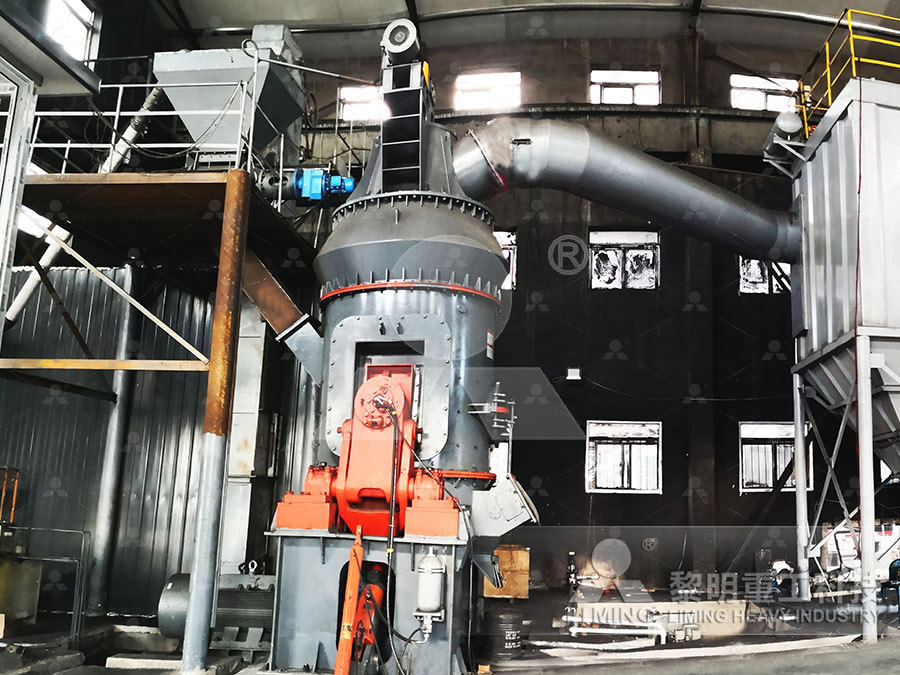

Electrolytic aluminum waste slag grinding machine Ore grinding machine sales point

.jpg)

Efficient lithium recovery from electrolytic aluminum slag via

2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe 2024年5月23日 Here, we review carbonrich solid wastes with focus on sources and hazards, detoxification, separation, recovery, recycling and disposal Treatment techniques include The recycling of carbonrich solid wastes from aluminum electrolytic 2024年2月1日 This process is easy to operate and highly controllable, achieving efficient separation and recovery of lithium, aluminum, and fluorine in the overhaul slag The research A novel approach for extracting lithium from overhaul slag 2023年9月1日 This study employed hydrometallurgical processes to selectively leach lithium from Licontaining aluminum electrolyte slag, using sodium carbonate solution as the leaching agent A notable leaching efficiency of Clean Process for Selective Recovery of Lithium

Research Progress of Electrolytic Aluminum Overhaul Slag

2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic 2023年10月1日 The process flow and optimized technical parameters for the efficient extraction and recovery of Li from waste aluminum electrolyte are shown in Fig 6 The sulfated roasting Efficient extraction and recovery of lithium from waste aluminum 2021年4月5日 With the rapid development of aluminium smelting industry in China, millions of tons of hazardous wastes such as carbon slag, overhaul slag and aluminum ash are Present situation of production, utilization and disposal of 2022年4月13日 Here we propose a solidstate electrolysis (SSE) process using molten salts for upcycling aluminium scrap The SSE produces aluminium with a purity comparable to that of A solidstate electrolysis process for upcycling aluminium scrap

制粉-10.25公众号.jpg)

Efficient lithium recovery from electrolytic aluminum slag via

2024年1月18日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe 2022年10月9日 In this work, electrolytic aluminum carbon anode slag was separated by flotation Using the selectivity index (SI) as an indicator, the influencing factors of the carbon slag flotation process were optimized, and Recovery of carbon and cryolite from spent 2023年5月15日 is that the electrolytic manganese waste slag can be turned into valuable, thereby reducing the water pollution, soil pollution and air pollution caused by the electrolytic manganese slag It is hoped to provide some references for the comprehensive resource recovery and utilization of electrolytic manganese slagResearch Progress on Recovery of Valuable Elements 2012年12月31日 The paper provides a brief introduction in the physical and chemical properties of waste aluminum cathodes, and its harmless treatment technology and resource comprehensive utilization technologyStudy on Harmless and Resources Recovery

A comprehensive review of aluminium electrolysis and the waste

2023年4月13日 Aluminium is produced by electrolysis using alumina (Al2O3) as raw material and cryolite (Na3AlF6) as electrolyte In this HallHéroult process, the energy consumption is relatively large, and 2024年5月23日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and The recycling of carbonrich solid wastes from aluminum electrolytic 2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe environmental pollution and wasting of Li resources This paper proposes a method for recovering Li from the slag using AlCl 3 as the leaching agent The effects of the leaching temperature, AlCl 3 Efficient lithium recovery from electrolytic aluminum slag via 2022年8月12日 slag mainly exist in the form of uoride, which is relatively stable and unreactive Therefore, the key point of recycling molten salt slag is the transformation of rareearth uorides Compared with bastnasite (REFCO 3), the conversion of rareearth uorides in molten salt slag is more dicult because of the higher uorine content (> 10%)Recovery of RareEarth Elements from Molten Salt

A novel approach for lithium recovery from waste lithium

2021年10月1日 On the other hand, lithium, the lightest metal element in the world, is an important strategic resource because of its contribution to the national economy (Vieceli et al, 2021)The demand for new energy vehicles and various hightech products is gradually increasing with the rapid development of economy (Yang et al, 2019, Li et al, 2021, Yelatontsev and 2022年2月19日 This paper investigated the recovery of rare earth elements (REEs) and aluminum (Al) from the waste slag discharged by FCC catalyst factory (FCC waste slag) via acid leaching and selective Recovery of RareEarth Elements from Molten Salt Electrolytic Slag 2021年3月2日 for electrolytic aluminum waste is proposed This mode is to pulverize the electrolytic aluminum waste, and then mix the crushed electrolytic aluminum waste with the raw coal of the circulating fluidized bed boiler [6], then send it to the circulating fluidized bed boiler for combustion In this study, a mixed combustion experiment ofResearch on the Coprocessing of Mixed Electrolytic 2024年2月1日 The electrolytic aluminum waste, which would inevitably be produced from the electrolytic process in the aluminum industry, is harmful to environment and human bodyEfficient lithium recovery from electrolytic aluminum slag via

.jpg)

(PDF) Recovery of Carbon and Cryolite from

2023年3月12日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and 2023年12月1日 Tong et al (2023) mixed aluminum sulfate and calcium oxide to treat the rare earth molten salt electrolytic slag and achieved the expected effect, indicating that the reaction with fluoride in rare earth molten salt electrolytic slag after mixed roasting is feasible, which is consistent with the thermodynamic calculation results of the Review of efficient recycling and resource utilization for rare Slag Grinding Machine (1882 products available) ADV 508SR800 flame cutting and plasma cutting plate sheet grinding heavy slag removal machine for metal $25,00000 $38,00000 Min Order: 1 setSimple Ore Extraction: Choose A Wholesale slag grinding machine 2023年3月12日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and it must be disposed of in a harmless manner On the other hand, it contains a few valuable resources, as well In order for the aluminum electrolysis industry to Recovery of Carbon and Cryolite from Spent Carbon Anode Slag

.jpg)

Clean Process for Selective Recovery of Lithium Carbonate from Waste

2023年9月1日 Lithium (Li)bearing aluminum electrolyte slag is an inevitable byproduct of the aluminum industry, and improper disposal or stacking it may lead to potential environmental hazards This study employed hydrometallurgical processes to selectively leach lithium from Licontaining aluminum electrolyte slag, using sodium carbonate solution as the leaching agent 2022年10月10日 In this work, electrolytic aluminum carbon anode slag was separated by flotation Using the selectivity index (SI) as an indicator, the influencing factors of the carbon slag flotation process were optimized, and the separation performance of carbon and cryolite in the carbon anode slag was investigated The raw carbon anode slag was ground for Recovery of carbon and cryolite from spent carbon anode slag Bauxite is the name given to aluminium ore To generate aluminium oxide, bauxite is purified, a white powder from which aluminium can be extracted Aluminium oxide has a very high melting point of more than 2000° C which makes melting very expensive Aluminium oxide in water does not dissolve, but in molten cryolite, it dissolvesExtraction of Aluminium (Aluminium Ore) HallHeroults Aluminium ash and slag are produced from molten slag cooling in the electrolytic aluminium production process,the recycling and utilization of the electrolytic aluminium ash and slag is attracting more and more attention at home and abroad for their valuable components such as 10%30% aluminium and 30% Al2O3The recovery utilization and technology of advantages Recycling and Utilization of the Electrolytic Aluminium Ash and Slag

Efficient extraction and recovery of lithium from waste aluminum

2023年10月1日 Cryolitealumina (Na 3 AlF 6Al 2 O 3) molten salt electrolysis is the only modern method for the industrial production of metallic aluminum (Ishak et al, 2017)Under the influence of direct current, Al 2 O 3 dissolved in the molten salt is reduced to monolithic aluminum at the cathode (Haraldsson and Johansson, 2020)As the blood of the electrolytic cell, the electrolyte 2024年4月1日 As a high energy consumption and high carbon emission industry, aluminum electrolysis is the global carbon reduction key concern industry From a global perspective, the global carbon emission of aluminum electrolysis in 2022 is more than 1 billion tons, accounting for about 46% of the total global carbon emission [9], [10]In the entire process of electrolytic Formation mechanism and treatment status of 2012年5月30日 Salt slag, a mixture of salts, aluminium oxide, aluminium metal and impurities, is a typical residue generated during remelting of scrap/dross under a salt layer in rotary furnaces (up to 500 kg of salt slag per tonne of aluminium metal) As it has been classified as toxic and hazardous waste (highly flammable, irritant, harmful and leachable Aluminium salt slag characterization and utilization – A review2021年11月1日 Spent carbon anode (SCA) is a dangerous solid waste that is continuously discharged from the aluminum electrolysis industry and has a large number of valuable resources and a high risk of Advances in the Safe Disposal and

Efficient lithium recovery from electrolytic aluminum slag via

2024年1月1日 Semantic Scholar extracted view of "Efficient lithium recovery from electrolytic aluminum slag via an environmentally friendly process: Leaching behavior and mechanism" by Li Cui et al A novel approach for lithium recovery from waste lithiumcontaining aluminum electrolyte by a roastingleaching process Shaohua Wu W Tao +4 authors 2023年11月1日 Additionally, electrolytic manganese production stands as a highemission sector, where the generation of 1 ton of electrolytic metal manganese results in the production of 10–12 tons of EMR, and the diminishing manganese Enhancing sustainable valorization: Harmless synergistic 2021年7月30日 Aluminum is the second mostconsumed metal in the world, only outranked by steel Primary aluminum is produced through the HallHeroult process1 In this process, alumina dissolves in a sodium cryolite melt, and aluminum is reduced at the aluminum liquid cathode pool while the anode products are significant amounts of \({\mathrm{CO}}{2}\) and other A Review of Secondary Aluminum Production and Its Byproducts2023年12月1日 As a broadly utilized metal, aluminum incorporates an assortment of special properties such as light weight, great electrical conductivity, ductility, erosion resistance and great reducibility (Mahinroosta and Allahverdi, 2018)Aluminum, known as the "universal metal", contains a wide run of employments within the aviation, development, marine businesses and Harmless recovery and utilization of electrolytic aluminum

Regeneration of raw materials for aluminum electrolysis

2023年5月20日 Due to chemical corrosion and erosion by molten aluminum liquid and electrolyte, the carbon anode of the aluminum electrolytic cell would fall off into the electrolyte during the primary aluminum electrolysis process to produce spent anode carbon (SCA), which has been listed as one of the typical hazardous solid wastes in the National Hazardous Waste 2018年9月3日 Slag of aluminum is a residue which results during the melting process of primary and secondary aluminum production Salt slag of aluminum is hazardous solid waste according to the European Recovery of Aluminum from Industrial Waste (Slag) by 2023年10月1日 The electrolytic aluminum waste, which would inevitably be produced from the electrolytic process in the aluminum industry, is harmful to environment and human bodyHarmless recovery and utilization of electrolytic aluminum 2022年1月10日 The recovery of spent carbon anode (SCA) materials plays important roles in environment protection and resources recycling, while this cannot be efficiently achieved without liberationSelective comminution and grinding mechanisms of spent

.jpg)

Research Progress on Recovery of Valuable Elements

2023年5月15日 is that the electrolytic manganese waste slag can be turned into valuable, thereby reducing the water pollution, soil pollution and air pollution caused by the electrolytic manganese slag It is hoped to provide some references for the comprehensive resource recovery and utilization of electrolytic manganese slag2012年12月31日 The paper provides a brief introduction in the physical and chemical properties of waste aluminum cathodes, and its harmless treatment technology and resource comprehensive utilization technologyStudy on Harmless and Resources Recovery 2023年4月13日 Aluminium is produced by electrolysis using alumina (Al2O3) as raw material and cryolite (Na3AlF6) as electrolyte In this HallHéroult process, the energy consumption is relatively large, and A comprehensive review of aluminium electrolysis and the waste 2024年5月23日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and The recycling of carbonrich solid wastes from aluminum electrolytic

Efficient lithium recovery from electrolytic aluminum slag via

2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe environmental pollution and wasting of Li resources This paper proposes a method for recovering Li from the slag using AlCl 3 as the leaching agent The effects of the leaching temperature, AlCl 3 2022年8月12日 slag mainly exist in the form of uoride, which is relatively stable and unreactive Therefore, the key point of recycling molten salt slag is the transformation of rareearth uorides Compared with bastnasite (REFCO 3), the conversion of rareearth uorides in molten salt slag is more dicult because of the higher uorine content (> 10%)Recovery of RareEarth Elements from Molten Salt 2021年10月1日 On the other hand, lithium, the lightest metal element in the world, is an important strategic resource because of its contribution to the national economy (Vieceli et al, 2021)The demand for new energy vehicles and various hightech products is gradually increasing with the rapid development of economy (Yang et al, 2019, Li et al, 2021, Yelatontsev and A novel approach for lithium recovery from waste lithium 2022年2月19日 This paper investigated the recovery of rare earth elements (REEs) and aluminum (Al) from the waste slag discharged by FCC catalyst factory (FCC waste slag) via acid leaching and selective Recovery of RareEarth Elements from Molten Salt Electrolytic Slag

.jpg)

Research on the Coprocessing of Mixed Electrolytic

2021年3月2日 for electrolytic aluminum waste is proposed This mode is to pulverize the electrolytic aluminum waste, and then mix the crushed electrolytic aluminum waste with the raw coal of the circulating fluidized bed boiler [6], then send it to the circulating fluidized bed boiler for combustion In this study, a mixed combustion experiment of2024年2月1日 The electrolytic aluminum waste, which would inevitably be produced from the electrolytic process in the aluminum industry, is harmful to environment and human bodyEfficient lithium recovery from electrolytic aluminum slag via