Grinding production line drive shaft

Crank line grindersJTEKT(China)CO, LTD

2024年4月12日 Flexible and highly precise crankshafts grinder driven by linear motor Features the TOYODA STAT BEARING Abundant functions achieving high accuracy grinding The 2021年9月3日 Transmission shafts Line production Grinding machines for Transmission shafts The specialist in cylindrical grinding GST has developed a wide range of highly productive The specialist in cylindrical grinding Transmission shaftsGMB provides only the most crucial component to the module, the universal joint, rather than the entire module, which consists of drive shafts or propeller shafts This approach allows us to be flexible in adapting to various shaft sizes and DRIVE LINE COMPONENTS PRODUCTS GMB Drive Shafts Drive shafts are used in various fields such as steel rolling, construction, railway and paper manufacturing High rigidity, high transmission and long life by our original technology contribute to energy saving and JTEKT MACHINE SYSTEMS CORPORATION

Increasing availability through advanced Gearless Drive

In this paper, we focus on the ore grinding and conveying applications, for which the gearless principle was expanded even further so that the motor and the mill respectively conveyor and 2024年3月15日 for grinding solutions We help you meet these challenges with our drive systems, which have a long track record in improving the performance and extending the Products and solutions Drive systems for all grinding2024年4月12日 Optimum cylindrical grinder for production with high accuracy and high productivity High rigidity and low vibration bed Features the TOYODA STAT BEARINGCylindrical grindersJTEKT(China)CO, LTD2017年1月1日 Today grinding spans from very crude and rough applications in cutting of materials at high materialremoval rates (MRR) to finishing and ultraprecision processes The Recent developments in grinding machines ScienceDirect

Gearless mill drives Grinding ABB

Our GMD eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings: By mounting the rotor poles directly onto the mill, the mill itself 2011年2月7日 It needs two jackshafts for the grinder head and work head, both are engaged via a belt sliding from an undersized pulley to a 5" pulley The work head jack shaft requires 450 RPM, so would need a 5 5/8" pulley on the main, and the grinder head jack shaft requires 850 RPM, so would need a 10 5/8" pulley on the main"The Machine Shed" Building a Line Drive Shop from Scratch2021年8月10日 Germany — The increasing quantities of emotors are challenging production planners: In many application areas, they have to establish new solutions with which components, such as the emotor drive shaft, can be manufactured faster and more efficiently — and with holistic production systems A new example Emag realised for a supplier company producing New production line for rotor shafts brings efficiency to e 2023年2月27日 That’s the sound of metal on metal and is the precursor to grinding Clicking or grinding sounds As well as clicking while turning or accelerating, you may notice the following noises: knocking; Spoiled or torn Is your driveshaft failing? Here are the signs and

.jpg)

The specialist in cylindrical grinding Transmission shafts

2021年9月3日 Output shafts Double Cycle Complete C/CBN Doublespindle external cylindrical grinder for shaft production (Double Cycle Complete C/CBN) Complete machining of the shaft in 1 single clamping setup Doublespindle external cylindrical grinder with 2 work stations (2 slides on the Zaxis) for the grinding of: Diameters, plane surfaces and FRANLI has several sets of wet grinding production lines, including PCB ink production line, ink production line, pesticide production line, automobile coating production line, etc Twin Shaft Disperser; High Speed Disperser; Basket mill; High Shear Mixer; Kneader; Filling Machine; Chemical Reactor; Drop us an Production Line Franli Machine2003年10月1日 Higher speeds increased the effectiveness of using large leather belts to drive horizontal line shafts According to period sales literature from JB Hoyt Co (New York), “a leather belt will safely and continuously resist a strain of 350 pounds per square inch and a section of 04 of a square inch over a turned castiron pulley will Line Shafts and Belts ASSEMBLYAGICO is a leading cement industry equipment supplier based in China It can not only supply all kinds of slag powder grinding equipment including ball mill, vertical roller mill, and roller press, but also provide you with a complete turnkey solution for ground granulated blastfurnace slag (GGBS) productionThrough cooperation with Luoyang Design Institue, Tianjin Design GGBS Production Line Slag Mill for Slag Powder Grinding

INSERT LINE UNITED GRINDING

2019年2月14日 with direct drive clamping system The 4axis highspeed peripheral grinding machine can thus achieve extremely high grinding speeds Large grinding wheel diameters increase chip removal rates and achieve maximum surface qualities on indexable inserts Over all, the grinding time is reduced by up to 50 per cent INSERT LINE Grinding Software2023年10月5日 Dimensional Inspection: Drive shafts are subjected to dimensional inspection to verify that they meet the specified length, diameter, and other geometric requirements Conclusion The drive shaft manufacturing process involves several intricate steps and specialized technologies that influence the performance and reliability of the final productDrive Shaft Manufacturing Process: From Materials to Proven CBN grinding technology with cutting speeds of up to 140 m/s and high feed rates, resulting in short cycle times JUNKER 3point mounting interface for fast changeover and excellent grinding wheel concentricity HF highpower grinding spindle (42 kW drive capacity) is extremely lowmaintenance thanks to lifetime lubrication and air sealGrinding machines: Lean Selection shaft junkergroup2019年12月2日 OP 80 and 90 consist of gearcutting the shaft and finishturning various shoulders on the outside The finishing with close tolerances and high demands on surface quality is provided by the final grinding process on a Production System for Lightweight Rotor Shafts

.jpg)

Half shafts Manufacturer, Spline shaft, Through Shaft

Jinan Qiangyu Automobile Parts Co,LTD,founded in 2007,He is a modern manufacturer specializing in the production of through shaft,input shaft,spindle,drive shaft and assembly,the products involve heavy trucks,construction machinery,agricultural machinery,light trucks,ships and etc Existing staff 103 people,annual output value of more than 50 million yuan,the company 2016年1月21日 A driveshaft is a cylindrical shaft that transmits torque from the engine to the wheels They are most commonly found on rearwheel drive vehicles and connect the rear of the transmission to the driveshaft As the Symptoms of a Bad or Failing Driveshaft2021年6月18日 A new production line for the rotor shaft of electric cars used by a German components supplier illustrates their approach The solution was delivered at the end of last year Here we have a conversation with Andreas Bucher, Key Account Manager at EMAG, and Michael Ihring from EMAG Systems about the reasons for this cooperationRotor Shafts Production Solutions for Electromobility2024年5月18日 300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system; 3000 t/d Cement Production Line Xinxiang Great Wall Machinery provides Cement Production Line

Design and Analysis of Drive Shaft with a Critical Review of

2020年6月19日 A review paper seeks to examine the numerous forms of shaft failure, shaft reliability and traditional material substitution for certain advanced lightweight alloys and composite materialsThe precision shaft, turned components and centreless grinding specialist Single Source for Bar to Shaft Production At Wharf Engineering we use the latest machine tool technology to enable us to produce precision engineering components for a large range of industrial sectors from electric motor and pump manufacturers to industrial power in batch sizes ranging from 30,000 to The precision shaft and centreless grinding specialist2024年10月28日 The Vortair powder processing system is designed and engineered specifically for the Vortair 500 autogenous grinder to maximise throughput, easy collection of milled powder material in a continuous automated production line The ancillary equipment features an automated feed hopper; conveyor , water chillerProducts Vortair Autogenous Grinding Technologies2019年3月26日 Superproductive and perfect for batch production Key data The ShaftGrind L as a singleslide or twoslide machine allows you to machine shafttype components with a length of up to 1,100 mm or 650 mm This superproductive grinding machine offers brand new design options for cylindrical grinding in mid to high volume production YouA member of the UNITED GRINDING Group ShaftGrind L

.jpg)

Understanding the Shaft Manufacturing Process

2021年1月6日 Face grooves: We build shafts with face grooves depths of varying geometry; Weight: Our typical shafts have a maximum weight of up to 1,000 lbs Machining Processes We bring many types of machining processes to bear when it comes to shaft manufacturing A sample of our production capabilities includes: Boring; Drilling; Turning; Internal and 2011年7月10日 I am looking at grinding a number of simple shafts between centers They are one diameter all the way across I would like to avoid flipping them over to grind the spot that was covered by the grinding dog Does anyone have ideas or techniques to drive these shafts differently so I could grinding them all at onceAlternative to drive dogs for grinding small shaftsAutomotive Shaft Production Line: Description: This state of the art machinery is being used to grind and polish the shafts of continuously variable transmissions Fully automated process consisting of: CNC Turning, internal and external Automotive Shaft Production Line krudoind2024年3月12日 Grinding is commonly one of the last machining operations performed to complete a part Cylindrical and centerless grinders are used for cylindrical parts Grinding machines for flat surfaces are called surface grinders Form grinders move the work and/or the wheel in various axes to grind surfaces that are precisely contouredGrinding for Precision Machining Production Machining

Flexible Drive Shaft Grinder Grinding Tools Chester

Quality flexible grinding tool, ideal for small delicate work The Flexi Grind comes complete with a full range of accessories, including: Wood Carving Attachment and Chisels, External Grinding Stones, Internal Grinding Stones, Flap Grinding Wheels, Deburring Stones and Drill Chuck2019年3月26日 Superproductive and perfect for batch production Key data The ShaftGrind L as a singleslide or twoslide machine allows you to machine shafttype components with a length of up to 1,100 mm or 650 mm This superproductive grinding machine offers brand new design options for cylindrical grinding in mid to high volume production YouA member of the UNITED GRINDING Group ShaftGrind L2024年4月12日 Optimum cylindrical grinder for production with high accuracy and high productivity Longterm grinding accuracy High rigidity and low vibration bed Features the TOYODA STAT BEARING Reduce thermal displacement High productivity Abundant variation Abundant grinding cycles Allstep grinding without driving dog (Option)Cylindrical grindersJTEKT(China)CO, LTD2023年12月15日 The CNC machine spins the shaft attached to the chuck while the cutting tool removes excess material from its surface CNC turning provides the required diameter and surface finish for machined shafts More importantly, CNC turning is your goto option for highvolume production situations when you need to produce many shafts quicklyCustom Shaft Manufacturing: Process Techniques and Tips

.jpg)

What is a Grinding Machine: Definition, Types, Components

2024年1月27日 Highvolume production grinding of cylindrical parts Achieving tight tolerances in roundness and diameter Grinding long, slender parts that could deform if held between centers Most Useful For: Centerless grinding is essential in mass production settings, particularly in the manufacturing of automotive components and precision parts2020年3月1日 Volume Production of Crankshafts and Drive Shafts with StateoftheArt Technologies March 1, 2020 including: procurement of new production lines, expansion or modification of existing plants, as well as reconfiguration of existing systems Can be drymachined and therefore no maintenance and disposal of grinding abrasive (oil or Volume Production of Crankshafts and Drive Shafts with 2011年2月7日 It needs two jackshafts for the grinder head and work head, both are engaged via a belt sliding from an undersized pulley to a 5" pulley The work head jack shaft requires 450 RPM, so would need a 5 5/8" pulley on the main, and the grinder head jack shaft requires 850 RPM, so would need a 10 5/8" pulley on the main"The Machine Shed" Building a Line Drive Shop from Scratch2021年8月10日 Germany — The increasing quantities of emotors are challenging production planners: In many application areas, they have to establish new solutions with which components, such as the emotor drive shaft, can be manufactured faster and more efficiently — and with holistic production systems A new example Emag realised for a supplier company producing New production line for rotor shafts brings efficiency to e

Is your driveshaft failing? Here are the signs and

2023年2月27日 That’s the sound of metal on metal and is the precursor to grinding Clicking or grinding sounds As well as clicking while turning or accelerating, you may notice the following noises: knocking; Spoiled or torn 2021年9月3日 Output shafts Double Cycle Complete C/CBN Doublespindle external cylindrical grinder for shaft production (Double Cycle Complete C/CBN) Complete machining of the shaft in 1 single clamping setup Doublespindle external cylindrical grinder with 2 work stations (2 slides on the Zaxis) for the grinding of: Diameters, plane surfaces and The specialist in cylindrical grinding Transmission shaftsFRANLI has several sets of wet grinding production lines, including PCB ink production line, ink production line, pesticide production line, automobile coating production line, etc Twin Shaft Disperser; High Speed Disperser; Basket mill; High Shear Mixer; Kneader; Filling Machine; Chemical Reactor; Drop us an Production Line Franli Machine2003年10月1日 Higher speeds increased the effectiveness of using large leather belts to drive horizontal line shafts According to period sales literature from JB Hoyt Co (New York), “a leather belt will safely and continuously resist a strain of 350 pounds per square inch and a section of 04 of a square inch over a turned castiron pulley will Line Shafts and Belts ASSEMBLY

.jpg)

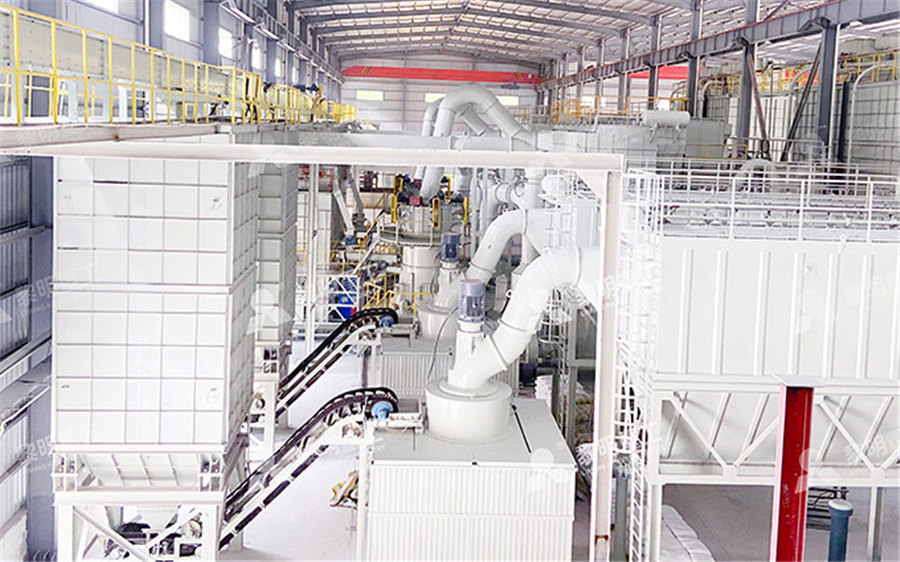

GGBS Production Line Slag Mill for Slag Powder Grinding

AGICO is a leading cement industry equipment supplier based in China It can not only supply all kinds of slag powder grinding equipment including ball mill, vertical roller mill, and roller press, but also provide you with a complete turnkey solution for ground granulated blastfurnace slag (GGBS) productionThrough cooperation with Luoyang Design Institue, Tianjin Design 2019年2月14日 with direct drive clamping system The 4axis highspeed peripheral grinding machine can thus achieve extremely high grinding speeds Large grinding wheel diameters increase chip removal rates and achieve maximum surface qualities on indexable inserts Over all, the grinding time is reduced by up to 50 per cent INSERT LINE Grinding SoftwareINSERT LINE UNITED GRINDING2023年10月5日 Dimensional Inspection: Drive shafts are subjected to dimensional inspection to verify that they meet the specified length, diameter, and other geometric requirements Conclusion The drive shaft manufacturing process involves several intricate steps and specialized technologies that influence the performance and reliability of the final productDrive Shaft Manufacturing Process: From Materials to Proven CBN grinding technology with cutting speeds of up to 140 m/s and high feed rates, resulting in short cycle times JUNKER 3point mounting interface for fast changeover and excellent grinding wheel concentricity HF highpower grinding spindle (42 kW drive capacity) is extremely lowmaintenance thanks to lifetime lubrication and air sealGrinding machines: Lean Selection shaft junkergroup