What certificate is required to open an ore powder mill

AusIMM – Leading the way for people in resources

%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 In mineral processing, a number of unit operations are required to prepare and classify ores before the valuable constituents can be separated or concentrated and then forwarded on for use or further treatmentIntroduction to Mineral Processing or 2017年8月24日 Thus, ores must go through a number of different operations to obtain the final products: comminution or size reduction, size separation, concentration or beneficiation, and Mineral Processing SpringerLink2024年9月20日 Understanding Mine to Mill is presented in five parts Part A – Setting the Scene provides some definitions of Mine to Mill (M2M) and the historical background A chronology of UNDErsTaNDINg MINE TO MILL 911 Metallurgist

SBM Ultrafine Powder Technology Industrial

The main products include: ore stone crushers (jaw crushers, cone crushers, hammer crushers, etc), ore grinding mills (ultrafine grinding mills, vertical mills, superfine wet mills, coarse powder mills, etc), milling production line 2011年10月7日 以邓小平理论和“三个代表”重要思想为指导,深入贯彻落实科学发展观,全面实施促进中部地区崛起战略,坚持以科学发展为主题,以加快转变经济发展方式为主线,探索不以 国务院关于支持河南省加快建设中原经济区的指导意见1 天前 CRC ORE and Mine to Mill expert Don McKee released a publication entitled Understanding Mine to Mill The publication documents the history of Mine to Mill, explaining Understanding Mine to Mill CEEC (Coalition for Eco 2013年6月25日 It could be a certification, a mill test report, test record or test data, statement of conformance – and the list goes on Some records simply state adherence to an applicable standard, but some contain data that can be overwhelming When we buy cement, we are provided with a cement mill certificate by the cement producerHow to Read a Cement Mill Certificate: Part 1 NPCA

.jpg)

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 rotation, the mill loading, the final product size required from a given feed size (coefficient of reduction), the work index of the material, the mill shaft power and the specific gravity of the 2016年3月21日 In calculating the Ratio of Concentration (R) of the mineral operations, the following formula has been found very useful Assays of heads, concentrate, and tailing are required Mill Water to Ore Ratio Requirements Common Basic Formulas for Mineral 2022年4月28日 News/Industry News/Kalium ore powder grinding mill machine Kalium ore powder grinding mill machine 28/04/2022 admin HGM superfine powder mill Fineness: 1502500mesh Yield: 0245t/h see More >> Clum ultrafine vertical Kalium ore powder grinding mill machine sbmmill2021年12月18日 Introduction: Pollution Certificate Is there any pollution certificate required for my business? This question is often asked by the owner of the business In fact, when they choose to open a new factory or heating plant, they will be required to have a Pollution Certificate License If they do not have it, they will be fined and even shut downPollution Certificate License For Business CORPSEED ITES

Converting a ball mill from overflow to grate discharge Metso

2020年6月23日 The installed motor power for a grinding mill is a key indicator, along with the physical dimensions of the mill itself, of the capacity of the mill to process tonnes of ore When an overflow mill is not drawing all available motor power during normal operation, this can indicate that there is potential to increase the mill throughput or 2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill integration 2020年3月17日 a Lump ore: a natural ore that is not selected by manual enrichment, with the grade of about 60% Since lump ore is raw ore, the proportion ores in blast furnace shouldn’t be too high, with a ratio of around 11% b Pellet: to produce a greenball with balanced viscosity and high intensity by adding certain water and binder to ore finesGeneral Introduction to Iron Ore I What is Iron Ore II2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911Metallurgist

Micro Powder Grinding Mill

The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can grind nonmetallic ore powder of 1503000 mesh Get MoreHGM Ultra fine powder mill is a high efficient device to break hard stone into micro powder, such as calcium carbonate, mica, limestone, etc The fluorite fine powder grinding mill is an industrial ore milling equipment independently Ultra Fine Powder Mill2019年11月30日 The iron ore produced is transported through trains to Saldhana which is approximately 861 km away from the mine The insitu ore types are laminated ore, conglomerate ore and detrital ore The major ore bearing mineral is Hematite (Fe 2 O 3) which constitutes 93% of the orebody mass The material mined is separated into ON grade ore, OFF grade Mine Planning and Optimisation Techniques Applied in an Iron Ore 2024年9月20日 Understanding Mine to Mill is presented in five parts Part A – Setting the Scene provides some definitions of Mine to Mill (M2M) and the historical background A chronology of Mine to Mill developments is followed by brief descriptions of the very wide range of Mine to Mill applications which have been implemented over the last 15 yearsUNDErsTaNDINg MINE TO MILL 911 Metallurgist

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as 2023年10月25日 Iron ore is a crucial raw material for the global steel industry, and its supply chain is a complex network that involves multiple stakeholders and activities The iron ore supply chain begins with the mining of iron ore, which is then transported to processing plants for beneficiation and further refinement The refined iron ore is then transported to steel mills for Iron Ore Supply Chain: From Mining to Steel ProductionThe Direct Reduction of Iron Thomas Battle, James McClelland, in Treatise on Process Metallurgy: Industrial Processes, 2014 1222 Agglomeration of Iron Ore The three major forms of iron used in ironmaking are pellets, lump, and sinter The major change in the past 50 years has been the development of costeffective pelletization technology allowing pellets to be a Iron Ore Pellet an overview ScienceDirect Topics2021年8月7日 Licenses Required for Rice Mill Plant Business To start a Rice Mill Plant, one needs licenses and a permit from your state government authority Step 1: Register a Company Let’s try and understand the types of business entity structures available in India Below is the list of some of them:How To Start Rice Mill Industry in India Manufacturing

.jpg)

Industries Exempted from obtaining NOC from Pollution Control

2020年8月31日 Some of the industries which are established or being established have been exempted for the list for obtaining the NCO or consent for the Pollution Control BoardThe exemption from obtaining NOC is provided on some specific criteria and according to the industry’s steps to control the hazardous activities2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpen2021年1月1日 Mill Scale, generated in a rolling steel mill can be a potential material for iron powder production Mill scale is a combination of different oxides like Hematite (Fe 2 O 3), Magnetite (Fe 3 O 4), and Wustite (FeO) [2], [3]Besides, this multioxide mill scale's conversion into single oxide (Fe 2 O 3) is the bestsuited route for further reduction into iron powder due to Overview on production of reduced iron powder from mill

.jpg)

(PDF) Planning an Iron Ore Mine: From

2013年1月1日 A second requirement is to sequence the ore extraction so that the variability in ore grade is controlled: failure to do so will result either in lowquality ore being marketed, or excessive re 2018年5月3日 The test certificate is an important reference document that reports on all elements relating to the applicable Australian Standard Compliance to the applicable Australian Standard is vital as it gives the specifier and purchaser confidence that the material obtained will perform as intended in the design and use phases of a projectAustralian Steel Institute Guide to using test certificates2024年11月21日 Once the ore is crushed to the appropriate size, it enters the grinding stage, where the manganese ore is refined into a fine powder using specialized equipment such as ball mills or vertical roller mills To achieve this, various crushing equipment such as jaw crushers, cone crushers, and ball mills are commonly used to crush and grind the oreEquipment Required To Build A Manganese Ore Processing 2023年8月23日 A Mill Certificate or Material Test Report is a document that confirms the chemistry, and physical properties of a material (Steel, bronze, etc) This can be for a commercial material or against a specification (such as ASME for castings, pipes, tubes, nuts and bolts, etc), or against materials specifications such as ASTM’s The report (Paper or Electronic media) What is a Mill Certificate? Certech Registration Inc

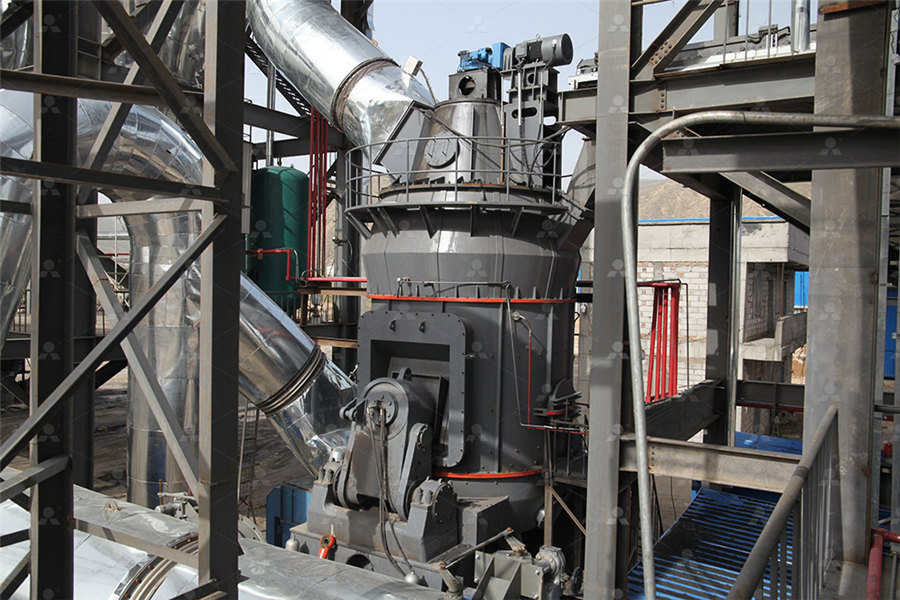

YGM Industrial Raymond Mill SBM Ultrafine Powder

YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, quartz stone, marble and other materials with Mohs hardness below 72021年9月8日 Abstract An analysis of flowsheets for processing sulfide and oxide copper ores, reagent modes, processing equipment, and flotation indicators in some domestic and foreign processing plants and productions is carried out Autogenous and semiautogenous mills are commonly used in the primary grinding stage in ore processing plants, which excludes Current Status of CopperOre Processing: A Review2022年7月30日 In order to study in depth the differences in basic characteristics between iron ore fines commonly used by a steel company, and guide the sintering performance plant to choose the best ore allocation method, experimental studies on the basic characteristics of seven iron ore powders of three sizes were carried out using microsintering equipment, mainly Study on the Basic Characteristics of Iron Ore Powder with2016年3月30日 In book: Encyclopedia of Iron, Steel, and Their Alloys (pppp 10821108) Chapter: i) Direct Reduced Iron: Production; Publisher: CRC Press, Taylor and Francis Group, New York(PDF) i) Direct Reduced Iron: Production ResearchGate

Processing Materials SBM Ultrafine Powder Technology

SBM has been focusing on the field of mining ore crushing and grinding machinery for many years Our grinding equipment can grind 100+ kinds of nonmetallic SBM ultrafine powder mills main include HGM series ultrafine grinding mills and CLUM series vertical roller mills They can process hundreds of ore materials, grind hard stone into fine 2013年6月25日 It could be a certification, a mill test report, test record or test data, statement of conformance – and the list goes on Some records simply state adherence to an applicable standard, but some contain data that can be overwhelming When we buy cement, we are provided with a cement mill certificate by the cement producerHow to Read a Cement Mill Certificate: Part 1 NPCA2012年6月1日 rotation, the mill loading, the final product size required from a given feed size (coefficient of reduction), the work index of the material, the mill shaft power and the specific gravity of the (PDF) Grinding in Ball Mills: Modeling and Process Control2016年3月21日 In calculating the Ratio of Concentration (R) of the mineral operations, the following formula has been found very useful Assays of heads, concentrate, and tailing are required Mill Water to Ore Ratio Requirements Common Basic Formulas for Mineral

Kalium ore powder grinding mill machine sbmmill

2022年4月28日 News/Industry News/Kalium ore powder grinding mill machine Kalium ore powder grinding mill machine 28/04/2022 admin HGM superfine powder mill Fineness: 1502500mesh Yield: 0245t/h see More >> Clum ultrafine vertical 2021年12月18日 Introduction: Pollution Certificate Is there any pollution certificate required for my business? This question is often asked by the owner of the business In fact, when they choose to open a new factory or heating plant, they will be required to have a Pollution Certificate License If they do not have it, they will be fined and even shut downPollution Certificate License For Business CORPSEED ITES 2020年6月23日 The installed motor power for a grinding mill is a key indicator, along with the physical dimensions of the mill itself, of the capacity of the mill to process tonnes of ore When an overflow mill is not drawing all available motor power during normal operation, this can indicate that there is potential to increase the mill throughput or Converting a ball mill from overflow to grate discharge Metso2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill integration

.jpg)

General Introduction to Iron Ore I What is Iron Ore II

2020年3月17日 a Lump ore: a natural ore that is not selected by manual enrichment, with the grade of about 60% Since lump ore is raw ore, the proportion ores in blast furnace shouldn’t be too high, with a ratio of around 11% b Pellet: to produce a greenball with balanced viscosity and high intensity by adding certain water and binder to ore fines2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911MetallurgistThe fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can grind nonmetallic ore powder of 1503000 mesh Get MoreMicro Powder Grinding Mill