Grinding lithium ore to extract lithium carbonate Equipment

Hard Rock Lithium Processing SGS

2022年3月25日 Working with the lithium concentrate, SGS’ team uses a standardized flowsheet to produce high grade lithium products such as lithium carbonate or lithium hydroxide These are reagents for the lithium battery industry The multistep process involves atmospheric leaching, 2023年1月1日 The process flow is to convert lithium in ore into lithium sulfate by mixing roasting lithium mineral and excessive potassium sulfate (or calcium sulfate or a mixture of both), leach Lithium extraction from hard rock lithium ores (spodumene, 2023年11月21日 Spodumene ores are typically consolidated from ore comprising 1–15% Li20 to a concentrate of about 6–65% Li20 To achieve this, the ore passes through a typical Lithium processing technology Complete solutions that Researchers have made numerous improvements based on the sulfate roasting process For instance, Thamsanqa [65] developed an alternative process using K 2 SO 4 to extract lithium Advances and promotion strategies of processes for extracting lithium

Processing of lithium ores: Industrial technologies and case

2021年5月1日 Some specific techniques of lithium extraction from ores and minerals are systematized Autoclave methods seem the most promising for poor alkaline Li 2023年1月15日 It is found that the sulfuric acid method has a high lithium recovery rate, but with a complicated process and high energy consumption; alkali and chlorination methods can directly react with lithium ores, reducing Lithium extraction from hard rock lithium ores 2024年5月14日 crushing and grinding to liberate the lithium minerals from the ore matrix followed by beneficiation processes such as dense media separation, (DMS) froth flotation, LESSONS LEARNED FROM NEW HARDROCK LITHIUM PDF On Jan 1, 2022, Tianming Gao and others published Lithium extraction from hard rock lithium ores: technology, resources, environment and cost Find, read and cite all the research (PDF) Lithium extraction from hard rock lithium ores:

Processing of lithium ores: Industrial technologies and case studies

2021年2月1日 The latest enhancements of the sulfation method significantly increase its overall technological efficiency: sulfuric acid treatment of spodumene is the most costeffective for Discover the different lithium extraction methods: exploring greener alternatives and the gamechanging technology of Lithium Harvest Lithium, the "white gold" of the energy transition, has become a critical resource in powering renewable Lithium Extraction MethodsDuring the evaporation process, a slurry of hydrated lime (Ca(OH) 2) is added to the brine to precipitate out unwanted elements, particularly magnesium and boron (as magnesium hydroxide and calcium boron salts)When lithium Lithium handling Carmeuse Systems6 天之前 Only after grinding the lithium ore to achieve monomer cleavage can the mineral processing flow effectively extract lithium resources Lithium ore ball mill In the grinding and grading stage of lithium ore, in order to ensure that Ball Mill Is The Key To Grinding Lithium Ore

Green Battery Minerals How to Get Lithium

2023年4月7日 With the rapid rise of new energy sources, lithium resources have been pushed to a boom in development As a green energy mineral, the most common type of lithium ore is spodumene This blog will focus on spodumene, 2024年6月13日 Here, the authors report an electrochemical leaching method which can directly extract lithium from natural state spodumene ores with low energy consumption, environmental impact, and high efficiencyDirect extraction of lithium from ores by electrochemical 2023年6月25日 Lithium, the least dense metal element in nature, exhibits high electrochemical activity as well as a large specific heat capacity [1], [2], [3]Lithium is applied in a variety of products, including batteries, ceramics, glass, and lubricating oil, owing to its exceptional properties [4]With the rapid development of power batteries and the application of lithium in An effective method for directly extracting lithium from α 2023年6月8日 Spodumene is the most abundant lithium ore, usually containing 5% to 8% lithium (by weight) It is commonly found in pegmatite rock formations and can be extracted by conventional mining methods Spodumene is widely used to produce lithium carbonate, which is used to make electric vehicle batteriesThree Common Beneficiation Process For Lithium Ore

.jpg)

(PDF) Lithium extraction from hard rock lithium ores:

2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environmentThe lithium extraction efficiencies were 9330 % and 9070 %, respectively (Fig 6 b) Compared to the current industrial sulfuric acid method, these methods are more environmentally friendly and costeffective Qiu [67] used different sulfates for roastingwater leaching of spodumene concentrates to extract lithium from αspodumene (Fig 6 c)Advances and promotion strategies of processes for extracting lithium 02 Lithium Ore Grinding and Classifying Stage Back In the grinding and classifying stage of lithium ore, in order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and grading process can be adopted, and the firststage grinding equipment can use wet grid ball mills, rod mills, etc A Comprehensive Guide to Lithium Processing Equipment2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car market, it is crucial to improve lithium recovery from its rich mineral deposits using the most effective extraction technique In recent years, both Aspects of Spodumene Lithium Extraction Techniques MDPI

.jpg)

Spodumene: The Lithium Market, Resources and

2019年5月29日 The expected growth rate for lithium carbonate and lithium hydroxide is respectively 10% and 145% until 2025 , since they are two of the raw materials used for LiBs In 2016, lithium carbonate prices were reported to 2021年10月7日 The paper discusses the process of lithium mining, from resource exploration to the production of batterygrade lithium salts(PDF) Lithium Mining, from Resource Exploration 2022年12月13日 The following is the process flow of lithium ore processing to obtain lithium carbonate: After the mining of lithium ore, the bulk material is first crushed by electromagnetic dressing equipment; Then under the action of belt conveyor, it is evenly sent to the grinding machine for deep grinding treatment; After grinding, lithium ore powder How to mine lithium ore, mineral processing, crushing, grinding2024年11月27日 In the complex production required to transform spodumene concentrate into lithium compounds such as lithium carbonate or lithium hydroxide, calcination plays a key role in not one, but two parts of the process, making it an essential technique in efforts to exploit this increasingly important lithium ore While the beneficiation of lithium from brines has long been The Role of Calcination in the Extraction of Lithium from

]@S0{UDKK%G24F3JGHC.jpg)

Lithium Processing Systems and Equipment Bepex

6 天之前 Bepex has been supplying processing technology for lithium carbonate or lithium hydroxide production since the early 1990s Now, with lithium producers straining to fulfill ever increasing demand, Bepex is pioneering systems to streamline lithium production while also reducing the energy needed and emissions resulting from processing2023年4月23日 Lithium (Li) ore is a type of rock or mineral that contains significant concentrations of lithium, a soft, silverwhite alkali metal with the atomic number 3 and symbol Li on the periodic table Lithium is known for its unique properties, such as being the lightest metal, having the highest electrochemical potential, and being highly reactive with waterLithium (Li) Ore Minerals, Formation, Deposits Geology 2021年2月1日 Lithium mica and spodumene (Dessemond et al, 2019;Su et al, 2020), as representatives of lithium ore resources are usually recovered by the sulfuric acid method (Rioyo et al, 2022; Yelatontsev Processing of lithium ores: Industrial technologies and case studies 2024年5月14日 other lithiumbearing minerals, and therefore, is a crucial resource for lithium extraction processes OVERVIEW OF LITHIUM HARDROCK PROCESSES The extraction process of lithium from spodumene (LiAlSi 2 O 6) begins with comminution such as crushing and grinding to liberate the lithium minerals from the ore matrix followed by beneficiationLESSONS LEARNED FROM NEW HARDROCK LITHIUM

.jpg)

Spodumene Processing And Production Equipment

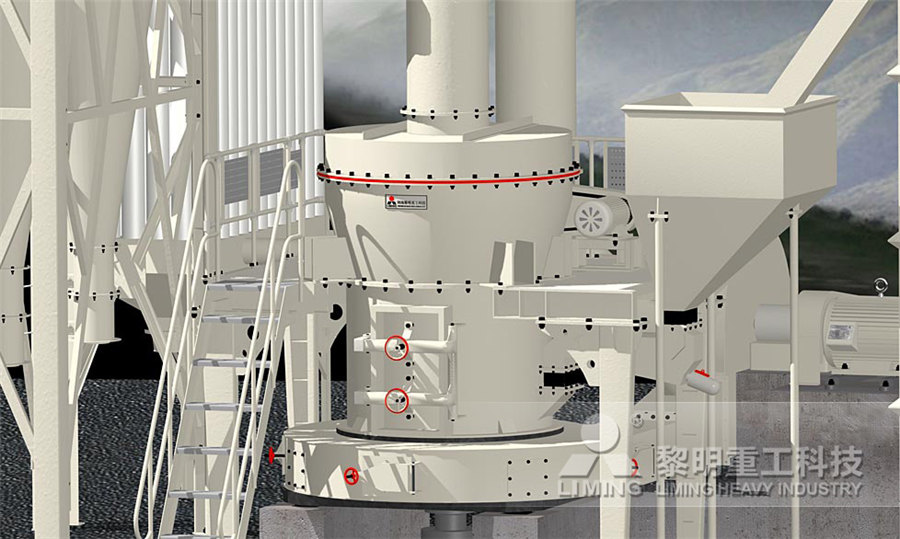

2023年11月7日 The processing of spodumene to extract lithium involves several steps, including mining, beneficiation, and chemical processing Crushing and Grinding Equipment: Spodumene ore is typically crushed and ground to reduce its size and prepare it for further processing Crushing equipment includes jaw crushers, cone crushers, and impact crushers 2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?2023年3月13日 Air is then bubbled through the mixture, causing the hydrophobic lithium minerals to rise to the surface and form a froth The froth is skimmed off and dried, producing a concentrate that contains about 67% lithium If you want to know more details about lithium ore flotation chemicals, you can browse 3 Types of Lithium Ore Flotation CollectorsLithium Ore Processing: An Overview You Must Know2024年7月9日 Lithium ore is mainly used to extract lithium, which is widely used in batteries, ceramics, glass, lubricants, aerospace, medicine and other fields In recent years, due to the increasing demand for lithium batteries in electric Lithium Ore Grinding Mills SBM Ultrafine

.jpg)

Hard Rock Spodumene Lithium Processing

2023年12月27日 In step 1, to convert spodumene into lithium sulfate (Li 2 SO 4), the raw ore is crushed and separated both mechanically and via floatationNext, the concentrate undergoes energy and chemically intensive 2024年6月8日 Lithiumbearing Ore: The raw material used to extract lithium Chemicals : Such as acid and other reagents used in the refining process Equipment and Machinery : Regular maintenance and How to start lithium refining business? GB Times2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical lithium ores, primarily spodumene and brine, into highpurity batterygrade precursors We systematically examine the study findings Transformations of Critical Lithium Ores to BatteryGrade2019年8月23日 Mining for Lithium: Lithium is often recovered from brine, or water with a high concentration of lithium carbonate Subsurface brines trapped in the Earth’s crust are major source material for lithium carbonate These sources are less expensive to mine than from rock such as spodumene, petalite, and other lithiumbearing mineralsLithium Processing Equipment, Process Flow, Cases JXSC

.jpg)

Lithium Extraction Methods

DLE technologies aim to extract lithium directly from brine or other lithiumrich sources with increased efficiency and reduced environmental footprint After mining the ore, it undergoes crushing, concentration, and chemical treatments, including roasting and leaching, to obtain a lithium concentrate Lithium carbonate production time 2021年12月1日 Due to lithium existing in a different form in carbonatehosted claytype lithium deposits, calcination and acid leaching processes were applied to extract lithium from Lirich clay rocks (Gu et al, 2020a) However, because the acid leaching process results in acidic residues, leaching processes that do not involve acid should be developed to Lithium extraction from claytype lithium resource using ferric sulfate 2024年8月22日 Impact crusher is suitable for processing softer ores and can produce finer ore particles 22 Grinding Equipment The choice of grinding equipment depends on the particle size requirement of the ore and the processing capacity Ball mills are widely used for grinding most ores, with the advantages of strong adaptability and good grinding effectHow to Choose the Best Lithium Ore Beneficiation Equipment 2023年3月28日 The increasing lithiumion battery production calls for profitable and ecologically benign technologies for their recycling Unfortunately, all used recycling technologies are always associated Universal and efficient extraction of lithium for lithiumion

Lithium handling Carmeuse Systems

During the evaporation process, a slurry of hydrated lime (Ca(OH) 2) is added to the brine to precipitate out unwanted elements, particularly magnesium and boron (as magnesium hydroxide and calcium boron salts)When lithium 6 天之前 Only after grinding the lithium ore to achieve monomer cleavage can the mineral processing flow effectively extract lithium resources Lithium ore ball mill In the grinding and grading stage of lithium ore, in order to ensure that Ball Mill Is The Key To Grinding Lithium Ore2023年4月7日 With the rapid rise of new energy sources, lithium resources have been pushed to a boom in development As a green energy mineral, the most common type of lithium ore is spodumene This blog will focus on spodumene, Green Battery Minerals How to Get Lithium 2024年6月13日 Here, the authors report an electrochemical leaching method which can directly extract lithium from natural state spodumene ores with low energy consumption, environmental impact, and high efficiencyDirect extraction of lithium from ores by electrochemical

An effective method for directly extracting lithium from α

2023年6月25日 Lithium, the least dense metal element in nature, exhibits high electrochemical activity as well as a large specific heat capacity [1], [2], [3]Lithium is applied in a variety of products, including batteries, ceramics, glass, and lubricating oil, owing to its exceptional properties [4]With the rapid development of power batteries and the application of lithium in 2023年6月8日 Spodumene is the most abundant lithium ore, usually containing 5% to 8% lithium (by weight) It is commonly found in pegmatite rock formations and can be extracted by conventional mining methods Spodumene is widely used to produce lithium carbonate, which is used to make electric vehicle batteriesThree Common Beneficiation Process For Lithium Ore2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environment(PDF) Lithium extraction from hard rock lithium ores: The lithium extraction efficiencies were 9330 % and 9070 %, respectively (Fig 6 b) Compared to the current industrial sulfuric acid method, these methods are more environmentally friendly and costeffective Qiu [67] used different sulfates for roastingwater leaching of spodumene concentrates to extract lithium from αspodumene (Fig 6 c)Advances and promotion strategies of processes for extracting lithium

.jpg)

A Comprehensive Guide to Lithium Processing Equipment

02 Lithium Ore Grinding and Classifying Stage Back In the grinding and classifying stage of lithium ore, in order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and grading process can be adopted, and the firststage grinding equipment can use wet grid ball mills, rod mills, etc 2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car market, it is crucial to improve lithium recovery from its rich mineral deposits using the most effective extraction technique In recent years, both Aspects of Spodumene Lithium Extraction Techniques MDPI