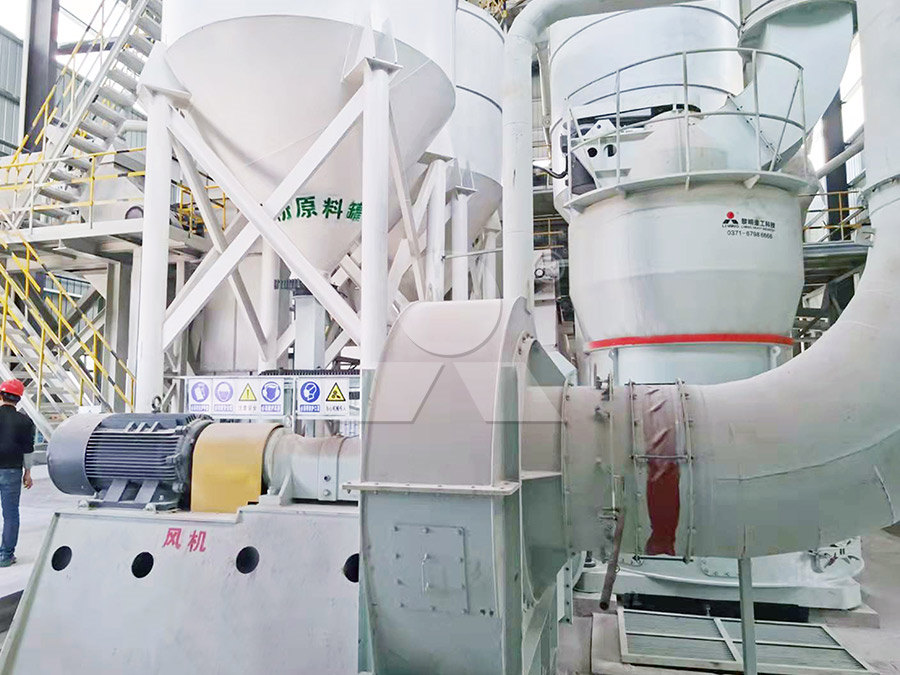

XP600 ore grinding mill matching motor

.jpg)

Choosing the Right Motors for your Mills

Overview of Mill Selection •Grinding testwork to characterise the project's oretypes •Characterise hardness variability or load grinding results into block model •Select mill sizes to achieve a Our GMD eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings: By mounting the rotor poles directly onto the mill, the mill itself Gearless mill drives Grinding ABB ABB Group2024年3月17日 Whether a mill is single or dual pinion, high or lowspeed, ABB offers the right solution Motors are fed by frequency converters that allow speed variation and soft control Ringgeared mill drives RMDplus ABBWEG offers the most reliable and efficient solutions for milling plants for ferrous and nonferrous products with their experience of mill drive systems In the heart of a processing plant, the ball and SAG mills must be driven by solutions that Mining Grinding and Processing WEG

.jpg)

The engineering and process effects of choosing a

Purchasing a fixedspeed or variablespeed mill drive requires the specification of several important engineering values: the motor rated output power, motor rated speed and the motor 2024年3月15日 All three mills are gear driven by a ring gear, dual pinion and two low speed synchronous motors Copper Mountain has installed on all three mills, the new stateofthe art Paper # 25 Copper Mountain Overview on the Grinding Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, roundtheclock reliability and the opportunity to mine in remote areas This makes low ore grades economical to Making remote mines and low ore grades Siemens performs electrical and mechanical design of Ring motors in their Dynamowerk factory in Berlin Ring Motor drive a grinding mill without contact between rotating and fixed parts This Design and dynamic behavior of large Ring Motors for

Products Solutions for the Mining Industry GE Vernova

2022年1月14日 GE provides flexible and innovative mill solutions across all types of grinding, from single and dual pinion AG, SAG and ball to hPGr This helps you to meet highcapacity 2021年7月7日 Industrial grinding mills are used to grind ores, construction waste, etc Common industrial grinding mills include vertical mills, ultrafine mills Raymond mills +17 [ protected]What are the types of industrial grinding mills?2014年4月1日 One critical issue in twinmotor drive systems is that the two motors must rotate coordinately [3] In twin motor drive systems, the slipring Induction motors are often preferred to synchronous (PDF) Evaluation of synchronous motors on 2023年10月10日 The rods grind the ore by tumbling within the mill, similar to the action of a rotating drum Rod mills can be operated at lower speeds than other types of mills, making them ideal for fine and coarse grinding applications Understanding the SAG Mill in Copper Ore

.jpg)

Breaking down energy consumption in industrial grinding mills

2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed behavior of large Ring Motors for grinding mills 3 1 Introduction The mining industry uses grinding mills to comminute tonnage Large grinding mills are driven by Gearless Drives, with the Ring Motor as its main component The Ring Motor is wrapped around the mill and its rotor poles installed at an extension of the mill headDesign and dynamic behavior of large Ring Motors for 2023年7月20日 According to the ore discharging method, the grinding mill is divided into overflow type, grating type, and peripheral discharging type According to the different grinding medium, the grinding mill is divided into three types: (1) ball mill – it is used widely, and almost all materials can be triturated by ball mill; (2) rod mill – its Ore Grinding SpringerLink2016年6月3日 This device offers a significant power savings on wet fine grinding applications when compared to conventional tumbling mills This paper describes the laboratory application of this mill wet grinding hydrated alumina to products of 50 percent passing 2 to 6 microns The basic grinding action in the Tower Mill is abrasionTower Mill Operating Work Index 911Metallurgist

How to Control a SAG Grinding Mill Circuit 911Metallurgist

2017年8月5日 The installed power in the primary mill is generally much greater than in conventional circuits Since the semiautogenous or autogenous mill is dependent at least in part, if not entirely, on the ore to grind itself, a small change in ore grinding characteristics can produce a relatively large change in the grinding capacity of the millCoarse powder grinding mill is engaging in crushing various rocks and stones into coarse powder and small particles, such as calcite, etc The main unit drives the main shaft through the motor and triangle belts, which, in turn, rotates the rollers CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultra Coarse Powder Grinding Mill SBM Ultrafine Powder China Grinding Mills wholesale Select 2024 high quality Grinding Mills products in best price from certified Chinese Mill Equipment manufacturers, Grinding Machine suppliers, wholesalers and factory on MadeinChinaChina Grinding Mills, Grinding Mills Wholesale, 2024年7月19日 The cylinder is mounted on bearings and rotates around its axis, either by an external motor or gears The cylinder features openings at both ends – an inlet for feeding materials and an outlet for discharging the ground material Grinding Mill equipment, such as MechProTech’s TITAN Grinding Mills and TITAN Automatic Ball Charger, can Grinding Mills in the Mineral Processing Industry

.jpg)

What Ore Testing is Required For Mill Selection

2015年4月15日 Bond rod mill grindability tests at 10 or 14 mesh for Work Index For each ball mill grinding step, a Bond ball mill grindability test for Work Index at one mesh size coarser than the desired 80% passing size and at the mesh 2024年4月26日 Grinding Mills: Grinding mills, such as ball mills and rod mills, are commonly used for grinding iron ore These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into smaller particles The choice of grinding mill depends on factors such as the desired product size, capacity requirements Iron Ore Processing: From Extraction to Manufacturing2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and (PDF) EnergyEfficient Advanced Ultrafine Grinding of Provides highest availability for your grinding mill ; Robustness of system allows for operation under the most extreme environmental conditions (high altitudes, varied climates, remote locations) Operator can react to changes in ore characteristics due to variablespeed; Process optimization leads to a more efficient use of grinding powerGearless mill drives Grinding ABB

Vertical Roller Mill SBM Ultrafine Powder Technology

The grinding wheel is driven by a motor through a reducer The material is fed into the main machine of the vertical roller mill through the feed screw and falls into the center of the grinding disc Totally closed negative pressure operation has been employed by this vertical grinding mill, so there is little dust during the operation High pressure grinding mill, also known as high pressure roller mill, can grind nonflammable and explosive materials with Mohs hardness not greater than 93 and humidity below 6%Its main components include main engine, reducer, analyzer, pipeline device, blower, dust collector, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric control system, etcYGM High Pressure Grinding Milla “SAG Mill limiting” condition, ie, harder ore, or a “Ball Mill limiting” condition, ie, softer ore exists For example, a ratio of 1:15 or up to 1:2 would indicate a trend away from processing harder ore types and an increasing bias toward processing softer ore types, whereas a ratio of 1:1 or higher would indicate a biasMill drives: the desire for increased power and the2023年4月23日 grinding media in a grinding mill with about 2630 wt% chrome by Chen et al [37] using a phosphate ore in a modified ball laboratory ball mill whose electrochemical potential could be controlled(PDF) Grinding Media in Ball MillsA Review ResearchGate

Effect of Water Density on Grinding Mill 911Metallurgist

2015年7月29日 The more water that is added, the faster the ore will go through the mill This means the time it has to be ground will be reduced and a poor grind will result At the other extreme, if not enough water is used, the ore will not be able to flow through the mill The result is the ore will not be able to move into the rod load Because there isn 2020年6月3日 The design of such grinding mills is extremely critical, requiring sophisticated software tools, proprietary calculation worksheets, and experienced technical engineers and drafters This blog will review how the mill design How grinding mill design changed over the last 2022年1月1日 The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill (eg power consumption and particle size breakage)Effect of grinding media on the milling efficiency of a ball mill2017年4月10日 The breakage rate function shape of the SAG mill is largely governed by the mill load particle size distribution and mill speed The feed in the mill contains fractions of ore that serves as the grinding media Larger ore fractions break the smaller particles but also breakdown themselves and exit the mill as a productSTEPPING FORWARD: USING VARIABLE SPEED DRIVES

Limestone Grinding Mill That You Need To Know Mortar

2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller 2024年9月24日 Mill size 7315 M [24 feet] diameter by 12039 M [395 feet] long Mill type Wet grinding, overflow discharge Mill drive motor size 17,000 HP Mill drive motor type Synchronous 200 RPM Inside diameter 7,315 mm Length 11,430 mm Effective grinding length (EGL) 11,886 mm Bearing type Partial Journal, 120 degree bronze insertPaper # 25 Copper Mountain Overview on the Grinding 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of 2021年10月26日 Graphite Production Line Equipment Intro – Crushing Grinding Link The equipment configuration of the complete graphite powder production line is complicated, and the equipment selection can be planned and adjusted according to the actual production needs of customers, and the production line has a high degree of automationGraphite Grinding Machine Powder Mill Equipment

.jpg)

Grinding Mill Design Ball Mill Manufacturer

2017年2月20日 Grinding Mill Specifications Data According to formula 423/√d, where d is equal to internal shell diameter within new liners In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger millsDrive System: The drive system comprises the motor, gearbox, and clutch assembly, which provide rotational power to the mill Mining and Ore Processing: Ball mills are used for grinding ores and minerals, enabling the extraction of valuable metals They are widely employed in both wet and dry grinding processes for the comminution of Ball Mill Grinding Machines: Working Principle, Types, Parts 2021年7月7日 Industrial grinding mills are used to grind ores, construction waste, etc Common industrial grinding mills include vertical mills, ultrafine mills Raymond mills +17 [ protected]What are the types of industrial grinding mills?2014年4月1日 One critical issue in twinmotor drive systems is that the two motors must rotate coordinately [3] In twin motor drive systems, the slipring Induction motors are often preferred to synchronous (PDF) Evaluation of synchronous motors on

Understanding the SAG Mill in Copper Ore

2023年10月10日 The rods grind the ore by tumbling within the mill, similar to the action of a rotating drum Rod mills can be operated at lower speeds than other types of mills, making them ideal for fine and coarse grinding applications 2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Breaking down energy consumption in industrial grinding millsbehavior of large Ring Motors for grinding mills 3 1 Introduction The mining industry uses grinding mills to comminute tonnage Large grinding mills are driven by Gearless Drives, with the Ring Motor as its main component The Ring Motor is wrapped around the mill and its rotor poles installed at an extension of the mill headDesign and dynamic behavior of large Ring Motors for 2023年7月20日 According to the ore discharging method, the grinding mill is divided into overflow type, grating type, and peripheral discharging type According to the different grinding medium, the grinding mill is divided into three types: (1) ball mill – it is used widely, and almost all materials can be triturated by ball mill; (2) rod mill – its Ore Grinding SpringerLink

.jpg)

Tower Mill Operating Work Index 911Metallurgist

2016年6月3日 This device offers a significant power savings on wet fine grinding applications when compared to conventional tumbling mills This paper describes the laboratory application of this mill wet grinding hydrated alumina to products of 50 percent passing 2 to 6 microns The basic grinding action in the Tower Mill is abrasion2017年8月5日 The installed power in the primary mill is generally much greater than in conventional circuits Since the semiautogenous or autogenous mill is dependent at least in part, if not entirely, on the ore to grind itself, a small change in ore grinding characteristics can produce a relatively large change in the grinding capacity of the millHow to Control a SAG Grinding Mill Circuit 911MetallurgistCoarse powder grinding mill is engaging in crushing various rocks and stones into coarse powder and small particles, such as calcite, etc The main unit drives the main shaft through the motor and triangle belts, which, in turn, rotates the rollers CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultra Coarse Powder Grinding Mill SBM Ultrafine Powder China Grinding Mills wholesale Select 2024 high quality Grinding Mills products in best price from certified Chinese Mill Equipment manufacturers, Grinding Machine suppliers, wholesalers and factory on MadeinChinaChina Grinding Mills, Grinding Mills Wholesale,