Mine crushing process

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more Mineral processing Metallurgy, Crushing2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations 911 Crushers have more efficient transfer of applied power to the breakage of rock than grinding mills Typically a crushing flowsheet for a mineral processing plant will have from onetothree stages of crushing There are some cases where AMIT 135: Lesson 5 Crushing – Mining Mill

.jpg)

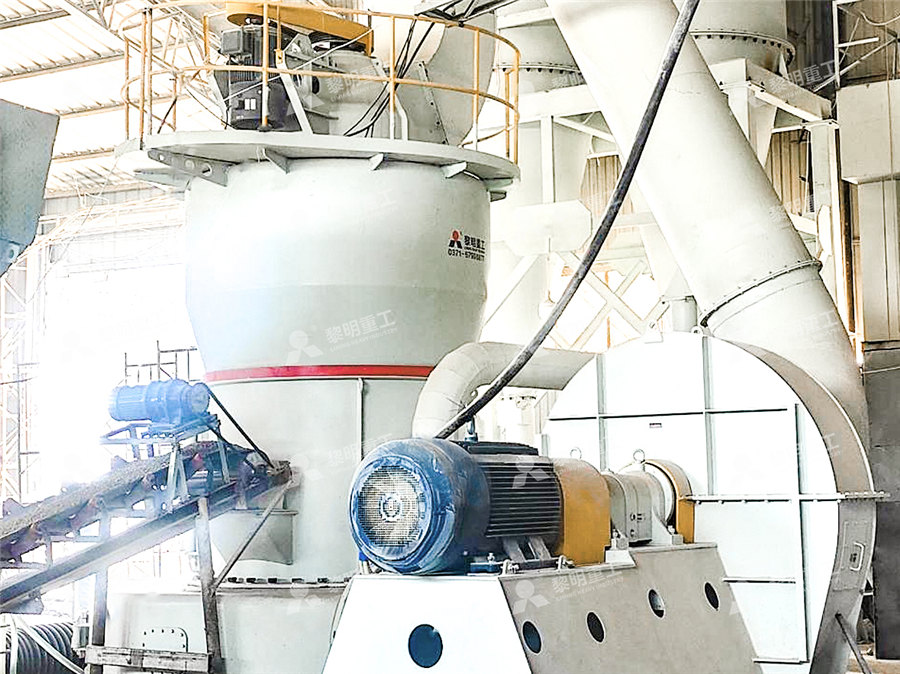

铜渣选矿碎磨流程优化探讨

摘要: 对目前铜渣选矿碎磨流程主要流程进行了探讨。 分析了“传统三段破碎+球磨”与“破碎+半自磨+球磨”(SAB)工艺的技术特性。 “传统三段破碎+球磨”系统具有灵活度高、磨矿易控制、运 2023年6月30日 MDE provides a more accurate overview of the various parameters of the crushing process, eg, how different particle densities and shapes affect the crushing process Modeling and Improving the Efficiency of 2022年10月4日 In hard rock mining, the ore mass is first broken down into various sized fragments by blasting, which is often called (blast) fragmentation In the downstream Reduction of Fragment Size from Mining to Mineral 2014年4月15日 This paper develops two optimal control models for the energy management of a mining crushing process based on jaw crushers The performance index for both models is Optimal energy management for a jaw crushing process in deep mines

Mineral processing Metallurgy, Crushing

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more A Comprehensive Guide on Mining Crushing Equipment Discover efficient and versatile mobile crushing plants for onsite crushing with portable crushers Enhance productivity and cost savings Explore now! read more Chileen Gao Mar 20, 2023 Introduction: What is Bauxite and What is the Process of Extracting Aluminum from Bauxite? read more Mineral Crushing Process Miningpedia2016年1月17日 Secondary Crushing: In mineral processing, it is assumed, for the present purpose that intermediate crushing is not necessary and that the runofmine or quarried mineral has, in one pass, been reduced in size so that all Crushing Mineral Processing 911Metallurgist2024年4月19日 The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is crushing the material by using larger crushers that can reduce the material into smaller sizes that will be used in the next stageTypes of Crushers Explained: Everything You Need to Know

.jpg)

Iron Ore Processing, General SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions It is the link between the mined raw materials 2020年4月20日 Crushing is the process of reducing the size of materials so that they can be further processed, the crushing process usually include 3 stages: primary crushing, secondary crushing, and the tertiary crushing Also, crushin processing is widely used in waste and recycling, mining, food processing, construction, and coalCrushing in Mineral Processing Eastman Rock Crusher%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources2024年6月7日 The content provides a comprehensive overview of the primary crushing process in the mining industry Skip to content 25 Nov 2024 Managing Dust Emissions in Mining: Key Factors and Control Measures; Sustainable Mining Practices: Environmental Conservation and Social Impact; Reliable and Efficient Power Supply in Mining: Exploring Key Primary Crushing Equipment: Jaw Crusher vs Gyratory Crusher

.jpg)

Crushing Plant Design and Layout Considerations 911

2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach Mine operators need to choose the correct mining machinery and processing equipment based on factors such as geological conditions and ore type Selecting the correct crusher depends on ore characteristics such as abrasiveness, fragility, softness or stickiness, and the desired outcome The crushing process can include primary, secondary Mining Crushers, Breakers Grinding Mills for the Mining 2016年3月11日 Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application crushers Crushing Plant Flowsheet DesignLayout2024年3月27日 Marine mining off Namibia’s coast is a big leap from the old days when divers would collect gravel from the shallows Namibia is now a leader in marine mining, with operations covering more than 6,000 square kilometers The Ultimate Guide to Diamond Processing

.jpg)

Cone crusher basics in 4 minutes SRP

Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feed It’s crucial that sampling is done regularly, especially when there are changes in blasting, mining or any other upstream processes If the mining process is not monitored properly, acid and other chemicals from chemical processing can run into nearby water systems such as rivers Today the mine has secondary crushing facilities, concentrators and a refinery on site In 1982 a series of cavities with wellcrystallised minerals were discovered, for example calcite 253 Crushing and milling Mining of mineral resources2024年10月24日 The crushing process of material particles in a vertical shaft impact (VSI) crusher is highly complex It is hard to quantify and characterize the crushing behavior of particles In this work, an experimental setup for active impact crushing is designed and constructed to investigate the crushing behavior of particles in a VSI crusher Impact crushing experiments Experimental Study of the Crushing Characteristics of Single 2022年5月19日 The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing Most medium and small gold processing plants use twostage closedcircuit crushing, and largescale processing plants use threestage closedcircuit crushing processHow to Process Gold Ore? 4 Gold Processing Steps Mining

.jpg)

Technology improvements of crushing process in Majdanpek Copper Mine

Process 4445 (l) 471483 Technology improvements of crushing process in Majdanpek Copper Mine MM Gruji Coper Mine Majdanpek, Majdanpek, Yugoslavia Abstract Within the crushing process, significant improvements in capacity and crushing product are obtained by the reconstruction of the secondary and tertiary crushers2023年6月30日 The crushing process is widely used in the metallurgical, construction, and mining industries The basic method of primary preparation of raw materials is to crush the minedModeling and Improving the Efficiency of Crushing EquipmentAn optimal crushing process reduces the ore to a desired size more efficiently, economically and safely The highcapacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications The Mining Crushing Stations are made up of 2 solutions: FIT Crushing MetsoAMIT 129: Surface Mine Safety; AMIT 130: Surface Mine Operations; AMIT 135: Introduction to Mining Systems and Equipment; Compare different equipment components and different methods to control the crushing process; Reading Lecture The Art of Crushing Crushing Gravel Rock Limited size reduction; Cubical shape; Over and undersize AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

.jpg)

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 capacity in primary crushing, increasing the total c apacity in the mining crushing process These crushers have a large feed opening and a groov ed mantle, making them suitable for cr ushing 2014年4月15日 This paper develops two optimal control models for the energy management of a mining crushing process based on jaw crushers The performance index for both models is defined as the energy cost to be minimized by accounting for the timeofuse electricity tariff The first model is referred to as a variable loadbased optimal control with the Optimal energy management for a jaw crushing process in deep mines2023年11月26日 The chrome plant process flow begins with exploration and mine development Geologists conduct surveys and studies to identify potential chrome ore deposits Once a suitable site is identified, the mining process StepbyStep Guide: Chrome Plant Process Flow Crushing Plant Process Optimisation Design of processes in order to find the most efficient solution to a specific task is a difficult problem Often the number of solutions are large and the optimal solution is therefore difficult to identifyx000D Crushing plant process design is no exception from this statement In order to find the best solution issues like equipment selection Crushing Plant Process Optimisation AusIMM

Ore Crushing SpringerLink

2023年7月22日 Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm The maximum crushing ratio of coarse crushing is about three The main force in the coarse crushing of ore is crushing Typical coarse crushing equipment includes jaw crusher, gyratory crusher, and rollertooth crusher Ore 2017年8月24日 The crushing process comprises reduction by compression between two confining faces and a subsequent freeing movement during which the material settles by gravity until it is caught and subjected to further compression and again released revenue recovery efficiency equal to that of any major kimberlite mine The recovery process on the Mineral Processing SpringerLink2014年4月1日 Numbi et al (2014) have demonstrated that applying optimal energy management to a mining crushing process can result in more than a 50% energy cost reduction Kusakana (2015b), has applied an Optimal energy management for a jaw crushing process in deep mines2023年8月9日 As an important link in openpit mining production, the crushing station produces a large amount of dust during the production process Dust has the characteristics of a wide spread area, great harm, and difficult governance Therefore, dust control has become a key issue that needs to be solved in openpit mining In this article, we assess results after high Research on the Physical and Chemical Characteristics of

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine The first crushing of the bauxite may often take place at the mine before transport to the alumina refinery if located nearby, or to the shipping port for export2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushingmineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more Mineral processing Metallurgy, CrushingA Comprehensive Guide on Mining Crushing Equipment Discover efficient and versatile mobile crushing plants for onsite crushing with portable crushers Enhance productivity and cost savings Explore now! read more Chileen Gao Mar 20, 2023 Introduction: What is Bauxite and What is the Process of Extracting Aluminum from Bauxite? read more Mineral Crushing Process Miningpedia

Crushing Mineral Processing 911Metallurgist

2016年1月17日 Secondary Crushing: In mineral processing, it is assumed, for the present purpose that intermediate crushing is not necessary and that the runofmine or quarried mineral has, in one pass, been reduced in size so that all 2024年4月19日 The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is crushing the material by using larger crushers that can reduce the material into smaller sizes that will be used in the next stageTypes of Crushers Explained: Everything You Need to Know2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions It is the link between the mined raw materials Iron Ore Processing, General SpringerLink2020年4月20日 Crushing is the process of reducing the size of materials so that they can be further processed, the crushing process usually include 3 stages: primary crushing, secondary crushing, and the tertiary crushing Also, crushin processing is widely used in waste and recycling, mining, food processing, construction, and coalCrushing in Mineral Processing Eastman Rock Crusher

.jpg)

AusIMM – Leading the way for people in resources

%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 2024年6月7日 The content provides a comprehensive overview of the primary crushing process in the mining industry Skip to content 25 Nov 2024 Managing Dust Emissions in Mining: Key Factors and Control Measures; Sustainable Mining Practices: Environmental Conservation and Social Impact; Reliable and Efficient Power Supply in Mining: Exploring Key Primary Crushing Equipment: Jaw Crusher vs Gyratory Crusher2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach Crushing Plant Design and Layout Considerations 911 Mine operators need to choose the correct mining machinery and processing equipment based on factors such as geological conditions and ore type Selecting the correct crusher depends on ore characteristics such as abrasiveness, fragility, softness or stickiness, and the desired outcome The crushing process can include primary, secondary Mining Crushers, Breakers Grinding Mills for the Mining