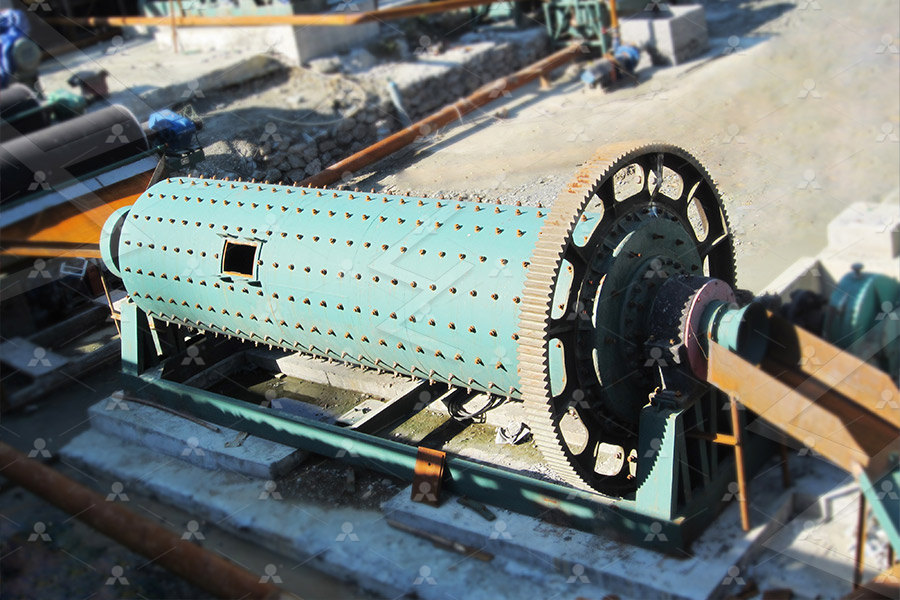

Construction vertical grinding ore grinding mill

.jpg)

RECENT DEVELOPMENTS IN COARSE GRINDING USING

2023年9月21日 Vertical stirred milling is a wellrecognized technology for the secondary, regrind and fine grinding applications and are increasingly replacing coarser ball mill applications in 2023年10月26日 The “flowsheet of the future” uses highpressure grinding rolls as an alternative to a semiautogenous grinding mill, and vertical stirred mills in open circuit as an alte rnative to Flowsheet of the Future: HighPressure Grinding Rolls, 2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are VRM's are state(PDF) LEARNING FROM OTHER INDUSTRIES; 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Operational parameters affecting the vertical roller mill

.jpg)

PROCESS OPTIMISATION FOR LOESCHE GRINDING

2017年8月12日 The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most 2014年10月20日 In Brazil, during the last 10 years, regrind P80 sizes of approximately 40 to 20 μm have been necessary in all new iron and copper plants The use of conventional ball mills, adequate for primaryRegrind of metallic ores with vertical mills: An 2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test Research of iron ore grinding in a verticalrollermill2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical

(PDF) Vertical mill simulation applied to iron

2014年11月1日 In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical mill Other three samples of pellet feed had already been tested with the methodology2015年3月10日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Copper ore grinding in a mobile vertical roller mill pilot plant2017年6月2日 Pebble mills use rock pebbles as the grinding media to cause friction and attrition between the pebbles and ore material Pebble mills may be used when metal balls must be avoided Buhrstone and disk attrition mills How it Works: Crushers, Grinding Mills and 4 天之前 A wet grinding 4 x 10 center peripheral discharge rod mill used for producing fine aggregates Twelve 7 x 24 Compeb mills grinding cement clinker to a product of 1750 surface area, 90% passing a 200 mesh screen An 8 x 7 Grinding Mills 911Metallurgist

RECENT DEVELOPMENTS IN COARSE GRINDING USING

2023年9月21日 Figure 3: Relationship between feed size (F80) and Bond efficiency factor (Huang et al, 2019) VERTICAL POWER MILL (VPM) – PRINCIPLE OF OPERATION Declining ore grades and more complex ore bodies, as well as waste management and global net zero initiatives, lead to a clear trend for high tonnage yet energy efficient grinding2023年10月10日 The Vertical Shaft Impactor Mill, also known as the VSI Mill, is a unique type of grinding mill that operates on a completely different principle compared to other types of mills This type of mill uses highspeed rotors with wearresistant tips to crush and grind materials into smaller particlesUnderstanding the SAG Mill in Copper Ore Mining Process2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles 2021年7月7日 Industrial grinding mills are used to grind ores, construction waste, etc Common industrial grinding mills include vertical mills, ultrafine mills Raymond mills It is an industrial grinding mill with extremely highcost performance for enterprises such as ore grinding powder The YGM Raymond mill produced by SBM is also an efficient What are the types of industrial grinding mills? sbmmill

How to choose a suitable ore powder grinding mill?

2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process Grinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low consumption, easy use +17Grinding Mill Industrial Grinding Mill, Vertical Mill, Raymond Mill 2023年2月28日 ③ Ore grinding: use grinding equipment to grind the ore to the required fineness Commonly used milling equipment includes ball mills, vertical mills, highpressure suspension roller mills, etc ④ Powder conveying: The powder produced by the milling equipment is transported to the finished product packaging area through the conveying equipmentBarium carbonate ore vertical mill sbmmill2015年3月15日 The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) Research of iron ore grinding in a verticalrollermill

Industrial Vertical Grinding Mill

The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball mill In addition, the vertical mill adopts a fully enclosed system, the system works under negative pressure, no dust, and the environment 2021年11月3日 At present, for the field of nonmetallic ore, there are ultrafine grinding mills, micropulverizers, superfine vertical roller mills, wet mills, and other industrial ore grinding equipment of the raw material phosphate so that the Phosphate Mineral Powder Grinding Mill SBM LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag READ MORE 5X Pendulum Roller Grinding MillStone Crushers, Mill and Grinding2021年10月29日 Magnesite grinding equipment includes ultrafine mills, vertical mills, highpressure mills, etc It can grind ores into a fine powder of up to 3000 mesh +17Magnesite Grinding Equipment Production Line SBM Ultra Mill

Understanding the operation of grinding mills in the mining

2024年10月13日 Autogenous mills use the ore itself as the grinding media, while semiautogenous mills use a combination of ore and steel balls These mills operate by rotating a large drum filled with the ore, which impacts and grinds the particles against the mill walls Autogenous and semiautogenous mills are more energyefficient and are suitable for fine 2024年10月13日 Ball mills come in two main types vertical and horizontal mills Horizontal mills typically have longer millshafts than vertical mills, which allows them to handle larger balls better Vertical mills are better suited for smaller balls because their shorter Millshafts allow them to move more quickly through the milling processFactors affecting ores grinding performance in ball mills2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2021年9月9日 Diatomite ultrafine grinding mill is an efficient ore stone powder making machine It can grind 100+ kinds of ores into a fine powder (1503000mesh) This vertical mill can grind nonmetallic minerals with Mohs hardness less than 6, such as limestone, calcium carbonate, marble, talc, calcite, etc construction crushing, tower sand Diatomite Ultrafine Grinding Mill SBM Ultrafine Powder

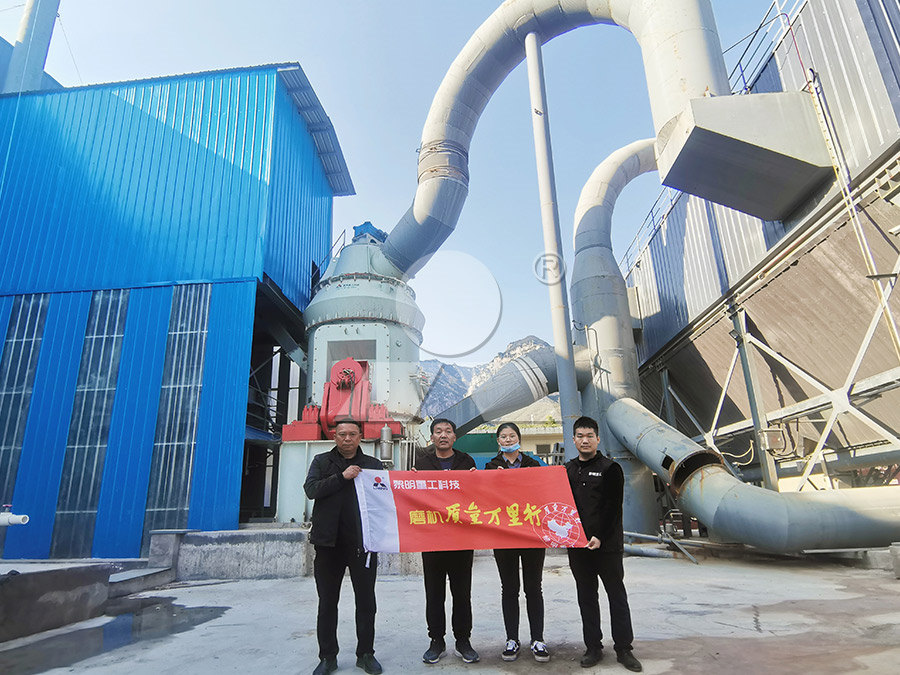

SBM Ultrafine Powder Technology Industrial

Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]Based on this and adopted with German and China Taiwan superfine vertical grinding technology, Dongguan Vsunny Machinery Co, Ltd developed the VSCM series coarse vertical grinding mill It use the highclass wearresistant parts, and the fineness of ground powder product will be from 60~500 meshesVSCM SERIES COARSE VERTICAL GRINDING MILL2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest Barite Industrial Ultrafine Grinding Mill SBM 2015年3月15日 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 2 Various different roller geometries Research of iron ore grinding in a verticalrollermill

Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]2024年11月6日 LUM ultrafine vertical mill is designed for nonmetallic mineral ultrafine grinding equipment For limestone, calcite, dolomite Mohs hardness of 6 or less nonflammable, nonexplosive brittle material grinding The wet ore slag needs to be dried firstly before grinding the ore slag powder, and then continuously and evenly sent to the main Grinding Mill ultrafine grinding mill, vertical ultrafine mill SBM has been focusing on the field of mining ore crushing and grinding machinery for many years Our grinding equipment can grind 100+ kinds of nonmetallic SBM ultrafine powder mills main include HGM series ultrafine grinding mills and CLUM series vertical roller mills which can process various ores, construction waste rock Processing Materials SBM Ultrafine Powder Technology2024年8月27日 Dry grinding using vertical roller mills (VRM) or HPGR [eg Iron Bridge] is the most energy efficient circuit However, energy requirements for air classification can offset this benefit Additionally, it has the potential to deliver ground products with narrower size distributions which in turn can result in improved flotation performance and Beyond SAG milling – The future of grinding AusIMM

Sepiolite Superfine Powder Grinding Mill SBM Ultrafine

2021年9月29日 Sepiolite superfine powder grinding mill is a highefficiency, energysaving, lowconsumption, and environmentally friendly industrial nonmetallic ore mill The equipment is independently developed and produced by SBM, and mainly includes HGM series ultrafine grinding mills and CLUM series vertical mills2017年6月2日 Pebble mills use rock pebbles as the grinding media to cause friction and attrition between the pebbles and ore material Pebble mills may be used when metal balls must be avoided Buhrstone and disk attrition mills How it Works: Crushers, Grinding Mills and 4 天之前 A wet grinding 4 x 10 center peripheral discharge rod mill used for producing fine aggregates Twelve 7 x 24 Compeb mills grinding cement clinker to a product of 1750 surface area, 90% passing a 200 mesh screen An 8 x 7 Grinding Mills 911Metallurgist2023年9月21日 Figure 3: Relationship between feed size (F80) and Bond efficiency factor (Huang et al, 2019) VERTICAL POWER MILL (VPM) – PRINCIPLE OF OPERATION Declining ore grades and more complex ore bodies, as well as waste management and global net zero initiatives, lead to a clear trend for high tonnage yet energy efficient grindingRECENT DEVELOPMENTS IN COARSE GRINDING USING

.jpg)

Understanding the SAG Mill in Copper Ore Mining Process

2023年10月10日 The Vertical Shaft Impactor Mill, also known as the VSI Mill, is a unique type of grinding mill that operates on a completely different principle compared to other types of mills This type of mill uses highspeed rotors with wearresistant tips to crush and grind materials into smaller particles2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles 2021年7月7日 Industrial grinding mills are used to grind ores, construction waste, etc Common industrial grinding mills include vertical mills, ultrafine mills Raymond mills It is an industrial grinding mill with extremely highcost performance for enterprises such as ore grinding powder The YGM Raymond mill produced by SBM is also an efficient What are the types of industrial grinding mills? sbmmill2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process How to choose a suitable ore powder grinding mill?

.jpg)

Grinding Mill Industrial Grinding Mill, Vertical Mill, Raymond Mill

Grinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low consumption, easy use +年2月28日 ③ Ore grinding: use grinding equipment to grind the ore to the required fineness Commonly used milling equipment includes ball mills, vertical mills, highpressure suspension roller mills, etc ④ Powder conveying: The powder produced by the milling equipment is transported to the finished product packaging area through the conveying equipmentBarium carbonate ore vertical mill sbmmill