2 How much power reducer is suitable for a 2meter ball mill

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Machinery Reference Manual I will also provide 2 Ball Mill Sizing (Design) example done ‘byhand’ from tables and charts Today, Different ball mills may be more suitable for certain materials and particle size requirements Capacity: Determine the required grinding capacity based on the expected throughput of the Technical specifications and selection guide for ball millsIn this module, you will learn how to characterize the performance of ball mill circuits Specifically, after completing this module, you will be able to: List and describe the four elements of the MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLINGthe ball mill had an average production rate of 190tph with a specific electrical energy consumption of 355kWh/t Its operational issues included: • oversized limestone • wornout BALL MILLS Ball mill optimisation Holzinger Consulting

Ball Mill an overview ScienceDirect Topics

Ball mill in operation: 79 m (26 ft) diameter ball mills (power rating 164 MW each) at Tintaya Antapaccay (Courtesy Antapaccay Perú) Since balls have a greater surface area per unit 2015年10月19日 The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside Ball Mill Motor Power Draw Sizing and Design Formula2001年8月1日 Typical power consumption for a 5m diameter by 7mlong ball mill is between 25 and 35 MW The actual proportion of this energy usefully used in size reduction is thought Charge behaviour and power consumption in ball mills: sensitivity In a dry grinding process, the balls should be at least a factor of 3 larger than the largest particle of the sample material The jar filling situation should follow the 1/3 rule, to protect the grinding Three rules for the optimum ball mill setup RETSCH

.jpg)

How to choose between ball mill and vertical roller mill?

2022年6月24日 In the ball mill, the material is mainly crushed by impact and friction In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary The residence time of the material in the vertical mill is 23 2002年10月1日 The design of gear speed reducers is contained in the present work, for spur, helical, bevel and worm gears Individual one stage reducers have been designed for each kind of gears(PDF) Design principles for speed reducers2001年10月1日 Speed reducers are mechanical devices generally used for two purposes The primary use is to multiply the amount of torque generated by an input power source to increase the amount of usable workSpeed reducers Machine Design2018年10月9日 A speed reducer is simply a gear train between the motor and the machinery that is used to reduce the speed with which power is transmitted Speed reducers, Second, speed reducers, much as the name implies, reduce the speed of the input so that the output is the correct speed How does a speed reducer increase the torque while What is a Speed Reducer ? How does a Speed Reducer work

25 mm Electrical Cable Amp Rating (Explained With Examples)

Therefore, before you install 25mm wire in your residential or commercial setting, you must first determine whether or not it is suitable for the application you have in mind 25mm2 cable can withstand 4800 watts of power Cable Size: Amps: Volt: Watt: 25mm: 16A: 120: 1920W: 25mm: 16A: 240: 3840W:2023年10月24日 Reducers come in different types, each tailored for specific applications Here are some types of reducers and their common applications: Helical Reducers Helical reducers have helical gears and are known for being quieter and producing less vibration They are commonly used in industrial machines, vehicle systems, and conveyor belts Bevel What is a Reducer and What are its Types? GAMAK2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a (PDF) Effects of Ball Size Distribution and Mill Speed and Their A reducer with a 20 service factor can accommodate double the torque compared to a 10 service factor And while the output will be the same in these two reducers, it’s the extra capacity that protects the one with the higher service factor Remember – reallife circumstances are much more important than specifications listed on paperGearbox Service Factor: What Is It Why Is It Important?

.jpg)

Ball Mill Critical Speed 911Metallurgist

2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the AESA 12M UK 1,300mm x 2,530mm Ball Mill AESA 12M UK Ball Mill Make: AESA UK Model: 12 M Size: 1,300mm Diameter, 2,530mm (Approx 4' x 8') Feed Type: Continuous, Spout Feed D ID: Quote + Denver 4' Dia x 5 Ft Long Ball Mill Denver 4' Diameter by 5 Foot Long Ball Mill Description: Excellent condition Denver Ball MillNew and Used Ball Mills for Sale Ball Mill Supplier WorldwideBased on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with selfaligned flanged motors, running on hydrodynamic oil lubricated bearings The TITAN design enables you to run full process load 40% Ball charge at Ball Mills – MechProTech MPTThe difference in speeds between balls and jars produces an interaction between frictional and impact forces, which releases high dynamic energies The interplay between these forces produces the high and very effective degree of size Planetary Ball Mill PM 100 RETSCH highest fineness

.jpg)

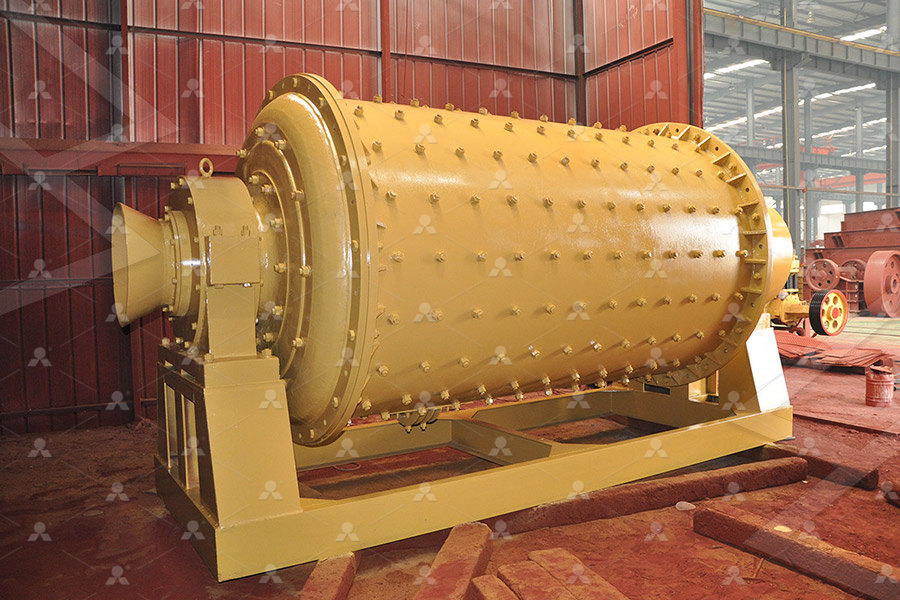

Ball Mill (Ball Mills Explained) saVRee saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish mill The torque and time requirements of the mill with the ballBALL MILL DRIVE MOTOR CHOICES Artec Machine2024年7月12日 Unlock ball mill technology Discover how these versatile machines are used for industries for grinding and blending materials efficiently ceramic production, and paint manufacturing In contrast, we find rod mills more suitable for tasks like preparing feed for gravimetric ore dressing methods and certain flotation processesWhat Is a Ball Mill and How Does It Work? Certified MTP Blog2016年10月20日 Concrete may be made up in different mixtures having different proportions of sand and aggregate These are expressed in parts – for example a 1:2:4 mixture indicates one bag of cement, 2 cubic feet of sand, and 4 cubic feet of gravel We recommend a mixture of 1:2:3 for ball mill and rod mill foundationsBall Mill Maintenance Installation Procedure 911Metallurgist

Sumitomo Concentric Gearboxes Speed Reducers

Limited torque capacity: Concentric gearboxes have a lower torque capacity than other gearbox designs and may not be suitable for hightorque applications Limited speed range: Concentric gearboxes may not be suitable for highspeed applications, as they are more prone to heat buildup and wear at high speeds2023年2月15日 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloaded Reasons17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles2017年2月20日 Grinding Mill Specifications Data According to formula 423/√d, where d is equal to internal shell diameter within new liners In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger millsGrinding Mill Design Ball Mill Manufacturer 911Metallurgist2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding

.jpg)

Concentric vs Eccentric Reducer A Comprehensive

2024年3月29日 Concentric Reducer: Suitable for handling clean fluids or nonabrasive materials where pressure drop and turbulence must be minimized Eccentric Reducer: This type is preferred for applications involving slurries, Google 提供的服務無須支付費用,可讓您即時翻譯英文和超過 100 種其他語言的文字、詞組和網頁。Google 翻譯Worm Gear Reducers This right angle speed reducer combines a worm wheel which makes it possible to obtain a large reduction ratio of about 1/10 to 1/60 Worm gear reducers are generally used for applications requiring very high What is a Speed Reducer? ATO2019年6月13日 And when d 1 = F R, that is, when the focal reducer is placed at a distance from the focal plane of the objective that's equal to the reducer's focal length, the focal length of the combined optical system is ½ F o, so it acts as a 05x reducer In this case, d 2 = F R /2, which means the back of the focal reducer is located at a distance F R Agena's Guide to Focal Reducers

.jpg)

DESIGN AND ANALYSIS OF A TWO STAGE REDUCTION GEARBOX

22 Gears: A gear is a rotating machine part having cut teeth, which mesh with another toothed part to transmit torque Geareddevicescanchange the speed, torque, and direction of a power source Gears almostalways produce Fig 2 Terms used in Gears a change in torque, advantage, through their ratio 23 TRESSES IN SHAFTSChanges in flow path area where a fluid may be accelerated and/or decelerated such as restriction orifices, pipe reducers and expanders, venturi meters etc will result in some pressure lost For L/D 2 > 5, use the equations for a square reduction and a square expansion, otherwise: Multiply K for a thin sharp orifice by, Square ExpansionExpansion and Reduction in Pipe Size NeutriumRotational speed: 172 rpm 250 rpm Power: 025 ch 5 ch Gear ratio: 7 unit 102 unit Bison's Stainless Steel S Series rightangle worm reducer is perfect for harsh washdown conditions in food processing or other applications with high temperature/high pressure sprays Highpower gear reducer, Highpower gearbox DirectIndustry Motor Power: The motor power of a ball mill is an important factor in determining its grinding capacity Ball mills can be equipped with motors ranging from 10 kW to 500 kW or more, depending on the size and desired output of the mill Speed: Ball mills are usually operated at speeds between 60% and 70% of the critical speedTechnical specifications and selection guide for ball mills

Ball Mills Orbis Machinery

Ball Mills Steel Ball Mill Lined Ball Mill Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction The basic construction of a ball mill is a cylindrical container with journals at its axis Inside this cylinder, grinding media – composed of ceramic, metallic balls, or rods – fills the space2023年7月13日 Some reducers are designed for oilbased paints, while others are more suitable for waterbased latex paints Understanding the compatibility between the paint reducer and your chosen paint type is crucial for achieving optimal results Additionally, consider the overall quality and reputation of the paint reducer brandThe Secret Ingredient: Discovering the Power of Car Paint Reducer2022年6月24日 In the ball mill, the material is mainly crushed by impact and friction In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary The residence time of the material in the vertical mill is 23 How to choose between ball mill and vertical roller mill?2002年10月1日 The design of gear speed reducers is contained in the present work, for spur, helical, bevel and worm gears Individual one stage reducers have been designed for each kind of gears(PDF) Design principles for speed reducers

.jpg)

Speed reducers Machine Design

2001年10月1日 Speed reducers are mechanical devices generally used for two purposes The primary use is to multiply the amount of torque generated by an input power source to increase the amount of usable work2018年10月9日 A speed reducer is simply a gear train between the motor and the machinery that is used to reduce the speed with which power is transmitted Speed reducers, Second, speed reducers, much as the name implies, reduce the speed of the input so that the output is the correct speed How does a speed reducer increase the torque while What is a Speed Reducer ? How does a Speed Reducer workTherefore, before you install 25mm wire in your residential or commercial setting, you must first determine whether or not it is suitable for the application you have in mind 25mm2 cable can withstand 4800 watts of power Cable Size: Amps: Volt: Watt: 25mm: 16A: 120: 1920W: 25mm: 16A: 240: 3840W:25 mm Electrical Cable Amp Rating (Explained With Examples)2023年10月24日 Reducers come in different types, each tailored for specific applications Here are some types of reducers and their common applications: Helical Reducers Helical reducers have helical gears and are known for being quieter and producing less vibration They are commonly used in industrial machines, vehicle systems, and conveyor belts Bevel What is a Reducer and What are its Types? GAMAK

制粉项目-2023.11.17.jpg)

(PDF) Effects of Ball Size Distribution and Mill Speed and Their

2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a A reducer with a 20 service factor can accommodate double the torque compared to a 10 service factor And while the output will be the same in these two reducers, it’s the extra capacity that protects the one with the higher service factor Remember – reallife circumstances are much more important than specifications listed on paperGearbox Service Factor: What Is It Why Is It Important?2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Ball Mill Critical Speed 911MetallurgistAESA 12M UK 1,300mm x 2,530mm Ball Mill AESA 12M UK Ball Mill Make: AESA UK Model: 12 M Size: 1,300mm Diameter, 2,530mm (Approx 4' x 8') Feed Type: Continuous, Spout Feed D ID: Quote + Denver 4' Dia x 5 Ft Long Ball Mill Denver 4' Diameter by 5 Foot Long Ball Mill Description: Excellent condition Denver Ball MillNew and Used Ball Mills for Sale Ball Mill Supplier Worldwide