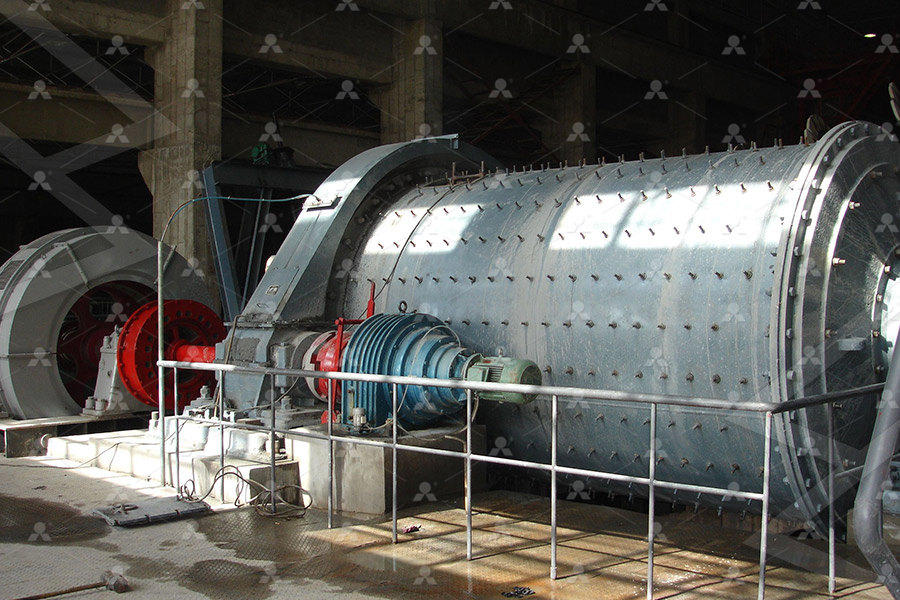

Industrial Grinding Machine Manufacturer Related Regulations and Procedures

.jpg)

American National Standard Safety Requirements for

2020年9月15日 By approving this American National Standard, the ANSI Board of Standards Review confirms that the requirements for due process, consensus, balance and openness have been met by B11 Standards, Inc, (the ANSIaccredited standards developing organization) 2018年7月9日 tools or pieces of equipment: Mill, Lathe, Planer, Drill Press, Pedestal Grinder, Band Saw GENERAL SAFETY TIPS • Safety glasses with side shields must be worn at all STANDARD OPERATING PROCEDURES for COMMON Significant differences between the European Standard and ISO 16089 are as follows a) Introduction of a subdivision of grinding machines into three groups, based on the degree of Machine tools ? Safety ? Stationary grinding machines ISOUsing grinding machines safely is not just a precaution; it is a critical aspect of workplace health, safety, and environmental (HSE) management Understanding the potential hazards, implementing robust safety measures, and adhering to Using grinding machines safely Safety Notes

ISO 160901:2017 (en), Machine tools safety — Machining

Milling machines present a wide range of hazards Protection of operators and other persons from contact with moving cutting tools, especially when being rapidly rotated in the spindle or being 2019年5月9日 manufacturers and suppliers of machinery Machinery is used in virtually all work activities, and thus presents certain safety and health risks in a larg number of workplaces all Safety and health in the use of machinery2023年12月7日 Angle grinders are versatile handheld tools commonly used in the manufacturing industry, in particular the metal fabrication sector Their ability to perform a Safe Angle Grinding Guidance Note1 Procedures on using, inspecting and maintaining equipment (machines, power tools) – in some cases, additional workplace procedures (such as Lock Out/Tag Out procedures) may be Machine Safety Guidelines Environmental Health Safety

PeerReviewed Working Safely With Grinders American

2017年7月28日 grinderrelated safety practices An abrasive wheel grinder is one of the most common pieces of machinery utilized in maintenance shops and in manufacturing These 6 天之前 Here is the checklist that an operator should consider before starting to work: Check the free speed of the tool, so that it cannot rotate faster than the maximum rpm stated on the wheelSafety checklist for working with grinders Atlas 2021年1月25日 12 Safety rules for this machinery Do Property of Kent Industrial (1)Only use grinding wheel with a maximum peripheral speed of 2000m/min or greater (2)Before inspecting or maintaining the power source,first make sure that you are adhering the instructions on the related warning signsINSTRUCTION MANUAL FOR PRECISION SURFACE 2023年11月28日 Established in the year 1971, 'Raj Works Industries' is counted amongst the leading manufacturers and suppliers of a wide range of Industrial Processing Machines Our complete range is precisely Pulverizer Machines, Industrial Grinding

How Regulation Is Affecting the US

The US manufacturing industry is a force to be reckoned with From its emergence during the Industrial Revolution in 1820, the sector has experienced repeated blows from the Great Depression to the Great Recession more 2017年7月28日 •An abrasive wheel grinder is one of the most common pieces of machinery utilized in maintenance shops and in manufacturing •Industry experience indicates that abrasive wheel safety needs greater attention from OSH professionals and employers •This article presents 10 best practices for grinder use that are based on several years ofPeerReviewed Working Safely With Grinders American 2021年11月26日 Adequate training to ensure all staff understand and follow health and safety procedures It’s also their duty to keep staff updated on policies and arrangements related to health and safety The main requirement under the regulation is that manufacturers produce machinery that’s safe for use Machinery is defined as:Engineering regulations in the UK to know about Countingup2009年7月1日 grinding Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc); centerless grinding; chamfering; thread and form Practicing routine grinding machine maintenance produces

INSTRUCTION MANUAL FOR PRECISION SURFACE

2021年1月25日 General Safety Rules Do 1 The employer must select trained and qualified personnel to operate machinery 2 The employer must adhere to local national safety laws and regulations when teaching operators safety and cleanly procedures 3 The employer must inform operators to look out for unsafe operating practices 42021年2月16日 This book contains rules for Safety Standards for machine safety, as adopted under the Washington Industrial Safety and Health Act of 1973 (Chapter 4917 RCW) The rules in this book are effective February 2020 A brief promulgation history, set within brackets at the end of this chapter, gives statutory authority, administrative order ofMachine Safety, Chapter 296806, WAC LaborDistance between centers: 1 mm 50 mm Grinding wheel diameter : 305, 405, 455, 510 mm Machine weight: 1,500, 2,400, 3,200, 3,700, 4,000 kg The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces with diameters between Grinding machine All industrial manufacturers2017年8月11日 ABSTRACT Economic activities are closely related to realworld environmental issues Currently, more attention is paid to the association between environmental regulations and industrial competitiveness (IC) because of pressures on economic development and environmental protectionEnvironmental regulations and industrial competitiveness: evidence

.jpg)

Industrial Grinder Manufacturers Suppliers in India

Industrial mixer grinder; Jig grinding machine make hauser countr switzerland mode 3hp three phase belt grinder machine, 17 inch, >2000 w; Stainless steel industrial mixers, automation grade: semiau Nilanjan industrial grinder; Electric engine iron clay mixer machine, model name/number: Neelkanth enterprises vertical industrial 1 天前 Holar Taiwan Made Kitchen Real Natural Marble Manual Salt And Pepper Grinder Application: Industrial Price Trend : 1299 1439 USD ($)Industrial Grinder at Best Price from Manufacturers2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles(PDF) A comprehensive review on the grinding process: 2020年6月11日 manufacturers’ specifications If damaged, remove from service until repaired Regulate compressed air and air tools to manufacturers’ specifications Always check the infeed conveyor Do not direct compressed air towards anyone or use to clean clothes PPE = Personal Protective Equipment WEAR IT! When working around a grinder, specific PORTABLE GRINDER SAFETY FOR WOODS EQUIPMENT

SECTION TWO – MIOSHA REGULATIONS Michigan

2021年2月8日 SECTION TWO – MIOSHA REGULATIONS PART 3: MIOSHA SAFETY REGULATIONS CHAPTER 29: Duty to have Fall Protection and Falling Object Protection 291 Holes or Openings in Floors and Walls The MIOSHA General Industry Safety Standards – Part 2, Walking Working Surfaces provides rules for safeguarding openings in floorsContact Info Corenco, Inc 3275 Dutton Avenue Santa Rosa, CA 95407 Phone: 1888CORENCO Fax: (707) 5283197Industrial Grinders for Food Processing: A Comprehensive 2015年11月19日 that the manufacturer’s recommended speed (as posted on the wheel) is compatible with the grinder and that the type of wheel is compatible with the material being ground An improperly installed or incompatible wheel can break or explode and cause injury Before starting the grinder, inspect the wheel to make sure it is not cracked or brokenSAFE OPERATING PROCEDUREGRINDERS 2024年4月1日 Purpose of Document Bench grinder SOPs outline a safe operating procedure for bench grinder use SOPs can also be used as a training and induction documentThe primary goal is to protect workers from injury or illness by outlining a safe system of work and providing adequate training and instruction This form is broadly aligned with AS45001:2018Free Bench Grinder SOP (Safe Operating Procedure) Template

Minigrinding machine All industrial manufacturers

Rotational speed: 2,500 rpm 25,000 rpm Power: 04 ch Diameter: 6 mm 360 degree Swivel air inlet, avoids tangled air inlet and operator fatigue TPR cover Prevents Hand Chill in Cold Environments2020年6月23日 Powered Industrial Truck (AKA Forklift) Accidents Forklifts, which OSHA likes to call “powered industrial trucks,” are useful vehicles Countless manufacturers rely on forklifts to move large/heavy objects However, the things that make forklifts useful also make them dangerous Accidents happen throughout businesses and industriesThe Basics of Manufacturing Safety and Compliance KPA2023年7月20日 Clarity and Simplicity: Explain the importance of clear and concise SOPs to ensure easy comprehension and adherence Flexibility and Adaptability: Discuss the need for flexible SOPs that can accommodate Standard Operating Procedures (SOPs) in 2023年7月26日 Poor Guarding and lack of safety equipment – Durning the metal fabrication processes lots of people don’t use all the personal protective equipment or they only use some These can vary depending on the work you Metal Fabrication Safety Workshop Hazards

.jpg)

Industrial mixer grinder, Mixer mincer All

Completely automatic grinder with 500 Kg premixer, stainless steel construction under USDA regulations and transmission gear completely separated from the grinding head and the premixing Compare this product Remove from 2024年10月29日 Title: Pedestal and Bench Grinder Safe Operation Procedure Authorized By: Chris Vandelaar Issue Date: May 2016 Last Reviewed: May 2016 Next Review Date: May 2018 Page Number: 1 of 2 THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED O:\Student Support and Training\Health and Safety\SOP's\SOPGrinder Pedestal and Bench GrinderdocSafe Work Procedure Grinder Pedestal and Bench Power: 06 ch Rotational speed: 3,450 rpm motor housing provide durability and prolong lifeMotor runs at 3,450 rpm for highspeed material removal The DW756 6" Bench Grinder has a powerful 5/8 HP 3,450 rpm induction motor for highspeed material Industrial bench grinder All industrial manufacturers2023年9月18日 Today, environmental consciousness is no longer a choice but an imperative for industries, especially in manufacturing The manufacturing sector, often perceived as a significant contributor to environmental degradation, is transforming sustainability Environmental compliance and regulations are pivotal in steering this transformation, ensuring manufacturers adhere to Environmental Compliance and Regulations in

.jpg)

All you need to know about angle grinder health and safety

Regulations The primary objective of PUWER 98 (the regulation covering Abrasive Wheels) is to ensure that work equipment, including Angle Grinders, does not give rise to risks to Health and Safety, regardless of the work equipment’s age, condition or origin2024年8月15日 In addition to looking at essential training needs, the guide also focuses on details such as: wheel characteristics; safety in grinding machine operations; wheel mounting procedures and issues; guards; extra considerations for portable or handheld grinders; and protective equipment requirementsSafety in the use of abrasive wheels2018年11月23日 "supplier", means any person who supplies or contracts or agrees to supply electricity Scope of application 2 (1) These Regulations shall apply to the designers, manufacturers, installers, sellers, users, employers and suppliers who design, manufacture, install, sell, generate or use electrical machineryELECTRICAL MACHINERY REGULATIONS, 年8月11日 This sturdy, impactresistant shield is designed for use when a wheel needs safeguarding These shields have a directmount base that attaches directly to the grinder table or pedestal In this photo, you can see a properly secured grinder, which includes an adequate tongue guard and work rest, with double wheel grinder shieldsGrinding Safety Precautions And Regulations WeldingPros

.jpg)

INSTRUCTION MANUAL FOR PRECISION SURFACE

2021年1月25日 12 Safety rules for this machinery Do Property of Kent Industrial (1)Only use grinding wheel with a maximum peripheral speed of 2000m/min or greater (2)Before inspecting or maintaining the power source,first make sure that you are adhering the instructions on the related warning signs2023年11月28日 Established in the year 1971, 'Raj Works Industries' is counted amongst the leading manufacturers and suppliers of a wide range of Industrial Processing Machines Our complete range is precisely Pulverizer Machines, Industrial Grinding The US manufacturing industry is a force to be reckoned with From its emergence during the Industrial Revolution in 1820, the sector has experienced repeated blows from the Great Depression to the Great Recession more How Regulation Is Affecting the US2017年7月28日 •An abrasive wheel grinder is one of the most common pieces of machinery utilized in maintenance shops and in manufacturing •Industry experience indicates that abrasive wheel safety needs greater attention from OSH professionals and employers •This article presents 10 best practices for grinder use that are based on several years ofPeerReviewed Working Safely With Grinders American

Engineering regulations in the UK to know about Countingup

2021年11月26日 Adequate training to ensure all staff understand and follow health and safety procedures It’s also their duty to keep staff updated on policies and arrangements related to health and safety The main requirement under the regulation is that manufacturers produce machinery that’s safe for use Machinery is defined as:2009年7月1日 grinding Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc); centerless grinding; chamfering; thread and form Practicing routine grinding machine maintenance produces 2021年1月25日 General Safety Rules Do 1 The employer must select trained and qualified personnel to operate machinery 2 The employer must adhere to local national safety laws and regulations when teaching operators safety and cleanly procedures 3 The employer must inform operators to look out for unsafe operating practices 4INSTRUCTION MANUAL FOR PRECISION SURFACE 2021年2月16日 This book contains rules for Safety Standards for machine safety, as adopted under the Washington Industrial Safety and Health Act of 1973 (Chapter 4917 RCW) The rules in this book are effective February 2020 A brief promulgation history, set within brackets at the end of this chapter, gives statutory authority, administrative order ofMachine Safety, Chapter 296806, WAC Labor

.jpg)

Grinding machine All industrial manufacturers

Distance between centers: 1 mm 50 mm Grinding wheel diameter : 305, 405, 455, 510 mm Machine weight: 1,500, 2,400, 3,200, 3,700, 4,000 kg The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces with diameters between 2017年8月11日 ABSTRACT Economic activities are closely related to realworld environmental issues Currently, more attention is paid to the association between environmental regulations and industrial competitiveness (IC) because of pressures on economic development and environmental protectionEnvironmental regulations and industrial competitiveness: evidence