What equipment is needed to open a heavy calcium carbonate ore powder making plant

Calcium Carbonate Manufacturing Process and Equipment

Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years) Chalk 展开2024年9月13日 Usually there are a complete set of machinery needed for the calcium carbonate production line And some calcium carbonate manufacturing plants are also equipped with Customize Suitable Calcium Carbonate Plant DASWELL2024年7月10日 Common surface modification equipment for heavy calcium carbonate includes SLG continuous powder surface modifier, HEM highefficiency hybrid modifier, highspeed Heavy calcium carbonate grinding, surface modification 2021年7月22日 In order to protect the environment, auxiliary calcium carbonate processing and dust removal equipment can be equipped Calcium carbonate jaw crusher The grinding What equipment does the calcium carbonate powder production line need?

.jpg)

4 Steps to Build a Calcium Carbonate Processing Plant

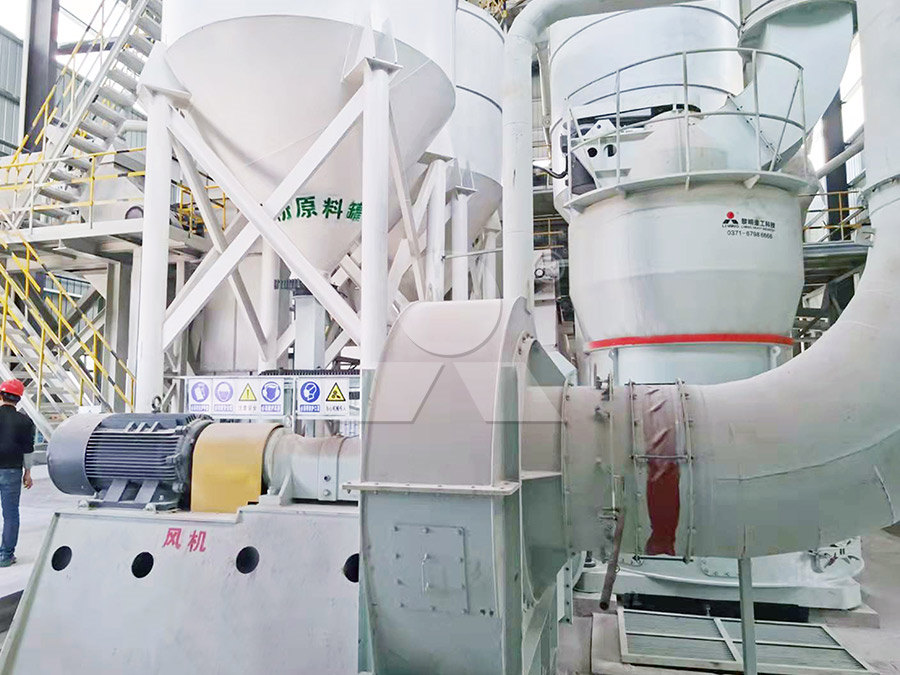

2022年9月29日 In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness 2024年8月23日 The main crushing equipment includes Raymond mill, impact mill, dry stirred mill, air flow mill, vertical mill, roller mill, vibration mill and ball mill 1 Raymond mill is widely used to produce heavy calcium carbonate products Heavy calcium carbonate dry production process 2023年10月10日 Common heavy calcium powder production equipment mainly includes MTW European version mill, Raymond mill, ball mill, vertical mill and ring roller mill To a certain What are the heavy calcium powder production equipment?2024年11月26日 The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and Calcium Carbonate Grinding Production Line TAYMACHINERY

.jpg)

How to Choose a Calcium Carbonate Grinding

2024年9月13日 Wet grinding mill, also known as ultrafine stirring mill, is widely used in the fine processing of heavy calcium carbonate, light calcium carbonate, barite, gypsum, talc and other nonmetallic minerals2022年9月29日 The raw calcium carbonate ore has just been mined from the mine The size of the raw materials is relatively large, and the stacking position is relatively simple In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The heavy calcium powder can be directly prepared by 4 Steps to Build a Calcium Carbonate Processing Plant2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the Guide to Calcium Carbonate Grinding: Mills, 2023年5月19日 Stone paper is a relatively sustainable alternative to traditional fibrebased paper Stone paper is made using resin such as highdensity polyethylene (HDPE) and a mineral such calcium carbonate (PDF) Biodegradable Stone Paper as a

Making Calcium Carbonate Making

Find production technology for making Calcium carbonate, and connect directly with leading machine manufacturers worldwide Spongy form of calcium carbonate could open up new applications Researchers stumbled upon a spongy form of calcium carbonate occurring naturally in mussels Ground shells of the mollusc reacted to acetic acid to form a 2021年12月28日 Since the invention of the paper by in 105 CE to Chai Lun many improvements have been made to the paper product we know today Today a paper machines can be over 600 m long and 115 m wide (PDF) InSitu Precipitated Calcium Carbonate Paper2017年1月1日 The method (solubilization) involved heavy dilution of the slurry at 0 o C, and reaction of the solution with carbon dioxide to produce calcium carbonate, the precipitated product is separated Precipitated Calcium carbonate production, synthesis and properties6 天之前 1 CK12 Textbook (2022) 610: Alkaline Earth MetalsIntroductory Chemistry (CK12) UC Davis LibreTexts 2 Because elemental calcium (Ca) is considered unstable, it is usually more present as Ca 2+This is called a cation because it is positively charged, and therefore it seeks negatively charged ions like carbonate (CO 3 2) to bind toThe result is calcium carbonate Understanding Calcium Carbonate Scale Orenda Tech

.jpg)

Dry surface modification of heavy calcium carbonate

Content from this work may be used under the terms of the CreativeCommonsAttribution 30 licence Any further distribution of this work must maintain attribution to the author(s) and the title of What Is Calcium Carbonate Four Uses of Calcium Carbonate Calcium Carbonate Production Process Ground calcium carbonate is also called known as heavy calcium carbonate,it is made by mechanical methods (using grinding mills such as roller mill or other highpressure grinding mills) to directly crush natural calcite, limestone, chalk, shells, etc Ground calcium carbonate Calcium Carbonate – What Is It And How To Make ItExceptional Value vs Precipitated Calcium Carbonate With HuberCal calcium carbonate powder, formulators can choose a more economical product vs precipitated calcium carbonate without compromising quality Independent analysis has validated the HuberCal powder calcium carbonate advantage The primary benefits of HuberCal calcium carbonate Calcium Carbonate Powder HuberCal Calcium Carbonate2024年11月26日 The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages Calcium Carbonate Grinding Production Line TAYMACHINERY

.jpg)

Calcium Carbonate: Uses, Dosage, and Potential

2023年11月14日 Calcium carbonate supplements come in tablet, chewable, oral suspension, or powder form Your body can get the most calcium from calcium carbonate in powder form, but other forms are also 2024年5月1日 Among the essential plant nutrients, calcium (Ca) is the third most abundant after nitrogen (N) and potassium (K) Plants require Ca (1–3 mM) for their normal growth and development (Saito and Uozumi, 2020)Ca ions (Ca ++), such as those involved in signaling, plant metabolism, and cell growth, contribute to several biological processes that affect all steps of Role of calcium nutrition in plant Physiology: Advances in 2024年7月12日 Sealants: The products filled with light calcium carbonate have good fluidity and high hardness, while heavy calcium carbonate has slightly lower hardness Papermaking: Light calcium carbonate has more advantages in improving the whiteness of paper, and thermal paper, highend cigarette paper, lightweight paper, etc prefer light calcium carbonateHeavy calcium and light calcium, 10 essential differences2023年12月7日 The carbon dioxide reacts with the calcium hydroxide to form calcium carbonate Equipment The equipment used in the manufacturing process for calcium carbonate varies depending on the type of calcium carbonate being produced For natural calcium carbonate, the equipment typically includes crusher, screens, grinder mill, and washersWhat is the steps in the Calcium Carbonate Liming Heavy

.jpg)

Which Plant Need Calcium Carbonate? Green Packs

2024年11月22日 In conclusion, calcium carbonate is a vital nutrient for a wide variety of plants, from green, leafy vegetables to flowering plants and herbs By understanding which plants benefit most from the presence of calcium carbonate in the soil, you can tailor your gardening practices to promote healthier growth and more bountiful harvests2024年8月15日 Heavy calcium carbonate, light calcium carbonate is based on the production method of calcium carbonate divided, can be distinguished from the following three aspects: LUMSeries Ultra Fine Vertical Grinding Mill 1 The shape of the particles are different Heavy calcium carbonate particles irregular shape, is polydisperse powder It's large The difference between heavy calcium carbonate and light calcium Calcium oxide can be produced by the thermal decomposition of calcium carbonate according to the equation: CaCO₃ CaO + CO₂ What is the minimum amount of calcium carbonate needed to produce 112 g of calcium oxide? [Ca = 40 g/mol, C = 12 g/mol, O = 16 g/mol]Question Video: Calculating the Mass of Calcium Carbonate NagwaSourcing Guide for Calcium Carbonate Plant: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: grinding mill, grinding machine, raymond millCalcium Carbonate Plant MadeinChina

.jpg)

what type of machines need to make calcium carbonate powder

Coal mining processing plant in Nigeria This coal mining project is an open pit mine located in Nigeria, announced by mining company Western Goldfields that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US$12 billion which could be used for the generation of electric powerStudy with Quizlet and memorize flashcards containing terms like order the steps required to predict the volume (in mL) of 0100 M calcium chloride needed to produce 100 g of calcium carbonate There is an excess of sodium carbonate, calculate the volume (in mL) of 0100 M CaCl2 needed to produce 100 g of CaCO3(s), lab data and moreLab 9: Stoichiometry: Synthesis of Calcium Carbonate Quizlet2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone 2020年10月31日 The golden apple snail is a significant pest that damages crops and can lead to crop failure because it has a habit of consuming various soft plants, including young rice plants(PDF) Calcium as a Plant Nutrient ResearchGate

.jpg)

Calcium Carbonate an overview ScienceDirect Topics

Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to 2023年4月8日 The paper industry is one of the largest markets for calcium carbonate As an important papermaking filler and coating pigment, calcium carbonate is rich in sources and cheap in price; fine particles and high whiteness can significantly improve the opacity of paper; fast ink absorption speed can increase Ink absorption of paper; it can make the paper softer, tighter 7 types of calcium carbonate commonly used in the paper Calcium Carbonate (CaCO 3) is a naturally found material in chalk, limestone, and marble It is composed of three elements which include carbon, oxygen, and calcium It is formed by reacting carbon dioxide with slaked or burnt lime It can be used for a variety of applications ranging from industrial, food to agricultureCalcium carbonate powder, particle size = 50um, 98 4713412023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry Calcium carbonate milling process SBM Ultrafine Powder

制粉项目-2023.11.17.jpg)

Formations of calcium carbonate minerals by bacteria and its

2016年3月1日 Biomineralization is a naturally occurring process in living organisms In this review, we discuss microbially induced calcium carbonate precipitation (MICP) in detail In the MICP process, urease plays a major role in urea hydrolysis by a wide variety of microorganisms capable of producing high levels of urease We also elaborate on the different polymorphs and 2024年3月21日 Heavy calcium carbonate is physical grinding and crushing of marble, limestone, dolomite and calcite through Raymond mill, vertical mill, ball mill and other equipment to obtain 1003000 mesh powder, and the sedimentation volume is smaller than that of light calcium carbonate Application Calcium carbonate powder is an important inorganic General Introduction of Calcium Carbonate Powder2022年9月29日 The raw calcium carbonate ore has just been mined from the mine The size of the raw materials is relatively large, and the stacking position is relatively simple In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The heavy calcium powder can be directly prepared by 4 Steps to Build a Calcium Carbonate Processing Plant2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the Guide to Calcium Carbonate Grinding: Mills,

(PDF) Biodegradable Stone Paper as a

2023年5月19日 Stone paper is a relatively sustainable alternative to traditional fibrebased paper Stone paper is made using resin such as highdensity polyethylene (HDPE) and a mineral such calcium carbonate Find production technology for making Calcium carbonate, and connect directly with leading machine manufacturers worldwide Spongy form of calcium carbonate could open up new applications Researchers stumbled upon a spongy form of calcium carbonate occurring naturally in mussels Ground shells of the mollusc reacted to acetic acid to form a Making Calcium Carbonate Making2021年12月28日 Since the invention of the paper by in 105 CE to Chai Lun many improvements have been made to the paper product we know today Today a paper machines can be over 600 m long and 115 m wide (PDF) InSitu Precipitated Calcium Carbonate Paper2017年1月1日 The method (solubilization) involved heavy dilution of the slurry at 0 o C, and reaction of the solution with carbon dioxide to produce calcium carbonate, the precipitated product is separated Precipitated Calcium carbonate production, synthesis and properties

.jpg)

Understanding Calcium Carbonate Scale Orenda Tech

6 天之前 1 CK12 Textbook (2022) 610: Alkaline Earth MetalsIntroductory Chemistry (CK12) UC Davis LibreTexts 2 Because elemental calcium (Ca) is considered unstable, it is usually more present as Ca 2+This is called a cation because it is positively charged, and therefore it seeks negatively charged ions like carbonate (CO 3 2) to bind toThe result is calcium carbonate Content from this work may be used under the terms of the CreativeCommonsAttribution 30 licence Any further distribution of this work must maintain attribution to the author(s) and the title of Dry surface modification of heavy calcium carbonate What Is Calcium Carbonate Four Uses of Calcium Carbonate Calcium Carbonate Production Process Ground calcium carbonate is also called known as heavy calcium carbonate,it is made by mechanical methods (using grinding mills such as roller mill or other highpressure grinding mills) to directly crush natural calcite, limestone, chalk, shells, etc Ground calcium carbonate Calcium Carbonate – What Is It And How To Make ItExceptional Value vs Precipitated Calcium Carbonate With HuberCal calcium carbonate powder, formulators can choose a more economical product vs precipitated calcium carbonate without compromising quality Independent analysis has validated the HuberCal powder calcium carbonate advantage The primary benefits of HuberCal calcium carbonate Calcium Carbonate Powder HuberCal Calcium Carbonate