Coal mill bearing cooling water

Cooling water use in thermoelectric power generation and

2018年6月1日 We summarize the average water requirements for several cooling systems in thermoelectric power generation, and identify the challenges of wet cooling systems in 2017年5月30日 Relative measurement of cooling performance of different Cold Mill Lubricants Heated aluminum block, instrumented with thermocouples, was cooled in a standard test using Roll in Hot and Cold Rolling Mills Society of 2021年1月18日 Depending of the type of rolling mill, dedicated roll cooling systems are required to fulfill the required functions Examples are suitable roll cooling and lubrication systems to GENERAL ASPECTS OF ROLL COOLING FOR HOT2019年6月15日 scale from water cooled Support Roller Assemblies, coal mill bearings, pipes, liquid ring pumps, catalytic crackers, green liquor lines, cooling towers, compressors, and any Anion D’Scale Application: Kiln Trunnion Bearings D’Scaling

Cooling water pump for coal and oilfired Sulzer

Cooling water pumps (CWP) provide fresh water to cool the exhaust steam in the condenser and pump it back to the wet cooling tower or the outlet of open cooling system The major 2017年8月12日 Loesche coal grinding mills are distinguished by other characte ristics that improve efficiency, safety and environmental protec tion, from the standard version to topof LOESCHEMILLS2022年11月18日 In recent years, studying the strength damage mechanism of coal–rock mass in waterbearing state has become a hot issue Moisture content has an effect on the Study on the Damage Mechanism and Energy Evolution2023年11月28日 In the industrial sector, circulating cooling water systems play a pivotal role, constituting 70–80% of the total water consumption and discharge [1] The cooling process involves the spraying of water over packing material, Analysis of Microbial Community in Circulating

Dynamic modeling and comprehensive analysis of direct aircooling coal

2023年1月15日 Coalfired power plants with direct aircooling condensers (DACCCFPP) are watersaving, ecofriendly and thus widely installed in regions rich in coal but short of water 2015年9月7日 The present study presents an overview of the qualitative and quantitative characteristics of the contact cooling water cycle at a steel hot rolling mill, where the cooling Cooling Water Management in Steel Hot Rolling Mills2023年1月15日 Coalfired power plants with direct aircooling condensers (DACCCFPP) are watersaving, ecofriendly and thus widely installed in regions rich in coal but short of water As such regions have better geological conditions for CO 2 storage, retrofitting these plants with carbon capture techniques provides a costefficient way to reduce carbon Dynamic modeling and comprehensive analysis of direct aircooling coal The cooling water is itself sprayed into the lower levels of a cooling tower where evaporation removes the unwanted heat from it Mills Coal from the boiler bunkers is fed under control into the mills The feed rate is determined by the Tutuka Power Station Heritage Eskom

Components for Power Plants, Cement Plants, Steel Plants,

Seperator/ Scrapper Body for XRP 763/803 Coal Mills Lower journal/Upper journal bearing housing for BHEL make XRP 763/803/1003/1043 Coal Mills Worm Gear Hub/Bowl Hub for XRP 763/803 Coal Mill Vertical Shaft for XRP 763/803 Coal Mill Rotary Mill Separator for MVM 32R (660 MW) LT make Coal Mills Densveyor for MVM 32R (660 MW) LT make Coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a ATOX® Coal Mill FLSmidth Cement5 天之前 Check whether the cooling water supply and circulation are regular, and ensure that the water pumps, coolers, and cooling pipes in the cooling system are not blocked or faulty Increase the flow of cooling water: If the temperature of the ball mill is too high, consider increasing the flow of cooling water By increasing the working pressure of Four Ways To Improve The High Temperature Problem Of Ball Mill2022年1月2日 The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator Operation Manual: HRM1700M Vertical Roller Coal Mill

Cooling Water Systems Fundamentals Handbook ChemTreat

5 天之前 Introduction to Cooling Water System Fundamentals Cooling of process fluids, reaction vessels, turbine exhaust steam, and other applications is a critical operation at thousands of industrial facilities around the globe, such as general manufacturing plants or mining and minerals plantsCooling systems require protection from corrosion, scaling, and microbiological 2024年7月1日 In the longterm practice of water inrush control, a waterconserving coal mining method based on filling mining has been gradually established in recent years [10], [11]This method, which involves controlling the development of the waterconducting fracture zone, can be summarized as overburden grouting and goaf filling in accordance with the waterloss mode of EcologicalBased Mining: A Coal–Water–Thermal2019年2月12日 Plants that use recirculating cooling systems require far less water Coalfired plants can make a megawatt of electricity with about 1,200 gallons, while nuclear plants with recirculating systems need about 2,600 gallons per megawatt In either case, it takes a lot of water to make electricityWater treatment and cooling applications for power plants2024年8月22日 springloaded, MB type, vertical spindle mills, each gravimetric belt feeder, seal air fan, 1800 rpm primary air fan, and four mill outlets supplying pulverized coal to one of the three horizontal rows of (4) dualfuel burners When operating at boiler MCR, each mill had a coal throughput of approximately 53,000 #ffirWorldProven Coal Pulverizer Technology Debuts in the

.jpg)

TOTAL WATER MANAGEMENT IN THE STEEL INDUSTRY

2006年1月12日 Direct Cooling Water Circuits In the hot strip mill, high pressure water is sprayed on the hot rolled plates/coils as they move on the turnout table for descaling Water is also sprayed to cool the rollers and bearings The hot return water, laden with mill scale and lubricating oil, is drained into scale pitsLarge and medium sized mill scales2023年6月28日 Cooling Water Pump berfungsi sebagai penyuplai air untuk sistem pendinginan di PLTA Asahan 1 yang mendinginkan minyak dan udara Sistem pendingin udara terdapat pada Generator Air Cooler, dan Studi Penggunaan dan Pemeliharaan Cooling 2023年2月3日 However, most large plants have a number of closed water systems that provide auxiliary cooling to such equipment as pump bearings, lube oil coolers, generator hydrogen coolers and so forth Figure 1Advanced cooling water treatment concepts The bearing of existing vibromill live axle, because judder causes heating to produce high temperature, bearing housing needs additional cooling jacket to lower the temperatureAs shown in Figure 3: cooling jacket is by bearing housing and two pieces of support plates, supports attached plate and the welding of water jacket circle forms; And need in auger shell hole, weld CNA Cooling water jacket of bearing sleeve of

.jpg)

Bearing and Shaft Seal Water Conditioning Systems Thordon Bearings

The Thordon Water Quality Package is designed to supply water to the main guide bearing for lubrication and cooling at a minimum flow rate of 03 litres/minute/mm (2 US gallons/minute/inch) of shaft diameter and to condition water from the water supply by removing suspended solids larger than 100 microns (0004” ) and with a specific gravity 2021年8月25日 1834 by increasing steam pressure to145 psig [9] Presently the efficiency of a coal based power plant is of the order of 40% Process description of a coalfired power plant In a coalfired power coal is burnt to produce electricity In a coalfired plant, pulverisers are used to mill the coal to a fine powder for burning in the combustion Auxiliary Power Analysis of a Coalbased Thermal Power 2022年10月1日 The waterbearing coal mass was 20 m long and 8 m high, where the cooling of the coal seam surface by LN 2 gradually slowed down as the horizontal distance increased and the cryogenic action continued Specifically, the horizontal temperature gradient was 52837 °C/h, 25530 °C/h and 13480 °C/h at 1 h, 5 h and 10 h within 10 m range Heatmass transfer coupling effects in waterice phase Cooling water pumps (CWP) provide fresh water to cool the exhaust steam in the condenser and pump it back to the wet cooling tower or the outlet of open cooling system The major characteristic of the CWP is their high flow In medium to large size coal and oilfired power plants, the CWP are vertical column typeSJTCWP vertical cooling water pump Sulzer

.jpg)

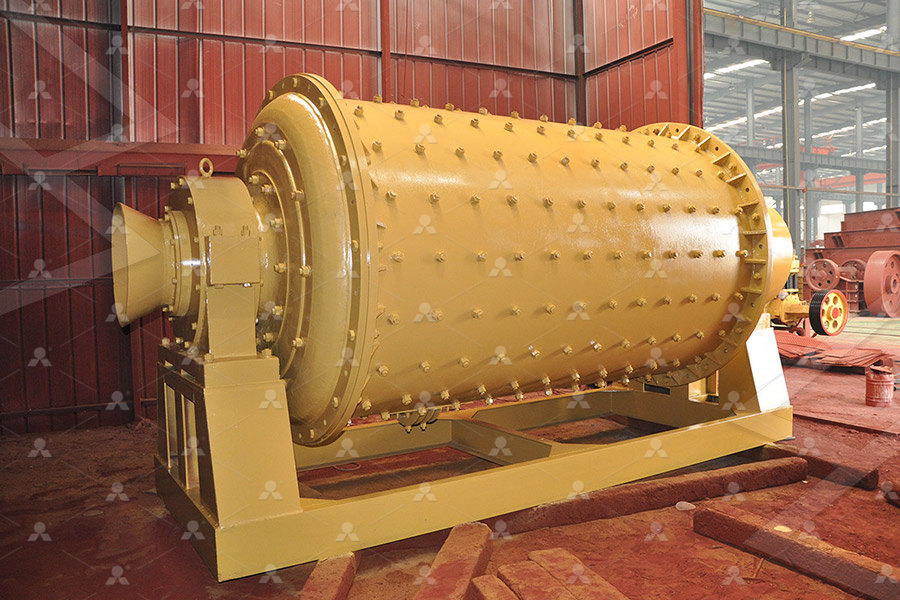

Coal Mill Great Wall

2023年4月12日 Coal ball mill is a machine that crushes and grinds the coal briquette into pulverized coal It is important auxiliary equipment of pulverized coal furnace During the coal grinding process, the coal is crushed and its superficial area increases continually To add new superficial area, the bond between solid molecules must be overcome, so the energy is 2021年6月7日 A 28” EXILOG and GR bearing fitted to a French aluminates ball mill Speed is 26 r/min and each bearing is carrying 15 tonnes (147 kN) Figure 4 Cement plant in the UK using SKF Cooper 280 mm bearing on the trunnion shaft Figures 5 and 6 South African plant using SKF Cooper 03BCP 320 mm on this ball mill In addition to these illustrations andSplit roller bearing applications2023年7月14日 36 All bearing of pump and motor are FAG/SKF only vendor to confirm 37 Bearing cooling air /oil/water if any required vendor to specify 38 Pump efficiency (minimum expected 65%) Vendor to specify 39 Rated RPM of the pump should not exceed 1500RPM (vendor to confirm ) 40 The operating speed shall be atleast 20%TECHNICAL DATA SHEET Bharat Heavy Electricals Limited2016年3月1日 The bearing cooling water system generally provides cooling for critical pump bearings and seals, hydrogen coolers for the generator, lube oil, and air compressor coolersMonitoring and Treatment of ClosedLoop

.jpg)

WATER CONSERVATION IN SUGAR INDUSTRY: A

2017年8月1日 Cold water for mill bearing cooling (30 m 3 /hr), shredder bearing cooling (20 m 3 /hr) and mill gearing cooling (76 m 3 /hr) Hot water requires for mill imbibition ranges from 2832% on cane2024年11月8日 WE'D LOVE TO HEAR FROM YOU! Our friendly team is on hand to assist your enquiry with a 24 hour support service available for urgent issues (0)11 822 1537COAL MILL COMPONENTS – CHASE Africa2010年2月1日 The cooling water circuit conducted water from the plant CWS, through the tube side of an exchanger, and back to the plant CWR Plant circulating pumps provided the driving force; no temporary Supplemental Cooling of Turbine Lube Oil Power Engineering2024年10月12日 The temperature of the 2 sets of bearings in the crusher rotor is around 85℃ all year round, especially in summer, the bearings must be cooled by compressed air, and even need to cool down with extra cooling water on the bearing pedestal of the pulley end, in order to maintain normal production of hammer mill Free end (nontransmission end Causes and Solutions of Bearing Problem of Hammer Mill

SHPHGLXPVSHHGFRDOPLOO IOPscience

longer service life and more convenient maintenance Hp1103 coal mill is a kind of HP coal mill Compared with similar coal mills, it has stronger adaptability to raw coal and is more suitable for large unit thermal power plants Taking hp1103 medium speed roller disc coal mill as the carrier, this paper mainly describes the2017年8月12日 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel LOESCHEMILLS2024年7月26日 Using cooling water jackets can prove disastrous to bearing life Cooling water jackets that only partially surround bearing outer rings have often restricted the uniform thermal expansion of operating bearings and have been known to force bearings into an oval shape There have been many instances where, as aCENTRIFUGAL PUMP COOLING AND LUBRICANT 2023年10月1日 bearingDuanetal[20]usedadeeplearningalgorithmto water free, M pc coal mill in a power plant in Hainan, China e current study obtains sets of fault data of coal interruption byApplicationofModel

Dynamic modeling and comprehensive analysis of direct aircooling coal

2023年1月15日 Coalfired power plants with direct aircooling condensers (DACCCFPP) are watersaving, ecofriendly and thus widely installed in regions rich in coal but short of water As such regions have better geological conditions for CO 2 storage, retrofitting these plants with carbon capture techniques provides a costefficient way to reduce carbon The cooling water is itself sprayed into the lower levels of a cooling tower where evaporation removes the unwanted heat from it Mills Coal from the boiler bunkers is fed under control into the mills The feed rate is determined by the Tutuka Power Station Heritage EskomSeperator/ Scrapper Body for XRP 763/803 Coal Mills Lower journal/Upper journal bearing housing for BHEL make XRP 763/803/1003/1043 Coal Mills Worm Gear Hub/Bowl Hub for XRP 763/803 Coal Mill Vertical Shaft for XRP 763/803 Coal Mill Rotary Mill Separator for MVM 32R (660 MW) LT make Coal Mills Densveyor for MVM 32R (660 MW) LT make Coal Components for Power Plants, Cement Plants, Steel Plants, Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a ATOX® Coal Mill FLSmidth Cement

Four Ways To Improve The High Temperature Problem Of Ball Mill

5 天之前 Check whether the cooling water supply and circulation are regular, and ensure that the water pumps, coolers, and cooling pipes in the cooling system are not blocked or faulty Increase the flow of cooling water: If the temperature of the ball mill is too high, consider increasing the flow of cooling water By increasing the working pressure of 2022年1月2日 The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator Operation Manual: HRM1700M Vertical Roller Coal Mill5 天之前 Introduction to Cooling Water System Fundamentals Cooling of process fluids, reaction vessels, turbine exhaust steam, and other applications is a critical operation at thousands of industrial facilities around the globe, such as general manufacturing plants or mining and minerals plantsCooling systems require protection from corrosion, scaling, and microbiological Cooling Water Systems Fundamentals Handbook ChemTreat2024年7月1日 In the longterm practice of water inrush control, a waterconserving coal mining method based on filling mining has been gradually established in recent years [10], [11]This method, which involves controlling the development of the waterconducting fracture zone, can be summarized as overburden grouting and goaf filling in accordance with the waterloss mode of EcologicalBased Mining: A Coal–Water–Thermal

Water treatment and cooling applications for power plants

2019年2月12日 Plants that use recirculating cooling systems require far less water Coalfired plants can make a megawatt of electricity with about 1,200 gallons, while nuclear plants with recirculating systems need about 2,600 gallons per megawatt In either case, it takes a lot of water to make electricity2024年8月22日 springloaded, MB type, vertical spindle mills, each gravimetric belt feeder, seal air fan, 1800 rpm primary air fan, and four mill outlets supplying pulverized coal to one of the three horizontal rows of (4) dualfuel burners When operating at boiler MCR, each mill had a coal throughput of approximately 53,000 #ffirWorldProven Coal Pulverizer Technology Debuts in the