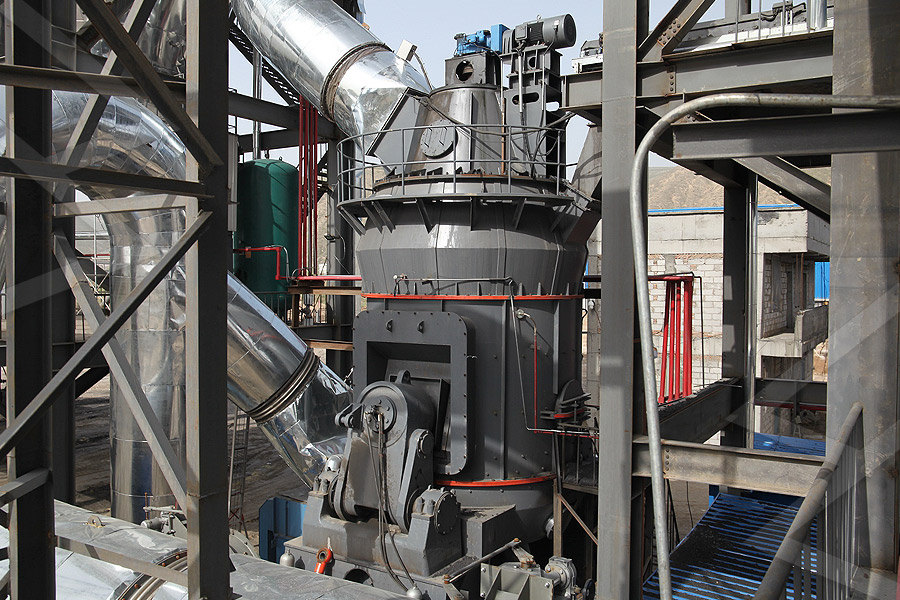

Explanation of process equipment of grinding station

.jpg)

(PDF) A comprehensive review on the grinding process:

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, Grinding, a machining process, involves removing material from a workpiece using a rotating abrasive wheel Here's a stepbystep breakdown of the grinding process: Select the Grinding in Engineering:Definition,Process,and 2024年1月27日 What is a Grinding Machine? A grinding machine, often known as a grinder, is a machine tool used for grinding It is a powerhouse of precision and versatility in the manufacturing and metalworking industry A grinding What is a Grinding Machine: Definition, Types, 2023年11月5日 Grinding is the process of removing material from a work piece using a grinding wheel as a cutting tool Surface roughness and material removal rate are essential output A REVIEW ON VARIOUS GRINDING PROCESSES Journal

Grinding Machine: Definition, Types, Parts,

A grinding machine or in short ‘grinder’ is a surface finishing and roughness removal machine with help of an abrasive wheel attached in different orientations and machines as per requirement It can also be defined as follows:2019年1月1日 The process properties of grinding are significantly different from those of milling This is also the source of deviations in architecture, machine layout, and equipment of grinding Grinding Machines SpringerLink5 天之前 We begin by explaining some technical terms and the concepts that lie behind them Three applications then form the heart of the guide We look at: This division is, we feel, the Pocket Guide to Grinding Technique Atlas CopcoThe industry requires parts with high dimensional accuracy and surface finish, which can be achieved through the grinding process Medical Industry: Grinding is also used in the medical industry for producing precision parts such as What is Grinding? – Working Principles

Phosphate Rock Processing: 6 Useful Ways and 4

2023年8月8日 To extract phosphorus from phosphate rock, Ftmmachinery will explain to you the process flow of phosphate rock and the equipment we can provide, from the four stages of crushing grinding flotation – dehydration 2022年11月30日 Grinding is one of the types of machining process ideal for improving the finish on a machined part’s surface and tightening its tolerance Furthermore, the process produces parts with identical shapes, finishes, and Types of Machining Process: Classifications and 2018年3月1日 Processing equipment for grinding of building powders R S Fediuk 1, R A Ibragimov 2, V S Lesovik 3 A A Pak 1, V V Krylov 1, which is explained by an increase in water demand (PDF) Processing equipment for grinding of building 2021年6月1日 The success of the manufacturing process which involves grinding as one of the stages depends solely on the accuracy of the grinding process Being the last stage of the manufacturing path, it is mostly done to provide the desired surface finish to the product This makes the stage very crucial To prevent the ruining of all the previous stages and efforts, the Development of Realtime Grinding Process Monitoring and Analysis

.jpg)

modular and portable grinding station plug and grind vertical

6 modules for raw material reception and dust precipitation: similar to PLUGGRIND® XL VRM: Preassemblied in modules Erection in situ 3 process modules: similar to PLUGGRIND® XL 3 modules for auxiliary and peripheral equipment: hot gas generator 2013年5月1日 Grinding, a complicated machining process which has been extensively studied and documented in order to understand the subtleties of the operation being performed in different methodologies and (PDF) Influence of Process Parameters on Grinding A Raw material proportion station is the place where the raw materials like limestone, sand stone and basalt are mixing together The vertical roller mill fulfills four main functions in one compact piece of equipment: Grinding; Drying; Separation; Transportation; The process is called a drying /grinding process, where most of the material Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, Intro to Grinding Methods, Machines and Tools Practical

.jpg)

Grinding Process and its Applications mechGuru

2011年9月21日 Grinding is the process which necessarily use grinding wheel as the cutting tool to make the surface smoother This process is normally performed after performing the various other machining operations like milling, drilling etc so that the surfaces get smoother Fig1: Grinding Process Image source: Wiki2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw 6 Cement Equipment For Dryprocess Cement 2013年1月1日 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, highspeed grinding technology, cost optimization, ultra (PDF) Principles of Modern Grinding Technology 2019年1月1日 Further parameters relevant for grinding processes are the width of the grinding wheel b s, the width of the workpiece b w, and the diameter of the grinding wheel d s as well as for cylindrical grinding the diameter of the Grinding Parameters SpringerLink

.jpg)

Grinding SpringerLink

2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been 2022年1月23日 Additionally, when the downstream process involved grinding mills, the fines created from highspeed crushing circuit were a benefit to the comminution process In general, if the feed material, application parameters, and downstream process match with the capabilities of a highspeed impact style crusher, this is the crusher type to usePhysical Bauxite Processing: Crushing and Grinding of Bauxite2023年8月1日 Food products often consist of several phases Comminuted meat products, for example, are multiphase systems consisting of structured meat particles and unstructured batterlike substanceA review on the relation between grinding process and 2024年4月8日 In practical machining, the grinding process of the grinding wheel needs to consider many factors, such as the elastic recovery height of the material, the effect of chips, and machine vibrations, but for the purpose of mathematical modeling, some necessary assumptions need to be made: (1) regardless of the effects of plastic deformation between the abrasive Modeling and validation of the grinding morphology of

(PDF) Optimization of Process Parameters in Surface Grinding

2013年5月9日 The grinding process is quick if coarse and larger grains are used, oppositely it can be obtained a better surface finish if smaller abrasive grains are adopted [6] [7] [8] In addition to 2019年9月27日 The optimization of the grinder’s working process was carried out using experimental design methodology The following factors were studied: the grain material feed, rotor speed (rpm), opening (PDF) Studies of a Rotary–Centrifugal Grain Grinder Using a 2014年1月22日 The grinding process can be optimized by means of a simulative prediction of the occurring forces In this paper, a geometrickinematic simulation coupled with a finite element analysis is presented Considering the influence of individual grains, an additional approximation to the resulting topography of the ground surface is possible Simulation of grinding processes using finite element analysis 2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon What is Grinding Process How It Works

.jpg)

Empirical estimation of grinding specific forces and

2014年6月6日 Advanced grinding processes include relatively new grinding processes such as Creep Feed, HEDG and VIPER grinding These processes are more productive than conventional grinding ones as a result of favourable process kinematics Proper understanding of grinding forces can be useful in designing grinding machine tools and fixtures Addi2022年10月1日 Grinding is one of the most widely used material removal methods at the end of many process chains Grinding force is related to almost all grinding parameters, which has a great influence on (PDF) Modelling of grinding mechanics: A review 2024年9月1日 In the grinding process, the grinding speed can reach the magnitude of m/s, thereby subjecting the material to dynamic loading and causing its deformation behavior to be distinct from that of static or quasistatic loading For hard and brittle materials, strain rate sensitivity has been demonstrated [[72], [73], [74]]Towards understanding the machining process in grinding of 2024年1月27日 The Grinding Process: The heart of the operation is the grinding process The rotating abrasive wheel comes into contact with the workpiece surface, removing material through a combination of crushing and shearing forces Medical Equipment Manufacturing: Used for creating precise and smooth surfaces on surgical instruments Woodworking What is a Grinding Machine: Definition, Types, Components

.jpg)

Grinding Process SpringerLink

Grinding Process, Table 1 Methodological overview of typical grinding methods in accordance with DIN 8589 Full size table For peripheral plungegrinding methods, after calculating the material removal rate Q w and subsequent division by the width of the active grinding wheel profile b s eff follows the specific material removal rate Q Grinding Station + Mikaeus, the Unhallowed + Optimus Prime, Hero // Optimus Prime, Autobot Leader Combo result Infinite LTB Infinite ETB Infinite sacrifice triggers Infinite death triggers Infinite mill Infinite selfmill Prerequisites It is your turn≫ MTG Grinding Station 39 combos explained MTG DECKS2014年2月11日 Grinding kinematics is one of the main mechanisms affecting the behaviour and efficiency of the creepfeed grinding process; it is thus essential in understanding the interplay of its parameters (PDF) CreepFeed Grinding: An Overview of Kinematics2023年4月25日 Under the opportunity of 'Made in China 2025', in the field of ultraprecision, China has broken through many key bottleneck technologies, achieved many remarkable scientific research results, built a number of highlevel ultraprecision processing technology innovation platforms, talent growth platforms and application demonstration bases, and Ultraprecision grinding and polishing processing

.jpg)

(PDF) Development of Realtime Grinding Process

2021年6月1日 The success of the manufacturing process which involves grinding as one of the stages depends solely on the accuracy of the grinding process Being the last stage of the manufacturing path, it is The industry requires parts with high dimensional accuracy and surface finish, which can be achieved through the grinding process Medical Industry: Grinding is also used in the medical industry for producing precision parts such as What is Grinding? – Working Principles2023年8月8日 To extract phosphorus from phosphate rock, Ftmmachinery will explain to you the process flow of phosphate rock and the equipment we can provide, from the four stages of crushing grinding flotation – dehydration Phosphate Rock Processing: 6 Useful Ways and 4 2022年11月30日 Grinding is one of the types of machining process ideal for improving the finish on a machined part’s surface and tightening its tolerance Furthermore, the process produces parts with identical shapes, finishes, and Types of Machining Process: Classifications and

.jpg)

(PDF) Processing equipment for grinding of building

2018年3月1日 Processing equipment for grinding of building powders R S Fediuk 1, R A Ibragimov 2, V S Lesovik 3 A A Pak 1, V V Krylov 1, which is explained by an increase in water demand 2021年6月1日 The success of the manufacturing process which involves grinding as one of the stages depends solely on the accuracy of the grinding process Being the last stage of the manufacturing path, it is mostly done to provide the desired surface finish to the product This makes the stage very crucial To prevent the ruining of all the previous stages and efforts, the Development of Realtime Grinding Process Monitoring and Analysis 6 modules for raw material reception and dust precipitation: similar to PLUGGRIND® XL VRM: Preassemblied in modules Erection in situ 3 process modules: similar to PLUGGRIND® XL 3 modules for auxiliary and peripheral equipment: hot gas generator modular and portable grinding station plug and grind vertical2013年5月1日 Grinding, a complicated machining process which has been extensively studied and documented in order to understand the subtleties of the operation being performed in different methodologies and (PDF) Influence of Process Parameters on Grinding A

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Raw material proportion station is the place where the raw materials like limestone, sand stone and basalt are mixing together The vertical roller mill fulfills four main functions in one compact piece of equipment: Grinding; Drying; Separation; Transportation; The process is called a drying /grinding process, where most of the material 2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, Intro to Grinding Methods, Machines and Tools Practical 2011年9月21日 Grinding is the process which necessarily use grinding wheel as the cutting tool to make the surface smoother This process is normally performed after performing the various other machining operations like milling, drilling etc so that the surfaces get smoother Fig1: Grinding Process Image source: WikiGrinding Process and its Applications mechGuru