HOME→Aluminum ash, overhaul slag, aluminum electrolyte processing machinery aluminum ash, overhaul slag , aluminum electrolyte processing machinery aluminum ash, overhaul slag, aluminum electrolyte processing machinery

Aluminum ash, overhaul slag, aluminum electrolyte processing machinery aluminum ash, overhaul slag , aluminum electrolyte processing machinery aluminum ash, overhaul slag, aluminum electrolyte processing machinery

.jpg)

Research Progress of Electrolytic Aluminum Overhaul Slag Disposal

2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic Coal gangue is a byproduct of the production of coalassociated minerals, Review of Research on the Pr2023年8月1日 Herein, a synergistic disposal strategy, ie, adopting the overhaul slag as a raw material together with aluminum oxide in the aluminum electrolysis process to produce Al–Si Dissolution behavior of overhaul slag from aluminum reduction 2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe Efficient lithium recovery from electrolytic aluminum slag via an

Comprehensive performance study of aluminum ash and calcium

2022年12月12日 In this paper, the first ultrahigh pressure contact molding technology was used to prepare highperformance building materials with aluminum ash and calcium carbide slag Aluminium ash and slag are produced from molten slag cooling in the electrolytic aluminium production process,the recycling and utilization of the electrolytic aluminium ash and slag is Recycling and Utilization of the Electrolytic Aluminium Ash and Slag2024年6月4日 Based on the life cycle assessment method, this study examined the environmental impacts of four major aluminum ash treatment methods in four categories: Assessing Environmental Impact of Aluminum Ash Disposal in Based on the life cycle assessment method, this study examined the environmental impacts of four major aluminum ash treatment methods in four categories: Resource Consumption, Assessing Environmental Impact of Aluminum Ash Disposal in

.jpg)

Fluorineretaining agent for overhaul slag of aluminum electrolytic

2020年1月2日 TL;DR: In this paper, a harmless treatment method of aluminum electrolysis overhaul slag is proposed, where materials are weighted according to a weight ratio, and the 2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic 电解铝大修渣处置研究进展2024年7月24日 The lithium was selectively recovered and enriched from spent aluminum electrolyte slag by using calcium salt roasting transformation followed by HBL121solvent Cleaner Process for the Selective Extraction of Lithium from Spent 2022年12月12日 First, aluminum ash and calcium carbide slag were separately passed through a 200 mesh sieve Aluminum ash and calcium carbide slag were mixed in different proportions and poured into a mold (steel mold), the grinder dimensions were 40 mm × 40 mm × 160 prehensive performance study of aluminum ash and calcium

A novel approach for lithium recovery from waste lithium

2021年10月1日 A novel approach for lithium recovery from waste lithiumcontaining aluminum electrolyte by a roastingleaching process Author links open Comprehensive performance study of aluminum ash and calcium carbide slag for brick making under ultra International Journal of Mineral Processing, Volume 160, 2017, pp 815 2024年6月4日 The main components of aluminum ash include single aluminum, aluminum oxide (Al 2 O 3), aluminum nitride (AlN), aluminum carbide (Al 4 C 3), fluoride and chlorinated salts, silicon, iron and other oxide (Kang et al 2022) Aluminum ash slag can be divided into primary aluminum ash and secondary aluminum ash according to the different degrees of Assessing Environmental Impact of Aluminum Ash Disposal in Aluminium ash should start from the potential value of quantity, nature, composition, etc, and the directions of use are as follows: 1 The aluminum ash ball mill production line of Henan Zhengzhou Mining Machinery Co, Ltd can effectively extract the elemental aluminum in the aluminum ash, which can be used for smelting aluminum ingotsAluminum Ash Processing Aluminum Ash Recovery Aluminum Ash 2020年8月1日 The aluminum ash particles interact with the molten particles of TC coal to capture the sodium in the deposit Consequently, aluminum ash can be a good additive for improving the ash deposition of TC coal However, aluminum ash is hard to produce strong chemical interaction with sodium in GT coal ash, which has a high fusion pointEvaluation of aluminum ash in alleviating the ash deposition of

.jpg)

Aluminium salt slag characterization and utilization A review

2012年3月27日 Aluminium salt slag (also known as aluminium salt cake), which is produced by the secondary aluminium industry, is formed during aluminium scrap/dross melting and contains 1530% aluminium oxide * High efficiency for recycling rate (91% of aluminum from the slag), short working time Equipment and machines Aluminum dross processing machine and dust collector The loading capacity can be 100 to 650kgs depending on aluminum dross processing machine modelsAluminium dross processing/Brightstar Aluminum Machinery2020年12月1日 The rapid development of the electrolytic aluminum industry in China and the increasing demand for aluminum products have led to the development of many lowgrade bauxite mines with an average Li 2 O content of at least 058% (Wang et al, 2013)Due to the use of this lowgrade bauxite in the electrolytic aluminum process, the content of lithium in the Novel process for the extraction of lithium carbonate from spent 2020年12月1日 A hydrometallurgical process was developed to extract lithium from a spent lithiumcontaining aluminum electrolyte, reduce the stacking of spent aluminum electrolyte, and recover the valuable elements In this study, we extracted lithium from an electrolyte using the following three steps: 1) leaching with HNO 3 − Al(NO 3) 3, 2) neutralizing the leachate Novel process for the extraction of lithium carbonate from spent

.jpg)

Present situation of production, utilization and disposal of

With the rapid development of aluminium smelting industry in China, millions of tons of hazardous wastes such as carbon slag, overhaul slag and aluminum ash are generated every year In order to promote the refined management of hazardous wastes in China, an indepth research had been done, the current generation process link, pollution characteristics, utilization and 2018年12月14日 Saltfree technologies of processing aluminum dross, which are based on the separation of metal and oxides by the mechanical effect on them under conditions of high temperatures in the medium of (PDF) THE USE OF ALUMINUM SLAG RECYCLING 2023年9月1日 Lithium (Li)bearing aluminum electrolyte slag is an inevitable byproduct of the aluminum industry, and improper disposal or stacking it may lead to potential environmental hazards This study employed hydrometallurgical Clean Process for Selective Recovery of Lithium 2021年5月1日 Aluminum Slag Separation Process Analysis Through a Vibratory Machine in the Foundry Process May 2021 International Journal for Innovation Education and Research 9(5):104120(PDF) Aluminum Slag Separation Process Analysis

.jpg)

Aluminum dross: aluminum metal recovery and emerging

2024年4月17日 Recycling plays an important role in today's world due to its considerable contributions to mitigating energy concerns and environmental challenges One of them is dross recycling from aluminum (Al) cast houses Unlike other recyclable materials, dross has an abundance of components, including rare earth elements, heavy metals, ferrous, and recycled 2024年5月1日 For example, in the collaborative disposal and recovery of valuable metals with red mud, the proportion of overhaul slag is only 10%, and the processing capacity is small (Mao et al, 2021) The above research is only limited to harmless disposal and the separation and recovery of high content elements, and has not yet paid attention to the high value of lithium in Selective preparation of lithium carbonate from overhaul slag by 2023年11月9日 The process of extracting aluminum with sulfuric acid from highalumina fly ash activated by roasting with Na2CO3 and NaOH as raw materials ware studied The results revealed that the aluminum in fly ash activated by sodium carbonate reached 932% under the optimum conditions (30% H2SO4, 90°C, 120 min, and liquidtosolid ratio was 5:1) Kinetics of aluminum extraction from roasting activated fly ash by 2018年10月1日 In the secondary aluminum industry (aluminum scrap recovery), about 200 kg of aluminum is produced per each ton of secondary aluminum (Seng et al, 2006) By 2020, annual global demand for aluminum will reach to about 97 million tons and almost 32% of which that equals to 31 million tons is expected to be supplied from scrap recycling ( Tsakiridis et al, 2013 )Hazardous aluminum dross characterization and recycling

Ash Frying Machine, Hot Aluminum Ash Separator 7001300, Metal Aluminum

Ash Frying Machine, Hot Aluminum Ash Separator 7001300, Metal Aluminum Slag Separation Equipment, Ash Rubbing Machine, US $ 11500 16500 / Set, Guangdong, China, Lvyuan, NewSource from Foshan Lvyuan Innovation Trade Co, Ltd on Alibaba2023年10月1日 The main components of waste aluminum cryolite electrolyte are cryolite (Na 3 AlF 6), potassium cryolite (K 2 NaAlF 6), lithium cryolite (Na 2 LiAlF 6), fluorite (CaF 2), and approximately 2% carbon black (Wang et al, 2019)The main treatment methods of waste aluminum cryolite electrolyte can be divided into two categories: combined thermalwet Efficient extraction and recovery of lithium from waste aluminum 2019年2月26日 Aluminum ash is an industrial waste residue produced during alumina electrolysis and aluminum processing and casting In the experiment, alumina powder with a purity of 9897% was prepared by (PDF) Preparation of Alumina from Aluminum Ash by2020年5月8日 The literature survey reveals that the aluminum extraction from FA is limited compared to the conventional Bayer process Microwave processing is employed because of its unique characteristics over conventional heating, such as noncontact, rapid, selective, volumetric heating, and better energy transfer [17, 18]A mixture of sodium bearing fluxes (Na 2 CO 3, Processing of Coal Fly Ash for the Extraction of Alumina Values

.jpg)

(PDF) Optimization of process for total recovery of

2013年12月1日 According to the European Waste Catalogue and Hazardous Waste List, the slag resulted from electric arc furnace is part of the wastes from thermal processes category and it has the codes 10 02 01 Download Citation On Aug 1, 2023, Jianping Yang and others published Dissolution behavior of overhaul slag from aluminum reduction cell in a cryolitebased molten salt system Find, read and Dissolution behavior of overhaul slag from aluminum reduction 2020年12月1日 The leaching ratio of lithium reached 9321% at 80 • C for 120 min Wu et al (2020) used Al(NO 3 ) 3HNO 3 solution as leaching reagents to extract lithium from waste aluminum electrolyte at 80 Novel process for the extraction of lithium carbonate from spent 2021年7月30日 The aluminum metal and molten salt flux are tapped after the process, where the cooled flux along with the mixture of nonmetallic components is called salt slag or salt cake54 Salt slag contains 5–7 wt% residual aluminum metal, 15–30 wt% aluminum oxide, 30–55 wt% sodium chloride, and 15–30 wt% potassium chloride and, depending upon the A Review of Secondary Aluminum Production and Its Byproducts

The Utilization Technology Analysis Of Secondary Aluminum Ash

2021年11月22日 The secondary aluminum ash of electrolytic aluminum is a hazardous waste containing a large amount of toxic and hazardous substances such as fluoride, cyanide, aluminum carbide dies, and aluminum nitride, and its treatment has always been a research focus in the electrolytic aluminum industry The traditional landfill and storage methods have been banned2022年4月1日 The paper therefore discusses the influence of scraprelated impurities on the thermodynamics and kinetics of precipitation reactions and their mechanical and electrochemical effects; impurity (PDF) Making sustainable aluminum by recycling scrap: The 2024年6月29日 Aluminum electrolyte is a necessity for aluminum reduction cells; however, its stock is rising every year due to several factors, resulting in the accumulation of solid waste Currently, it has become a favorable material for the resources of lithium, potassium, and fluoride In this study, the calcification roasting–twostage leaching process was introduced to extract Stepwise extraction of lithium and potassium and recovery of 2021年10月1日 To recover valuable elements such as lithium from waste aluminum electrolyte, Wu et al (2021) mixed Na 2 CO 3 with waste aluminum electrolyte and roasted them at 650 • C for 25 h, and Na 2 A novel approach for lithium recovery from waste lithium

Research on the Preparation Parameters and Basic Properties of

Aluminum dross is slag floating on the surface of molten aluminum during the elec trolytic process, which is composed of unreacted alumina, cryolite and other raw materials,2022年12月12日 First, aluminum ash and calcium carbide slag were separately passed through a 200 mesh sieve Aluminum ash and calcium carbide slag were mixed in different proportions and poured into a mold (steel mold), the grinder dimensions were 40 mm × 40 mm × 160 prehensive performance study of aluminum ash and calcium 2021年10月1日 A novel approach for lithium recovery from waste lithiumcontaining aluminum electrolyte by a roastingleaching process Author links open Comprehensive performance study of aluminum ash and calcium carbide slag for brick making under ultra International Journal of Mineral Processing, Volume 160, 2017, pp 815 A novel approach for lithium recovery from waste lithium 2024年6月4日 The main components of aluminum ash include single aluminum, aluminum oxide (Al 2 O 3), aluminum nitride (AlN), aluminum carbide (Al 4 C 3), fluoride and chlorinated salts, silicon, iron and other oxide (Kang et al 2022) Aluminum ash slag can be divided into primary aluminum ash and secondary aluminum ash according to the different degrees of Assessing Environmental Impact of Aluminum Ash Disposal in

.jpg)

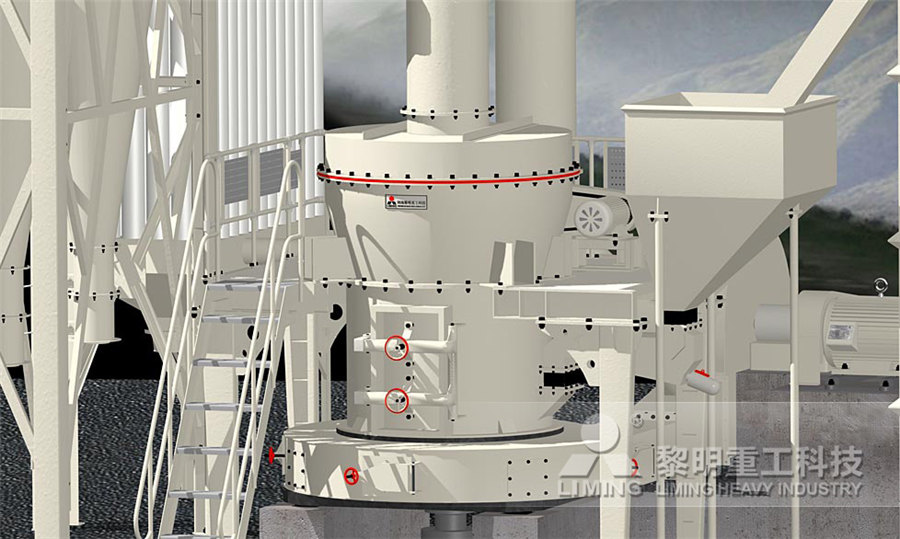

Aluminum Ash Processing Aluminum Ash Recovery Aluminum Ash

Aluminium ash should start from the potential value of quantity, nature, composition, etc, and the directions of use are as follows: 1 The aluminum ash ball mill production line of Henan Zhengzhou Mining Machinery Co, Ltd can effectively extract the elemental aluminum in the aluminum ash, which can be used for smelting aluminum ingots2020年8月1日 The aluminum ash particles interact with the molten particles of TC coal to capture the sodium in the deposit Consequently, aluminum ash can be a good additive for improving the ash deposition of TC coal However, aluminum ash is hard to produce strong chemical interaction with sodium in GT coal ash, which has a high fusion pointEvaluation of aluminum ash in alleviating the ash deposition of 2012年3月27日 Aluminium salt slag (also known as aluminium salt cake), which is produced by the secondary aluminium industry, is formed during aluminium scrap/dross melting and contains 1530% aluminium oxide Aluminium salt slag characterization and utilization A review* High efficiency for recycling rate (91% of aluminum from the slag), short working time Equipment and machines Aluminum dross processing machine and dust collector The loading capacity can be 100 to 650kgs depending on aluminum dross processing machine modelsAluminium dross processing/Brightstar Aluminum Machinery

.jpg)

Novel process for the extraction of lithium carbonate from spent

2020年12月1日 The rapid development of the electrolytic aluminum industry in China and the increasing demand for aluminum products have led to the development of many lowgrade bauxite mines with an average Li 2 O content of at least 058% (Wang et al, 2013)Due to the use of this lowgrade bauxite in the electrolytic aluminum process, the content of lithium in the 2020年12月1日 A hydrometallurgical process was developed to extract lithium from a spent lithiumcontaining aluminum electrolyte, reduce the stacking of spent aluminum electrolyte, and recover the valuable elements In this study, we extracted lithium from an electrolyte using the following three steps: 1) leaching with HNO 3 − Al(NO 3) 3, 2) neutralizing the leachate Novel process for the extraction of lithium carbonate from spent With the rapid development of aluminium smelting industry in China, millions of tons of hazardous wastes such as carbon slag, overhaul slag and aluminum ash are generated every year In order to promote the refined management of hazardous wastes in China, an indepth research had been done, the current generation process link, pollution characteristics, utilization and Present situation of production, utilization and disposal of