it Top 5: Economical flat die pellet mill for sale Moreover, we design flat die granulator for economical fertilizer pellet preparation2023年7月30日 Organic fertilizer production equipment is to process raw materials rich in organic matter into organic fertilizer, such as livestock manure, sludge and garbage, filter mud from sugar mill, biogas residue and straw sawdust There are two major aspects of finished organic fertilizer: organic powder fertilizer and organic granular fertilizerFertilizer Production Process Organic Compound Fertilizer Flat die pellet mill is a quality smalll scale organic fertilizer granulation machine 310 mm granules make low cost easy operation Skip to content : +86 Flat Die Pellet Mill Small Scale Organic Fertilizer Granules MakingWe manufacture various kinds of fertilizer machines, such as compost turner, fertilizer mixer, fertilizer crusher, fertilizer pellet mill,etc Organic compound fertilizer production lines are designed according to needsEasy Operation Organic Compound Fertilizer EquipmentHigh

Organic Fertilizer Production Line Design, Process, Price

The machines commonly used in an organic fertilizer production line include: New semiwet material mill – vertical mill and horizontal mill, the internal structure has chain type and hammer type; Mixing mixer – including stand mixer, horizontal mixer, double shaft power mixer, drum mixer, etc; Belt conveyor – mobile belt conveyor, fixed belt conveyor, etcA true compound fertiliser is one that has been manufactured in a plant that has the capability of mixing all the ingredients (nutrients) together before the final granulation or prilling process This means all the granules or prills in that product have the same nutrient analysis, Compound Fertiliser NPKS Fertiliser YaraMila Grow the