Equipment performance advantages of grinding kaolin

.jpg)

Kaolin Processing Plant MachinerySBM Industrial

2023年1月3日 Compared with the combined grinding system of traditional Raymond mill and ball mill, vertical roller mill has the advantages of large output, wide adaptability, simple operation, rapid adjustment, low use and maintenance cost, energy saving, etc, and is the preferred 2020年4月13日 Based on the comprehensive investigation and analysis of the application status and the existing problems of suspension calcination technology in these industries, we Research and Design of Suspension Calcining 2020年4月14日 A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introduced The pretreatment process can be Research and Design of Suspension Calcining Technology and Equipment 2023年8月1日 Kaolin is a natural clay mineral with potential applications as a filler in improving the performance of thermosetting polymers like mechanical properties, thermal stability, An overview of kaolin and its potential application in

Brief introduction of kaolin deep processing equipment and

2023年10月10日 In the deep processing industry of kaolin, dry process and wet process are generally adopted, both of which require crushing and grinding of raw ore Lets briefly 2023年5月16日 This study examined the effects of various grinding parameters (addition of trass, ball to powder mass ratio (BPR), material of grinding bodies and jars, rotational speed, and mill type) to minimize the energy consumption Optimization of Grinding Parameters for the 2023年11月23日 XRD and SEM results showed that the structural properties of kaolin depend on the grinding time as well as the solid/ball ratio, and the grinding time was more effective Effect of solid/ball ratio and grinding time on the mechanical 2021年5月17日 The particle size of the ground kaolin samples decreased and the particlesize distribution was more concentrated, indicating that the steam jet milling was more effective for Effects of grinding and dehydration on kaolin in a steam jet

Kaolin: processing, properties and applications ScienceDirect

1991年9月1日 Kaolins are white raw materials, their essential constituent being fine grained white clay, which are amenable for beneficiation that make them ideal for an assortment of 2008年1月1日 The characteristics of beneficiating kaolin mineral by liberation (selective grinding) and air classification have been investigated, comparing the grinding rates of ball mill and (PDF) Effect of Grinding Method and Grinding Rate on the The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of Ultra Fine Powder Mill5 天之前 It involves crushing, screening, grinding, sorting, etc of kaolin ore using mechanical equipment to obtain the desired products Dry beneficiation is usually suitable for some fields with less strict product requirements, such as Kaolin Dry And Wet Beneficiation Method JXSC

News The advantages of kaolin vertical

The is shown that with the increase of particle size, the covering force of calcined kaolin is gradually increased, the main reason is that the finer the kaolin particles, the greater the covering force Kaolin grinding is a production equipment used 2023年1月3日 Raymond mill is also frequent used grinding equipment for kaolin processing It has the following advantages: 1 good dust collection The equipment adopts pulse dust collector to collect dust, and the efficiency can reach 99%, which is favored by many customers 2 Kaolin Processing Plant MachinerySBM Industrial If you want to grind kaolin, the superfine vertical grinding mill is the ideal choice HLMX superfine vertical grinding mill made by HCM is an environmentfriendly and energysaving grinding mill equipment It has lots of advantages, such as high production capacity, low energy consumption and more environmental protectionThe Best Kaolin Superfine Vertical Grinding Mill Made By HCM2023年8月1日 To synthesize kaolinKAc compound (KKAc), a dry grinding method was employed, whereby 15 gm of potassium acetate (KAc) and 5 gm of kaolin (containing 5 wt% moisture) were thoroughly mixed for 40 min in an agate mortar at room temperature ethylenediamine Epoxy resins, enormously used for their highperformance are strengthened An overview of kaolin and its potential application in

.jpg)

Weifang Zhengyuan Powder Engineering Equipment Co, Ltd

Performance Advantages LHE wet ultrafine grinding machine is the newlydeveloped grinding equipment of our company Designed with totallynew machine structure, optimized machinery size, uniquely designed machinery parts, and simplified production process, this wet ultrafine grinding machine has higher performance Its advantages include:2021年11月17日 Dry grinding process; Dry grinding is mostly used for ultrafine grinding of hard kaolin or kaolin, especially for directly processing kaolin into ultrafine powder that can meet user requirements At present, the product fineness that can be achieved by dry production is generally D90≤10μm, that is, the final product is about 1250 meshUltrafine grinding of kaolin ALPA Powder Equipment2022年8月10日 The kaolin bulk material is crushed by the crusher to the fineness (15mm30mm) that can enter the mill Stage 2: Grinding The crushed small pieces of kaolin are sent to the storage hopper through the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grindingKaolin grinding production line and equipment selection2024年10月13日 The advanced kaolin grinding production line equipment represents a significant leap forward in the processing of this valuable mineral By offering a combination of high efficiency, precision, and environmental responsibility, these systems are empowering the kaolin industry to meet the stringent demands of modern applications As the global Advanced kaolin grinding production line equipment:

Kaolin production equipment: Screening and stone grinding

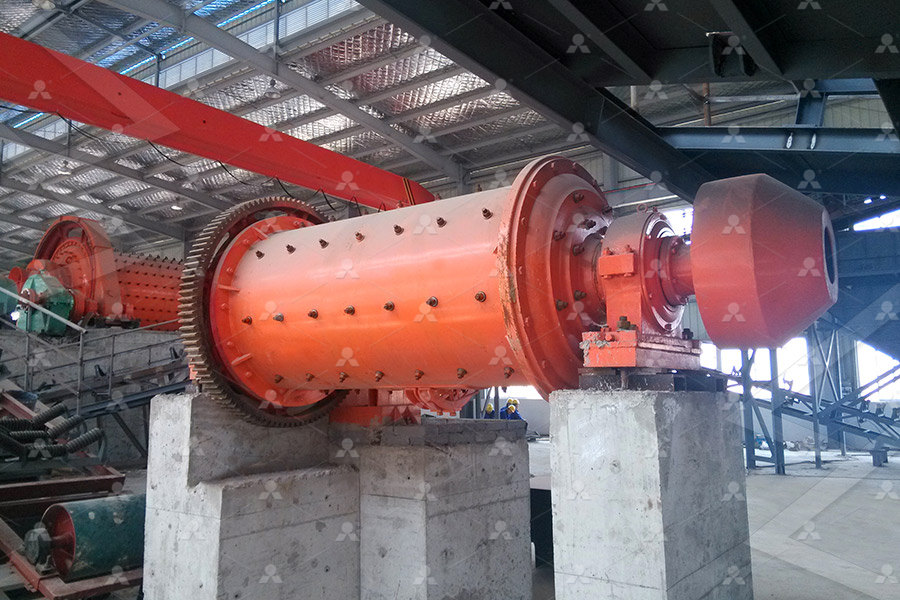

2024年10月13日 Grinding is the process of reducing kaolin lumps to a fine powder The following equipment is used for stone grinding: Ball Mills: These mills use steel balls to crush and grind the kaolin They are reliable and can produce a wide range of particle sizes Raymond Mills: These are vertical roller mills that are efficient in grinding kaolin 2021年5月7日 Whether it is quality, performance or price, it has the advantage that other manufacturers can't surpass Advantages of kaolin superfine grinding mill: (1) The equipment can not only grind kaolin, but also coarsely crush the material, which can form an independent kaolin grinding production line The milling process is greatly simplified, and What kind of grinding mill is used to process kaolin?Stone Grinding Kaolin is a common nonmetallic mineral It is important to select special equipment for grinding such non mineral fine powder Among them, the ultrafine mill machine is an ideal equipment to create value for the fine powder project The grinding mill has the comprehensive mechanical crushing performance of rolling, grinding and impactBuy The Best Ultrafine Mill Equipment For Grinding Kaolin2024年3月5日 Advantages: The wet magnetic separator has the advantages of deep magnetic field intensity on the cylinder surface, large magnetic system wrapping angle, stable magnetic field intensity, and stable and reliable transmission system, which can significantly improve the grade of ore entering the grinding process Disadvantages:Wet magnetic Magnetic Separator Basic Introduction How To Choose

.jpg)

The Details of Accurate Grinding: A Practical Guide

2023年8月2日 What Are the Advantages of Precision Grinding? Precision grinding is a preferred manufacturing process in various industries due to its numerous advantages: High Accuracy: Precision grinding can achieve incredibly tight tolerances, up to 00001″ Smooth Surface Finishes: It can create exceptionally smooth surface finishes, down to Ra 01 µm2023年6月30日 The advantage of using MDO is that the optimum overall solution, as compared to the optimum found by optimizing each solution sequentially , also takes into account the interaction between themModeling and Improving the Efficiency of Crushing EquipmentCLUM series calcium carbonate ultrafine vertical mill, a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging, focusing on the largescale production field of nonmetallic mineral ultrafine powder processingCalcium Carbonate Ultrafine Vertical Mill SBM Ultrafine 2024年2月3日 With the advantages of kaolin vertical grinding mill, it can completely replace coarse powder equipment such as Raymond mill and process kaolin fine powder products on a large scale Moreover, the kaolin vertical mill has the advantages of high output, low power consumption, low wear, environmentally friendly and dustfree negative pressure Advantages of Kaolin Vertical Grinding Mill hcmills

Kaolin Rotary Kiln XKJ Group,Crusher,Ball mill,Mineral

Kaolin rotary kiln is also called kaolin calcining kiln The advantages of this equipment can be seen from the name of the equipment It is a specialized equipment developed based on the characteristics of kaolin In the actual application process, it has large production capacity and work efficiencykaolin grinding mill used in this process flow is a Raymond mill This kind of mill machine has high efficiency, low energy consumption, small occupation area, little capital investment, and other characteristics Moreover, the kaolin mill has many performance advantages: Firstly, the mill’s main driving device adopts an airtight gear box Kaolin Crusher Turns Kaolin Into Industrial Raw Material2022年8月10日 It has the advantages of low vibration, low noise, convenient maintenance, simple operation, low energy consumption, high efficiency, and durable wearing parts In addition, it produces a high degree of grinding purity without impurities The above three types of grinding equipment can meet the requirements of the grinding process of kaolinWhat equipment is used for kaolin grinding?What equipment 2023年2月15日 This blog will introduce you to what is kaolin, the best way and equipment for grinding kaolin, to meet the market needs for ultrafine kaolin powder What is kaolin clay? Together with mica, quartz, and calcium Grinding Kaolin Clay? Now Is the Time to Know

.jpg)

The Advantages of Surface Grinding Machines: A

2023年9月1日 The grinding wheel is typically made of bonded abrasive materials, such as aluminum oxide or silicon carbide, which are harder than the material being ground The Advantages of Surface Grinding Machines Surface grinding machines offer several advantages over other grinding methods, making them a popular choice in many industries2023年6月23日 The production process involves several steps, from mining the raw material to grinding and packaging the final product First, the kaolin clay is extracted from the earth and transported to a processing plant Once there, it is crushed and ground into a fine powder using specialized equipmentWhat is Calcined Kaolin Powder and its Unique PropertiesThis mill is widely used to grind any nonmetal minerals with Moh's hardness below 7 and moisture below 6%, such as talc, calcite, calciumcarbonate, dolomite, bentonite, kaolin, graphite, carbon black, etc HCH Ultrafine Grinding Mill features in spacesaving, completeness, wide usage, easy operation, smooth performance, high performancecost HCH Ultrafine Grinding Mill, Micro powder grinding mill, Kaolin rotary kiln is also called kaolin calcining kiln The advantages of this equipment can be seen from the name of the equipment It is a specialized equipment developed based on the characteristics of kaolin In the actual application process, it has large production capacity and work efficiencyKaolin Rotary Kiln XKJ Group,Crusher,Ball mill,Mineral

Roller Mill SpringerLink

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table) causticburned magnesia powder, kaolin, wollastonite, gypsum, lime, bentonite, etc), and the particle size can be adjusted between 10 2021年12月1日 As a result, the agglomeration between kaolin particles increased, leading to the increase in the slurry shear stress (ie, viscosity) and thus reducing the grinding performance significantly The grinding performance was reduced by the addition of Ca 2+ ions when there was a high clay percentage (40%) and a high solid percentage (70%) This Detrimental effect of calcium on grinding performance of a kaolin 2021年5月5日 Grinding Machine Disadvantages: The following disadvantages of Grinding Machine are: The Grinding Machine is a little costly The cost of this machine is more than 25 lacks Unlike another machine (Lathe Machine) the material removal rate is not fast It takes more time for removing the materialGrinding Machine: Definition, Parts, Working Principle, Operation 2024年11月26日 The structure of the hydrocyclone is relatively simple Its upper end is a cylindrical part, and its lower part is a conical container The slurry is fed into the cyclone at a certain speed (generally 5 to 12 meters per second) along the tangential direction, and obtains a rotary motion, thus generating a large centrifugal force (usually tens of times or even hundreds Hydrocyclone JXSC Machinery

Ultra Fine Powder Mill

The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of 5 天之前 It involves crushing, screening, grinding, sorting, etc of kaolin ore using mechanical equipment to obtain the desired products Dry beneficiation is usually suitable for some fields with less strict product requirements, such as Kaolin Dry And Wet Beneficiation Method JXSC The is shown that with the increase of particle size, the covering force of calcined kaolin is gradually increased, the main reason is that the finer the kaolin particles, the greater the covering force Kaolin grinding is a production equipment used News The advantages of kaolin vertical 2023年1月3日 Raymond mill is also frequent used grinding equipment for kaolin processing It has the following advantages: 1 good dust collection The equipment adopts pulse dust collector to collect dust, and the efficiency can reach 99%, which is favored by many customers 2 Kaolin Processing Plant MachinerySBM Industrial

.jpg)

The Best Kaolin Superfine Vertical Grinding Mill Made By HCM

If you want to grind kaolin, the superfine vertical grinding mill is the ideal choice HLMX superfine vertical grinding mill made by HCM is an environmentfriendly and energysaving grinding mill equipment It has lots of advantages, such as high production capacity, low energy consumption and more environmental protection2023年8月1日 To synthesize kaolinKAc compound (KKAc), a dry grinding method was employed, whereby 15 gm of potassium acetate (KAc) and 5 gm of kaolin (containing 5 wt% moisture) were thoroughly mixed for 40 min in an agate mortar at room temperature ethylenediamine Epoxy resins, enormously used for their highperformance are strengthened An overview of kaolin and its potential application in Performance Advantages LHE wet ultrafine grinding machine is the newlydeveloped grinding equipment of our company Designed with totallynew machine structure, optimized machinery size, uniquely designed machinery parts, and simplified production process, this wet ultrafine grinding machine has higher performance Its advantages include:Weifang Zhengyuan Powder Engineering Equipment Co, Ltd2021年11月17日 Dry grinding process; Dry grinding is mostly used for ultrafine grinding of hard kaolin or kaolin, especially for directly processing kaolin into ultrafine powder that can meet user requirements At present, the product fineness that can be achieved by dry production is generally D90≤10μm, that is, the final product is about 1250 meshUltrafine grinding of kaolin ALPA Powder Equipment

Kaolin grinding production line and equipment selection

2022年8月10日 The kaolin bulk material is crushed by the crusher to the fineness (15mm30mm) that can enter the mill Stage 2: Grinding The crushed small pieces of kaolin are sent to the storage hopper through the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding2024年10月13日 The advanced kaolin grinding production line equipment represents a significant leap forward in the processing of this valuable mineral By offering a combination of high efficiency, precision, and environmental responsibility, these systems are empowering the kaolin industry to meet the stringent demands of modern applications As the global Advanced kaolin grinding production line equipment: