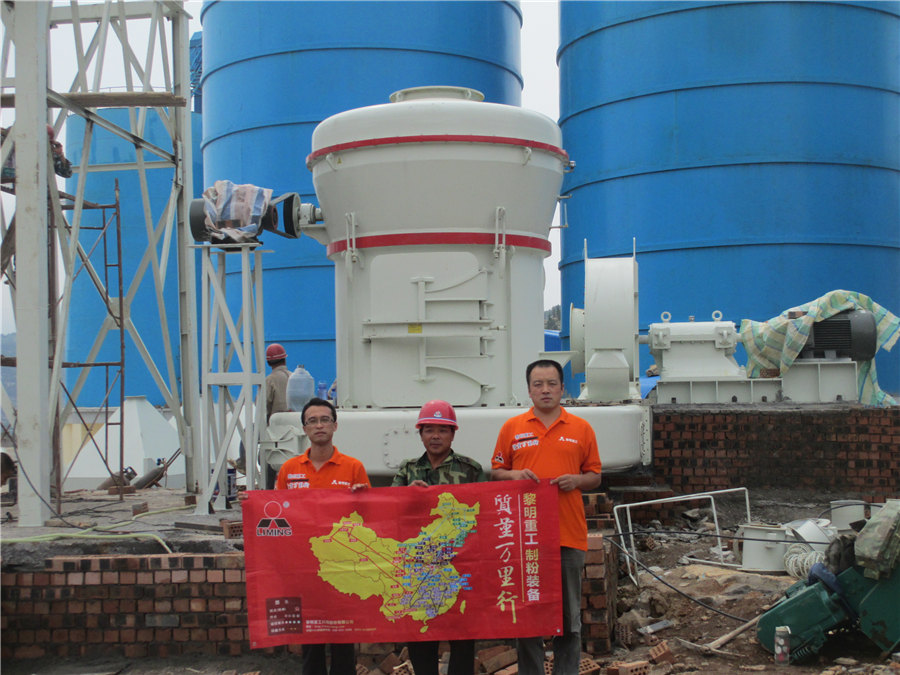

Calcium carbide mud mill quotation Zhengzhou sulfur equipment processing and supply

.jpg)

Recycling and utilization of calcium carbide slag ScienceDirect

2022年5月1日 The goal is to efficiently convert secondary Ca(OH) 2 and CaCO 3 into highpurity massive CaO or powdered CaO, and to realize the circulation process of calcium in the chlor The process equipment optimization comprises the following modules, known as optimization of wet calcium carbide slag feeding system and drying system, improvement of batching and Application technology of calcium carbide slag: a case study ZKG2023年9月15日 When the proportion of calcium carbide slag in raw materials reaches 60 %, approximately 200 kg CO 2 /tclinker can be reduced over the calcination process of limestone Historical trend and decarbonization pathway of China's cement 2022年7月14日 The kinetics of carbide slag desulfurization process conforms to pseudofirstorder kinetics, and the sulfur content of calcium carbide slag reaches to 1000 mgSO2g−1 A Desulphurization mechanism and engineering practice of carbide

EnergyEfficient Rotary Dryer for Calcium Carbide Slag and Red

EnergyEfficient Rotary Dryer for Calcium Carbide Slag and Red Mud, Find Details and Price about Industrial Drum Dryer Machine Rotary Drying Machine from EnergyEfficient Rotary 2022年8月1日 Life cycle assessment is employed in this study to provide a comprehensive analysis of the environmental performance of CaC 2 production in China The results show Life cycle assessment and sustainable production evaluation of 2022年5月1日 Results revealed that the proposed calcium looping system with highefficiency, lowcarbon and clean for calcium carbideacetylene production, could be a promising process Life cycle assessment and sustainable production evaluation of Diversified development of calcium carbide industry, resource utilization of solid waste carbide slag and its application of carbon emission reduction have been fully reviewed In 2020, the Resource utilization of solid waste carbide slag: a brief review of

Calcium carbide the allrounder in secondary metallurgy

2022年7月13日 This is where calcium carbide comes into play: Thanks to its high affinity for oxygen and sulfur, calcium carbide is used as a highly efficient agent in various secondary 2020年9月21日 A type of calcium coke was developed for use in the oxythermal process of calcium carbide production The calcium coke was prepared by the copyrolysis of coking coal Development of calcium coke for CaC2 production using calcium 2019年11月27日 Aiming to make full use of three kinds of solid wastes from calcium carbide industry, this paper first investigated elements and mineral compounds of them through inductively coupled plasma and Xray diffraction (XRD) The three solid waste samples, removed dust (RD), coke dust (CD) and purified dust (PD), have higher Ca/S molar ratios than Fundamental characteristics of solid wastes from calcium carbide Request PDF On Feb 1, 2023, Yuxuan Shi and others published Preparation and curing method of red mudcalcium carbide slag synergistically activated fly ashground granulated blast furnace slag Preparation and curing method of red mudcalcium carbide slag

Calcium carbide Wikipedia

Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2Its main use industrially is in the production of acetylene and calcium cyanamide [3]The pure material is colorless, while pieces of technicalgrade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P 2020年9月21日 A type of calcium coke was developed for use in the oxythermal process of calcium carbide production The calcium coke was prepared by the copyrolysis of coking coal and calcium carbide slag, which is a solid waste generated from the chloralkali industry The characteristics of the calcium cokes under different conditions were analyzed experimentally Development of calcium coke for CaC2 production using calcium carbide 2021年11月1日 In China, the calcium carbide and methane partial oxidation methods are used to produce acetylene, with the former being predominantly used China is the largest producer and consumer of calcium carbide worldwide, with 2018 output reaching 2608 million tons, 90% of which was used to produce polyvinyl chloride, 1,4butanediol, and vinyl acetate through Life cycle assessment of acetylene production from calcium carbide 114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US Environmental

.jpg)

Use of Calcium Carbide and Alumina based Slag ResearchGate

Use of Calcium Carbide and Alumina based Slag Conditioner Briquettes in steelmaking at JSPL, Angul Soumya 1Kanta Nayak , Amiy Srivastava 1 , Sabyasachi Bandyopadhyay 2A laboratoryscale spoutfluid bed reactor with a dc plasma torch was used to study the solidphase synthesis of calcium carbide Calcium oxide powder with a mean particle size of 170 μm was reacted with graphite powder (130 μm) Argon was used to initiate the plasma and hydrogen gas was then added to increase power and raise the plasma jet enthalpy Experimental results SolidPhase Synthesis of Calcium Carbide in a Plasma Reactor2022年2月1日 Calcium carbide is produced industrially from coke and lime in an electric arc furnace The furnace is heated to ~2000 • C by electricity, resulting in an energy consumption of >3000 kW h/kg CaC Energy and exergy analysis of a new calcium carbide1 megagram (2,205 lb) of calcium carbide Calcium carbide is used primarily in generating acetylene and desulfurizing iron The Standard Industrial Classification (SIC) code for calcium carbide manufacturing is 2819, industrial inorganic chemicals, not elsewhere classified The sixdigit Source Classification Code (SCC) for calcium carbideEmission Factor Documentation for AP42 Calcium Carbide

.jpg)

News Calcium Silicate Production Raw Materials And Technology

2 Calcareous materials: slaked lime powder, cement, calcium carbide mud, etc 3 Reinforcing fiber: wood paper fiber, wollastonite, cotton fiber, etc 4Main ingredients and formula: silicon powder + calcium powder + natural log pulp fiber Quartz powder silica powder calcium powder diatomite wollastonite grinding mill2022年2月1日 Calcium carbide can be used as the basic raw material of organic synthetic chemical industry, and many organic compounds, such as polyethylene (PE), ethyne, polyvinyl chloride(PVC), etc, can be produced or synthesized by using calcium carbide [1, 2]As a result, CaC 2 has become an important chemical platform for sustainable development because of its Energy and exergy analysis of a new calcium carbideAt Carbide Industries, calcium carbide production in different sizes (grades) is all we do Generally speaking, the different grades of carbide that we make correspond to different reactivities of the carbide For example, we produce Calcium Carbide Applications Carbide Industries LLC2024年1月5日 A mixture of calcium carbide residue and coal fly ash with a Ca/(SiO2 + Al2O3) ratio of 15 resulted in the highest compressive strength at long curing periods in both pastes and mortarsEvaluation of calcium carbide residue and fly ash as sustainable

.jpg)

114 Calcium Carbide Manufacturing US EPA

114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO2022年11月21日 The increased production of industrial waste accompanies global industrialization The discharge and storage of industrial wastes seriously pollute the natural environment and limit the development of related industries [1]Red mud (RM), also known as bauxite residue, is a category of industrial waste produced from alumina plantsStrength development and microstructure of sustainable 2022年12月1日 At present, calcium carbide production includes electrothermal method (ETM) and oxythermal method (OTM) Electrothermal method (ETM) originated early, and calcium carbide is formed by the reaction of calcium oxide and coke at a high temperature about 2000 °C produced by electric arc [10], [11]Generally, the power consumption of producing 1 ton of Carboncalcium composite conversion of calcium carbide The equipment includes improved Raymond mill (hanging roller mill or pendulum mill), roller mill (including pressure roller mill/vertical mill, ring roller mill, etc ) and ball mill, etc Ultrafine heavy calcium carbonate with d97≥5μm generally adopts dry production process, and some use wet grinding + drying processNews Calcium powder processing machinery and equipment

Desulphurization mechanism and engineering practice of carbide

2022年7月14日 The kinetics of carbide slag desulfurization process conforms to pseudofirstorder kinetics, and the sulfur content of calcium carbide slag reaches to 1000 mgSO2g1114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US Environmental 2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on Precipitated Calcium carbonate production, Chinesemade chlorine bypass system has been implemented to achieve stable and troublefree kiln operation using calcium carbide residue (CCR) with high chlorine concentration as main alternative material, avoid dangerous blockage, problematic buildups and coatings, stoppage and corrosion caused by high recirculation of volatile materials in kiln Compared with the chlorine Demonstration application of Chinesemade chlorine bypass

.jpg)

Comprehensive performance study of aluminum ash and calcium carbide

2022年12月12日 Calcium carbide slag is a waste slag produced after the hydrolysis of calcium carbide to obtain acetylene gas, with very fine particles, offwhite color due to the presence of trace carbon and sulfur impurities, slightly odorous, with Ca(OH) 2 as the main component, and a slag liquid pH value of 12 or more, thus often causing serious pollution to the environment [18]2020年8月5日 Lime mud, a kind of industrial waste that produced in paper mill, was proposed as CO2 sorbent in calcium looping process The carbonation performance of the lime mud was investigated in a dual Kinetic analysis about the CO 2 capture capacity of lime mud from Calcium carbide in a dry state is noncombustible Dusts of calcium carbide are classified as nuisance dusts and do not constitute a fire or explosion hazard except in the presence of moisture or at temperatures in excess of 1,000°C Calcium carbide will react with ANY form of CALCIUM CARBIDE HOT METAL DESULFURIZATION GRADE 2021年11月1日 As the world's largest producer of FGD gypsum, China occupies a very prominent position in the world, and its utilization is also imminent This article reviews the production and development of China's FGD gypsum in the past 20 years, and determines its production process, composition, and environmental impactProduction and resource utilization of flue gas desulfurized

.jpg)

Calcium Carbonate Manufacturing Process and Equipment

2021年12月20日 The equipment used during the processing of calcium carbonate powder affects grain types and particle size distribution Prater Equipment for Calcium Carbonate Manufacturing Processes Prater Industries makes a number of machines wellsuited for breaking apart aggregates like limestone, chalk, or marble to make calcium carbonate2022年5月1日 Request PDF Recycling and utilization of calcium carbide slag current status and new opportunities Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride Recycling and utilization of calcium carbide slag ResearchGateZhengzhou Hengxing Heavy Equipment Co, Ltd: We're known as one of the most professional stone crusher, grinding ball mill, rotary drying equipment, calcination equipment, coal briquetting equipment manufacturers and suppliers in China Please rest assured to buy highgrade equipment for sale here from our factory All our products are with high quality and competitive China Stone Crusher, Grinding Ball Mill, Rotary Drying Equipment 1 School of Chemistry and Chemical Engineering, University of Jinan, Jinan , Shandong, China 2 CAS Key Laboratory of Green Process and Engineering, National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology, Institute of Process Engineering, Chinese Academy of Sciences, Beijing , China 3 Faculty of Metallurgical Properties analysis of dryprocess calcium carbide slag and study

.jpg)

Fundamental characteristics of solid wastes from calcium carbide

2019年11月27日 Aiming to make full use of three kinds of solid wastes from calcium carbide industry, this paper first investigated elements and mineral compounds of them through inductively coupled plasma and Xray diffraction (XRD) The three solid waste samples, removed dust (RD), coke dust (CD) and purified dust (PD), have higher Ca/S molar ratios than Request PDF On Feb 1, 2023, Yuxuan Shi and others published Preparation and curing method of red mudcalcium carbide slag synergistically activated fly ashground granulated blast furnace slag Preparation and curing method of red mudcalcium carbide slag Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2Its main use industrially is in the production of acetylene and calcium cyanamide [3]The pure material is colorless, while pieces of technicalgrade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P Calcium carbide Wikipedia2020年9月21日 A type of calcium coke was developed for use in the oxythermal process of calcium carbide production The calcium coke was prepared by the copyrolysis of coking coal and calcium carbide slag, which is a solid waste generated from the chloralkali industry The characteristics of the calcium cokes under different conditions were analyzed experimentally Development of calcium coke for CaC2 production using calcium carbide

Life cycle assessment of acetylene production from calcium carbide

2021年11月1日 In China, the calcium carbide and methane partial oxidation methods are used to produce acetylene, with the former being predominantly used China is the largest producer and consumer of calcium carbide worldwide, with 2018 output reaching 2608 million tons, 90% of which was used to produce polyvinyl chloride, 1,4butanediol, and vinyl acetate through 114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US Environmental Use of Calcium Carbide and Alumina based Slag Conditioner Briquettes in steelmaking at JSPL, Angul Soumya 1Kanta Nayak , Amiy Srivastava 1 , Sabyasachi Bandyopadhyay 2Use of Calcium Carbide and Alumina based Slag ResearchGateA laboratoryscale spoutfluid bed reactor with a dc plasma torch was used to study the solidphase synthesis of calcium carbide Calcium oxide powder with a mean particle size of 170 μm was reacted with graphite powder (130 μm) Argon was used to initiate the plasma and hydrogen gas was then added to increase power and raise the plasma jet enthalpy Experimental results SolidPhase Synthesis of Calcium Carbide in a Plasma Reactor

Energy and exergy analysis of a new calcium carbide

2022年2月1日 Calcium carbide is produced industrially from coke and lime in an electric arc furnace The furnace is heated to ~2000 • C by electricity, resulting in an energy consumption of >3000 kW h/kg CaC 1 megagram (2,205 lb) of calcium carbide Calcium carbide is used primarily in generating acetylene and desulfurizing iron The Standard Industrial Classification (SIC) code for calcium carbide manufacturing is 2819, industrial inorganic chemicals, not elsewhere classified The sixdigit Source Classification Code (SCC) for calcium carbideEmission Factor Documentation for AP42 Calcium Carbide