HOME→Quicklime mill steel ball steel section equipment proportions Quicklime mill steel ball steel section equipment proportions Quicklime mill steel ball steel section equipment proportions

Quicklime mill steel ball steel section equipment proportions Quicklime mill steel ball steel section equipment proportions Quicklime mill steel ball steel section equipment proportions

.jpg)

Structural Characteristics of Active Quicklime Flux and

2024年10月25日 Two types of quicklimes with different activity levels are selected for comparative analysis in three aspects: microstructure, sinter quasiparticle granulation 2016年10月19日 In this study, laboratory scale ball mill and vibrated ball mill with steel balls were used to obtain micronized lime product Specific surface area and whiteness of ground Optimization of Grinding Parameters of Quicklime CaO at 2018年9月21日 Experimental research and practice show that quicklime powder is an essential additive in sintering production And high active quicklime powder can significantly improve The Influence Analysis of Quicklime Quality on Output The dissolution rate of lime in the molten slag is important for the efficient of steelmaking reactions The dissolution rates of quicklime were conventionally measured by a rotating Effect of CO 2 Content in Quicklime on Dissolution Rate of Quicklime

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy 2017年10月15日 In this study, the dissolution rate of quicklime with the accompanying gas formation is quantitatively investigated by using quicklimes with different CO2 contents produced by a rotary kiln (PDF) Effect of CO2 Content in Quicklime on 2020年5月1日 Too small a material ball ratio increases the probability of ballball collision, which not only reduces the processing capacity of the mill but also increases direct impact, ballto Enhancing the capacity of largescale ball mill through 2018年6月1日 In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size Effect of ball and feed particle size distribution on the milling

.jpg)

Effect of lifters and mill speed on particle behaviour, torque,

2017年5月1日 The changes in the torque and power of a ball mill can be effectively explained using two factors: lifter and particle area ratio Crushing and grinding consume most of the It can also be noted that quicklime is insoluble in methanol It is also insoluble in octanol and diethyl ether Applications of Quicklime Quicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industryQuicklime Preparation, Properties, and Applications with 2 天之前 Selecting the Right Steel Ball When sourcing steel balls, consider your application and the function you need the ball to perform Sports Equipment; Toys Carbon Steel Ball Material Available Low Carbon: AISI 1008~ AISI Steel Balls STR IndustriesTypically, 30 to 50 kilograms (65–110 lb) of quicklime is used per ton of steel produced In this process, quicklime effectively neutralizes acidic oxides, resulting in the formation of a basic molten slag, essential for steel productionQuicklime Supplier, Price, Specification SteelScope

}@~3SRDG`IA1KP_ICWAA.jpg)

Guidance of Ball Mill Steel Balls Miningpedia

Steel balls of different sizes in the bin have different proportionsFor example, when the ball mill is used for the first time, three kinds of ball proportions of large, medium and small are required for proportioning, and when adding ball mill steel balls for the first time, the steel balls should be added according to 80% of the maximum ball capacity given by the manufacturerMill Steel Stainless and Aluminum is a leading distributor and processor of flatrolled stainless steel and aluminum products With six strategically located facilities across the United States and a vast network of reliable processing partners, Mill Steel provides quick order turnaround backed by excellent customer serviceMill Steel Premium Stainless Steel and Aluminum SolutionsIn 2010, we invested one 1,000,000TPA Angle Steel 30 ~ 80mm, Channel steel 50 ~ 160mm, Flat steel 40 ~ 100mm production line by ourselves at Liyang city of Ji angsu province, China In 2012, we invested one 1,000,000TPA Section Steel 100 ~ 250mm production line by ourselves at Liyang city of Jiangsu province, ChinaJiangsu Fumin Xinke Heavy Machinery Co,Ltd – Rolling,mill,steel2018年12月18日 Mill ball charging systems have undergone little change during the past two decades Most operations utilize a locomotive/ball car combination to load and The grinding section at Island Copper is a semiautogenous, twostage circuit comprising six 975 m diameter by 427 m primary mills with 6000 HP drives and three 503 m diameter by 671 Ball Mill Charging System 911Metallurgist

.jpg)

Green steel: design and cost analysis of hydrogenbased

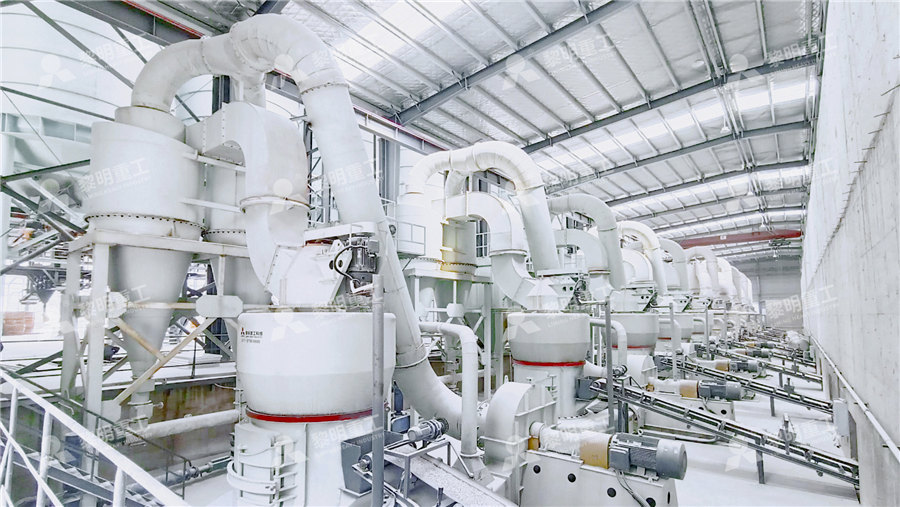

2023年3月23日 Hydrogenbased direct reduced iron (H2DRI) is an alternative pathway for lowcarbon steel production Yet, the lack of established process and business models defining “green steel” make it 2012年6月1日 is lined with mill liners protecting the steel body of the mill and incorporating mill lifters which help to raise the content of the mill to greater heights before it drops and cascades down [36](PDF) Grinding in Ball Mills: Modeling and Process Control2024年9月5日 Quicklime in Steel Manufacturing Quicklime plays a crucial role in the steel manufacturing process, offering numerous benefits that enhance efficiency and improve the quality of the final product Through its unique Uses Of Quicklime2023年10月31日 The crushed small pieces of quicklime are sent to the silo by the elevator, and then sent to the mill grinding chamber for grinding evenly and quantitatively by the vibrating feederFine powder processing can choose LM vertical mill, MTW European mill, 5X European intelligent mill; The ultrafine powder processing generally adopts LUM ultrafine quicklime processing plant, quicklime grinding machine, quicklime

.jpg)

Quicklime Preparation, Properties, Health Hazards, and

2023年7月31日 Quicklime has a wide range of applications, including in the manufacture of iron and steel, paper and pulp, water and flue gas treatment, and the mining industry In the basic oxygen steelmaking (BOS) process, quicklime plays a crucial roleMill Steel offers highquality steel, stainless steel, aluminum, and SFIA certified metal studs that meet industry standards Building Made Easy with Mill Steel Mill Steel is a true partner to the construction industry We have decades of experience in carbon steel, coil coatings, stainless steel, aluminum, and metal framing productsConstruction Mill Steel2023年7月20日 Oily cold rolling mill (CRM) sludge, a kind of solid waste produced in the rolling process, is a vicious and smelly mixture of lubricating oil, cooling water, metal particles, etc (Biswal et al, 2009; Jirasripongpun, 2002)According to statistics, about 086 t of oily sludge is generated for every 1000 t of steel produced (Li et al, 2023)The high content of organic Oily cold rolling mill sludge conditioned by quicklime to 2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLink

JoJo's Bizarre Adventure Part 7: Steel Ball Run AnimePlanet

Art Before Steel Ball Run was in Ultra Jump, it was in Weekly Shonen Jump For the most part it was following the same artstyle from Stone Ocean When the author moved to a monthly magazine, it allowed him more time to focus on the art That is where the art starts to get really good This may in fact be the Jojo series with the best art6 天之前 Judian small steel hot rolling mill production line is highly used in steel plants to produce rebar, wire, steel rod, flat steel, etc Feed section (mm2) Rolling specification (mm) H2002: 90KW: 15: 30*30: Ø1016: H2202: 95KW: 152: 40*40: Ø1024: The equipment has stable performance and has been running stably in many countries Small Steel Rolling Mill Production Line Judian2024年10月5日 Shanghai Metallurgy Equipment Group,(abbreviated as SME steel) established in 2001, focusing on providing a full set of steel plant services from iron making, steel making, CCM, steel rolling process, to various metallurgical equipments including blast furnace, EAF, induction furnace, converter, ladle funace, CCM, rolling mill etc, for global small and medium Shanghai Metallurgy Equipment Group2023年2月15日 A beneficiation plant in Singapore loads balls into a ϕ 1500mm×3000mm wet grid type ball mill, determines the filling rate ϕ = 50%, and selects cast steel grinding balls δ = 45 t/m 3 The ball mill processes the Method of Steel Grinding Ball Proportioning and

.jpg)

Lime, an essential component in the steel industry

The UNE 36001 norm includes the following classification of steel products: Irons, steels, foundry or pigiron, ferroalloys, ferrous aggregates and special ferric alloysEspecially worth highlighting is steel, a very versatile material that 2016年10月19日 In this study, laboratory scale ball mill and vibrated ball mill with steel balls were used to obtain micronized lime product Specific surface area and whiteness of ground quicklimeOptimization of Grinding Parameters of Quicklime CaO at 2021年2月11日 Use our chart to help learn more about the various steel grades, their applications, ASTM standards For Immediate Service, Call: 8006759929 Standard classification for hierarchy of equipment identifiers and boundaries for reliability, availability, and maintainability (ram) performance data exchange expansiontype ball joints Types of Steel Steel Grades Chart Service Steel2018年8月31日 a steel mill before making a decision to switch from low quality lime to high CaO lime The results summarized in T able 5 clearly reflect that high CaO lime improves the sulphide capacity and (PDF) Management of Lime in Steel ResearchGate

.jpg)

THEORETICAL CALCULATION OF MILL STEEL BALL SIZE

From the principle of crushing machanics, a theoretical formula for calculating ballsizes for ball mills has been derived Empirical parameters are obtained from experimentaland practical data, and a semitheoretical formula for calculating precise ball diametersis established2013年9月4日 The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln such as temperature, particle size of the limestone, rate of temperature rise, retention time, and CO2 concentration Factors Affecting The Quality of QuicklimeIt is inexpensive and abundant Also, quicklime is caustic and alkaline at standard conditions Quicklime and its derivatives like calcium hydroxide or slaked lime are very important chemical commodities How to Prepare Quicklime? Quicklime can be easily prepared from the decomposition of limestones or sea shells that are readily availableQuicklime Properties, Uses and Application VedantuFind your ball mill easily amongst the 83 products from the leading brands (Fritsch GmbH, Retsch, NETZSCH, ) on DirectIndustry, the industry specialist for your professional purchases and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which Ball mill, Ball grinding mill All industrial manufacturers

Steel Mill Machinery: The Basic Equipment and Roles in Steel

4 天之前 Steel mill machinery is one of the most important equipment in steel production These machines are used in many different stages of steel production, from processing raw materials to shaping steel sheets, plates, and bars Blast furnaces are one of the largest pieces of equipment in a steel plant and are equipped with modern technology to It can also be noted that quicklime is insoluble in methanol It is also insoluble in octanol and diethyl ether Applications of Quicklime Quicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industryQuicklime Preparation, Properties, and Applications with 2 天之前 Selecting the Right Steel Ball When sourcing steel balls, consider your application and the function you need the ball to perform Sports Equipment; Toys Carbon Steel Ball Material Available Low Carbon: AISI 1008~ AISI Steel Balls STR IndustriesTypically, 30 to 50 kilograms (65–110 lb) of quicklime is used per ton of steel produced In this process, quicklime effectively neutralizes acidic oxides, resulting in the formation of a basic molten slag, essential for steel productionQuicklime Supplier, Price, Specification SteelScope

Guidance of Ball Mill Steel Balls Miningpedia

Steel balls of different sizes in the bin have different proportionsFor example, when the ball mill is used for the first time, three kinds of ball proportions of large, medium and small are required for proportioning, and when adding ball mill steel balls for the first time, the steel balls should be added according to 80% of the maximum ball capacity given by the manufacturerMill Steel Stainless and Aluminum is a leading distributor and processor of flatrolled stainless steel and aluminum products With six strategically located facilities across the United States and a vast network of reliable processing partners, Mill Steel provides quick order turnaround backed by excellent customer serviceMill Steel Premium Stainless Steel and Aluminum SolutionsIn 2010, we invested one 1,000,000TPA Angle Steel 30 ~ 80mm, Channel steel 50 ~ 160mm, Flat steel 40 ~ 100mm production line by ourselves at Liyang city of Ji angsu province, China In 2012, we invested one 1,000,000TPA Section Steel 100 ~ 250mm production line by ourselves at Liyang city of Jiangsu province, ChinaJiangsu Fumin Xinke Heavy Machinery Co,Ltd – Rolling,mill,steel2018年12月18日 Mill ball charging systems have undergone little change during the past two decades Most operations utilize a locomotive/ball car combination to load and The grinding section at Island Copper is a semiautogenous, twostage circuit comprising six 975 m diameter by 427 m primary mills with 6000 HP drives and three 503 m diameter by 671 Ball Mill Charging System 911Metallurgist

Green steel: design and cost analysis of hydrogenbased

2023年3月23日 Hydrogenbased direct reduced iron (H2DRI) is an alternative pathway for lowcarbon steel production Yet, the lack of established process and business models defining “green steel” make it