Fly ash processing block equipment

Fly Ash Processing Equipment FEECO

6 天之前 FEECO provides custom, highquality agglomeration and bulk material handling equipment for dedusting fly ash and turning it into a more marketable productThe fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste Fly Ash Processing Plant Cement Equipment We are Leading Manufacturers of Fly Ash Brick Making Machine in Pune And offers various model such as Manual Fly Ash Brick Making Machine, Semi Auto Fly Ash Brick Making Fly Ash Brick Making Machine Brickvision Equipment2024年4月7日 Dongyue Machinery Group AAC block production line has been introduced from Germany and reformed, and now it has entered the innovative research level The FLY ASH AAC BLOCK PLANTAAC BLOCK

Fly Ash Separation Equipment ST Equipment

Maximize fly ash utilization with STET's highrate, dry fly ash separation equipment Unlock highquality ash for concrete productionThe Fly ash Brick Making Machine is designed for efficient and reliable production of fly ash bricks, with an automated system that streamlines the manufacturing process This machine is capable of producing a large volume of highquality Fly ash brick making machine Flyash Block China Fly Ash Block Cutting Machine wholesale Select 2024 high quality Fly Ash Block Cutting Machine products in best price from certified Chinese Block Making Machine manufacturers, China Fly Ash Block Cutting Machine, Fly Ash Block Cutting Fly Ash Aac Block Equipment Line 6,018 products found from 115 Fly Ash Aac Block Equipment Line manufacturers suppliers Product List ; Supplier ListChina Fly Ash Aac Block Equipment Line, Fly Ash Aac Block Equipment

Fly Ash Processing and Equipment to Collect Fly

Our equipment can handle large volumes and can even be used for processing coal fly ash recovered from landfills and reclamation ponds Rotary calciners act as decarbonizers to improve the quality of the fly ash so the material 2024年4月7日 The manufacturing process and equipment of aerated block production line have been exported to Uzbekistan, Kazakhstan, Cambodia, Myanmar, UAE, Mongolia, India, Bangladesh, Indonesia, Vietnam and Nepal etc Dongyue Machinery Group FLY ASH AAC Block production line has the following characteristics: 01FLY ASH AAC BLOCK PLANTAAC BLOCK 2012年2月1日 By Jayant Khambekar, PhD and Roger A Barnum, Jenike Johanson, Inc, USA Fly ash is a general name used for the residual products of combustion that rise with flue gases More than 100 million Fly Ash Handling: Challenges and Solutions2014年6月25日 KEYWORDS: fly ash, separation, dry method, micron, submicron ABSTRACT Significant variations in the chemical and physical compositions of fly ash are recognized as critical issues for fly ash to be used in various applications The quality of fly ash depends not only on the coal types and sources (chemical composition), but alsoFly Ash Separation Technology and its Potential

Fly Ash Processing and Equipment to Collect Fly Ash Heyl

Cyclone furnaces: These produce the least amount of coal fly ash, composition of which is between 70 to 80 percent fly ash and 20 to 30 percent molten bottom ash Wetbottom boilers: Also known as a slagtap furnace, these produce less fly ash, with only about half leaving the plant along with the flue gas, while the rest remains in the furnace2015年4月1日 The article introduces raw materials of fly ash brick, production process and key control points Experimental equipment and production process Main equipments Forming machine (H240, Korea) included hydraulic device, control and operator’s desk, chained conveyor and some molds, and the motor power was 3625 KW, vibration frequency was New technology and application of brick making with coal fly ashFly ash is generally a solid waste generated by the incineration boilers in thermal power plants, coalfired power plants, paper mills, and chemical factories, as well as the collection of ash from dust collectors It consists of tiny ash particles emitted during the combustion of fuel, primarily coal, with particle sizes typically ranging from 1 to 100 micrometersFly Ash Processing Plant Ball Mill, Raymond Mill, EPC ProjectFly ash bricks and AAC blocks both are used to construct walls They have their own properties In this article, I have given Fly ash bricks vs aac blocks in What is Autoclaved aerated concrete block – AAC block This process depends upon the use of the mechanical equipment and desire of the owner to provide the required size Then the Fly ash bricks vs AAC blocks – Features, Preparation, and

Headwaters Block Group prepares to integrate fly ashbased CalStar process

2016年4月29日 Headwaters Inc has acquired the fly ashcentered technology of recently liquidated brick, paver and masonry trim operator CalStar ProductsThe intellectual property will be integrated into the Block Group, with concrete masonry production and distribution in Texas and Louisiana, through Headwaters Construction Materials, the leader in ASTM C618 fly ash 2024年10月22日 The global construction industry is witnessing a steady rise in cement demand, contributing significantly to CO2 emissions, while concurrently generating substantial quantities of waste materials, notably construction and demolition waste (CDW) This study explores the utilization of these waste streams in developing sustainable construction materials, focusing Mechanical, microstructural, durability, and energy analysis of fly ash 2021年9月2日 The fly ash material enters the mill from the feeding device and is fed between the grinding roller and the grinding ring The mill is driven by the transmission device to move the grinding roller device suspended on the plum blossom frame, as it moves around the vertical axis With its revolution and its own rotation, the grinding roller is constantly swinging outward and Fly Ash Production ProcessFly Ash Processing Equipment2019年1月3日 Fly ash handling is an essential process in any coalfired or biomass power plant due to stringent environmental regulations – not to mention the need to maintain general plant efficiency This is because the Overcoming Challenges with Fly Ash Handling

Fly ash properties, characterization, and applications: A review

2021年9月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides (Si, Fe, Ca, and Al), and other inorganic substances This process forms solid glassy, and hollow spheres with a smooth surface, and their size range from 05 to 200 2023年2月20日 A critical review on mechanochemical processing of fly ash and fly ashderived materials Author links open overlay panel Ewelina GrabiasBlicharz, Wojciech (“planetary”) ball mill is the most popular The equipment of a planetary ball mill includes a milling vessel (‘cup’) fixed on a ‘sun wheel’ which moves in the direction A critical review on mechanochemical processing of fly ash and fly ash 2017年9月17日 AAC blocks are light weight Aerated Autoclave Concrete Block It is manufactured through a reaction of aluminium powder and a proportionate blend of lime, cement, and fly ash or sand(PDF) MANUFACTURING PROCESS OF AAC BLOCKQ Green Techcon is Leading Manufacturer Of Fly Ash Bricks Making Machines, Concrete Brick, Block Making Machines, Paver Block Making Machine, Material Handling Equipment United Conveyor Corporation UCC Equipment FEECO has been processing fly ash for over 65 years, providing custom, highquality agglomeration and material handling fly ash handling equipment kooksco

.jpg)

China Concrete Block Making Production Line, Hollow Bricks Machine, Fly

Hesheng Heavy Machinery (Wuhan) Co, Ltd: Welcome to buy concrete block making production line, hollow bricks machine, fly ash machine, pave making machine, concrete mixer for sale here from professional suppliers in China Our factory offers high quality machines made in China with competitive price Please feel free to contact us for customized service2023年12月13日 Fly ash can be turned into more than just an industrial byproduct With economically effective and environmentally sound strategies for processing, like those provided by Economy Ball Mill and our stateoftheart ball mills, fly ash can become a valuable commodity in the industrial and construction marketplaceUsing Ball Mills for Fly Ash Processing Economy Ball Mill2024年3月1日 As a common industrial solid waste, fly ash requires proper processing and utilization to alleviate environmental pressure In contrast to earlier lowvalue treatment methods for fly ash, such as its use in construction materials, it is more practical to explore the highvalue utilization of fly ash, considering its elemental ingredient and morphological characteristicsReview A review on fly ash highvalue synthesis utilization 2023年6月15日 After processing raw materials such as fly ash through a series of processes, they can be made into different block bricks, such as fly ash hollow bricks and solid bricks 3Be used in the chemical industry Highpurity alum can be extracted from fly ash, which can be used to synthesize bauxite, and can also be used to produce SiC powder, a non Fly Ash Properties, Source, Advantages, Uses DASWELL

Fly Ash SpringerLink

Figure 1 shows fly ash produced in a typical pulverizedcoalfired utility boiler and collected by an electrostatic precipitator There are two commonly used methods for removing the fine powdery fly ash from the fly ash hopper of the precipitator – a wet method or a dry method [12–15]In the wet method, water is used to flush the fly ash out of the hoppers and the ash slurry is pumped Q Green Techcon is Leading Manufacturer Of Fly Ash Bricks Making Machines, Concrete Brick, Block Making Machines, Paver Block Making Machine, Material Handling CAll Us: +7 Submit Ticket Menu Home; Paver Q Green Techcon Leading Manufacturer Of Fly We are a leading fly ash supplier in Pakistan, using advanced facilities to make various fly ash products Our range includes items like bricks, lightweight blocks, coal ash, pumice stone, and special tiles like pavers, curbstones (kerbstones), edgestones, hollow blocks, CLC blocks, and pumice blocks These products are great because they Flyash SupplierWe are dealing wide range of Fly Ash Bricks Making Machine, Block Making Machine, Mixer Equipment, Sand Filter Machine, Special Purpose Machine, Tile Making Machine, Stone Processing Machine, PVC Rubber Mould, Conveyor Belts and many moreFly Ash Brick Block Making Machine Manufacturer from

TECHNICAL BULLETIN Fly Ash Eco Material

2022年8月30日 Fly Ash for Block Manufacturing Fly ash improves block manufacturing in two basic ways It gives producers the strength required and, at the same time, the added plasticity that fly ash contributes (reported by Belot, 1976) to the relatively harsh block mixes ensures improved finish and texture, better mold life, and better, sharper cornersThe production process of fly ash brick making equipment includes the processing and preparation of raw materials, metering and batching according to a certain proportion, stirring, digestion, wheel rolling, pressing and forming, static stop maintenance of blanks, autoclave maintenance, finished product inspection and stacking and other major stepsThe production process of fly ash machine2023年8月16日 Fly Ash Processing Equipment and Solutions The Atritor Dryer Pulveriser offers simultaneous drying, deagglomeration, and classification in a single stage It can produce a product feed rate of up to 20 tonnes per hour and evaporation rates of up to 4,000 kilograms per hour, utilising inlet gas temperature as high as 550 degrees centigrade Fly ash processing: Tailored solutions for reclaimed fly ash2019年9月22日 Fly ash utilization reduces the requirement of clay, sand, lime stone in cement manufacturing and hence conserves natural resources Fly ash utilization reduces the cement requirement and hence carbon‐dioxide liberation during cement manufacturing is reduced Fly ash utilization reduces the top soil requirement for land filling / brickFLY ASH BRICKS kviconlinegov

PROJECT PROFILE ON FLY ASH BRICKS

2018年6月2日 There is ample scope for fly ash brick and block units In Chennai alone 1 crore bricks are required for constructional MANUFACTURING PROCESS: Fly ash (70%)Lime (10%) Gypsum (5%) and sand(15%) are manually Machinery and Equipment : SN DESCRIPTION QTY RATE AMOUNT 1 Automatic Fly ash Brick making 2014年12月8日 Studies of the Properties of Paver Block using Fly Ash Ritesh Mall1 Sharda Shrama2 Prof RDPatel3 1,2MTech (Structural Engineering) In this process use the partial replacement of Cement with Fly Ash in percentage of 0%, 5%, 10%, 15%, 20%, 25%, and 30% respectively and also, and easily repaired without any special equipment or Studies of the Properties of Paver Block using Fly AshMany contractors, construction companies and civil engineers rely on our range of Sai Hollow Block Machines, Fly Ash Brick Machine, Concrete Block Machine, Electric Concrete Mixer Machines, Earth Rammers, Automatic Concrete Block Making Machines, etc completely They bestow their complete trust on our array because of the high quality, extreme Fly Ash Brick Machine Manufacturer, Concrete Block 2024年4月7日 The manufacturing process and equipment of aerated block production line have been exported to Uzbekistan, Kazakhstan, Cambodia, Myanmar, UAE, Mongolia, India, Bangladesh, Indonesia, Vietnam and Nepal etc Dongyue Machinery Group FLY ASH AAC Block production line has the following characteristics: 01FLY ASH AAC BLOCK PLANTAAC BLOCK

.jpg)

Fly Ash Handling: Challenges and Solutions

2012年2月1日 By Jayant Khambekar, PhD and Roger A Barnum, Jenike Johanson, Inc, USA Fly ash is a general name used for the residual products of combustion that rise with flue gases More than 100 million 2014年6月25日 KEYWORDS: fly ash, separation, dry method, micron, submicron ABSTRACT Significant variations in the chemical and physical compositions of fly ash are recognized as critical issues for fly ash to be used in various applications The quality of fly ash depends not only on the coal types and sources (chemical composition), but alsoFly Ash Separation Technology and its Potential Cyclone furnaces: These produce the least amount of coal fly ash, composition of which is between 70 to 80 percent fly ash and 20 to 30 percent molten bottom ash Wetbottom boilers: Also known as a slagtap furnace, these produce less fly ash, with only about half leaving the plant along with the flue gas, while the rest remains in the furnaceFly Ash Processing and Equipment to Collect Fly Ash Heyl 2015年4月1日 The article introduces raw materials of fly ash brick, production process and key control points Experimental equipment and production process Main equipments Forming machine (H240, Korea) included hydraulic device, control and operator’s desk, chained conveyor and some molds, and the motor power was 3625 KW, vibration frequency was New technology and application of brick making with coal fly ash

.jpg)

Fly Ash Processing Plant Ball Mill, Raymond Mill, EPC Project

Fly ash is generally a solid waste generated by the incineration boilers in thermal power plants, coalfired power plants, paper mills, and chemical factories, as well as the collection of ash from dust collectors It consists of tiny ash particles emitted during the combustion of fuel, primarily coal, with particle sizes typically ranging from 1 to 100 micrometersFly ash bricks and AAC blocks both are used to construct walls They have their own properties In this article, I have given Fly ash bricks vs aac blocks in What is Autoclaved aerated concrete block – AAC block This process depends upon the use of the mechanical equipment and desire of the owner to provide the required size Then the Fly ash bricks vs AAC blocks – Features, Preparation, and 2016年4月29日 Headwaters Inc has acquired the fly ashcentered technology of recently liquidated brick, paver and masonry trim operator CalStar ProductsThe intellectual property will be integrated into the Block Group, with concrete masonry production and distribution in Texas and Louisiana, through Headwaters Construction Materials, the leader in ASTM C618 fly ash Headwaters Block Group prepares to integrate fly ashbased CalStar process2024年10月22日 The global construction industry is witnessing a steady rise in cement demand, contributing significantly to CO2 emissions, while concurrently generating substantial quantities of waste materials, notably construction and demolition waste (CDW) This study explores the utilization of these waste streams in developing sustainable construction materials, focusing Mechanical, microstructural, durability, and energy analysis of fly ash

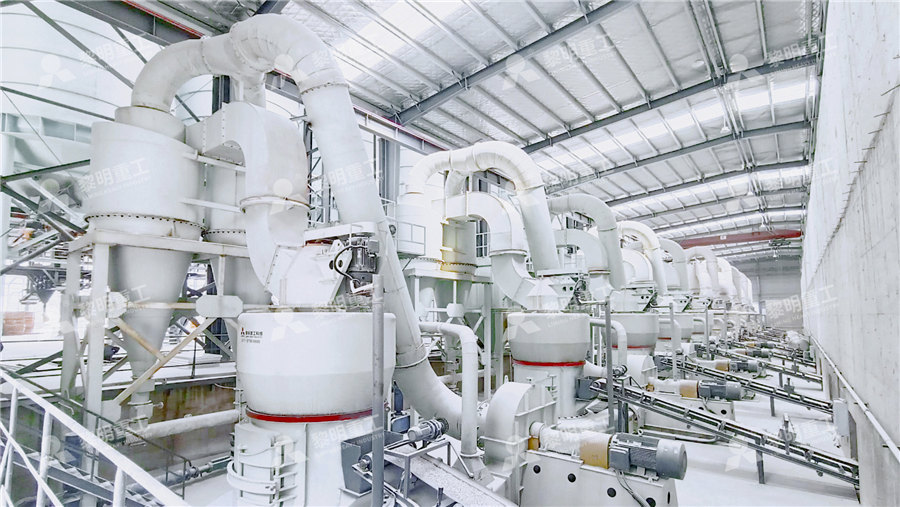

Fly Ash Production ProcessFly Ash Processing Equipment

2021年9月2日 The fly ash material enters the mill from the feeding device and is fed between the grinding roller and the grinding ring The mill is driven by the transmission device to move the grinding roller device suspended on the plum blossom frame, as it moves around the vertical axis With its revolution and its own rotation, the grinding roller is constantly swinging outward and