Quartz stone crushing and classification

.jpg)

Resource, characteristic, purification and application of

2022年6月15日 In this review, by introducing the resources and application distribution of high purity quartz, and comparing with the import and export in the world, it is concluded that quartz has a good future for development; by introducing the types of quartz ores and the 2015年9月10日 Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous 11192 Crushed Stone Processing and Pulverized 2023年11月30日 Highpurity quartz products are categorized into four grades based on SiO 2 purity: ultrahigh purity (ω (SiO 2) ≥ 99998% or 4N8), highpurity (ω (SiO 2) ≥ 99995% or 4N5), mediumpurity (ω (SiO 2) ≥ 9999% or 4N), Research Status and Challenges of HighPurity 2024年11月15日 Higher gradations cause more crushing, lower more grinding, while quartzlimestone ratio affects degradation Microcrack evolution varies with gradation, impacting Effects of particle gradation and material proportions on the

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Based on the mechanism and the type of forces applied crushers are basically classified into three types namely Jaw crusher, Cone crusher and Impact crushers However, 2022年6月15日 In this review, by introducing the resources and application distribution of high purity quartz, and comparing with the import and export in the world, it is concluded that quartz Resource, characteristic, purification and application of quartz2020年6月22日 The content and distribution of impurities in quartz significantly affect the processing methods This paper provides an insightful review on the processing of highpurity A Critical Review on the Mineralogy and Processing for HighGrade QuartzQuartz (trigonal, lowtemperature αquartz) is the most important polymorph of the silica (SiO 2) group and one of the purest minerals in the Earth crust The mineralogy and mineral chemistry of quartz are determined mainly by its Mineralogy and mineral chemistry of quartz: A

Mineralogy and mineral chemistry of quartz: A review

2021年9月28日 The mineralogy and mineral chemistry of quartz are determined mainly by its defect structure Certain point defects, dislocations and microinclusions can be incorporated 2021年5月14日 114 Crushing and classification include Jaw and Cone Crushers Secondary crushing can be by rotating surfaces such as swing hammer mills, for brittle materials, and roll 11 Crushing and classification particlesuk2023年4月13日 The quartz stone after medium crushing becomes a small stone of less than 5cm, and then it is finely crushed by the sandmaking machine to make sand After making sand, it becomes quartz sand of different Selection Of Quartz Stone Crushing And 2021年9月27日 Quartz artefacts are common components of flaked stone assemblages worldwide However, flaked quartz can appear similar to quartz fractured by natural and other (nonflaking) cultural processesRevisiting the “Quartz Problem” in Lithic Studies: A Review

Identifying quartz artefacts in archaeology and

The results have shown that the identification and classification of vein quartz artefacts is particularly challenging, even for analysts with substantial experience in quartz artefact analysis Experimental studies indicate that the presence 1 Appearance and Colour Stone must be of good appearance and uniform in colour; Stones light in colour resist weathering action better; 2 Crushing Strength The crushing strength of stone should be greater than 100 N/mm2; Rock preference on the basis of Crushing strength: Igneous rocks > Metamorphic rocks > Sedimentary rocksBuilding Stone Properties Classification Durability and Artificial Silica quartz stone crushing and screening process The raw silica quartz stone enters the jaw crusher for primary crushing The material from the jaw crusher enters the circular vibrating screen by a belt conveyor for screening The classification tower separates overflow material, silica sand under 01mm, silica sand 0106mm, over 06mm Silica Sand Processing Plant JXSCTeam2019年4月29日 The cone crusher is used as a fine stone crushing machine for use in secondary or tertiary crushing processes Mainly used in metal and nonmetal mines, cement plants, sand and stone metallurgy and other industries Which crushers can be used for the crushing of quartz stone; classification of jaw crusher; Buying recommendations for the stone crushers classification and buying skills News of Joyal

SILICA DUST, CRYSTALLINE, IN THE FORM OF QUARTZ OR CRISTOBALITE

The classification and nomenclature of silica forms are summarized in Table 11 For more detailed information, refer to the previous IARC Monograph Table 11 (2008) described the personal exposure to respirable dust and respirable quartz in stonecrushing units located in western Islamic Republic of Iran A total of 40 personal samples 2024年11月21日 Physical properties of quartz sand Quartz sand is quartz particles made by crushing and processing quartz stone Quartz is a nonmetallic mineral, a hard, wearresistant and chemically stable silicate mineral Its main mineral component is SiO2, with a melting point of 1713°C The luster is glasslike, and the fracture is shelllike or staggered The []Quartz Sand Purification Treatment And Technology2022年6月15日 Silicon (Si) is the second most chemical element in the earth’s crust Quartz is the most common form of silica, accounting for 126% of the earth’s crust volume (Götze, 2009)And, quartz is mainly composed of silicon dioxide (SiO 2), which is widely used in both traditional basic industries and hightech fields due to its stable physical and chemical Resource, characteristic, purification and application of quartz5 天之前 Quartz sand is a quartz particle produced by crushing quartz stone Quartz stone is a nonmetallic, hard, wearresistant, and chemically stable silicate mineral The color of quartz sand is milky white, or colorless and translucent, with a Mohs hardness of 7 and then further purifying the quartz sand through classification operations Quartz Sand VS Silica Sand JXSC Machinery

Quartz Crushing Solution Eastman Rock Crusher

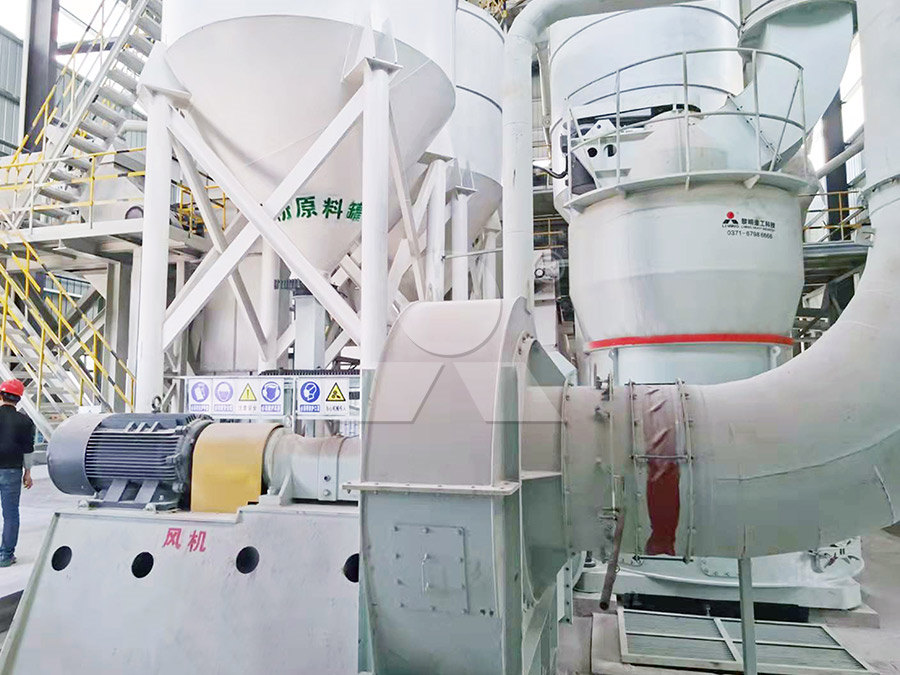

The flow of the quartz stone crushing line is: (silo) → vibrating feeder → (jaw crusher) → cone crusher → vibrating screen → finished crushed stone (using several layers of vibrating screens, you can get several size of the finished Now let me briefly introduce these quartz crushing machines to you Jawtype Quartz Crusher – Coarse Crushing Jawtype quartz crusher is the most powerful crusher that many people choose as it can process a maximum feed particle size of 1020mm It is suitable for materials with all kinds of hardness, so we can use it to crush quartz stoneQuartz Crusher Producing Highquality Quartz Sand2019年11月11日 Crushed stone: The term “crushed stone” usually refers to stone that has a mixture of stone dust in it This type of stone is best used for a base when heavy compaction is needed As a result, it is typically used for the The Complete Guide to Crushed Stone and 2024年10月18日 Technical parameters Firstly, Quartz fall under the hopper,quartz stone is broken into the coarse material after primary crushing, and be transported by belt conveyor for further crushing to the second crushing machine, then the smaller stone will be taken into the vibrating screen for screening out two type size quartz stones, exceed size stone will be Process flow of Quartz sand Production Line

Source and Classification of Stones

1 For a good building stone how much is the required crushing strength? a) Less than 50 N/mm2 b) Greater than 100 N/mm2 c) 155 N/mm2 d) 10 N/mm2 View Answer Answer: b Explanation: Crushing strength or compressive strength of a stone is 2020年11月8日 Jaw Mobile Crushing Station 31 Application: Sand quarry, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc 32 Primary Jaw Plants/ Jaw Mobile Crushing Station 32Crusher; Crushing; and Classification Equipment PPTBased on manufacturing process, the market is categorized as quartz stone crushing, quartz stone grinding, classification, and others The quartz stone crushing segment is projected to dominate the market during the forecast period, due to its fundamental role in the initial processing of quartz stone to produce quartz sand of various sizes and Quartz Sand Market Size, Share Trends Growth [2032]2024年1月25日 engineered quartz stone products sourced/imported by Arizona Tile, LLC) Engineered Stone, Quartz Arizona Tile, LLC Corporate Office 8829 S Priest Dr Tempe, AZ 85284 (480)8939393 VP of Operations Rick Collins (480) 797 4739 Building Material – Engineered Stone products sourced/imported by Arizona Tile, LLC areSAFETY DATA SHEET Engineered Stone Quartz

.jpg)

Which Crusher Is Suitable for Your Hard Rock? Fote

2023年2月15日 Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock f = 1520: Extremely strong rocks, such as very strong granite, This process only uses a heavy hammer crusher, because it has a good effect of onetime crushing and shaping of quartz stone Crushing process three2023年4月11日 Method 1: Gravity separation Due to the difference in density between quartz ore particles and gangue mineral particles, gravity separation equipment such as spiral chutes, and shaking tables are commonly used to separate quartz ore particles Gravity separation has a certain effect of removing impurities, but it is difficult to meet the production requirements, so it High Purity Quartz Sand: What Is It Used for and How to Get Sandstone is a type of sedimentary rock which is mainly consisting of sand or quartz grains accumulated together where quartz grains are a resisting component to weathering process Scientific Classification of Stones Classification of Building Stones with Uses, 2022年2月22日 Quartz sand is the mainly production of quartz application It is crushed by crushing plant from quartz, tridymite, cristobalite The complete quartz crushing and screening plant ensure high process efficiency, combining fieldwork with our engineering expertise results in a specific system that delivers the desired end products in a profitable wayQuartz Ore Ore Crushing Solutions DSMAC dscrusher

.jpg)

Research Status and Challenges of HighPurity

2023年11月30日 Quartz deposits are widely dispersed in nature, but the presence of ore bodies capable of yielding highpurity quartz is exceedingly rare As a result, the effective purification and processing of highpurity quartz from 2022年5月14日 It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing Right from hard stones to delicate minerals, stone can incorporate slag, limestone, quartz, rock, iron metal, sandstone, copper metal, marble, concrete and that is just the beginningStone Crushers: A Technical Review on Significant Part ofDespite its worldwide use as a stone tool raw material, quartz is known to be a difficult material for archaeologists Archaeological Congress (WAC) conference held in Dublin, Ireland The results have shown that the identification and classification of vein quartz artefacts is particularly challenging, even for analysts with substantial Revisiting the 'quartz problem' in lithic studies: a review and Crushing, grinding and classification Future Materials has crushing, grinding and classification equipment for various particle sizes ranging from cm to µm at its disposal After the crushing and grinding process is complete the sample could go through equipment to split the material into the desired particle sizes and fractionsCrushing, grinding and classification Future Materials

Identifying quartz artefacts in archaeology and cultural

2020年1月10日 Quartz has long been a popular material in many parts of the world for making stone tools However, the properties and fracture mechanics of quartz complicate the identification and classification Crushing Process Transportation of raw materials: Use a dump truck or excavator to dump the raw materials onto the vibrating feeder, and then the feeder will slowly transport the quartz stone into the jaw crusher for primary crushing Primary crushing: In the primary crushing stage, use a jaw crusher to crush the raw quartz stone into sizes within 100mm, so that these raw materials Quartz Sand Applications and How to Make Quartz Sand2019年9月3日 The present study evaluates the effects of two different aggregate production (crushing) mechanism, ie JawHorizontal Shaft Crusher (HSI) named as JH and JawJawHSIVertical Shaft Impact Crusher (VSI) known as JJHV on aggregate dimension distribution Both crushing mechanisms represents wide range of crushers and stage of crushing (ie JH and Quantify effects of stage crushing on dimensional 2018年1月2日 Quartz Stone Group Joint Stock Company is a company specializing in consulting and providing high quality quartzbased artificial stone products for domestic and foreign projects We want to create eternal values, masterpieces that make the luxury and class for all projects with quartz stone highclass quartzbased artificial stone Home page Quartz Stone

Selection Of Quartz Stone Crushing And

2023年4月13日 The quartz stone after medium crushing becomes a small stone of less than 5cm, and then it is finely crushed by the sandmaking machine to make sand After making sand, it becomes quartz sand of different 2021年9月27日 Quartz artefacts are common components of flaked stone assemblages worldwide However, flaked quartz can appear similar to quartz fractured by natural and other (nonflaking) cultural processesRevisiting the “Quartz Problem” in Lithic Studies: A Review The results have shown that the identification and classification of vein quartz artefacts is particularly challenging, even for analysts with substantial experience in quartz artefact analysis Experimental studies indicate that the presence Identifying quartz artefacts in archaeology and 1 Appearance and Colour Stone must be of good appearance and uniform in colour; Stones light in colour resist weathering action better; 2 Crushing Strength The crushing strength of stone should be greater than 100 N/mm2; Rock preference on the basis of Crushing strength: Igneous rocks > Metamorphic rocks > Sedimentary rocksBuilding Stone Properties Classification Durability and Artificial

Silica Sand Processing Plant JXSCTeam

Silica quartz stone crushing and screening process The raw silica quartz stone enters the jaw crusher for primary crushing The material from the jaw crusher enters the circular vibrating screen by a belt conveyor for screening The classification tower separates overflow material, silica sand under 01mm, silica sand 0106mm, over 06mm 2019年4月29日 The cone crusher is used as a fine stone crushing machine for use in secondary or tertiary crushing processes Mainly used in metal and nonmetal mines, cement plants, sand and stone metallurgy and other industries Which crushers can be used for the crushing of quartz stone; classification of jaw crusher; Buying recommendations for the stone crushers classification and buying skills News of Joyal The classification and nomenclature of silica forms are summarized in Table 11 For more detailed information, refer to the previous IARC Monograph Table 11 (2008) described the personal exposure to respirable dust and respirable quartz in stonecrushing units located in western Islamic Republic of Iran A total of 40 personal samples SILICA DUST, CRYSTALLINE, IN THE FORM OF QUARTZ OR CRISTOBALITE2024年11月21日 Physical properties of quartz sand Quartz sand is quartz particles made by crushing and processing quartz stone Quartz is a nonmetallic mineral, a hard, wearresistant and chemically stable silicate mineral Its main mineral component is SiO2, with a melting point of 1713°C The luster is glasslike, and the fracture is shelllike or staggered The []Quartz Sand Purification Treatment And Technology

.jpg)

Resource, characteristic, purification and application of quartz

2022年6月15日 Silicon (Si) is the second most chemical element in the earth’s crust Quartz is the most common form of silica, accounting for 126% of the earth’s crust volume (Götze, 2009)And, quartz is mainly composed of silicon dioxide (SiO 2), which is widely used in both traditional basic industries and hightech fields due to its stable physical and chemical 5 天之前 Quartz sand is a quartz particle produced by crushing quartz stone Quartz stone is a nonmetallic, hard, wearresistant, and chemically stable silicate mineral The color of quartz sand is milky white, or colorless and translucent, with a Mohs hardness of 7 and then further purifying the quartz sand through classification operations Quartz Sand VS Silica Sand JXSC Machinery