Equipment settings and operation and maintenance required for stone

.jpg)

Operating and Maintenance Regulations for Stone Cutting

2024年10月12日 Correct operation and maintenance of stone cutting machines can not only improve work efficiency but also extend the machine's service life and reduce the failure rate This article will introduce the operating and maintenance regulations for stone cutting machines to 2024年10月14日 What machines are required for a stone crusher plant, and what is the function of each? Here, you'll discover 11 stone crushing equipment needed for stone crushing, from primary crushers to fine crushers and What Machines Do Stone Crushing Plants Need?2024年11月26日 Do not use acids or flame tools to strip paint from stone Paint strippers can etch the rock’s surface; if repolishing is necessary, contact a professional stone restoration Care Maintenance Natural Stone Stone Source2024年10月17日 Any machine requires maintenance and upkeep, especially largescale engineering machinery Today, let’s learn about the maintenance methods for stone cutting Maintenance of stone cutting machines at different time

Safety Operation and Maintenance Regulations for Stone

2024年10月31日 Here are the maintenance methods for the stone machine: During the use of the stone machine, regular inspections should be conducted on all components of the 2020年3月19日 By putting together rock solid maintenance processes and practices, operations can ensure maximum availability of the equipment and reduce total production costs 1 Regular equipment inspectionsSix steps to a rock solid maintenance program2018年9月15日 • Quarry operations required to remove stone from deposit including drilling, cutting, prying, and use of explosive charges • Onsite transport of stone using heavy Limestone Quarrying and Processing: A LifeCycle 2024年10月23日 Focusing on CNC stoneworking centers, bridge saws, saw/jets, water and air recycling and filtration, line polishers and more Exploring equipment trends and extraction practices in stone quarrying Advances in Fabricator Machinery Equipment Stone World

.jpg)

A Guide to the Care Cleaning of Natural Stone Atlas

2020年9月11日 Approach,” Cleaning Stone and Masonry,by Rudder, TH, ASTM STP 935, 1986 “A Case Study of the Cleaning of Marble at the Schenectady, New York, City Hall,” 2023年12月13日 Stone construction requires specialized equipment for precision and safety Basic techniques include stormproofing the foundation, filling gaps, layering with butter, narrowing the design, topcapping, joint 10 Essential Stone Construction Equipment Pieces2024年10月6日 Impact Crusher Maintenance 6 Hammer Crusher Maintenance 7 Fine Crusher Maintenance 8 Mobile Crusher Maintenance 9 Troubleshooting Guide 10 Spare Parts Management 1 General Safety Precautions • Always turn off and disconnect power before performing any maintenance • Wear appropriate personal protective equipment (PPE), such Maintenance Manual stonecrushers2024年10月14日 The steel used for sand making equipment is not refined, and has a large number of defects in smelting; Improper raw materials result in poor material performance and bad wear resistance of rotor The rotor of sand 4 Types of Stone Crushers' Maintenance and

OM MANUALS Guide, Format, Documents,

2023年8月28日 🟩 Why Do We Issue Operating Manuals? Operating and Maintenance [OM] manuals are issued for several important reasons: Effective Operation: Providing detailed instructions on operating the various systems 2023年3月16日 A110 Where maintenance access to the service ledge is via windows or wall apertures, the size of the openings should allow safe and easy access for maintenance personnel carrying tools, equipment and component parts Maintenance activities should not require the dismantling of services and building elementsDESIGN FOR MAINTAINABILITY GUIDE Building and 2019年3月16日 This mixing operation of more than one material is called blending The blending operation, when applied to only one material to make it uniform in characteristics, is termed as homogenizing operation Stackers and reclaimers are also required for homogenization / blending of bulk materialsConstruction, Working and Maintenance of Practical 2023年2月24日 The labor required to operate and maintain the plant is another significant cost factor Labor costs vary depending on the location and availability of skilled workers Equipment: The type of equipment used in the stone crusher plant also affects the setup cost For instance, if you want a mobile plant, the cost will be higher than a stationary Understanding the Factors Involved in Setting Up a Stone

.jpg)

The Essential Guide to Operation and Maintenance Manual

2024年11月15日 An Operations and Maintenance (OM) manual for a factory environment should cover equipment operation procedures, maintenance schedules, safety protocols, troubleshooting guides, emergency procedures, contact information, and regulatory compliance requirements to ensure efficient and safe operations2019年10月5日 In short, the OM manual AKA "Operation and Maintenance Manual" (OM Manual) is a file containing all the information required for the operation , maintenance, decommissioning and demolition of a building or structure Operation/MaintenanceSignificant drawings; Equipmentspecific OM information, organized in a vendor / manufacturer data Building Operation and Maintenance Manual (OM) Domitos6 Maintenance of harvesting equipment: a) Maintenance of combine harvester: Maintenance at proper time and with proper techniques increases the workability, quality of work and life of machine Hence during the operation the maintenance should be undertaken as per maintenance schedule given below in order to cutdown break downsMTFM: LESSON 15 Adjustment, operation and maintenance 2024年6月9日 Tips for implementing an effective operation and maintenance mangement, but using tools such as CMMS, predictive and preventive maintenance reducing operational disruptions while promoting a secure workplace setting Careful compilation of these core components yields an OM manual that informs and safeguards operations and refines the Top Tips for Effective Operation and Maintenance

.jpg)

Create an Operation Maintenance Manual StepbyStep

2023年6月10日 Articles Create an Operation Maintenance Manual StepbyStep Guide Create an Operation Maintenance Manual StepbyStep Guide 6/11/202315 minutes to read Include relevant information such as equipment settings, required tools, or safety precautions for each procedure This helps users understand the purpose and importance of 2024年9月24日 These can include the owner’s engineering staff, safety personnel, operations and maintenance personnel, equipment manufacturers, and the engineering consultant Ideally, the consultant combines his knowledge and experience with an understanding of all parties’ needs, to provide a balanced, workable, safe and economic plant designCrushing Plant Design and Layout Considerations 911 2023年11月16日 This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation, clearing of blockages, and the associated need for electrical isolation People required to work on equipment should understand these rules, be appointed, be suitably trained and be capable ofSafe maintenance of equipment (including machinery)2023年8月9日 Operations and Maintenance Division Functions Design and Construction; Operations and Management; Master Planning; Real Estate Planning; Energy; NASA’s maintenance philosophy is to aggressively and proactively pursue and adopt the safest, most costeffective, best blend of Reliability Centered Maintenance Guide (RCM – Accessible Operations and Maintenance NASA

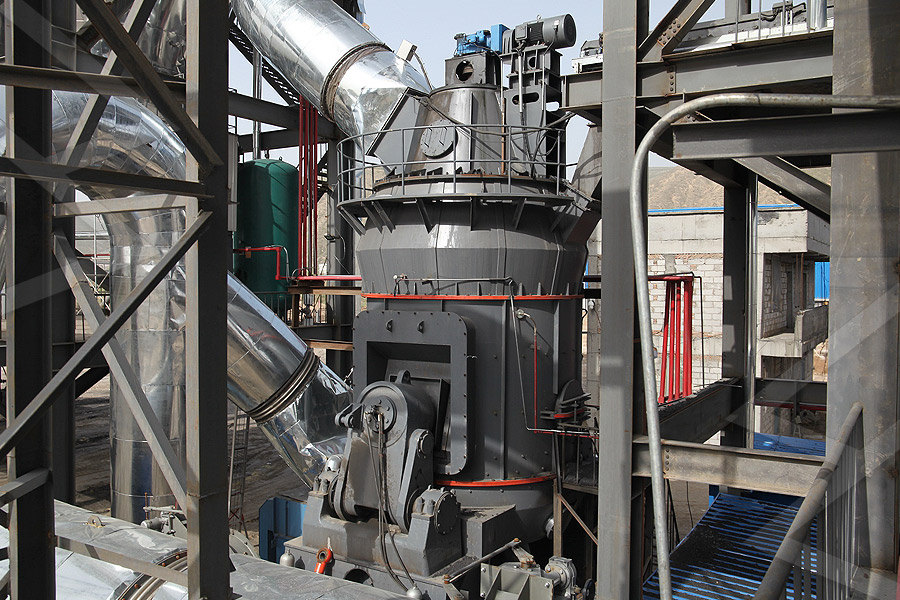

Commonly Used Stone Crushers and The Maintenance

2024年11月7日 Reasonably arrange the monthly, quarterly, and annual inspections of equipment to form a practical operation and maintenance system, and establish emergency measures Impact crusher Get Latest Price The impact crusher is mainly suitable for coarse, medium, and fine crushing of soft and medium hard materials, and also has a certain shaping 2021年1月19日 Maintenance Refer to the Operation and Maintenance Manual for your machine to determine all maintenance requirements Proper maintenance and repair are essential to keep the equipment and systems operating correctly As the owner, you are responsible for the performance of the required maintenance listed in the OwnerOperation and Maintenance Manual Scene72024年3月15日 This document provides a method statement for stone works It outlines procedures for delivery and storage of stone materials, use of equipment like drills and grinders, and safety measures Responsibilities are assigned to project managers, engineers, and safety personnel Proper execution of stone installation is described in 9 steps, including delivery to Method Statement For Stone Works2019年2月13日 First aid equipment Where the maintenance of electrical equipment is carried out especially inside switchrooms, a notice giving instructions on treatment of a person suffering from electric shock should be affixed and first aid equipment should be made available for the treatment of personnel Operations and Maintenance Manual Switchboards and Operations and Maintenance ManualSwitchboards and

.jpg)

5 Operation and Maintenance Manuals ps

2022年11月8日 Contractor shall be required to supply one high quality microfilm reader/printer to the Service Weights of assemblies shall be shown on the drawings 14 Maintenance Drawings 141 The Contractor shall provide such drawings as may be required for the operation and maintenance of the equipment by the Employer/ Concessionaire2024年2月5日 Maintenance testing and inspections are essential practices carried out to ensure the ongoing functionality and reliability of machinery and equipment in various industrial settings The process involves systematic examinations and assessments of equipment to identify potential issues, while inspections focus on visually examining components 9 Maintenance Inspection: Types, Example and Best Practices2020年1月3日 repaired locally if required If several components are broken in the same area such that it will affect other parts of the wall or loss of the infill stone, advice should be sought from Phi Group or a structural Engineer 52 Major collision damageOPERATION MAINTENANCE GABION Phi GroupPlant Clearance and Access Consideration for proper Accessibility Proper Access shall be provided to equipment, valves, and instruments requiring operational control or normal maintenance during plant operation, by A Guide to Plant Clearances and Access

.jpg)

Expert Tips for Natural Stone Care Maintenance

2024年3月12日 Caring for and maintaining natural stone is essential to preserve its beauty and longevity With the right care and regular maintenance, your natural stone surfaces can last a lifetimeThis article provides expert tips and 2023年2月22日 Stone crusher machines are widely used in the construction and mining industries to break down large stones into smaller pieces To ensure that these machines operate efficiently and remain in good condition, regular maintenance and repair are necessary In this article, we provide a comprehensive guide to the maintenance and repair of stone crusher Maintenance and Repair of Stone Crusher Machines2023年6月26日 Check out our guide to boiler operation and maintenance here! Skip to content 24/7 Service calls — 8779276873; BHP denotes the amount of energy required to produce 345 pounds of steam per hour from a pressure of 0 Psig and at a temperature of 212 degrees Fahrenheit Check chemical feed equipment against the checklist The Complete Guide To Boiler Operation and Maintenance2023年11月1日 To address key scientific issues such as realtime perception, precise evaluation and hazard warning of equipment status in complex and everchanging environments, research is conducted on the failure mechanism and longterm maintenance strategy of equipment in extreme environments, achieving refined management and efficient maintenance of Exploration of Key Technologies for Equipment Operation and Maintenance

.jpg)

Care Maintenance Natural Stone Stone Source

2024年11月26日 Clean with bleach, hydrogen peroxide (lightcolored stone only), lacquer thinner, or acetone (dark stones only) Metal Iron, rist, copper, etc Metal stains must be removed with a poultice Deepseated, rusty stains are tough to remove, and the stone may be permanently stained Water Spots and Rings Surface accumulation of hard water2018年9月15日 • Onsite transport of stone using heavy equipment • Transport of scrap stone to onsite storage • Onsite generation of energy and compressed air • Capture and treatment of wastewater • Upstream production of energy and fuels Equipment and ancillary materials (eg drill bits, maintenance items) are listed in Tables 5 and 6 but haveLimestone Quarrying and Processing: A LifeCycle 2012年1月1日 A bimodal training programme (maintenance and operation) on tractor system, packaged and presented in this book is all that is required for managerial decision making on(PDF) Farm Tractor Systems: Operations and Maintenance2024年3月28日 Operations and Maintenance is an inherently proactive maintenance strategy, and therefore differs from reactive maintenance and corrective maintenance models OMbased strategies are rooted in ongoing upkeep and preventive maintenance , and are aimed at reducing unexpected equipment failure or prolonged downtime What Is Operations and Maintenance (OM)? Limble

.jpg)

Maintenance Manual stonecrushers

2024年10月6日 Impact Crusher Maintenance 6 Hammer Crusher Maintenance 7 Fine Crusher Maintenance 8 Mobile Crusher Maintenance 9 Troubleshooting Guide 10 Spare Parts Management 1 General Safety Precautions • Always turn off and disconnect power before performing any maintenance • Wear appropriate personal protective equipment (PPE), such 2024年10月14日 The steel used for sand making equipment is not refined, and has a large number of defects in smelting; Improper raw materials result in poor material performance and bad wear resistance of rotor The rotor of sand 4 Types of Stone Crushers' Maintenance and 2023年8月28日 🟩 Why Do We Issue Operating Manuals? Operating and Maintenance [OM] manuals are issued for several important reasons: Effective Operation: Providing detailed instructions on operating the various systems OM MANUALS Guide, Format, Documents, 2023年3月16日 A110 Where maintenance access to the service ledge is via windows or wall apertures, the size of the openings should allow safe and easy access for maintenance personnel carrying tools, equipment and component parts Maintenance activities should not require the dismantling of services and building elementsDESIGN FOR MAINTAINABILITY GUIDE Building and

.jpg)

Construction, Working and Maintenance of Practical

2019年3月16日 This mixing operation of more than one material is called blending The blending operation, when applied to only one material to make it uniform in characteristics, is termed as homogenizing operation Stackers and reclaimers are also required for homogenization / blending of bulk materials2023年2月24日 The labor required to operate and maintain the plant is another significant cost factor Labor costs vary depending on the location and availability of skilled workers Equipment: The type of equipment used in the stone crusher plant also affects the setup cost For instance, if you want a mobile plant, the cost will be higher than a stationary Understanding the Factors Involved in Setting Up a Stone2024年11月15日 An Operations and Maintenance (OM) manual for a factory environment should cover equipment operation procedures, maintenance schedules, safety protocols, troubleshooting guides, emergency procedures, contact information, and regulatory compliance requirements to ensure efficient and safe operationsThe Essential Guide to Operation and Maintenance Manual2019年10月5日 In short, the OM manual AKA "Operation and Maintenance Manual" (OM Manual) is a file containing all the information required for the operation , maintenance, decommissioning and demolition of a building or structure Operation/MaintenanceSignificant drawings; Equipmentspecific OM information, organized in a vendor / manufacturer data Building Operation and Maintenance Manual (OM) Domitos

MTFM: LESSON 15 Adjustment, operation and maintenance

6 Maintenance of harvesting equipment: a) Maintenance of combine harvester: Maintenance at proper time and with proper techniques increases the workability, quality of work and life of machine Hence during the operation the maintenance should be undertaken as per maintenance schedule given below in order to cutdown break downs2024年6月9日 Tips for implementing an effective operation and maintenance mangement, but using tools such as CMMS, predictive and preventive maintenance reducing operational disruptions while promoting a secure workplace setting Careful compilation of these core components yields an OM manual that informs and safeguards operations and refines the Top Tips for Effective Operation and Maintenance